spark order PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 347 of 1825

6-2 ENGINE GENERAL INFORMATION

6E3 - Fuel Injection (Ported) This section has information

on all exhaust

system parts, such as tailpipes, mufflers, and the

SECTION 6F - EXHAUST SYSTEM catalytic converter.

GENERAL INFORMAflION

CLEANLINESS AND CARE

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten-thousandths of

an inch. When any internal engine parts are serviced,

care and cleanliness are important. A liberal coating of

engine oil should be applied to friction areas during

assembly, to protect and lubricate the surfaces on

initial operation. Throughout this section, it should be

understood that proper cleaning and protection of

machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice, even if not specifically stated. PREVENTING

DAMAGE AND IN

CONTRIBUTING TO RELIABLE ENGINE

PERFORMANCE.

When raising or supporting the engine for any

reason, do not use a jack under the oil pan. Due to the

small clearance between the oil pan and the oil pump

screen, jacking against the oil pan may cause it to be

bent against the pump screen resulting in a damaged

oil pick-up unit.

When working on the engine, remember that the

12-volt electrical system is capable of causing short

circuits. When performing any work where electrical terminals could possibly be grounded, the ground cable

of the battery should be disconnected at the battery.

Any time the carburetor or air cleaner is

train components are removed removed, the intake opening should be covered. This for service, they should be in order' will protect against entrance of foreign be installed in the same locations, and with the same material, which could follow the intake passage into mating surfaces, as when removed

the cylinder and cause extensive damage when the -

Battery cables should be disconnected before any engin; is started.

major work is performed on the engine. Failure to IN THE MECHANICAL PROCEDURES

disconnect cables may result in damage to wire harness DESCRIBED IN THIS SECTION, GENERALLY

or other electrical parts. NO

REFERENCES WILL BE MADE TO THE

REMOVAL OF OPTIONAL EQUIPMENT SUCH

ENGINE SERVICE AS POWER STEERING PUMP, AIR

CONDITIONING COMPRESSOR, ETC.

THE FOLLOWING INFORMATION ON SHOULD IT BECOME NECESSARY TO

ENGINE SERVICE SHOULD BE NOTED REMOVE ANY SUCH ITEM TO

PERFORM

CAREFULLY, AS IT IS IMPORTANT IN OTHER SERVICE, REFER TO THE

APPROPRIATE SECTION OF THIS SERVICE

MANUAL FOR SPECIFIC INFORMATION.

ENGINE PERFORMANCE DIAGNOSIS

INTRODUCTION interchangeably for so long, it was necessary to decide

on the most common usage and then define them. If the

Engine Performance procedures are definition is not understood, and the exact Symptom is

guides that will lead to the most probable causes of not used, the Diagnostic procedure will not work. engine performance complaints. They cover the

components of the fuel, ignition, and mechanical It

is important to keep two facts in mind:

systems that could cause a particular

complaint, and 1. The procedures are written to diagnose problems

then outline repairs in a logical sequence. on cars

that have

"run well at one time" and

that time and wear have created the condition.

It is important to determine if the

"Service ~~~i~~ soon- light is "ON,~' or has come for 2. All possible causes cannot be covered,

a short interval while driving. If the

"Service Engine particularly with regard to emission controls. If

Soon" light has come "ON," the Computer doing the work prescribed does not correct the

Command Control System or DECS should be complaint, then either the wrong Symptom was

checked for stored

"Trouble Codes" (See Diagnostic used, or a more detailed analysis will have to be

Circuit Check, Section 6E, for the engine you are made.

working on) which may indicate the cause for the All of the Symptoms can be caused by worn out

performance

complaint.Each Symptom is defined, and or defective parts such as Spark Plugs, Ignition

it is important that the correct one be selected, based Wiring, etc. If time and/or mileage indicate that

on the complaints reported or found. The definition of parts should be replaced, it is recommended that

each symptom is included with the symptom. it

be done.

The words used may not be what you are used to Refer to:

in all cases, but because these terms have been used

@ Section 6E - Driveability and Emissions

Page 359 of 1825

6A2-8 2.8 LITER V-6

6. Install new mount.

7. Lower transmission.

8. Torque nuts to specifications.

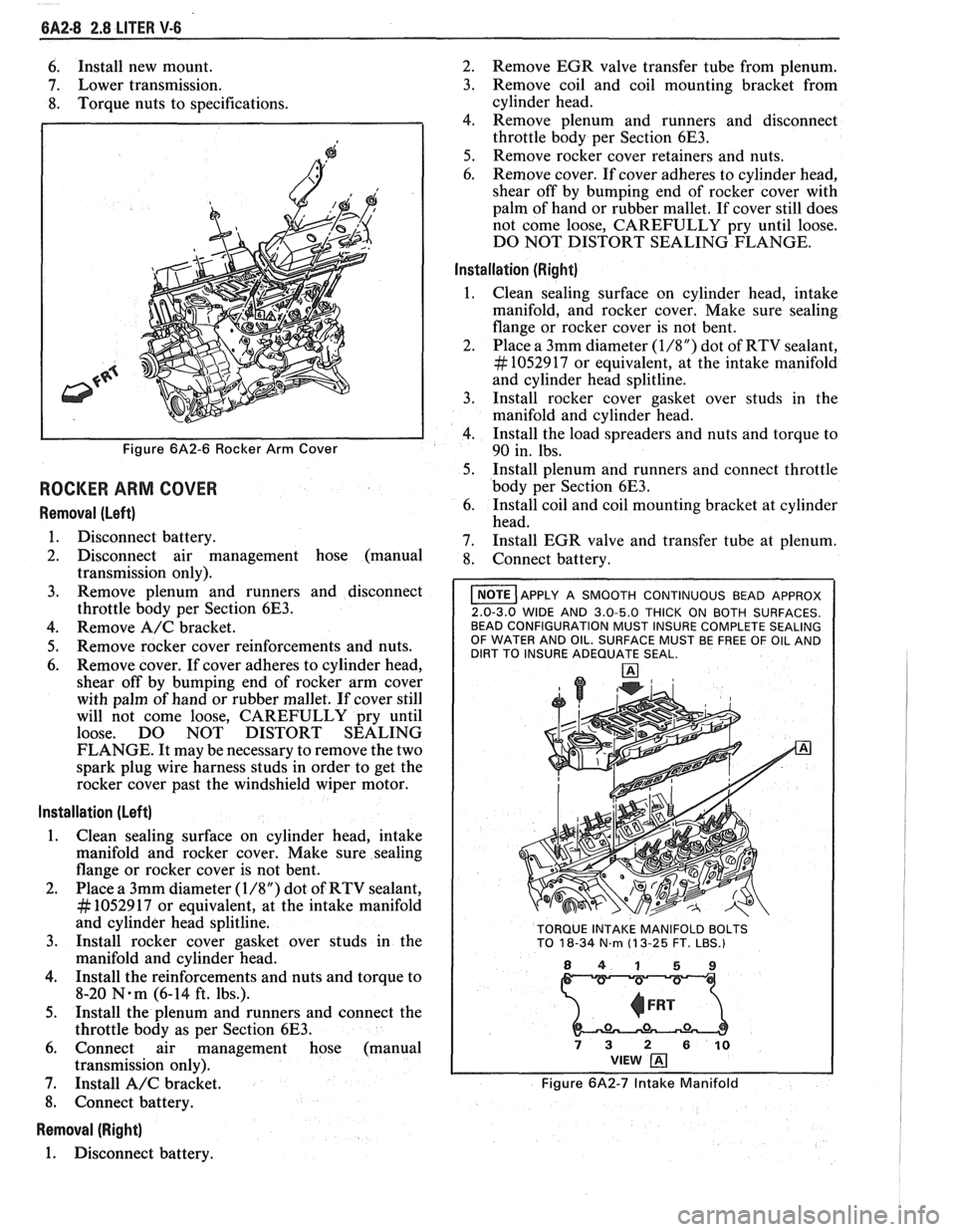

Figure 6A2-6 Rocker Arm Cover

ROCKER ARM COVER

Removal (Left)

1. Disconnect battery.

2. Disconnect air management hose (manual

transmission only).

3. Remove plenum and runners and disconnect

throttle body per Section

6E3.

4. Remove A/C bracket.

5. Remove rocker cover reinforcements and nuts.

6. Remove cover. If cover adheres to cylinder head,

shear off by bumping end of rocker arm cover

with palm of hand or rubber mallet. If cover still

will not come loose, CAREFULLY pry until

loose. DO NOT DISTORT SEALING

FLANGE. It may be necessary to remove the two

spark plug wire harness studs in order to get the

rocker cover past the windshield wiper motor.

Installation (Left)

1. Clean sealing surface on cylinder head, intake

manifold and rocker cover. Make sure sealing

flange or rocker cover is not bent.

2. Place a 3mm diameter

(1/8") dot of RTV sealant,

# 1052917 or equivalent, at the intake manifold

and cylinder head splitline.

3. Install rocker cover gasket over studs in the

manifold and cylinder head.

4. Install the reinforcements and nuts and torque to

8-20

N.m (6-14 ft. lbs.).

5. Install the plenum and runners and connect the

throttle body as per Section

6E3.

6. Connect air management hose (manual

transmission only).

7. Install

A/C bracket.

8. Connect battery.

Removal (Right)

1. Disconnect battery. 2.

Remove EGR valve transfer tube from plenum.

3. Remove coil and coil mounting bracket from

cylinder head.

4. Remove plenum and runners and disconnect

throttle body per Section

6E3.

5. Remove rocker cover retainers and nuts.

6. Remove cover. If cover adheres to cylinder head,

shear off by bumping end of rocker cover with

palm of hand or rubber mallet. If cover still does

not come loose, CAREFULLY pry until loose.

DO NOT DISTORT SEALING FLANGE.

Installation (Right)

Clean sealing surface on cylinder head, intake

manifold, and rocker cover. Make sure sealing

flange or rocker cover is not bent.

Place a 3mm diameter

(1/8") dot of RTV sealant,

# 1052917 or equivalent, at the intake manifold

and cylinder head splitline.

Install rocker cover gasket over studs in the

manifold and cylinder head.

Install the load spreaders and nuts and torque to

90 in. lbs.

Install plenum and runners and connect throttle

body per Section

6E3.

Install coil and coil mounting bracket at cylinder

head.

Install EGR valve and transfer tube at plenum.

Connect battery.

I NOTE ]APPLY A SMOOTH CONTINUOUS BEAD APPROX

2.0-3.0 WIDE AND 3.0-5.0 THICK ON BOTH SURFACES.

BEAD CONFIGURATION MUST INSURE COMPLETE SEALING

OF WATER AND OIL. SURFACE MUST BE FREE OF OIL AND

DIRT TO INSURE ADEQUATE SEAL.

TORQUE INTAKE MANIFOLD BOLTS

TO

18-34 N.m (1 3-25 FT. LBS.)

841 59

73 2 610 VIEW

Figure 6A2-7 Intake Manifold

Page 377 of 1825

6A2-26 2.8 LITER V-6

2. Remove the spark plugs. Installation

3. Remove

crankshaft pulley and torsional damper. 1. Install rear main bearing oil seal in cylinder block

4. Remove oil pan and oil pump. and

rear bearing cap grooves.

5. Remove water pump, crankcase front cover, 2. Lubricate seal with engine oil. Keep oil off

camshaft sprocket and timing chain. parting

line surface.

3. Install main bearings in cylinder block and main

6. Check the connecting rod caps for cylinder

bearing caps then lubricate bearing surface with

number identification. If necessary mark them.

engine oil.

7. Remove the connecting rod caps and

push the

4. 1n;tall crankshaft, being careful not to damage

pistons to top of bores.

bearing surfaces.

8. Remove main bearing caps and lift crankshaft out 5. Recheck bearing clearances using plastigage.

of cylinder block. 6.

Apply a thin coat of anaerobic sealant

# 1052357

9. Remove rear

main bearing oil seal and main or

equivalent to rear of the block mating surface

bearings from cylinder block and main bearing or corresponding

surface or rear main cap only.

caps. Do

not allow sealer on crankshaft or seal.

7. Install main bearing caps with arrow pointing

Cleaning and Inspection toward front of engine.

8. Torque all except

#3 main bearing cap bolts to

1. Wash crankshaft in solvent and dry with

specifications. Torque

#3 main bearing cap bolts

compressed air. to 14-16

N-m (10-12 lbs. ft.) then tap end of

2. Measure

dimensions of main bearing journals and crankshaft, first rearward then forward with a

crankpins with a micrometer for out-of-round, lead

hammer. This will line up rear main bearing

taper or undersize (See Specifications). and crankshaft

thrust surfaces.

Retorque all main

3. Check

crankshaft for run-out by supporting at bearing

cap bolts to specifications.

the front and rear main bearings journals in "V" 9. Measure crankshaft

end play with a feeler gage.

blocks and check at the front and rear Force crankshaft forward and measure clearance

intermediate journals with a dial indicator (See between the front of the

#3 main bearing and

Specifications). crankshaft thrust surface.

4. Replace or recondition the crankshaft if out of 10.

Install flywheel and torque to specifications.

specifications.

SPROCKET OR GEAR REPLACEMENT

Remove crankshaft sprocket using Tool J-5825,

install using Tool J-5590.

GENERAL DATA

TYPE .................................................................................................................................... 60" V-6

DISPLACEMENT

............................................................................................................. 2.8 Liter

RPO

........................................................................................................................................... LB8

BORE ......................................................................................................................................... 89

STROKE

................................... .... ............................................................................................... 76

COMPRESSION RATIO

....................................................................................................... 8.9: 1

FIRING ORDER

.......................................................................................................... 1-2-3-4-5-6

Cylinder Bore

DIAMETER .............................................................................................................. 88.992-88.070

OUT OF ROUND

............................................................................................................. .02 Max.

TAPER-THRUST SIDE

................................................................................................. .02 Max.

Piston

CLEARANCE .................................................................................................................. .O 17-,043

Piston Ring

Page 407 of 1825

6A3-28 V-8 ENGINE

16. Install

radiator and fan shroud and reconnect

radiator and heater hoses.

17. Fill cooling system.

18. Fill

crankcase with oil. See owner's manual for

specifications.

19. Install air cleaner.

20. Install hood.

21. Connect battery cables.

NOTICE: To avoid possible arcing of battery,

connect positive battery cable first.

22. Start engine, check for leaks and check timing.

CRANKSHAFT

The crankshaft can be removed while the engine

is disassembled for overhaul, as previously outlined, or

without complete disassembly.

Removal

With the engine removed from the vehicle and the

transmission and/or clutch housing removed

from the engine, mount engine in stand and

clamp securely.

Remove the oil dip stick and oil dip stick tube, (if

applicable).

Remove the starting motor, clutch assembly (if

equipped) and flywheel.

Remove the spark plugs.

Remove crankshaft pulley and torsional damper.

Remove oil pan and oil pump.

Remove crankcase front cover, and if so

equipped, remove timing chain and camshaft

sprocket.

Check the connecting rod caps for cylinder

number identification. If necessary, mark them.

Remove the connecting rod caps and push the

pistons to top of bores.

Remove main bearing caps and lift crankshaft out

of cylinder block.

Remove rear main bearing oil seal and main

bearings from cylinder block and main bearing

caps.

Cleaning and Inspection

1. Wash crankshaft in solvent and dry with

compressed air.

2. Measure dimensions of main bearing journals and

crankpins with a micrometer for out-of-round,

taper or undersize. (See Specifications.) 3.

Check crankshaft for run-out by supporting at

the front and rear main bearings journals in

"V"

blocks and check at the front and rear

intermediate journals with a dial indicator. (See

Specifications.)

4. Replace or recondition the crankshaft if out of

specifications.

SPROCKET OR GEAR REPLACEMENT

e Remove crankshaft sprocket using Tool

5-5825, install using Tool J-5590.

Installation

1.

Install rear main bearing oil seal in cylinder block

and rear main bearing cap grooves. Install with

lip of seal toward front of engine. Where seal has

two lips install lip with helix towards front of

engine.

2. Lubricate lips of seal with engine oil. Keep oil off

parting line surface.

3. Install main bearings in cylinder block and main

bearing caps then lubricate bearing surface with

engine oil.

4. Install crankshaft, being careful not to damage

bearing surfaces.

5. Recheck bearing clearances using plastigage.

6. Apply a thin coat of brush-on type oil sealing

compound to block mating surface and

corresponding surface of cap only. Do not allow

sealant on crankshaft or seal.

7. Install main bearing caps with arrows pointing

toward front of engine.

8. Torque all except rear main bearing cap bolts to

specifications. Torque rear main bearing cap bolts

to 10-12 lbs. ft. (14-16

N.m)then tap end of

crankshaft, first rearward then forward with a

lead hammer. This will line up rear main bearing

and crankshaft thrust surfaces.

Retorque all main

bearing cap bolts to specifications.

9. Measure crankshaft end play with a feeler gage.

Force crankshaft forward and measure clearance

between the front of the rear main bearing and the

crankshaft thrust surface.

10. Install flywheel and torque to specifications. A

wood block placed between the crankshaft and

cylinder block will prevent crankshaft from

rotating.

Align dowel hole in flywheel with dowel

hole in crankshaft. On vehicles equipped

with automatic transmissions, install

flywheel with the converter attaching pads

towards transmission.

GENERAL DATA

TYPE .................................................................................................................................. 90" V-8

DISPLACEMENT

............................................................................... 305 Cu. In., 350 Cu. In.

......................................................... LITER (VIN) ................................... ...... 5.0, (E), (F), 5.7 (8)

RPO ......................................................................................................................... L03, LB9, L98

BORE ........................................................................................................................ 3.736, 4.000

STROKE

........................... .. ....................................................................................... 3.480, 3.480

COMPRESSION RATIO

................................................................................... 931, 931, 9.5:1

FIRING ORDER .................................................................................................... 1-8-4-3-6-5-7-2

Page 890 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-CZ-3

Deceleration Mode

The ECM looks at changes in throttle position and

air flow to reduce the amount of fuel. When

deceleration is very fast, the ECM may shut off fuel

completely for short periods.

Battery Voltage Correction Mode

When battery voltage is low, the ECM can

compensate for the weak spark delivered by the

distributor by:

@ Increasing the amount of fuel delivered;

@ Increasing the idle rpm; and

@ Increasing ignition dwell time.

Fuel Cutoff Mode

No fuel is delivered by the injector when the

ignition is "OFF". This prevents dieseling. Also, fuel

is not delivered if no reference pulses are seen from

the distributor, which means the engine is not

running. This prevents flooding.

FUEL CONTROL SYSTEM

Basic System Operation

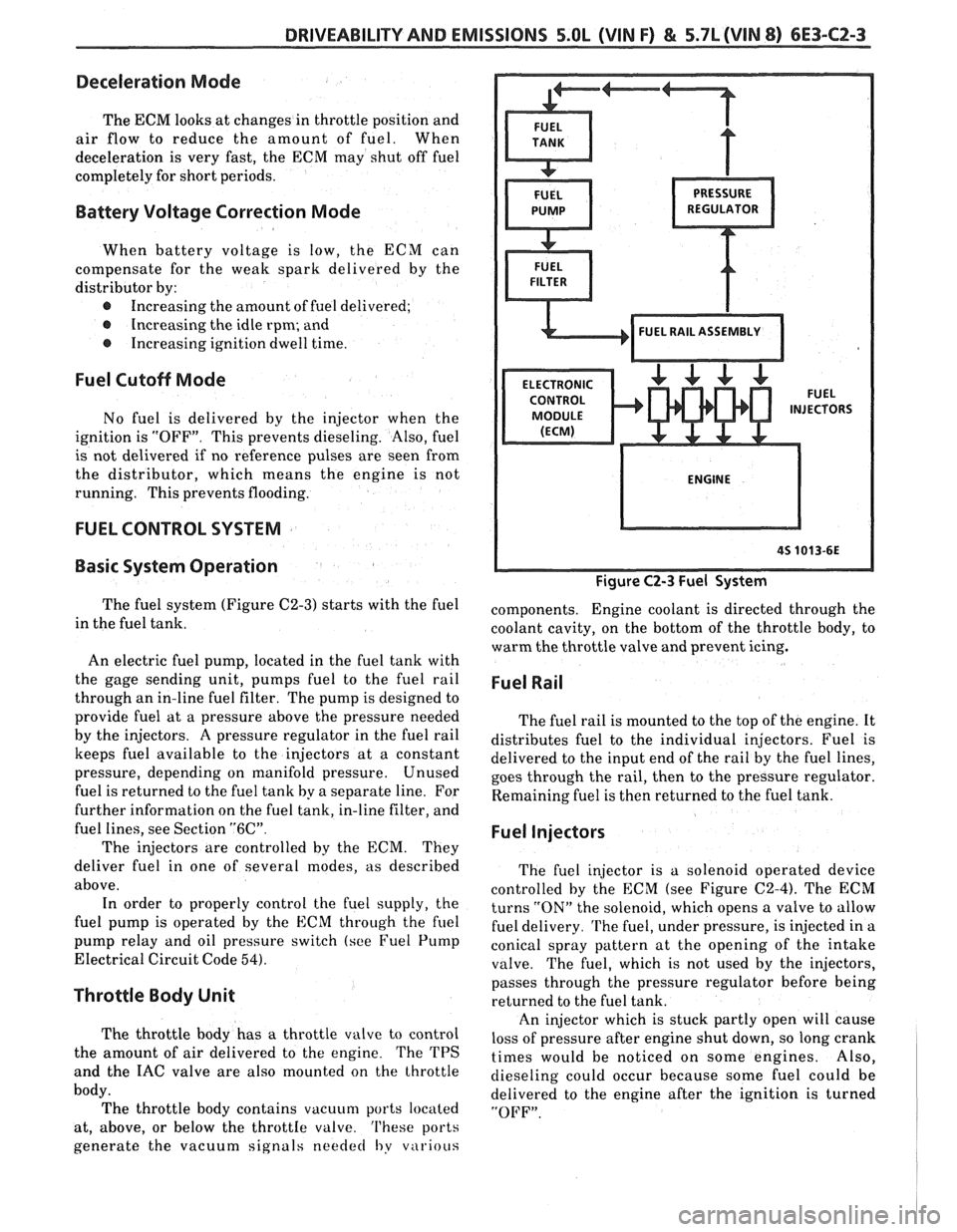

The fuel system (Figure C2-3) starts with the fuel

in the fuel tank.

An electric fuel pump, located in the fuel tank with

the gage sending unit, pumps

fuel to the fuel rail

through an in-line fuel filter. The pump is designed to

provide fuel at a pressure above the pressure needed

by the injectors. A pressure regulator in the fuel rail

keeps fuel available to the injectors at

a constant

pressure, depending on manifold pressure. Unused

fuel is returned to the fuel tank by a separate line. For

further information on the fuel tank, in-line filter, and

fuel lines, see Section

"6C".

The injectors are controlled by the ECM. They

deliver fuel in one of several modes, as described

above. In order to properly control the fuel supply, the

fuel pump is operated by the

ECM through the fuel

pump relay and oil pressure switch (see Fuel Pump

Electrical Circuit Code

54).

Throttle Body Unit

The throttle body has a throttle valve to control

the amount of air delivered to the engine. The TPS

and the IAC valve are also mounted on the throttle

body. The throttle body contains vacuum ports located

at, above, or below the

throttIe valve. 'I'hese ports

generate the vacuum signals

needed I,y v~irious

Figure C2-3 Fuel System

components. Engine coolant is directed through the

coolant cavity, on the bottom of the throttle body, to

warm the throttle valve and prevent icing.

Fuel Rail

The fuel rail is mounted to the top of the engine. It

distributes fuel to the individual injectors. Fuel is

delivered to the input end of the rail by the fuel lines,

goes through the rail, then to the pressure regulator.

Remaining fuel is then returned to the fuel tank.

Fuel Injectors

The fuel injector is a solenoid operated device

controlled by the ECM (see Figure

C2-4). The ECM

turns

"ON" the solenoid, which opens a valve to allow

fuel delivery.

The fuel, under pressure, is injected in a

conical spray pattern at the opening of the intake

valve. The fuel, which is not used by the injectors,

passes through the pressure regulator before being

returned to the fuel tank.

An injector which is stuck partly open will cause

loss of pressure after engine shut down, so long crank

times would be noticed on some engines. Also,

dieseling could occur because some fuel could be

delivered to the engine after the ignition is turned

"OFF".

Page 972 of 1825

DRIVEABILITY AND EMISSIONS - FUEL INJEC"F0N 6E-11

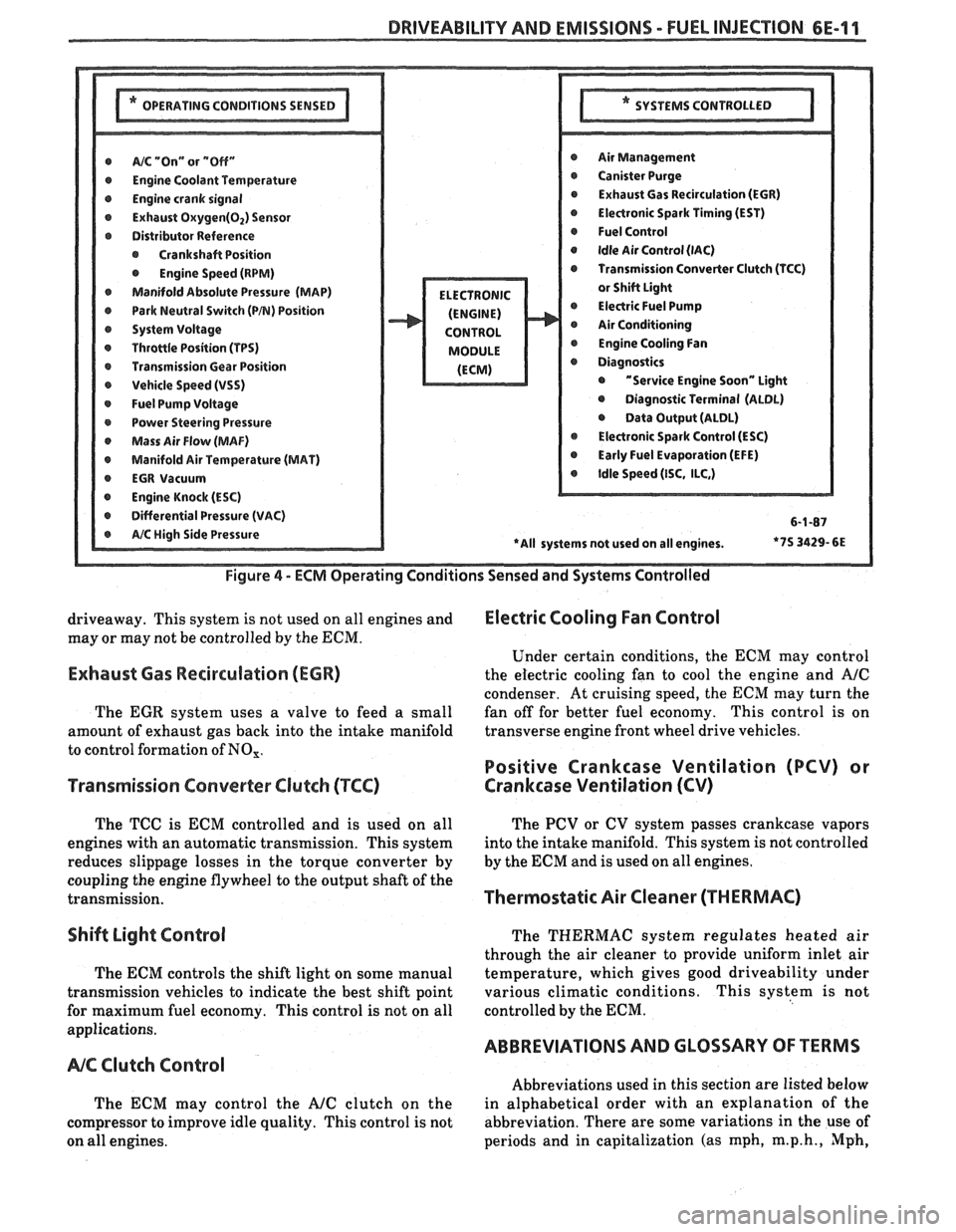

@ A/% "On" or "Off" r Air Management

r Engine Coolant Temwrature r Canister Purge

@ Engine crank signal r Exhaust Gas Recirculation (EGR)

@ Exhaust Oxygen(02) Sensor @ Electronic Spark Timing (EST)

r Distributor Reference @ Fuel Control

@ Crankshaft Position @ Idle Air Control (lAC)

@ Engine Speed (RPM) Transmission Converter Clutch (TCC)

Manifold Absolute Pressure (MAP)

@ Park Neutral Switch (PB) Position @ Electric Fuel Pump

r System Voltage Air Conditioning

r Throttle Position (TPS) @ Engine Cooling Fan

r Transmission Gear Position

r Vehicle Speed (VSS) @ "Service Engine Soon" Light

@ Fuel Pump Voltage @ Diagnostic Terminal (ALDL)

r Power Steering Pressure @ Data Output (ALDL)

Mass Air Flow (MAF) @ Electronic Spark Control (ESC)

@ Manifold Air Temperature (MAT) @ Early Fuel Evaporation (EFE)

r EGR Vacuum @ Idle Speed (ISC, ILC,)

@ Engine Knock (ESC)

r Differential Pressure (VAC) 6-1-87

*7S

3429- 6E

Figure

4 - ECM Operating Conditions Sensed and Systems Controlled

driveaway. This system is not used on all engines and Electric Cooling Fan Control

may or may not be controlled by the ECM.

Under certain conditions, the

ECM may control

Exhaust Gas Recirculation (ECR) the electric cooling fan to cool the engine and A/C

condenser. At cruising speed, the ECM may turn the

The

EGR system uses a valve to feed a small fan

off for better fuel economy. This control is on

amount of exhaust gas back into the intake manifold transverse

engine front wheel drive vehicles.

to control formation of

NO,.

Positive Crankcase Ventilation (PCV) or

Transmission Converter

Clutch (TCC) Crankcase Ventilation (CV)

The TCC is ECM controlled and is used on all

engines with an automatic transmission. This system

reduces slippage losses in the torque converter by

coupling the engine flywheel to the output shaft of the

transmission.

Shift Light Control

The ECM controls the shift light on some manual

transmission vehicles to indicate the best shift point

for maximum fuel economy. This control is not on all

applications.

NC Clutch Control

The ECM may control the AJC clutch on the

compressor to improve idle quality. This control is not

on all engines. The

PCV or CV system passes crankcase vapors

into the intake manifold. This system is not controlled

by the

ECM and is used on all engines.

Thermostatic Air Cleaner (THERMAC)

The THERMAC system regulates heated air

through the air cleaner to provide uniform inlet air

temperature, which gives good driveability under

various climatic conditions. This system is not

controlled by the

ECM.

ABBREVIATIONS AND GLOSSARY OF TERMS

Abbreviations used in this section are listed below

in alphabetical order with an explanation of the

abbreviation. There are some variations in the use of

periods and in capitalization (as mph,

m.p.h., Mph,

Page 1553 of 1825

RADIO I

(Continued from previous page) from back of Radio

If noise persists with replacement antenna, the

problem must be repaired at the source of noise

(generator, ignition system, accessory, etc.). See

Delco Manual for noise "Sniffing" procedures.

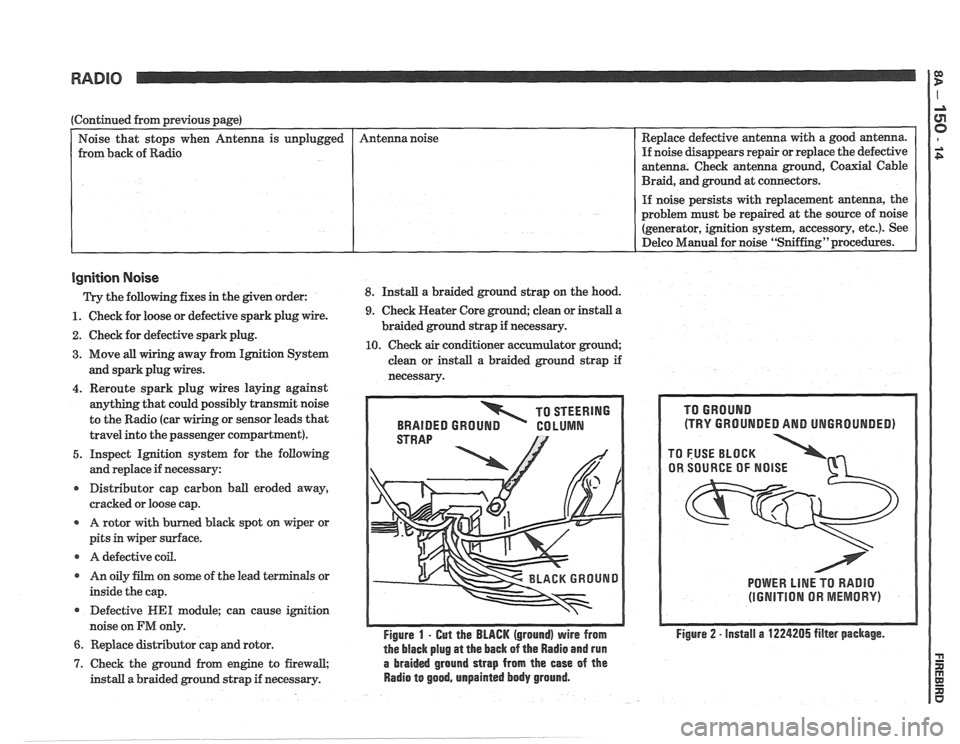

Ignition Noise

Trv the following. fixes in the piven order: 8. Install a braided ground strap on the hood. Replace

defective antenna with a good antenna.

If noise disappears repair or replace the defective

antenna. Check antenna ground, Coaxial Cable

Braid, and ground at connectors.

unplugged

- -

1. Check

for loose or defective spark plug wire.

2. Check for defective spark plug.

3. Move all wiring away from Ignition System

and spark plug wires. Antenna

noise

4. Reroute spark plug wires laying against

anything that could possibly transmit noise

to the Radio (car

g or sensor leads that

travel into the passenger compartment).

5. Inspect Ignition system for the following

and replace if necessary:

r Distributor cap carbon ball eroded away,

cracked or loose cap.

A rotor with burned black spot on wiper or

pits in wiper surface.

r A defective coil.

r An oily film on some of the lead terminals or

inside the cap.

Defective

WE1 module; can cause ignition

noise on

FM only.

6. Replace distributor cap and rotor.

9. Check Heater Core ground; clean or install a

braided ground strap if necessary.

10. Check air conditioner accumulator ground;

clean or install a braided ground strap if

necessarv.

TO STEERING

BRAIDED

GROUN GO LUMN

Figure 1 - Gut the BLACK (ground) wire from

the black plug

at the back of the Radio and run

7. Check the ground from engine to firewall, a braided ground strap from the ease of the

install a braided ground strap if necessary. Radio to good, unpainted body ground.

(TRY GROUNDED AND UNGROUNDED)

POWER LlNE TO RADIO

(IGNITION OR MEMORY)

Figure 2 - install a 1224205 filter package.