jump start terminals PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 446 of 1825

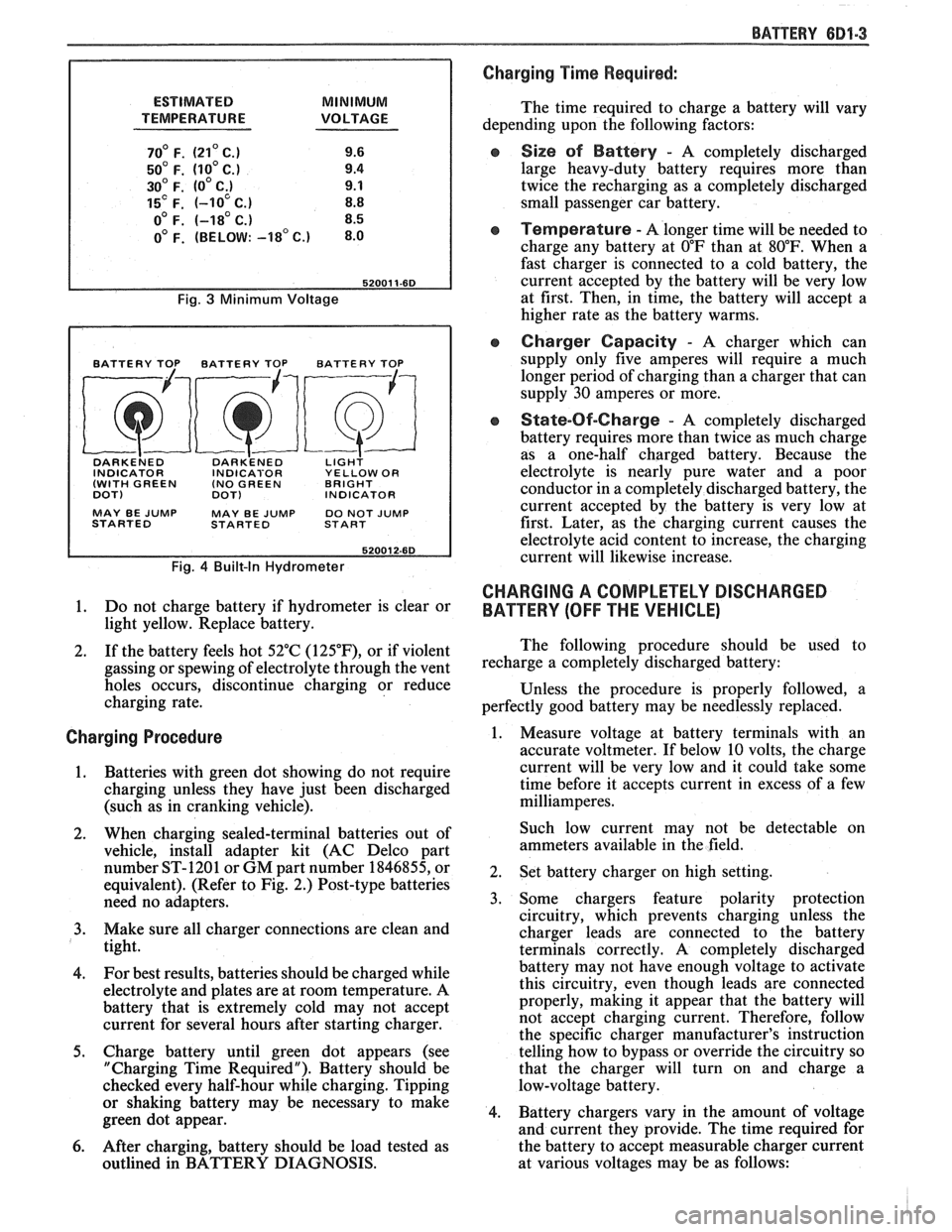

ESTIMATED MINIMUM

TEMPERATURE VOLTAGE

70' F. (21' C.) 9.6

50' F. (10' C.) 9.4

30' F. (0' C;) 9.1

15' F. (-10 C.) 8.8

o0 F. (-18' C.) 8.5

0' F. (BELOW: -18' c.) 8.0

Fig. 3 Minimum Voltage

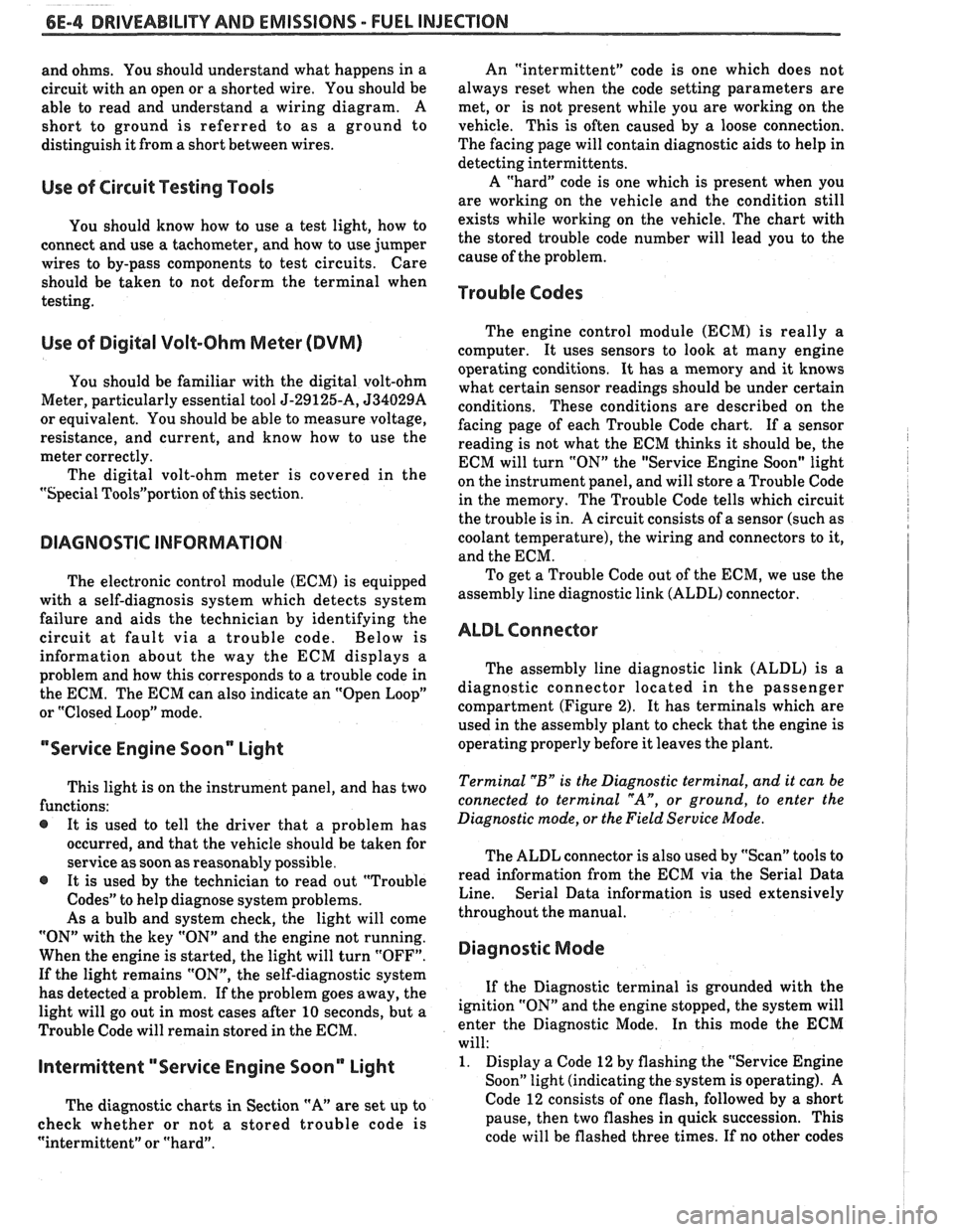

BATTERY TOP BATTERY TOP BATTERY TOP

DARKE~ED DARK'ENED LIGH? INDICATOR INDICABOR YELLOW OR

(WITH GREEN (NO

GREEN BRIGHT

DOT)

DOT) INDICATOR

MAY BE

JUMP MAY BE JUMP DO NOT JUMP

STARTED STARTED START

Fig. 4 Built-In Hydrometer

1. Do not charge battery if hydrometer is clear or

light yellow. Replace battery.

2. If the battery feels hot 52°C

(125"F), or if violent

gassing or spewing of electrolyte through the vent

holes occurs, discontinue charging or reduce

charging rate.

Charging Procedure

1. Batteries with green

dot showing do not require

charging unless they have just been discharged

(such as in cranking vehicle).

2. When charging sealed-terminal batteries out of

vehicle, install adapter kit (AC Delco part

number ST-1201 or GM part number 1846855, or

equivalent). (Refer to Fig. 2.) Post-type batteries

need no adapters.

3. Make sure all charger connections are clean and

tight.

4. For

best results, batteries should be charged while

electrolyte and plates are at room temperature. A

battery that is extremely cold may not accept

current for several hours after starting charger.

5. Charge battery until green dot appears (see

"Charging Time Required"). Battery should be

checked every half-hour while charging. Tipping

or shaking battery may be necessary to make

green dot appear.

6. After charging, battery should be load tested as

outlined in BATTERY DIAGNOSIS.

BATTERY 681-3

Charging Time Required:

The time required to charge a battery will vary

depending upon the following factors:

e Size sf Battery - A completely discharged

large heavy-duty battery requires more than

twice the recharging as a completely discharged

small passenger car battery.

Temperature - A longer time will be needed to

charge any battery at

O"F than at 80°F. When a

fast charger is connected to a cold battery, the

current accepted by the battery will be very low

at first. Then, in time, the battery will accept a

higher rate as the battery warms.

Charger Capacity - A charger which can

supply only five amperes will require a much

longer period of charging than a charger that can

supply

30 amperes or more.

e State-Of-Charge - A completely discharged

battery requires more than twice as much charge

as a one-half charged battery. Because the

electrolyte is nearly pure water and a poor

conductor in a completely discharged battery, the

current accepted by the battery is very low at

first. Later, as the charging current causes the

electrolyte acid content to increase, the charging

current will likewise increase.

CHARGING A COMPLETELY DISCHARGED

BATTERY

(OFF THE VEHICLE)

The following procedure should be used to

recharge a completely discharged battery:

Unless the procedure is properly followed, a

perfectly good battery may be needlessly replaced.

1. Measure voltage at battery terminals with an

accurate voltmeter. If below 10 volts, the charge

current will be very low and it could take some

time before it accepts current in excess of a few

milliamperes.

Such low current may not be detectable on

ammeters available in the field.

2. Set battery charger on high setting.

3. Some chargers feature polarity protection

circuitry, which prevents charging unless the

charger leads are connected to the battery

terminals correctly. A completely discharged

battery may not have enough voltage to activate

this circuitry, even though leads are connected

properly, making it appear that the battery will

not accept charging current. Therefore, follow

the specific charger manufacturer's instruction

telling how to bypass or override the circuitry so

that the charger will turn on and charge a

low-voltage battery.

4. Battery chargers vary in the amount of voltage

and current they provide. The time required for

the battery to accept measurable charger current

at various voltages may be as follows:

Page 965 of 1825

6E-4 DRIVEABILITY AND EMISSIONS - FUEL INJECnON

and ohms. You should understand what happens in a

circuit with an open or a shorted wire. You should be

able to read and understand a wiring diagram. A

short to ground

is referred to as a ground to

distinguish it from a short between wires.

Use of Circuit Testing Tools

You should know how to use a test light, how to

connect and use

a tachometer, and how to use jumper

wires to by-pass components to test circuits. Care

should be taken to not deform the terminal when

testing.

Use of Digital Volt-Ohm Meter (DVM)

You should be familiar with the digital volt-ohm

Meter, particularly essential tool J-29125-A,

J34029A

or equivalent. You should be able to measure voltage,

resistance, and current, and know how to use the

meter correctly.

The digital volt-ohm meter is covered in the

"Special

ToolsJ'portion of this section.

DIAGNOSTIC INFORMATION

The electronic control module (ECM) is equipped

with a self-diagnosis system which detects system

failure and aids the technician by identifying the

circuit at fault via a trouble code. Below is

information about the way the ECM displays a

problem and how this corresponds to a trouble code in

the ECM. The ECM can also indicate an "Open Loop"

or "Closed Loop" mode.

"'Service Engine Soonw Light

This light is on the instrument panel, and has two

functions:

@ It is used to tell the driver that a problem has

occurred, and that the vehicle should be taken for

service as soon as reasonably possible.

@ It is used by the technician to read out "Trouble

CodesJ' to help diagnose system problems.

As a bulb and system check, the light will come

"ON" with the key "ON" and the engine not running.

When the engine is started, the light will turn "OFF".

If the light remains "ONJ', the self-diagnostic system

has detected a problem. If the problem goes away, the

light will go out in most cases after 10 seconds, but a

Trouble Code will remain stored in the ECM.

Intermittent "Service Engine Soon" Light

The diagnostic charts in Section "A" are set up to

check whether or not a stored trouble code is

"intermittent" or "hard". An

"intermittent" code is one which does not

always reset when the code setting parameters are

met, or is not present while you are working on the

vehicle. This is often caused by

a loose connection.

The facing page will contain diagnostic aids to help in

detecting

intermittents.

A "hard" code is one which is present when you

are working on the vehicle and the condition still

exists while working on the vehicle. The chart with

the stored trouble code number will lead you to the

cause of the problem.

Trouble Codes

The engine control module (ECM) is really a

computer. It uses sensors to look at many engine

operating conditions. It has

a memory and it knows

what certain sensor readings should be under certain

conditions. These conditions are described on the

facing page of each Trouble Code chart. If a sensor

reading is not what the ECM thinks it should be, the

ECM will turn "ON" the "Service Engine Soon" light

on the instrument panel, and will store a Trouble Code

in the memory. The Trouble Code tells which circuit

the trouble is in. A circuit consists of a sensor (such as

coolant temperature), the wiring and connectors to it,

and the ECM.

i

To get a Trouble Code out of the ECM, we use the

assembly line diagnostic link (ALDL) connector.

!

ALDL Connector I

I

The assembly line diagnostic link (ALDL) is a

diagnostic connector located in the passenger

compartment (Figure 2). It has terminals which are

used in the assembly plant to check that the engine is

operating properly before it leaves the plant.

Terminal "B" is the Diagnostic terminal, and it can be

connected to terminal

"A", or ground, to enter the

Diagnostic mode, or the Field Service Mode.

The ALDL connector is also used by "ScanJ' tools to

read information from the ECM via the Serial Data

Line. Serial Data information

is used extensively

throughout the manual.

Diagnostic Mode

1

If the Diagnostic terminal is grounded with the

ignition "ON" and the engine stopped, the system will

enter the Diagnostic Mode. In this mode the ECM

will:

1. Display a Code 12 by flashing the "Service Engine

Soon" light (indicating the system is operating). A

Code 12 consists of one flash, followed by a short

pause, then two flashes in quick succession. This

code will be flashed three times. If no other codes

Page 1186 of 1825

TROUBLESHOOTING TESTS m r rn 0

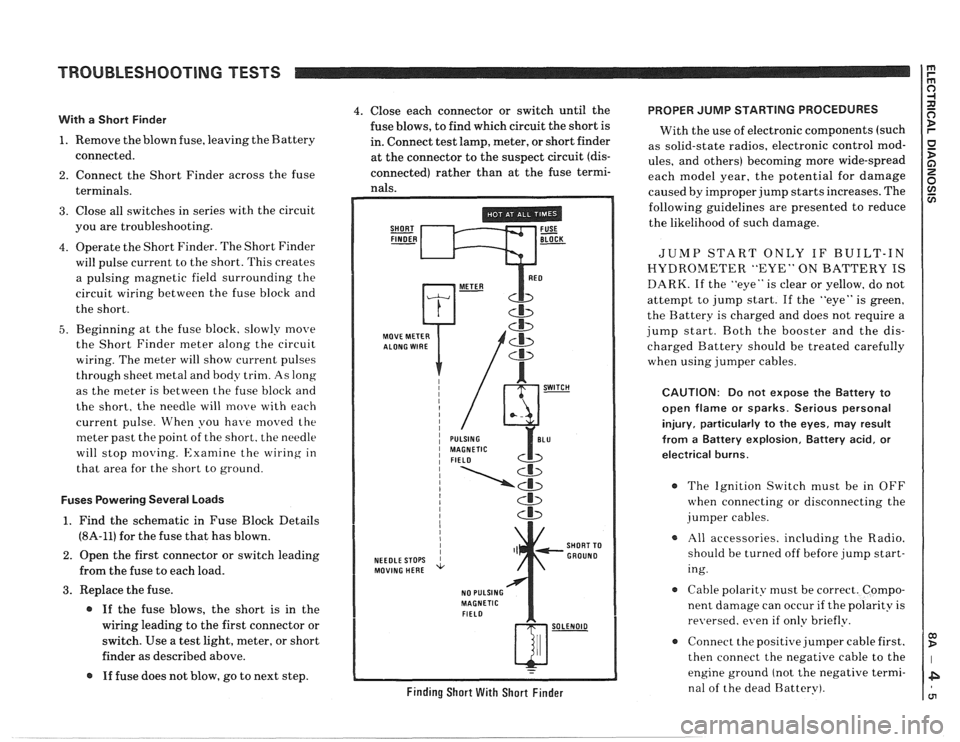

With a Short Finder

1. Remove the blown fuse, leaving the Battery

connected.

2. Connect the Short Finder across the fuse

terminals.

3. Close all switches in series with the circuit

you are troubleshooting.

4. Operate the Short Finder. The Short Finder

will pulse current to the short. This creates

a pulsing magnetic field surrounding the

circuit wiring between the fuse block and

the short.

5. Beginning at the fuse block. slowly move

the Short Finder meter along the circuit

wiring. The meter will show current pulses

through sheet

inetal and body trim. As long

as the meter is between the fuse block and

the short, the needle will move with each

current pulse. When you have

moved the

meter past the point of the short. the needle

will stop

moving. Examine the wiring in

that area for the short to ground.

Fuses Powering Several Loads

1. Find the schematic in Fuse Block Details

(8A-11) for the fuse that has blown.

2. Open the first connector or switch leading

from the fuse to each load.

3. Replace the fuse.

@ If the fuse blows, the short is in the

wiring leading to the first connector or

switch. Use a test light, meter, or short

finder as described above.

@ If fuse does not blow, go to next step.

4. Close each connector or switch until the PROPER JUMP STARTING PROCEDURES

fuse blows, to find which circuit the short is

With the use of electronic components (such

in. Connect test lamp, meter, or short finder

as solid-state radios, electronic control

mod- at the connector to the suspect circuit (dis- ules, and others) becoming more wide-spread

connected) rather than at the fuse termi- each model year, the potential for damage nals. caused by improper jump starts increases. The

SHORT FUSE FINDER - BLOCK -

MOVE METER

NEEDLE STOPS

MOVING HERE

NO PULSING

MAGNETIC

FIELD

Cb

SHORT TO

GROUND

w-

Finding Short With Short Finder

following guidelines are presented to reduce

the likelihood of such damage.

JUMP START ONLY IF BUILT-IN

HYDROMETER "EYE" ON BATTERY IS

DARK. If the "eye" is clear or yellow, do not

attempt to jump start. If the "eye" is green,

the Battery is charged and does not require a

jump start. Both the booster and the dis-

charged Battery should be treated carefully

when using jumper cables.

CAUTION: Do not expose the Battery to

open flame or sparks. Serious personal

injury, particularly

to the eyes, may result

from

a Battery explosion, Battery acid, or

electrical burns.

The Ignition Switch must be in OFF

when connecting or disconnecting the

jumper cables.

All accessories. including the Radio.

should be turned off before jump start-

ing.

Cable polarity must be correct. Compo-

nent damage can occur

if the polarity is

re~~ersed. even if only briefly.

a Connect the positive jumper cable first.

then connect the negative cable to the

engine ground (not the negative termi-

nal of the dead Battery).

Page 1298 of 1825

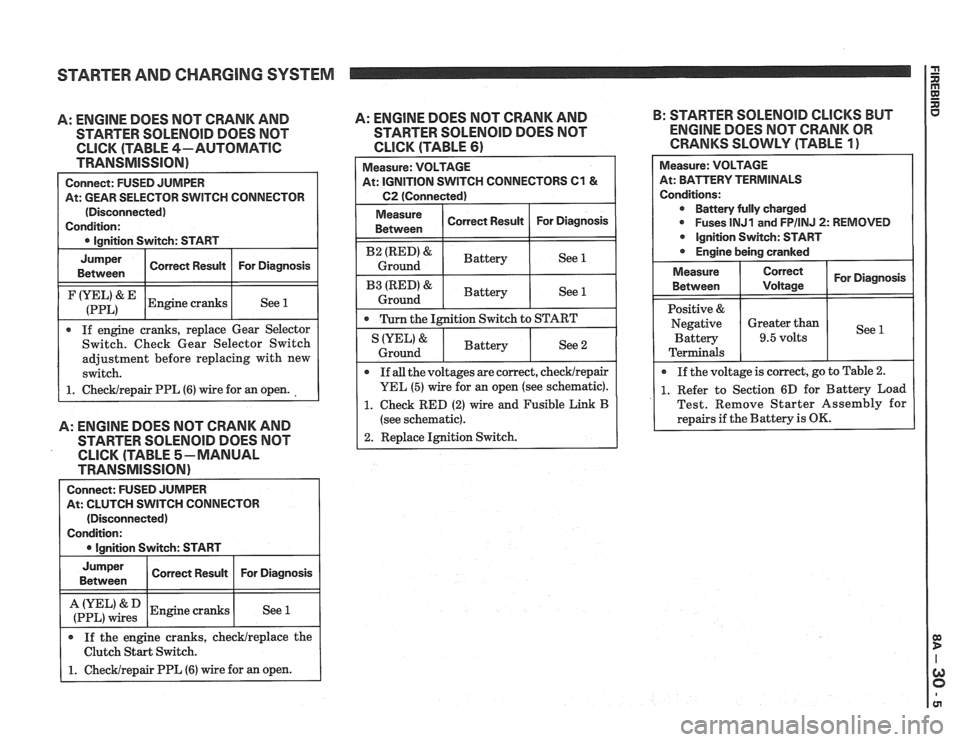

STARTER AND CHARGING SYSTEM

A: ENGINE DOES NOT CRANK AND

STARTER SOLENOID DOES NOT

CLICK (TABLE 4-AUTOMATIC

TRANSMISSION)

Connect: FUSED JUMPER

At: GEAR SELECTOR SWITCH CONNECTOR

(Disconnected)

Condition:

0 Ignition Switch: START

I

Jumper I Corren Resuk I For Diagnosis I Between

I (:::LI& IEngine cranks I See 1 1

If engine cranks, replace Gear Selector

Switch. Check Gear Selector Switch

adjustment before replacing with new

switch.

1. ChecWrepair PPL (6) wire for an open.

A: ENGINE DOES NOT CRANK AND

STARTER SOLENOlD DOES NOT

CLICK (TABLE 5-MANUAL

TRANSMISSION)

Connect: FUSED JUMPER

At: CLUTCH SWITCH CONNECTOR

(Disconnected)

Condition:

I 0 lanition Switch: START I

I :if,",":: 1 Engine cranks I See 1 I

Jumper

Between

If the engine cranks, checklreplace the

Clutch Start Switch.

1. Checklrepair PPL (6) wire for an open.

A: ENGINE DOES NOT CRANK AND B:

STARTER SOLENOID CLICKS BUT

STARTER

SOLENOID DOES NOT ENGINE DOES NOT CRANK OR

CLICK (TABLE 61 CRANKS SLOWLY (TABLE 1)

Correct Result Measure:

VOLTAGE

At: IGNITION SWITCH CONNECTORS

C1 &

C2 (Connected)

For Diagnosis

I Measure ( Correct Result I For Diagnosis 1 Between

I B2 (RED)& I Battery ( See 1 I Ground

I B3 IRED'& I Battery ( See 1 1 Ground

0 Turn the Ignition Switch to START

Measure: VOLTAGE

At: BPirTERV TERMINALS

Conditions: Battery fully charged

0 Fuses lNJ1 and FPIINJ 2: REMOVED

Ignition Switch: START

Engine being cranked

See 2 IYEL' &

Ground

For Diagnosis

See

Measure

Between

Positive &

Negative Battery

Terminals

If

all the voltages are correct, checklrepair

YEL (5) wire for an open (see schematic).

1. Check RED (2) wire and Fusible Link B

(see schematic).

2. Replace Ignition Switch.

Battery

0 If

the voltage is correct, go to Table 2.

1. Refer to Section 6D for Battery Load

Test. Remove Starter Assembly for

repairs if the Battery is

OK.

Correct

Voltage

Greater than

9.5 volts

Page 1515 of 1825

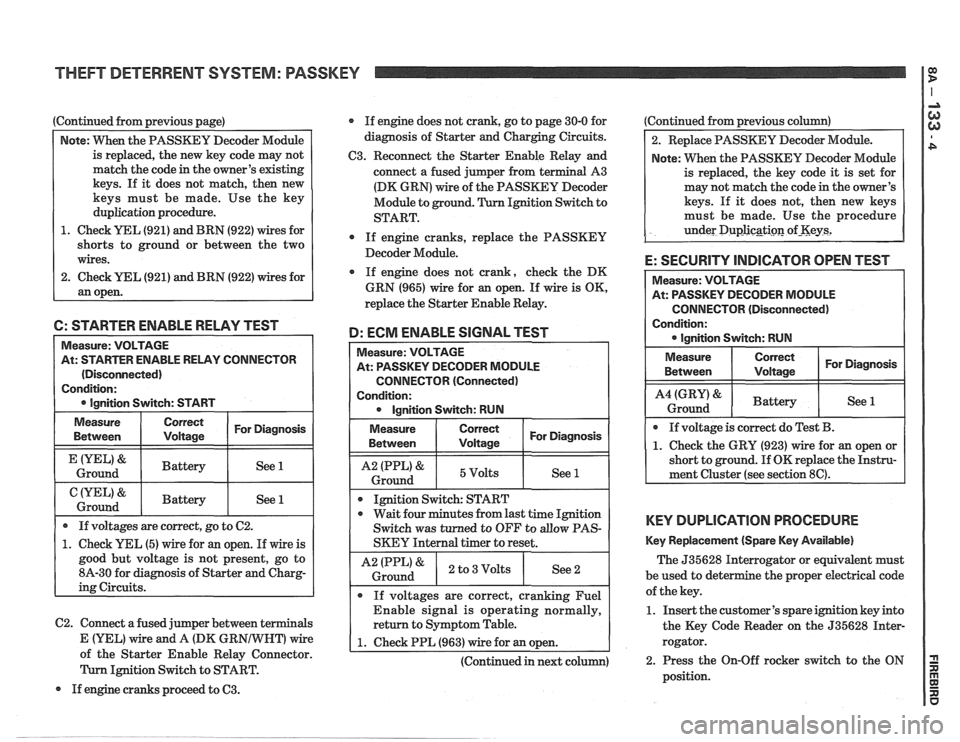

Continued from previous page)

Note: VVhen the PASSKEY Decoder Module

is replaced, the new key code may not

match the code in the owner's existing

keys. If it does not match, then new

keys must be made. Use the key

duplication procedure.

1. Check YEL (921) and BRN (922) wires for

shorts to ground or between the two

wires.

2. Check

UEL (921) and BRN (922) wires for

an open. If

engine does not crank, go to page 30-0 for

diagnosis of Starter and Charging Circuits.

C3. Reconnect the Starter Enable Relay and

connect a fused jumper from terminal A3

(DK GRN) wire of the PASSKEY Decoder

Module to ground. Ignition Switch to

START.

0 If engine cranks, replace the PASSKEY

Decoder Module.

If engine does not crank, check the DK

GRN (965) wire for

an open. If wire is OK,

replace the Starter Enable Relay.

6: STARTER ENABLE RELAY TEST

D: ECM ENABLE SIGNAL TEST

C2. Connect a fused jumper between terminals

Measure: VOLTAGE

At: STARTER ENABLE RELAY CONNECTOR

(Disconnected)

Condition:

0 Ignition Switch: START Measure:

VOLTAGE

At: PASSKEY DECODER MODULE

CONNECTOR (Connected)

Condition: 0 Ignition Switch: RUN

Measure

Between

&

Ground

&

Ground

Measure

Between I I For Diagnosis ( Voltage

1 I 5Volts I See 1 1

If voltages are correct, go to C2.

1. Check YEL (5) wire for an open. If wire is

good but voltage is not present, go to

8A-30 for diagnosis of Starter and Charg-

ing Circuits.

Correct

Voltage

Battery

Battery

I I

Ignition Switch: START

For Diagnosis

See 1

See 1

0 wait four minutes from last time Ignition

Switch was turned to OFF to

allow PAS-

SKEY Internal timer to reset.

I A2 IPPL)& ) 2 to3Volts I See2 i Ground

If voltages are correct, cranking Fuel

Enable signal is operating normally,

return to Symptom Table.

E (YEL) Vfire and A (DK GR wire 1 1. Check PPL (963) wire for an open. A of the Starter Enable Relay Connector. I I

(Continued in next column)

Ignition Switch to START.

If engine cranks proceed to

63.

Continued from previous column)

2. Replace PASSKEY Decoder Module.

Note: When the PASSKEY Decoder Module

is replaced, the key code

it is set for

may not match the code in the owner's

keys. If

it does not, then new keys

must be made. Use the procedure

under

Duplicgti~n of-Keys2

E: SECURITY INDICATOR OPEN TEST

CONNECTOR (Disconnected)

Condition:

KEY DUPLICATION PROCEDURE

Key Replacement (Spare Key Available)

The 535628 Interrogator or equivalent must

be used to det e

the proper electrical code

of the key.

1. Insert the customer's spare ignition key into

the Key Code Reader on the 535628 Inter-

rogator.

2. Press the On-Off rocker switch to the ON

position.