drain bolt PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 18 of 1825

MAINTENANCE AND LUBRICATION OB-1

SECTION OB

NTENANCE AND LUBR

CONTENTS

Maintenance Schedule, Gasoline .............................................. OB-l

Maintenance Schedules I and 11 .............................................. OB-2

Owner Inspections

......................................................... OB-3

Recommended Fluids and Lubricants ......................................... OB-6

PASSENGER CAR MAINTENANCE SCHEDULE

VEHICLES

WITH GASOLINE ENGINE

NORMAL CAR USE ITEM 4

The maintenance services contained in Schedules I Carburetor or Throttle Body Mounting Bolt

and 11 are based on the assumption that your car will be Torque* used as designed:

Check torque of mounting bolts and/or nuts. @ To carry passengers and cargo within the limits

shown on the Tire Placard located on the edge of the ITEM 5 driver's door.

@ On reasonable road surfaces within legal driving Engine Idle Speed Adjustment*

limits. (Engines

without Idle Speed Control or Idle Air

Control) - Adjust to specifications shown on the under- @ On unleaded gasoline.

hood label. If no specifications are shown on the label, no

adjustment is necessary. Calibrated test equipment must

EXPLANATION OF SCHEDULED MAINTENANCE be used. SERVICES

The services listed in Maintenance Scheduies I and ITEM 6

11 are further explained below. When the following main- ~i~~ and wheel aotation tenance services are performed, make sure all parts are

replaced and all necessary repairs are done before driving To equalize wear and obtain maximum tire life,

your car. Be sure to use the proper fluid and lubricants as rotate in accordance with patterns shown in Owner's

shown in Figure OB-2. Manual.

ITEM 1

Engine Oil and Oil Filter Change*

ALWAYS USE SFICC OR SF/CD ENERGY CON-

SERVING OILS OF PROPER VISCOSITY

- Also.

always change oil and filter as soon as possible after

driving in a dust storm. See your Owner's Manual for

further details.

ITEM 2

Chassis Lubrication

Lubricate all grease fittings in suspension and steer-

ing linkage. Lubricate

transmissionltransaxle shift

linkage, parking brake cable guides, underbody contact

points and linkage. Also lubricate clutch cross shaft lever

every

30,000 miles (50 000 km) on rear-wheel-drive cars

only.

ITEM 3

Carburetor Choke and Hoses*

If your car is equipped with a carburetor, verify that

choke and vacuum break work properly and are within

specifications. Correct any binding caused by damage or

gum on the choke shaft. Inspect hoses for proper hookup,

cracks, chafing or decay. Correct as necessary.

Vacuum or A.I.R. Pump Drive Belt Inspection*

When a separate belt is used to drive the vacuum or

A.I.R.

pump, inspect it for cracks, fraying, wear and

proper tension. Adjust or replace as needed.

ITEM 8

Cooling System Service*

Drain, flush and refill system with new coolant. See

your Owner's Manual

for further details.

ITEM 9

Wheel Bearing Repack (Rear-Wheel-Drive Cars

Only Except Corvette)

Clean and repack front wheel bearings at each brake

relining or 15,000 miles

(25 000 km), whichever comes

first, when car is used in such service as police, taxi or

door-to-door delivery. If you do not use your car in such

service, clean and repack bearings at each brake relining

or 30,000 miles

(50 000 km), whichever comes first.

Corvette models do not require wheel bearing repack.

Page 196 of 1825

POWER STEERING 387-3

crocus cloth or fine hone. If the system 4. If the pump checks within specifications, leave

contains some dirt, flush it. If it is the valve open and turn (or have turned) the

exceptionally dirty, both the pump and the steering wheel into both corners. Record the

gear must be completely disassembled, highest pressures and compare with the

cleaned, flushed and reassembled before maximum pump pressure recorded. If this

further usage. pressure cannot be built in either (or one) side of

- the gear, the gear is leaking internally and must

c. If

the pressures recorded are constant, but

be disassembled and repaired. See "Unit Repair"

more than

100 PSI (690 kPa), below the

at the end of this section.

spec.9 rep1ace the flow 8. Shut off engine, remove testing gage, spare hose,

valve and recheck. If the pressures are still

low, replace the rotating group in the pump. reconnect pressure hose, check fluid

level and/or

make needed repairs.

ON-VEHICLE SERVICE

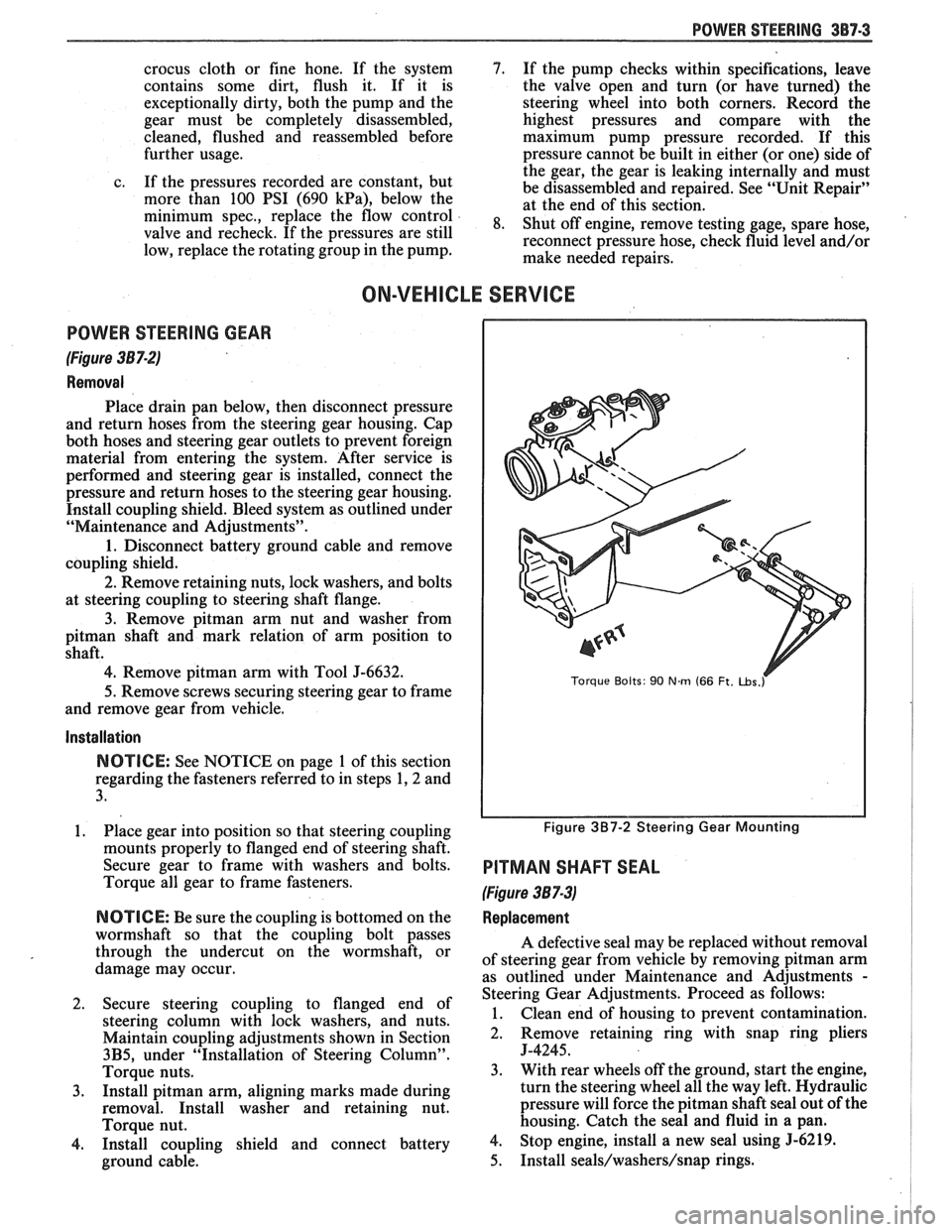

POWER STEERING GEAR

(Figure 387-2)

Removal

Place drain pan below, then disconnect pressure

and return hoses from the steering gear housing. Cap

both hoses and steering gear outlets to prevent foreign

material from entering the system. After service is

performed and steering gear is installed, connect the

pressure and return hoses to the steering gear housing.

Install coupling shield. Bleed system as outlined under

"Maintenance and Adjustments".

1. Disconnect battery ground cable and remove

coupling shield.

2. Remove retaining nuts, lock washers, and bolts

at steering coupling to steering shaft flange.

3. Remove pitman arm nut and washer from

pitman shaft and mark relation of arm position to

shaft.

4. Remove pitman arm with Tool J-6632.

5.

Remove screws securing steering gear to frame

and remove gear from vehicle.

Installation

NOTICE: See NOTICE on page 1 of this section

regarding the fasteners referred to in steps 1,2 and

3.

1. Place gear into position so that steering coupling

mounts properly to flanged end of steering shaft.

Secure gear to frame with washers and bolts.

Torque all gear to frame fasteners.

NOTICE: Be sure the coupling is bottomed on the

wormshaft so that the coupling bolt passes

through the undercut on the wormshaft, or

damage may occur.

2. Secure steering coupling to flanged end of

steering column with lock washers, and nuts.

Maintain coupling adjustments shown in Section

3B5, under "Installation of Steering Column".

Torque nuts.

3. Install pitman arm, aligning marks made during

removal. Install washer and retaining nut.

Torque nut.

4. Install coupling shield and connect battery

ground cable.

Torque Bolts: 90 Nm (66 Ft. ~bs.r

Figure 3B7-2 Steering Gear Mounting

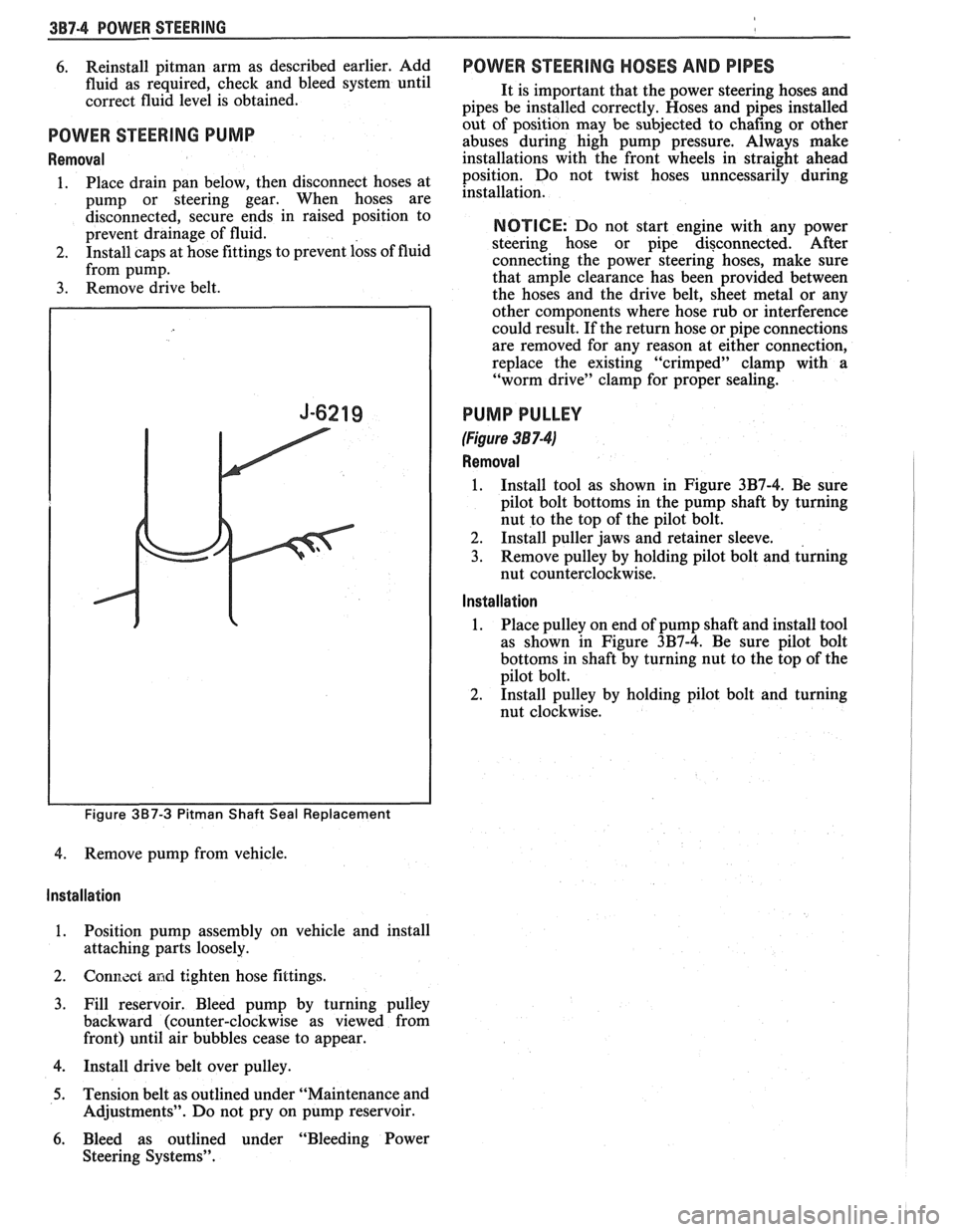

PITMAN SHAFT SEAL

(Figure 387-3)

Replacement

A defective seal may be replaced without removal

of steering gear from vehicle by removing

pitman arm

as outlined under Maintenance and Adjustments

-

Steering Gear Adjustments. Proceed as follows:

1. Clean end of housing to prevent contamination.

2. Remove retaining

ring with snap ring pliers

J-4245.

3. With rear wheels off the ground, start the engine,

turn the steering wheel all the way left. Hydraulic

pressure will force the

pitman shaft seal out of the

housing. Catch the seal and fluid in a pan.

4. Stop engine, install a new seal using 5-6219.

5. Install seals/washers/snap rings.

Page 197 of 1825

3B7-4 POWER STEERING

6. Reinstall pitman arm as described earlier, Add

fluid as required, check and bleed system until

correct fluid level is obtained.

POWER STEERING PUMP

Removal

1. Place drain pan below, then disconnect hoses at

pump or steering gear. When hoses are

disconnected, secure ends in raised position to

prevent drainage of fluid.

2. Install caps at hose fittings to prevent loss of fluid

from pump.

3. Remove drive belt.

Figure 3B7-3 Pitman Shaft Seal Replacement

4. Remove pump from vehicle.

Installation

1. Position pump assembly on vehicle and install

attaching parts loosely.

2. Gonl7.zct and tighten hose fittings.

3. Fill reservoir. Bleed pump by turning pulley

backward (counter-clockwise as viewed from

front) until air bubbles cease to appear.

4. Install drive belt over pulley.

5. Tension belt as outlined under "Maintenance and

Adjustments". Do not pry on pump reservoir.

6. Bleed as outlined under "Bleeding Power

Steering Systems".

POWER STEERING HOSES AND PIPES

It is important that the power steering hoses and

pipes be installed correctly. Hoses and pipes installed

out of position may be subjected to chafing or other

abuses during high pump pressure. Always make

installations with the front wheels in straight ahead

position. Do not twist hoses unncessarily during

installation.

NOTICE: Do not start engine with any power

steering hose or pipe disconnected. After

connecting the power steering hoses, make sure

that ample clearance has been provided between

the hoses and the drive belt, sheet metal or any

other components where hose rub or interference

could result. If the return hose or pipe connections

are removed for any reason at either connection,

replace the existing "crimped" clamp with a

"worm drive" clamp for proper sealing.

PUMP PULLEY

(Figure 38 7-41

Removal

1. Install tool as shown in Figure 3B7-4. Be sure

pilot bolt bottoms in the pump shaft by turning

nut to the top of the pilot bolt.

2. Install puller jaws and retainer sleeve.

3. Remove pulley by holding pilot bolt and turning

nut counterclockwise.

Installation

1. Place

pulley on end of pump shaft and install tool

as shown in Figure 3B7-4. Be sure pilot bolt

bottoms in shaft by turning nut to the top of the

pilot bolt.

2. Install pulley by holding pilot bolt and turning

nut clockwise.

Page 218 of 1825

FRONT SUSPENSION 3C-7

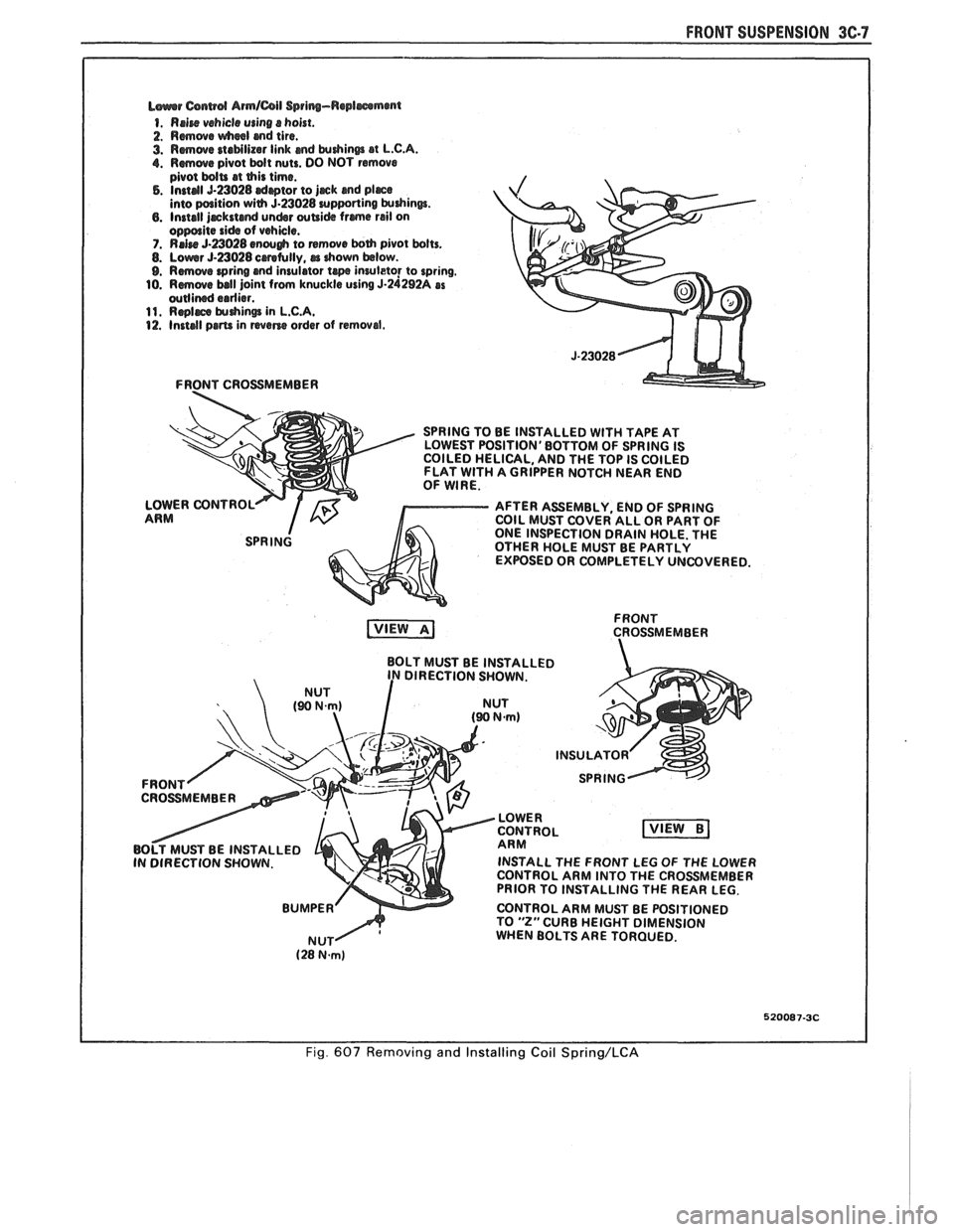

L~urrr Csnwd Armlail Spring-Replmmmt

1. Rrire vehicle using s hoist.

2. Rmwe wheel md tire.

3. Rmwe staMlizar link md krdrinm at L.C.A. 1. Rmwe pivot bdt nuts. DO NOT remove

pivot bdU at this time. 5. Instal 5-23028 drptor to jjrck and pljrce into paition with 5.23028 urpporting krdrinw. 6. Install jrckstcmd undsr wUi& frme rail on oppolite side of vehicle. 7. RrJre 5-a028 enough to remwe both pivot bolts. 8. Lowr 5-23028 crretully, rr drown below. 9. Rmove wring and insulator te inruleto! to spring.

10. Rmwe ball joint from knuckle using 5-24292A as wllined erdier. 11. Rqlrce $uhin@ in L.C.A. 12. Install prm in wane order of removal.

FRONT CROSSMEMBER

SPRING TO BE INSTALLED

WlTH TAPE AT

LOWEST POSITION'BOTTOM OF SPRING IS

COILED HELICAL, AND THE TOP IS COILED

FLAT

WlTH A GRIPPER NOTCH NEAR END

OF WIRE.

LOWER CONTROL

AFTER ASSEMBLY, END OF SPRING

ARM COIL MUST COVER ALL OR PART OF

ONE INSPECTION DRAIN HOLE. THE

OTHER HOLE MUST BE PARTLY

EXPOSED OR COMPLETELY UNCOVERED.

FRONT

CROSSMEMBER

BOLT MUST BE INSTALLED

DIRECTION SHOWN.

INSTALL THE FRONT LEG

OF THE LOWER

CONTROL ARM INTO THE CROSSMEMBER

PRIOR TO INSTALLING THE REAR LEG.

CONTROL ARM MUST BE POSITIONED

TO

"2" CURB HEIGHT DIMENSION

WHEN BOLTS ARE TORQUED.

520087-3C

Fig. 607 Removing and Installing Coil Spring/LCA

Page 254 of 1825

REAR AXLE 481-1

SECTION 4B4

BORG WARNER REAR AXLE

NOTICE: All rear axle attaching fasteners are an

necessary. Do not use a replacement part of lesser

important part in that they could affect the

quality or substitute design. Torque values must

performance of vital parts and systems, and/or

be used as specified during reassembly to assure

could result in major repair expense. They must

proper retention of all parts. (There is to be no

be replaced with one of the same part number or

welding as it may result in extensive damage and

with an equivalent part if replacement becomes

weakening of the metal.)

CONTENTS

General Description ............................... 4B 1- I

......... Standard Rear Axle ................... ..... 4B 1 - 1

General Information ............................. .... 4B 1- 1

Limited-Slip Rear Axle .............................. 4B 1-2

Operation

............................................ 4B 1-3

Diagnosis and Testing .......................... 4B 1-2

Axle Noises

..................... .... .................. 4B 1-2

Gear Noise

................................... .... .. 4B 1-4

Bearing Noise

......................... ...... ... 4B 1-4

Rear Wheel Bearing Noise ..................... 4B 1-4

Knock At Low Speeds

....................... ..... 4B 1-4

Backlash Clunk

................................... 4B 1-4

Diagnosis

................................................ 4B 1-4

Pre-Repair Investigation and Trouble

Diagnosis

....................... .. .................... 4B 1-4

...................................... On-Vehicle Sewice 4B 1-7

Carrier Cover and Gasket .......................... 4B 1-7

.............. Axle Shaft ......................... ....., 4B 1-7

Tooth Contact Pattern Test

................... 4B 1-8

Procedure

.................... .. ...................... 4B 1-8

Effects of Increasing Load on

Teeth Contact Pattern

......................... 4B 1-8

Adjustments Affecting Tooth

................................................ Contact 4B 1-8

Effects of Pinion

Postion on Tooth Pattern

............................................... 4B

1-8

Pinion Oil Seal and Companion

Flange Replacement

................... .. ...... 4B 1-8

Rear Wheel Bolt

........................................ 4B 1 - 10

Rear Axle Assembly

................................... 4B I - 10

Unit Repair

............................................... 4Bl-1 1

Drain Rear Axle Assembly ........................ 4B I - I I

Differential Assembly ............................. 4B 1 - 1 1

Hypoid Pinion & Pinion Bearings .......... 4B 1- I I

Four Pinion Standard Differential

Assembly

....................... ... ........... 4B 1 - 1 3

Inspection

............................................ 4B 1 - I:!

Differential Assembly .......................... 4B 1 - 14

Differential Bearing Preload Spacer

................... ...................... Selection .. 4B I - 11

.................................................. Pinion 4B 1 - 15

Operation of Limited Slip Rear Axle

........................................... (Cone Type) 4B 1 - 17

Checking Limited-Slip Function

............ 4B 1 - 17

......................... Limited Slip Differential 4B 1 - 18

.............. Disassembly Inspection Chart 4B

1- 18

......................... Limited Slip Differential 4B I - 1 X

............................................. Specifications

4B 1- 19

Axle Code Identification Chart

............ 4B 1-19

............................................. Special Tools 4B 1-20

GENERAL DESCRIPTION

STANDARD REAR AXLE All parts necessary to transmit power from the

propeller shaft to the rear wheels are enclosed in a

The rear axle assembly is of the semi-floating type salisbury type axle housing (a carrier casting with tubes

in which the car weight is carried on the axle housing.

pressed and welded into the carrier to form a complete The rear axle assembly is designed for use with an open carrier and tube assembly). A removable steel cover drive line and coil springs. The rear axle has a hypoid bolted to the rear of the carrier permits service of the type ring gear and pinion with the centerline of the rear axle without removing the entire assembly from

pinion gear below the centerline of the ring gear.

the car.

GENERAL INFORMATION

NOTICE: Most rear axle service repairs can be

Two pre-loaded tapered roller bearings support the

made with the rear axle assembly in the car, by

hypoid pinion gear in the carrier. The inner race of the

raising the rear end of the car with the rear axle

rear bearing is a tight press fit on the pinion stem. The

hanging on the shock absorbers.

inner race of the front bearing combines a light press

fit to a close sliding fit on the pinion flange end of the

A universal joint connects the rear end of the pinion stem. The outer race of each bearing is pressed

propeller shaft to a companion flange having a splined against a shoulder recessed in the carrier. Tightening

end which fits over and drives the

hypoid pinion gear. the pinion nut compresses a collapsible spacer which

Page 260 of 1825

REAR AXLE 481-7

ON-VEHICLE SERVICE

CARRIER COVER AND GASKET

Remove or Disconnect

1. Having

a container in place remove drain plug

with tool

J-35117,remove cover bolts and pry

cover loose to drain lubricant.

2. Make sure both

gasket sealing surfaces are clean.

Install or Connect

Use cover gasket (do not assemble with

sealant alone).

NOTICE: Apply locktite part No. 573, GM Part

Nos. 1052080, or 1052279 or equivalent to cover

bolts before installing cover. If sealant is not applied

bolts may loosen causing fluid leak and damage to

rear axle assembly.

1. Torque cover bolts in a crosswise pattern to

insure uniform draw on gasket. Torque

26 N.m

(20 1b.ft.).

2. Fill with lubricant to bottom of filler plug hole.

Refer to specifications for correct lubricant usage

and quantity.

AXLE SHAFT

Remove or Disconnect

1. Wheel

and brake components as necessary.

2. The

four nuts holding the brake anchor plate and

outer bearing retainer.

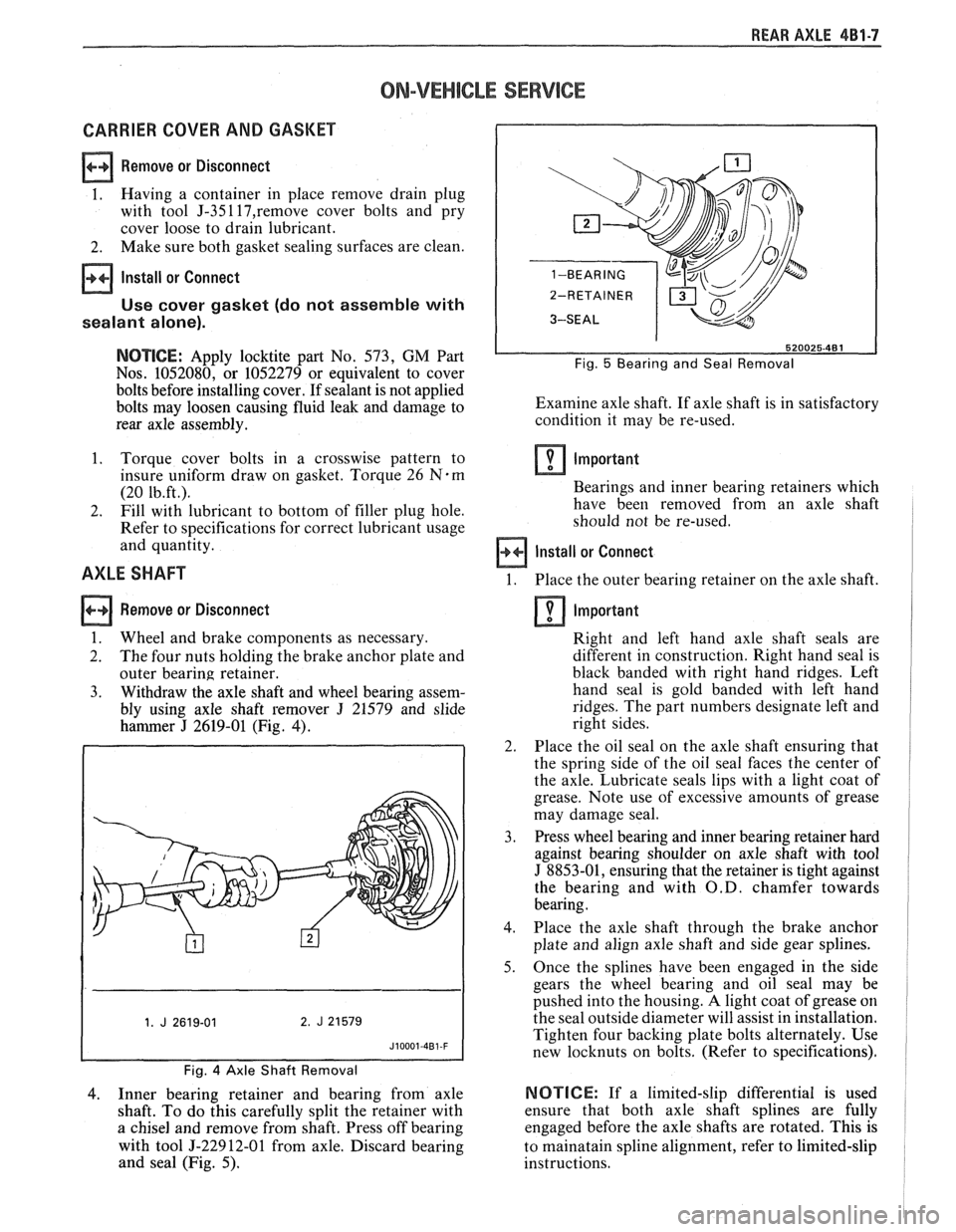

3. Withdraw the axle shaft and wheel bearing assem-

bly using axle shaft remover

J 21579 and slide

hammer

J 2619-01 (Fig. 4).

Fig. 4 Axle Shaft Removal

4. Inner

bearing retainer and bearing from axle

shaft. To do this carefully split the retainer with

a chisel and remove from shaft. Press off bearing

with tool

5-22912-01 from axle. Discard bearing

and seal (Fig. 5).

Fig. 5 Bearing and Seal Removal

Examine axle shaft. If axle shaft is in satisfactory

condition it may be re-used.

Important

Bearings and inner bearing retainers which

have been removed from an axle shaft

should not be re-used.

Install or Connect

1. Place the outer bearing retainer on the axle shaft.

Important

Right and left hand axle shaft seals are

different in construction. Right hand seal is

black banded with right hand ridges. Left

hand seal is gold banded with left hand

ridges. The part numbers designate left and

right sides.

2. Place the oil seal on the axle shaft ensuring that

the spring side of the oil seal faces the center of

the axle. Lubricate seals lips with a light coat of

grease. Note use of excessive amounts of grease

may damage seal.

3. Press wheel bearing and inner bearing retainer hard

against bearing shoulder on axle shaft with tool

J 8853-01, ensuring that the retainer is tight against

the bearing and with

O.D. chamfer towards

bearing.

4. Place the axle shaft through the brake anchor

plate and align axle shaft and side gear splines.

5. Once the splines have been engaged in the side

gears the wheel bearing and oil seal may be

pushed into the housing.

A light coat of grease on

the seal outside diameter will assist in installation.

Tighten four backing plate bolts alternately. Use

new locknuts on bolts. (Refer to specifications).

NOTICE: If a limited-slip differential is used

ensure that both axle shaft splines are fully

engaged before the axle shafts are rotated. This is

to mainatain spline alignment, refer to limited-slip

instructions.

Page 261 of 1825

481.8 REAR AXLE

6. Replace

brake components and wheel.

7. Tighten wheel nuts and lower vehicle.

Tooth Contact Pattern Test

The side of the ring gear tooth which curves

outward, or is convex, is referred to as the "drive" side.

The concave side is the "coast" side. The end of the

tooth nearest center of ring gear is referred to as the

"toe" end. The end of the tooth farthest away from the

center is the "heel" end. Toe end of tooth is smaller

than heel end.

It is very important that tooth contact be tested

before the rear axle carrier assembly is disassembled.

Variations in the carrier or pinion rear bearing may

cause the pinion to be too far away from, or close to,

the ring gear. Thus, the tooth contact must be tested

and corrected, if necessary, or the gears may be noisy.

Procedure

1. Drain

oil out of carrier and carefully clean each

tooth of ring gear.

2. Apply parking brake until a torque of 54 to 70

N-m (40-50 lb. ft.) is required to turn the pinion.

3. Tighten bearing cap bolts to 52 N-m (40 lb. ft.).

4. Use gear marking compound part number

1052351 or equivalent and apply this mixture

sparingly to all ring gear teeth, using a medium

stiff brush. When properly used, the area of

pinion tooth contact will be visible when hand

load is applied.

A test made without loading the gears will not

give a satisfactory pattern. Turn pinion flange

with wrench so that ring gear rotates five full

revolutions, then reverse rotation so that ring

gear rotates five

revolutio~ls in opposite direction.

5. Observe pattern on ring gear teeth and compare

with Fig.

6.

Effects of Increasing Load on Teeth Contact

Pattern

When "load" on ring and pinion gear is

increased, such as when car is accelerated forward

from standstill or from normal drive, the tooth contact

will tend to spread out and, under very heavy load, will

extend from near toe to near heel on the drive side. The

entire contact also tends to shift toward heel under

increasingly heavier loads and will become somewhat

broader with respect to tops and bottoms of teeth. The

patterns obtained by this tooth contact pattern test

approximate a light load and, for this reason, they will

extend only about halfway.

The important thing to note is that the contact

pattern is centrally located up and down on the face of

the ring gear teeth.

Adjustments Affecting Tooth Contact

Two adjustments can be made which will affect

tooth contact pattern, backlash and position of drive

pinion in carrier. The effects of bearing pre-loads are

not readily apparent

on (hand-loaded) tooth contact

pattern tests; however, these adjustments should be within

specifications before proceeding with backlash

and drive pinion adjustments.

Backlash is adjusted by means of the side bearing

adjusting shims, which moves the entire case and ring

gear assembly closer to, or farther from, the drive

pinion (the adjusting shims are also used to set side

bearing pre-load). The position of the drive pinion is

adjusted by increasing or decreasing the shim thickness

between the rear pinion cup and axle housing

. The

shim is used in the rear axle case to compensate for

manufacturing tolerances. Increasing shim thickness

will move the pinion closer to centerline of the ring

gear. Decreasing shim thickness will move pinion

farther away from centerline of the ring gear.

Effects of Pinion Position on Tooth Pattern

When the drive pinion is too far away from

centerline of the ring gear, the pattern will be a high

heel contact on the drive side and high toe contact on

coast side (Fig. 6). Moving the pinion closer to

centerline of the ring gear by increasing shim thickness

will cause the high heel contact on drive side to lower

and move toward the toe; the high toe contact on coast

side will lower and move toward the heel.

When the pinion is too close to the centerline of

the ring gear, the pattern will be a low toe contact on

drive side and a low heel contact on the coast side.

Moving the pinion farther away from the ring gear by

decreasing shim thickness will cause low toe contact on

drive side to raise and move toward the heel; the low

heel contact on coast side will raise and move toward

the toe.

PINION OIL SEAL AND COMPANION FLANGE

REPLACEMENT

Remove or Disconnect

1. Mark the propeller shaft and companion flange

so they can be reassembled in the same position.

Remove four nuts and lock washers from two

saddles retaining

U-joints to companion flange

and remove propeller shaft.

2. Measure and record preload at pinion - this

includes pinion bearing, differential bearings,

effect of grease and oil seal. (Figure

7).

3. Pinion nut with companion flange remover

J-8614-01. (Figure 8).

4. Companion flange with companion flange

remover

5-8614-01. (Figure 8).

5. Seal and discard.

NOTICE: Before installing a new seal examine the

surface of the companion flange on which the seal

runs. Should this surface be damaged or the splines

excessively worn, a new companion flange should

be installed. Also examine the housing bore and

remove any nicks or burrs.

Page 264 of 1825

REAR AXLE 4Bl-I I

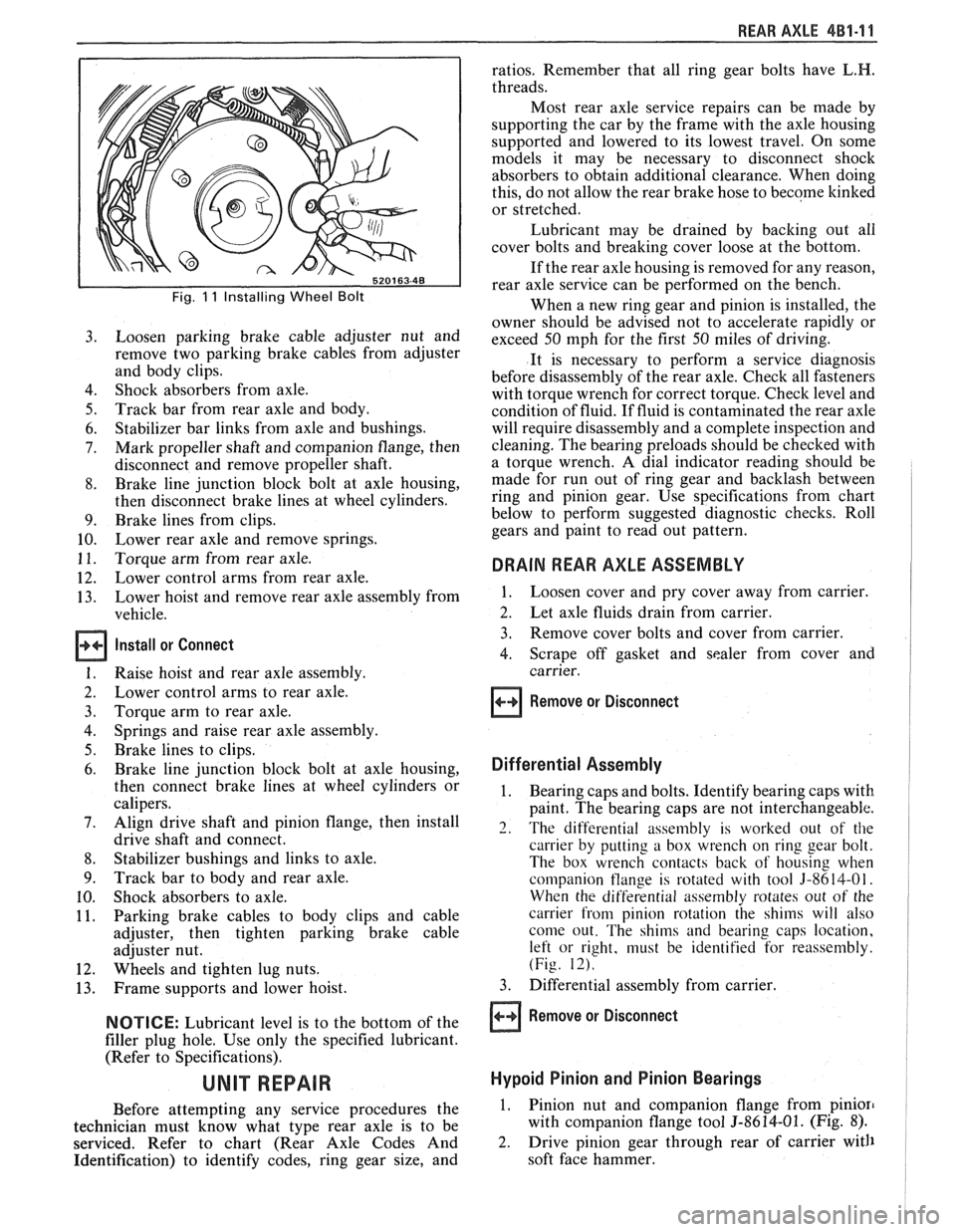

Fig. 11 Installing Wheel Bolt

Loosen parking brake cable adjuster nut and

remove two parking brake cables from adjuster

and body clips.

Shock absorbers from axle.

Track bar from rear axle and body.

Stabilizer bar links from axle and bushings.

Mark propeller shaft and companion flange, then

disconnect and remove propeller shaft.

Brake line junction block bolt at axle housing,

then disconnect brake lines at wheel cylinders.

Brake lines from clips.

Lower rear axle and remove springs.

Torque arm from rear axle.

Lower control arms from rear axle.

Lower hoist and remove rear axle assembly from

vehicle.

Install or Connect

Raise hoist and rear axle assembly.

Lower control arms to rear axle.

Torque arm to rear axle.

Springs and raise rear axle assembly.

Brake lines to clips.

Brake line junction block bolt at axle housing,

then connect brake lines at wheel cylinders or

calipers.

Align drive shaft and pinion flange, then install

drive shaft and connect.

Stabilizer bushings and links to axle.

Track bar to body and rear axle.

Shock absorbers to axle.

Parking brake cables to body clips and cable

adjuster, then tighten parking brake cable

adjuster nut.

Wheels and tighten lug nuts.

Frame supports and lower hoist.

NOTICE: Lubricant level is to the bottom of the

filler plug hole. Use only the specified lubricant.

(Refer to Specifications).

Before attempting any service procedures the

technician must know what type rear axle is to be

serviced. Refer to chart (Rear Axle Codes And

Identification) to identify codes, ring gear size, and ratios.

Remember that all ring gear bolts have

L.H.

threads.

Most rear axle service repairs can be made by

supporting the car by the frame with the axle housing

supported and lowered to its lowest travel. On some

models it may be necessary to disconnect shock

absorbers to obtain additional clearance. When doing

this, do not allow the rear brake hose to become

kinked

or stretched.

Lubricant may be drained by backing out all

cover bolts and breaking cover loose at the bottom.

If the rear axle housing is removed for any reason,

rear axle service can be performed on the bench.

When a new ring gear and pinion is installed, the

owner should be advised not to accelerate rapidly or

exceed 50 mph for the first 50 miles of driving.

It is necessary to perform a service diagnosis

before disassembly of the rear axle. Check all fasteners

with torque wrench for correct torque. Check level and

condition of fluid.

If fluid is contaminated the rear axle

will require disassembly and a complete inspection and

cleaning. The bearing preloads should be checked with

a torque wrench. A dial indicator reading should be

made for run out of ring gear and backlash between

ring and pinion gear. Use specifications from chart

below to perform suggested diagnostic checks. Roll

gears and paint to read out pattern.

DRAIN REAR AXLE ASSEMBLY

1. Loosen cover and pry cover away from carrier.

2. Let axle fluids drain from carrier.

3. Remove cover bolts and cover from carrier.

4. Scrape off gasket and sealer from cover and

carrier.

Remove or Disconnect

Differential Assembly

1. Bearing caps and bolts. Identify bearing caps with

paint. The bearing caps are not interchangeable.

2. The differential assembly is worked out of the

carrier by putting a box wrench on ring gear bolt.

The box wrench contacts back of housing when

companion

tlange is rotated with tool 3-8614-01.

When the differential assembly rotates out of the

carrier from pinion rotation the shims will also

come out. The shims and bearing caps location,

left or right, must be identified for reassembly.

(Fig. 12).

3. Differential assembly from carrier.

Remove or Disconnect

Hypoid Pinion and Pinion Bearings

1. Pinion nut and companion flange from pinion

with companion flange tool 5-8614-01. (Fig. 8).

2. Drive pinion gear through rear of carrier with

soft face hammer.

Page 281 of 1825

4B-8 REAR AXLE

GENERAL lNFORMATlON

A universal joint connects the rear end of the

propeller shaft to a pinion flange, having a splined end

which fits over and drives the

hypoid pinion gear. The

housing is attached to the underbody through a center

bearing support. Inside the housing, an extension shaft

is splined to the drive pinion at the rear end, and to the

companion flange at the other end. Two pre-loaded

tapered roller bearings support the

hypoid pinion gear

in the carrier. The inner race of the rear bearing is a

light press fit on the pinion stem. The inner race of the

front bearing combines a light press fit to a close sliding

fit on the pinion flange end of the pinion stem. The

outer race of each bearing is pressed against a shoulder

recessed in the carrier. Tightening the pinion nut

compresses a collapsible spacer which bears against the

inner race of the front bearing and a shoulder on the

pinion stem. This spacer is used to enable accurate

bearing pre-load adjustment and

maintain a pre-load

on both front and rear pinion bearings. Adjustment of the

fore and aft position of the pinion is obtained by

placing

shims between the head of the drive pinion and

the rear pinion bearing.

The rear axle case is of

one-piece construction and is supported in the carrier

by two tapered roller side bearings. These are

pre-loaded by inserting

shims between the bearings and

the carrier. The rear axle case assembly is positioned

for proper ring gear to pinion backlash by varying the

shin1 thickness from side to side. The ring gear is bolted

to the case. Two side gears have splined bores for

driving the axle shafts. They are positioned to turn in

counterbored cavities in the case. The two rear axle

pinions have

smooth bores and are held in position by

a solid pinion cross shaft, mounted and locked in the

rear axle case. All four gears are in

mesh with each

other and because the pinion gears turn freely

on their

shaft, they act as idler gears when the rear wheels are

turning at different speeds. The pinions and side gears

are backed by steel thrust washers.

LIMITED-SLIP REAR AXLE

The operation of the Limited-Slip differential is

the same as the standard differential, except that there

is additional friction provided by the clutches or cones.

Under ordinary driving and cornering conditions, the

clutches or cones slip, allowing the outside wheel to

turn faster than the inner. Under poor traction

conditions, such as ice, snow, or loose gravel under one

driving wheel, the increased friction provided by the clutches

or cones increases the driving torque available

to the wheel with the better traction. The clutches or

cones are spring loaded to provide the increased

driving torque under extremely low traction

conditions.

Most rear axle service repairs can be made with

the rear axle assembly in the car, by raising the rear end

of the car with the rear axle hanging

on the shock

absorbers.

ON-VEHICLE SERVICE

CARRIER COVER AND GASKET

Remove or Disconnect

1. Having a container in place, remove cover bolts

and pry cover loose to drain lubricant.

2. Make sure both gasket sealing surfaces are clean.

Install or Connect

Use sealant

1052366 or cover gasket

only.

1. Torque cover bolts in a crosswise pattern to

insure uniform draw on gasket. Torque

27 N.m

(20 Ib.fr.).

2. Fill with lubricant to a level within 4.5mm (3116")

or filler plug hole. Refer to specifications for correct

lubricant usage and quantity.

Axle Shaft

a Remove or Disconnect

1. Raise car and remove wheel and brake drum.

2. Clean all dirt from area of carrier.

3. Remove bolts and differential carrier cover and

allow lubricant to drain.

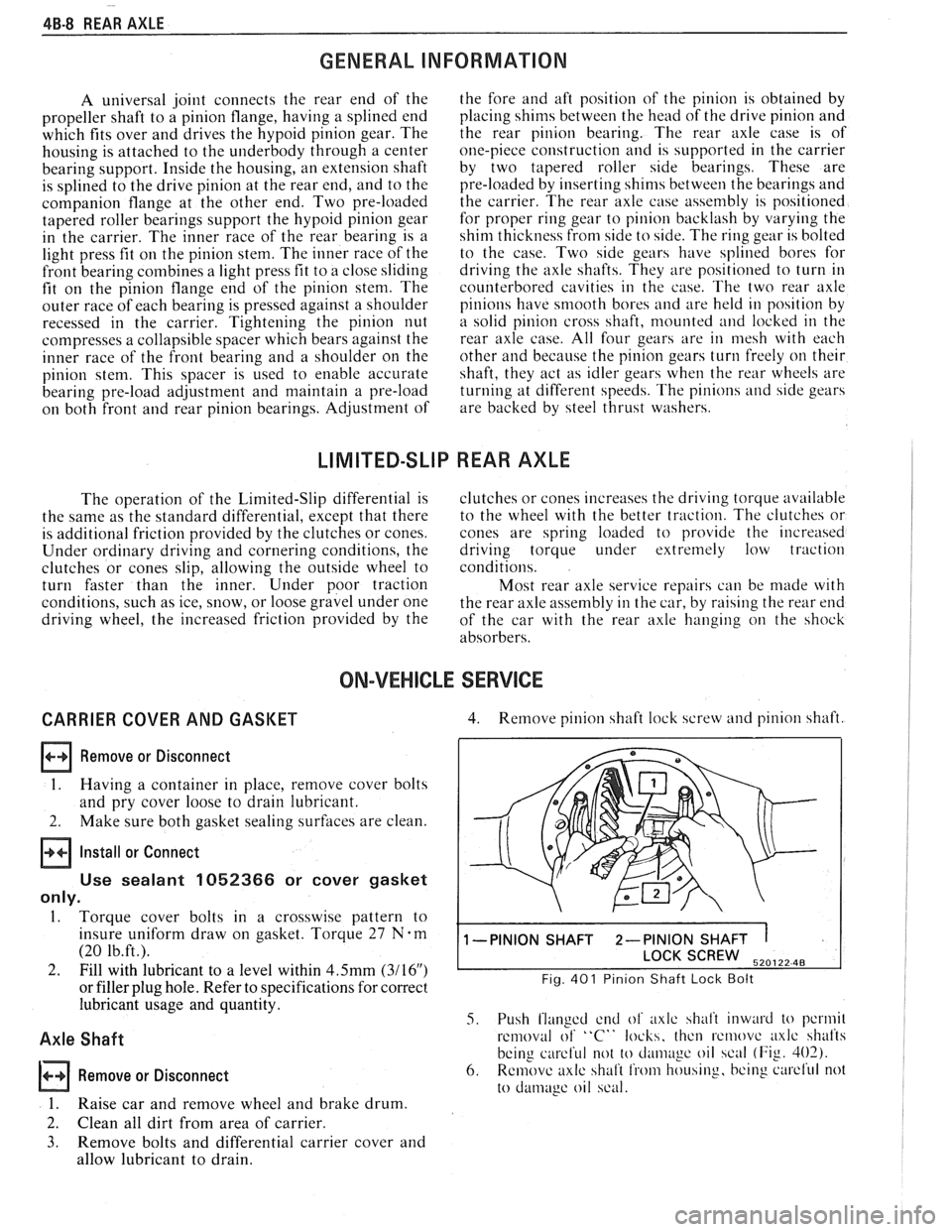

4. Remove pinion shaft lock screw and pinion shaft.

1 -PINION SHAFT 2-PINION SHAFT 1

SCREW 520122 48

Fig. 401 Pinion Shaft Lock Bolt

5. Push flanged end of axlc shalt inward to pcrmil

removal of "C" locks, thcn rcmovc axlc shafts

being

careful not to cl;uii~~gc oil scal (Fig. 402).

6. Remove axlc shaft from housing, bcing curcl'ul not

to

damage oil scal.

Page 284 of 1825

REAR AXLE 48-1 1

Rear Wheel Bolt

Remove or Disconnect 1.

1. Raise vehicle on hoist allowing axle to hang

freely. 2.

2. Remove

wheel, tire and brake drum.

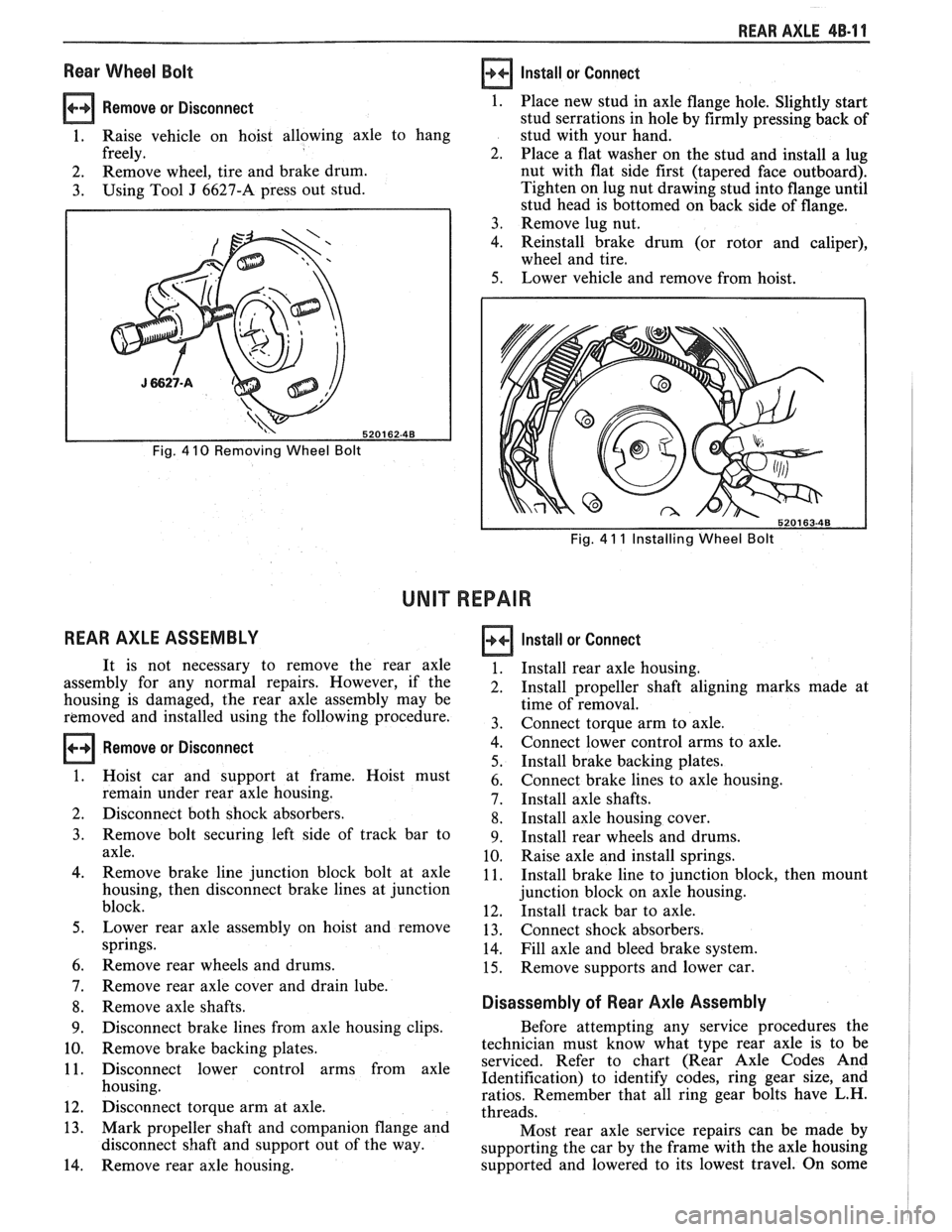

3. Using Tool J 6627-A press out stud.

Fig. 4 10 Removing Wheel Bolt

REAR AXLE ASSEMBLY

Install or Connect

Fig. 4 11 Installing Wheel Bolt

UNIT REPAIR

Remove or Disconnect

Place new stud in axle flange hole. Slightly start

stud serrations in hole by firmly pressing back of

stud with your hand.

Place a flat washer on the stud and install a lug

nut with flat side first (tapered face outboard).

Tighten on lug nut drawing stud into flange until

stud head is bottomed on back side of flange.

Remove lug nut.

Reinstall brake drum (or rotor and caliper),

wheel and tire.

Lower vehicle and remove from hoist.

It is not necessary to remove the rear axle

assembly for any normal repairs. However, if the

housing is damaged, the rear axle assembly may be

removed and installed using the following procedure.

Hoist car and support at frame. Hoist must

remain under rear axle housing.

Disconnect both shock absorbers.

Remove bolt securing left side of track bar to

axle.

Remove brake line junction block bolt at axle

housing, then disconnect brake lines at junction

block.

Lower rear axle assembly on hoist and remove

springs.

Remove rear wheels and drums.

Remove rear axle cover and drain lube.

Remove axle shafts.

Disconnect brake lines from axle housing clips.

Remove brake backing plates.

Disconnect lower control arms from axle

housing.

Disconnect torque arm at axle.

Mark propeller shaft and companion flange and

disconnect shaft and support out of the way.

Remove rear axle housing.

Install or Connect

Install rear axle housing.

Install propeller shaft aligning marks made at

time of removal.

Connect torque arm to axle.

Connect lower control arms to axle.

Install brake backing plates.

Connect brake lines to axle housing.

Install axle shafts.

Install axle housing cover.

Install rear wheels and drums.

Raise axle and install springs.

Install brake line to junction block, then mount

junction block on axle housing.

Install track bar to axle.

Connect shock absorbers.

Fill axle and bleed brake system.

Remove supports and lower car.

Disassembly of Rear Axle Assembly

Before attempting any service procedures the

technician must know what type rear axle is to be

serviced. Refer to chart (Rear Axle Codes And

Identification) to identify codes, ring gear size, and

ratios. Remember that all ring gear bolts have L.H.

threads.

Most rear axle service repairs can be made by

supporting the car by the frame with the axle housing

supported and lowered to its lowest travel. On some