width PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 233 of 1825

3E.2 TIRES AND WHEELS

P-METRIC SIZED TIRES

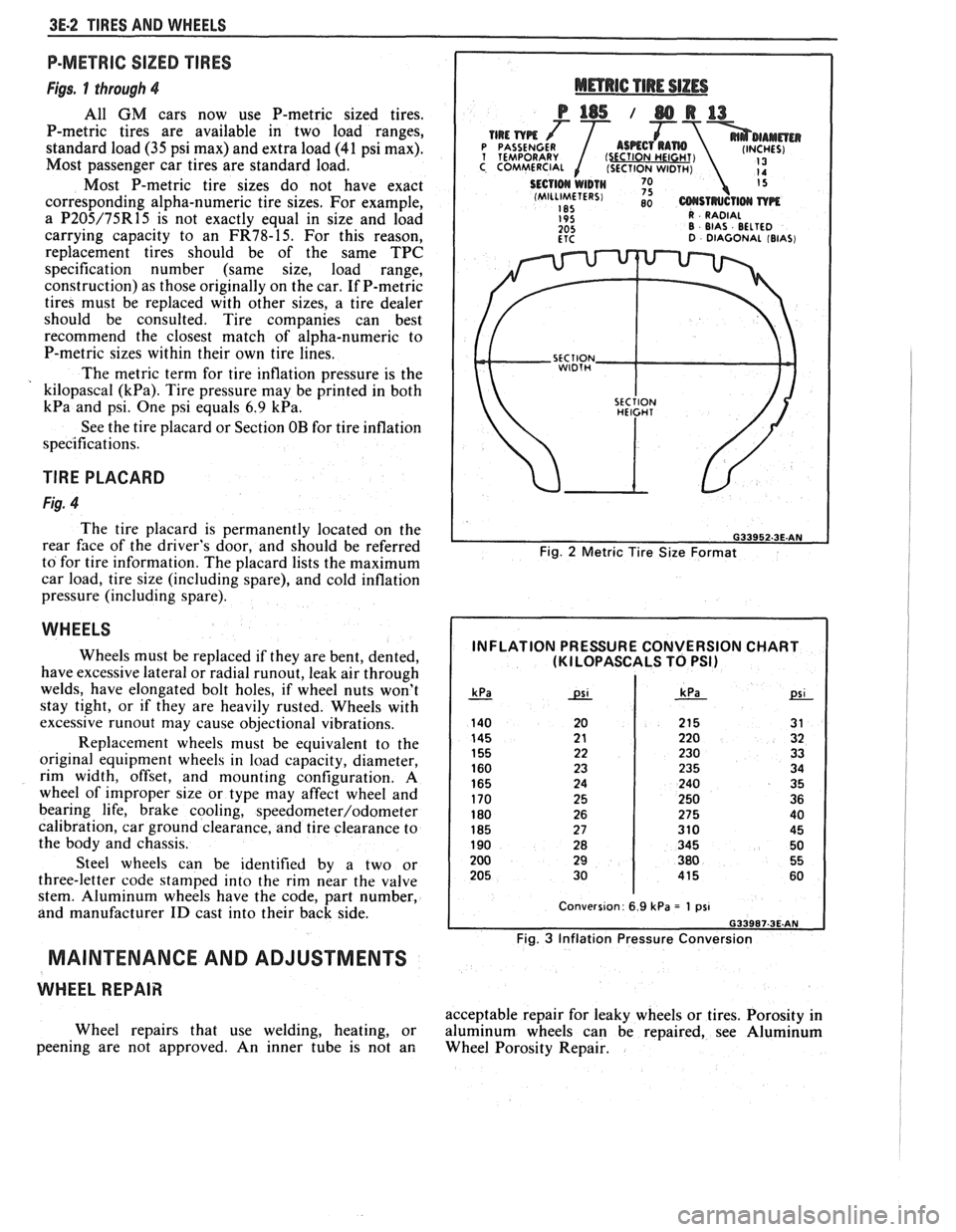

Figs. 1 through 4

All GM cars now use P-metric sized tires.

P-metric tires are available in two load ranges,

standard load

(35 psi max) and extra load (41 psi max).

Most passenger car tires are standard load.

Most P-metric tire sizes do not have exact

corresponding alpha-numeric tire sizes. For example,

a

P205/75R15 is not exactly equal in size and load

carrying capacity to an

FR78-15. For this reason,

replacement tires should be of the same TPC

specification number (same size, load range,

construction) as those originally on the car. If P-metric

tires must be replaced with other sizes, a tire dealer

should be consulted. Tire companies can best

recommend the closest match of alpha-numeric to

P-metric sizes within their own tire lines.

The metric term for tire inflation pressure is the

kilopascal

(kPa). Tire pressure may be printed in both

kPa and psi. One psi equals 6.9 kPa.

See the tire placard or Section OB for tire inflation

specifications.

TlRE PLACARD

Fig. 4

The tire placard is permanently located on the

rear

face of the driver's door, and should be referred

to for tire information. The placard lists the maximum

car load, tire size (including spare), and cold inflation

pressure (including spare).

WHEELS

Wheels must be replaced if they are bent, dented,

have excessive lateral or radial

runout, leak air through

welds, have elongated bolt holes, if wheel nuts won't

stay tight, or if they are heavily rusted. Wheels with

excessive

runout may cause objectional vibrations.

Replacement wheels must be equivalent to the

original equipment wheels in load capacity, diameter,

rim width, offset, and mounting configuration.

A

wheel of improper size or type may affect wheel and

bearing life, brake cooling,

speedometer/odometer

calibration, car ground clearance, and tire clearance to

the body and chassis.

Steel wheels can be identified by a two or

three-letter code stamped into the rim near the valve

stem. Aluminum wheels have the code, part number,

and manufacturer

ID cast into their back side.

MAINTENANCE AND ADJUSTMENTS

WHEEL REPAIR

Wheel repairs that use welding, heating, or

peening are not approved. An inner tube is not an

Fig. 2 Metric Tire Size Format

INFLATION PRESSURE CONVERSION CHART (KI LOPASCALS TO PSI)

Fig. 3 Inflation Pressure Conversion

acceptable repair for leaky wheels or tires. Porosity in

aluminum wheels can be repaired, see Aluminum

Wheel Porosity Repair.

Page 262 of 1825

REAR AXLE 481-9

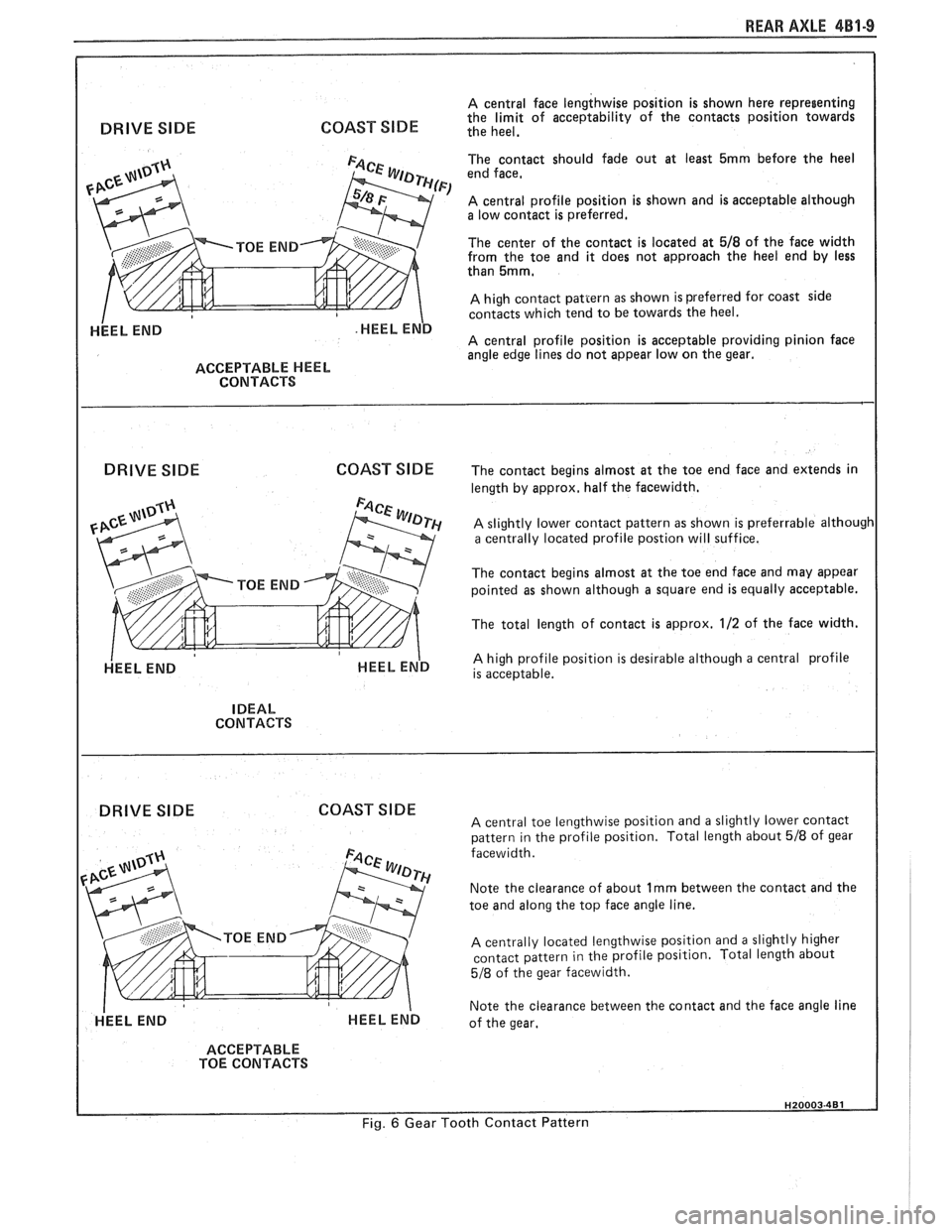

A central face lengthwise position is shown here representing

COAST SlDE the limit of acceptability of the contacts position towards DRIVE SIDE the heel.

ACCEPTABLE HEEL

CONTACTS

DRIVE SlDE COAST

SlDE

HEEL END

The contact should fade out at least 5mrn before the heel

end face,

A central profile position is shown and is acceptable alrhough a low contact is preferred.

The center of the contact is located at

518 of the face width

from the toe and it does not approach the heel end by less

than

5mm,

A high contact pattern as shown is preferred for coast side

contacts which tend to be towards the heel.

A central profile position is acceptable providing pinion face

angle edge lines do not appear low on the gear.

The contact begins almost at the toe end face and extends in

length by approx, half the facewidth.

A slightly lower contact pattern as shown is preferrable although a centrally located profile postion will suffice.

The contact begins almost at the toe end face and may appear

pointed as shown although a square end is equally acceptable.

The total length of contact is approx.

112 of the face width.

A high profile position is desirable although a central profile

is acceptable.

IDEAL

CONTACTS

DRIVE SIDE COAST SIDE A central toe lengthwise position and a slightly lower contact

pattern in the profile position. Total length about 518 of gear

facewidth.

Note the clearance of about

1 rnrn between the contact and the

toe and along the top face angle line.

A centrally located lengthwise position and a slightly higher

contact pattern in the profile position. Total length about

518 of the gear facewidth.

Note the clearance between the contact and the face angle line

of the gear.

ACCEPTABLE

TOE CONTACTS

Fig. 6 Gear Tooth Contact Pattern

Page 370 of 1825

2.8 LITER V-6 6A2-19

4. Measure the crankpin for out-of-round or taper

with a micrometer. If not within specifications,

replace or recondition the crankshaft. If within

specifications and a new bearing is to be installed,

measure the maximum diameter of the crankpin,

to determine new bearing size required.

5. If within specifications, measure new or used

bearing clearance with Plastigage or its

equivalent.

NOTICE: If a bearing is being fitted to an

out-of-round crankpin, be sure to fit to the

maximum diameter of the crankpin. If the bearing

is fitted to the minimum diameter and the

crankpin is out-of-round .025mm interference

between the bearing and

crankpin will result in a

rapid bearing failure.

a.

Place a piece of gaging plastic the full width

of the

crankpin as contacted by the bearing

(parallel to the crankshaft).

b. Install

the bearing in the connecting rod and

cap.

c. Install

the rod cap and evenly torque nuts

to specifications. Do not turn the crankshaft

with gaging plastic installed.

d. Remove

the rod cap and using the scale on

the gaging plastic envelope, measure the

gaging plastic width at the widest point.

6. If

the clearance exceeds specifications, select a

new, correct size, bearing and remeasure the

clearance.

If clearance cannot be brought to within

specifications, the

crankpin will have to be

ground undersize. If the

crankpin is already

at maximum undersize, replace crankshaft.

7. Coat the

bearing surface with oil, install the rod

cap and torque nuts to 50

N-m (37 lb. ft.).

8. When all connecting rod bearings have been

installed tap each rod lightly (parallel to the

crankpin) to make sure they have clearance.

9. Measure all connecting rod side clearances (see

specifications) between the rod cap and

crankshaft throw (Figure 6A2-23).

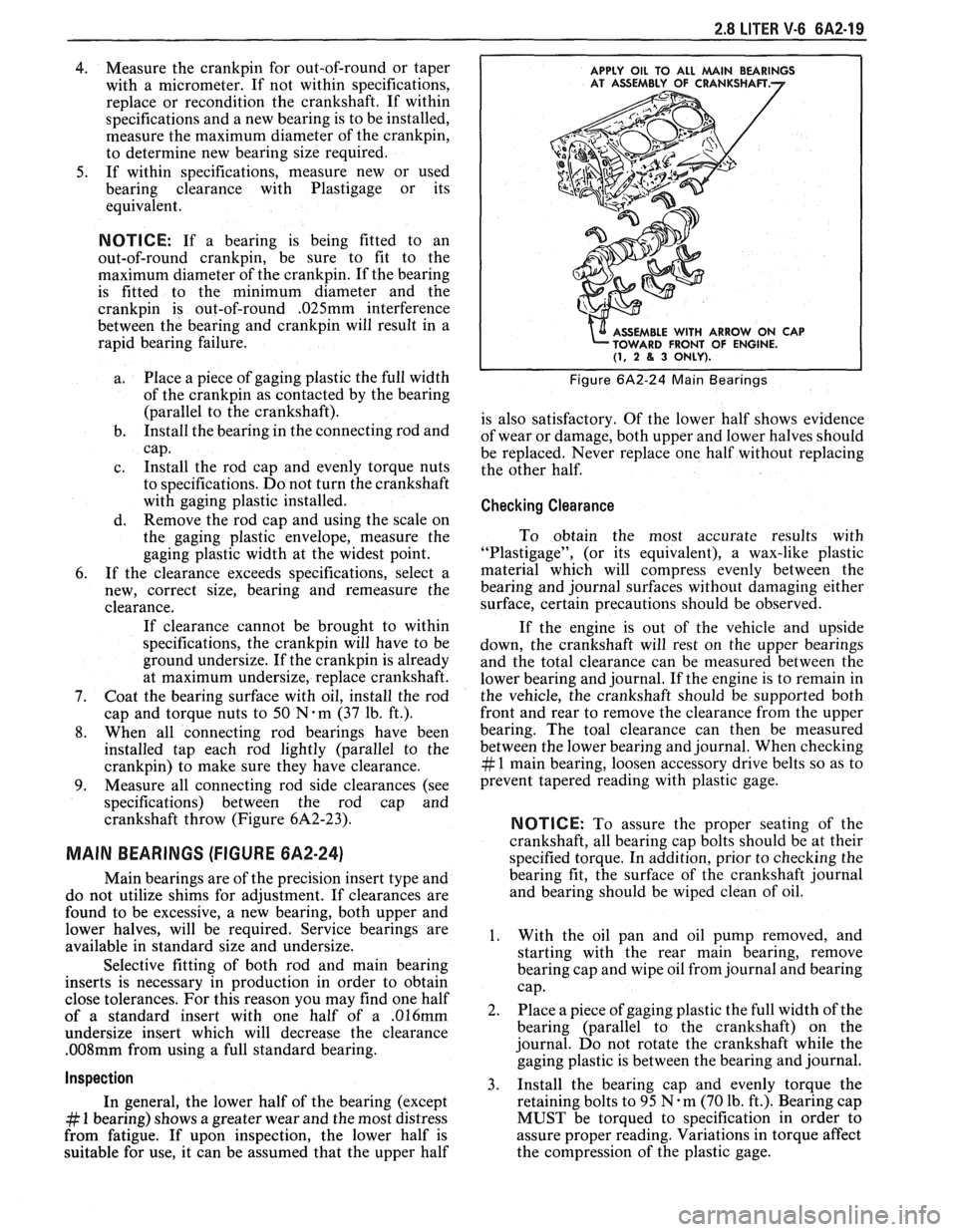

MAIN BEARINGS (FIGURE 6A2-24)

Main bearings are of the precision insert type and

do not utilize shims for adjustment. If clearances are

found to be excessive, a new bearing, both upper and

lower halves, will be required. Service bearings are

available in standard size and undersize.

Selective fitting of both rod and main bearing

inserts is necessary in production in order to obtain

close tolerances. For this reason you may find one half

of a standard insert with one half of a

.016mm

undersize insert which will decrease the clearance

.008mm from using a full standard bearing.

Inspection

In general, the lower half of the bearing (except

# 1 bearing) shows a greater wear and the most distress

from fatigue. If upon inspection, the lower half is

suitable for use, it can be assumed that the upper half

APPLY OIL TO ALL MAlN BEARINGS

E WITH ARROW ON CAP

FRONT OF ENGINE.

(1, 2 8, 3 ONLY).

Figure 6A2-24 Main Bearings

is also satisfactory. Of the lower half shows evidence

of wear or damage, both upper and lower halves should

be replaced. Never replace one half without replacing

the other half.

Checking Clearance

To obtain the most accurate results with

"Plastigage", (or its equivalent), a wax-like plastic

material which will compress evenly between the

bearing and journal surfaces without damaging either

surface, certain precautions should be observed.

If the engine is out of the vehicle and upside

down, the crankshaft will rest on the upper bearings

and the total clearance can be measured between the

lower bearing and journal. If the engine is to remain in

the vehicle, the crankshaft should be supported both

front and rear to remove the clearance from the upper

bearing. The toal clearance can then be measured

between the lower bearing and journal. When checking

# 1 main bearing, loosen accessory drive belts so as to

prevent tapered reading with plastic gage.

NOTICE: To assure the proper seating of the

crankshaft, all bearing cap bolts should be at their

specified torque. In addition, prior to checking the

bearing fit, the surface of the crankshaft journal

and bearing should be wiped clean of oil.

1. With the oil pan and oil pump removed, and

starting with the rear main bearing, remove

bearing cap and wipe oil from journal and bearing

cap.

2. Place a piece of gaging plastic the full width of the

bearing (parallel to the crankshaft) on the

journal. Do not rotate the crankshaft while the

gaging plastic is between the bearing and journal.

3. Install

the bearing cap and evenly torque the

retaining bolts to 95

N.m (70 lb. ft.). Bearing cap

MUST be torqued to specification in order to

assure proper reading. Variations in torque affect

the compression of the plastic gage.

Page 371 of 1825

4. Remove bearing cap. The flattened gaging plastic

will be found adhering to either the bearing shell

or journal.

5. On the edge of gaging plastic envelope, there is a

graduated scale which is correlated in

thousandths of a millimetre. Without removing

the gaging plastic, measure its compressed width

(at the widest point) with the graduations on the

gaging plastic envelope. Normally, main bearing

journals wear evenly and are not out-of-round.

However, if

a bearing is being fitted to an

out-of-round (.025mm max.), be sure to fit to the

maximum diameter of the journal: If the bearing

is fitted to the minimum diameter and the journal

is out-of-round

.025mm, interference between the

bearing and journal will result in rapid bearing

failure. If the flattened gaging plastic tapers

toward the middle or ends, there is a difference

in clearance indicating taper, low spot or other

irregularity of the bearing or journal. Be sure to

measure the journal with a micrometer if the

flattened gaging plastic indicates more than

,025mm difference.

6. If the bearing clearance is within specifications,

the bearing insert is satisfactory. If the clearance

is not within specifications, replace the insert.

Always replace both upper and lower inserts as

a unit.

7. A standard,

.016mm and .032mm undersize

bearing may produce the proper clearance. If not,

it will be necessary to regrind the crankshaft

journal for use with the next undersize bearing.

After selecting new bearing, recheck clearance.

8. Proceed to the next bearing. After all bearings

have been checked rotate the crankshaft to see

that there is no excessive drag.

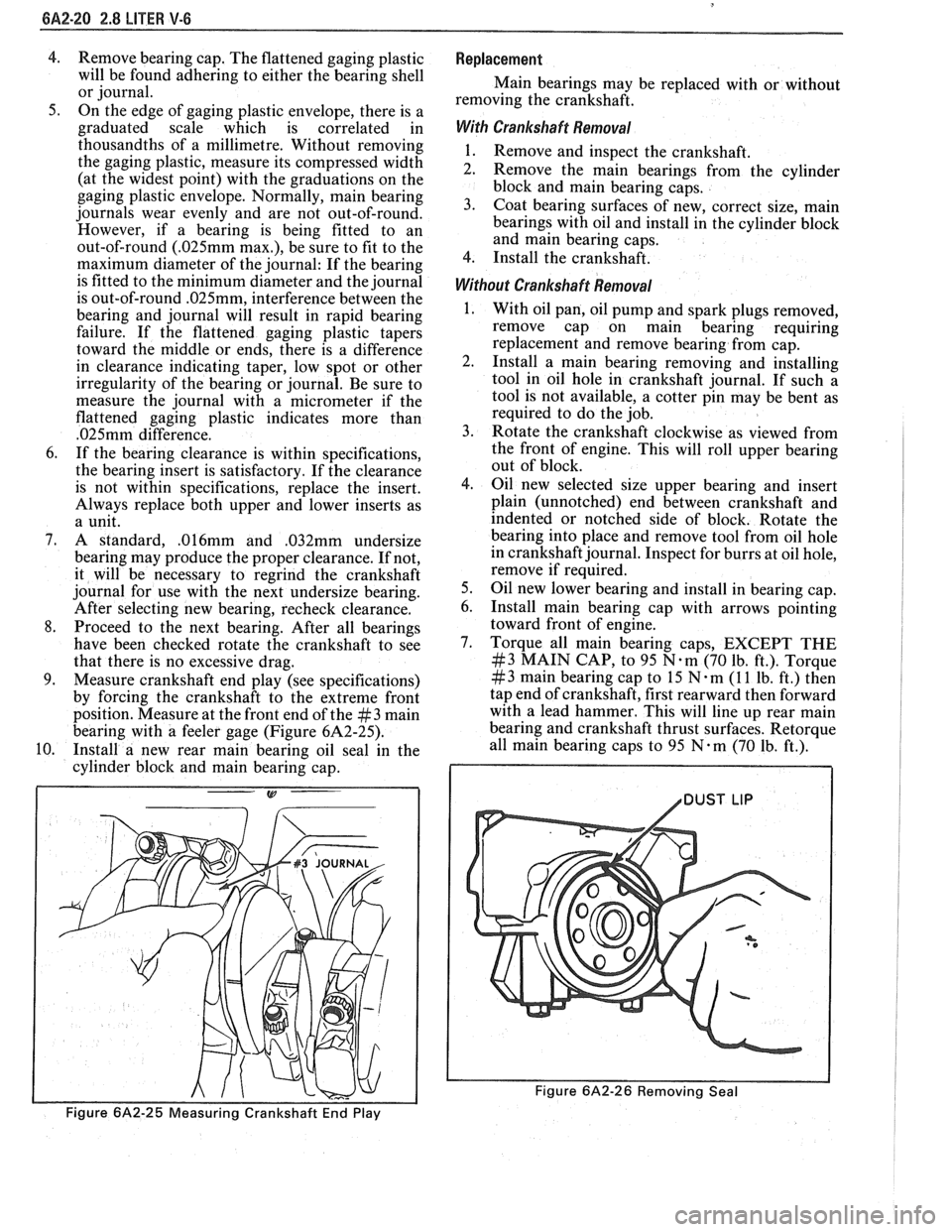

9. Measure crankshaft end play (see specifications)

by forcing the crankshaft to the extreme front

position. Measure at the front end of the

#3 main

bearing with a feeler gage (Figure 6A2-25).

10. Install a new rear main bearing oil seal in the

cylinder block and main bearing cap.

Figure 6A2-25 Measuring Crankshaft End Play

Replacement

Main bearings may be replaced with or without

removing the crankshaft.

With Crankshaft Removal

1. Remove and inspect the crankshaft.

2. Remove the main bearings from the cylinder

block and main bearing caps.

3. Coat bearing surfaces of new, correct size, main

bearings with oil and install in the cylinder block

and main bearing caps.

4. Install the crankshaft.

Without Crankshaft Removal

With oil pan, oil pump and spark plugs removed,

remove cap on main bearing requiring

replacement and remove bearing from cap.

Install a main bearing removing and installing

tool in oil hole in crankshaft journal. If such a

tool is not available, a cotter pin may be bent as

required to do the job.

Rotate the crankshaft clockwise as viewed from

the front of engine. This will roll upper bearing

out of block.

Oil new selected size upper bearing and insert

plain (unnotched) end between crankshaft and

indented or notched side of block. Rotate the

bearing into place and remove tool from oil hole

in crankshaft journal. Inspect for burrs at oil hole,

remove if required.

Oil new lower bearing and install in bearing cap.

Install main bearing cap with arrows pointing

toward front of engine.

Torque all main bearing caps, EXCEPT THE

#3 MAIN CAP, to 95 N.m (70 lb. ft.). Torque

# 3 main bearing cap to 15 N m (1 1 lb. ft.) then

tap end of crankshaft, first rearward then forward

with a lead hammer. This will line up rear main

bearing and crankshaft thrust surfaces.

Retorque

all main bearing caps to 95 N.m (70 Ib. ft.).

1 /DUST LIP

Figure 6A2-26 Removing Seal

Page 375 of 1825

6A2-24 2.8 LITER V-6

out-of-round or taper. Each bore must be final honed

to remove all stone or cutter marks and provide a

smooth surface. During final honing, each piston must

be fitted individually to the bore in which it will be

installed and should be marked to insure correct

installation.

After final honing and before the piston is

checked for fit, each cylinder bore must be thoroughly

washed to remove all traces of abrasives and then dried

thoroughly. The dry bore should then be brushed clean

with a power-driven fibre brush. If all traces of the

abrasives are not removed, rapid wear of new pistons

and rings will result.

FITTING PISTONS

1. Remove all rings

from pistons which will be

fitted. It is not necessary to separate rods from

pistons. If an excess amount of varnish or carbon

appears as a ridge at the top of the cylinder,

remove by scraping or sanding.

2. Wipe bores

and pistons clean, removing oil or

other foreign material. Select a piston-rod

assembly for the bore to be fitted (or piston and

pin if a new piston is being fitted) and position

down into the bore with the top of piston down.

The piston should fall free by its own weight

through the bore when when the bottom of the

piston skirt is 12 to 25mm from top of block.

Caution must be used to insure piston is not

damaged when it "falls" through the cylinder. If

it does not, the piston fit is too tight and another

piston should be selected until the piston will slide

freely through the bore without any force being

applied. Mark piston and bore for proper

assembly.

3. After a piston has been slected, which will slide

freely through a bore, it must be determined if

piston fit will be too loose. This is done by placing

a ,060 mm feeler gage for used pistons and a

.050

mm feeler gage for new pistons at least 150mm

long and not over 12mm wide, down into the

same bore with selected piston while holding

feeler to top of the bore.

Position selected piston and feeler down into the

bore until the bottom of the skirt is again 12 to

25 mm from top of block, being sure that the

feeler gage is

90" from the pin. If the piston hangs

on the feeler gage and does not fall free, it

indicates that the piston is correctly fitted to that

respective bore. Mark both piston and bore before

going to the next bore. If the piston fell free

during this check with the

.060mm feeler gage (.

050mm feeler gage for new pistons) then that

particular piston is too small for the bore and a

larger diameter piston will be required.

When checking more than one bore, it is very

possible that what may be a piston too small for one

bore will be a correct fit in another.

PISTON RINGS

When new piston rings are installed without

reboring cylinders, the glazed cylinder walls should be

slightly dulled, but without increasing the bore

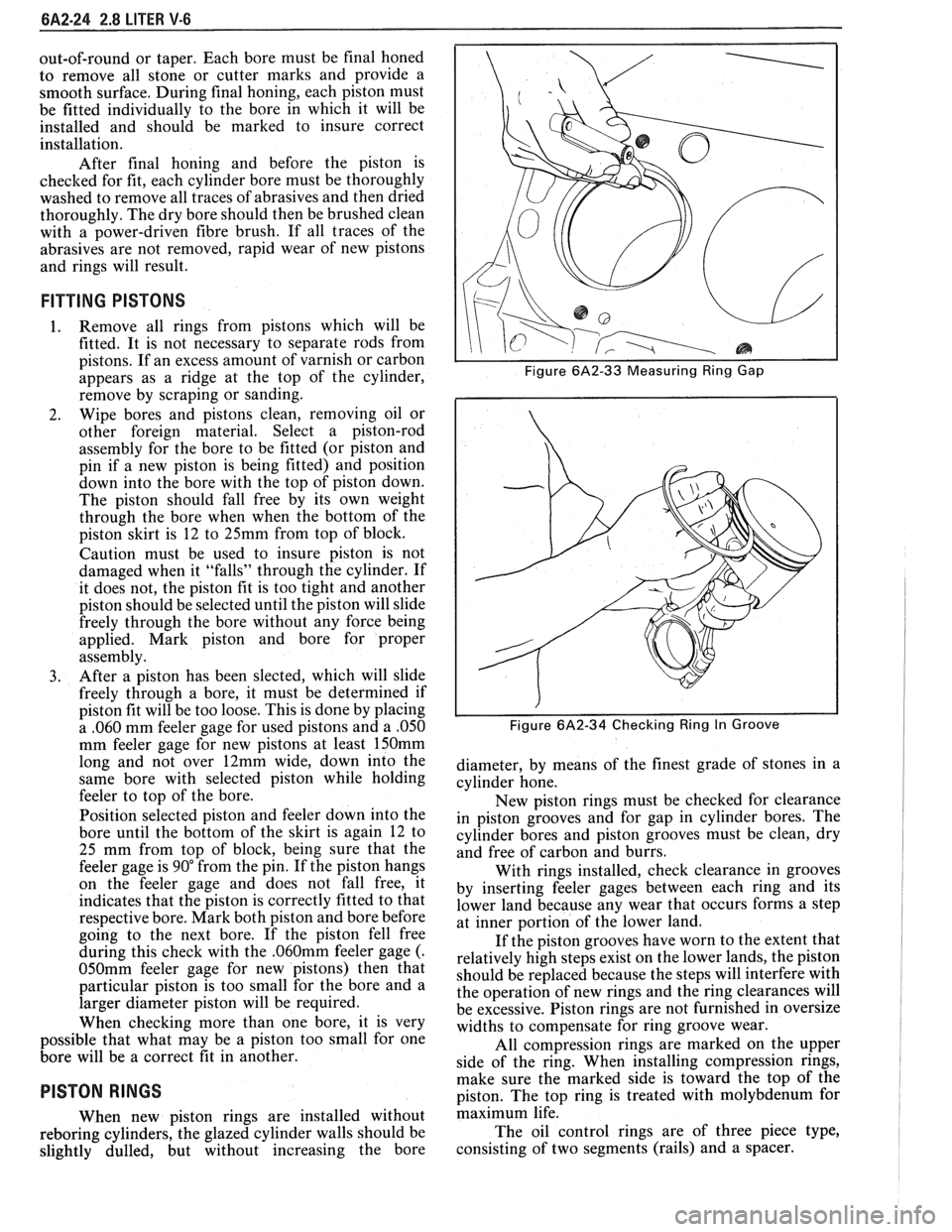

I I Figure 6A2-33 Measuring Ring Gap

i I

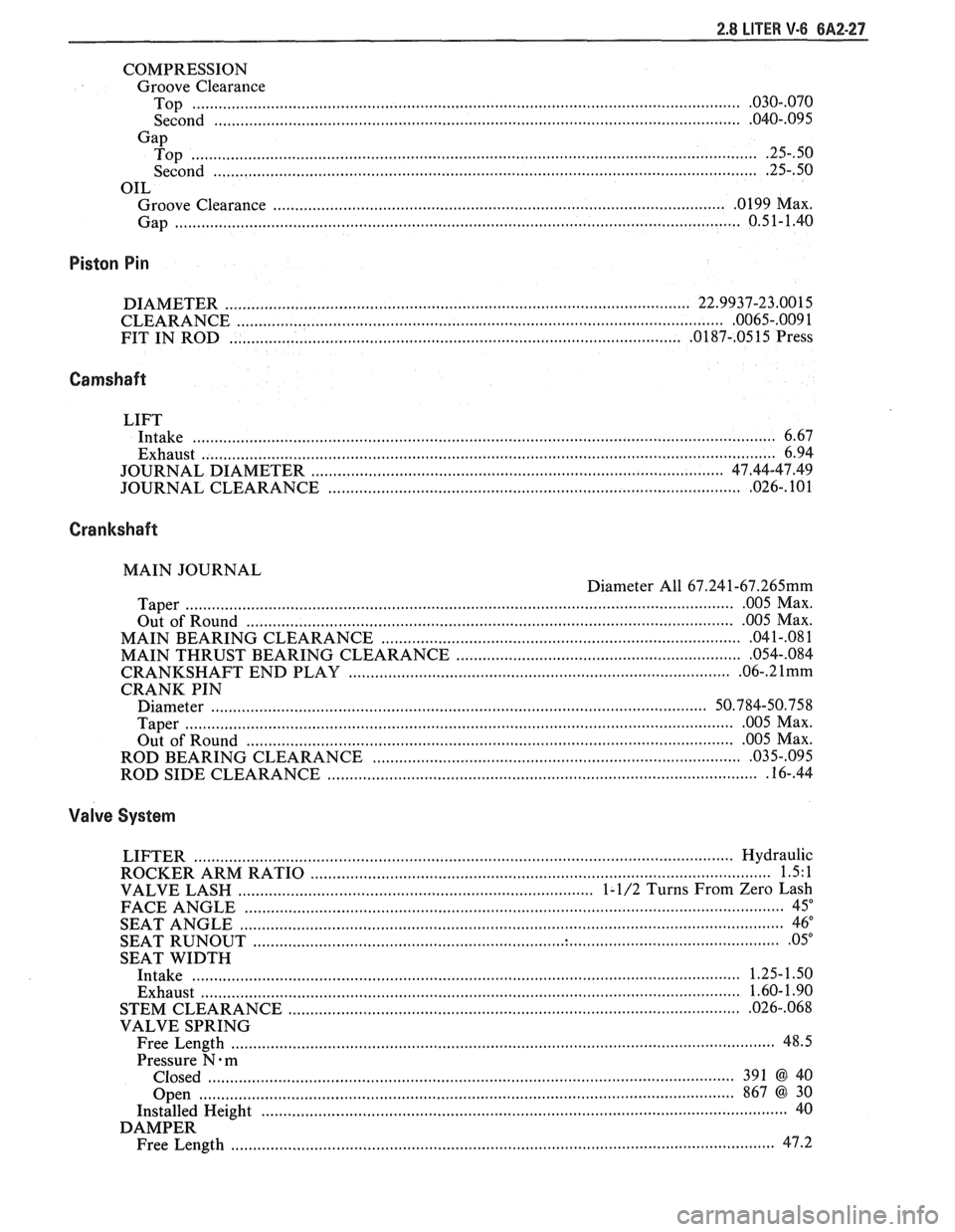

I I Figure 6A2-34 Checking Ring In Groove

diameter, by means of the finest grade of stones in a

cylinder hone.

New piston rings must be checked for clearance

in piston grooves and for gap in cylinder bores. The

cylinder bores and piston grooves must be clean, dry

and free of carbon and burrs.

With rings installed, check clearance in grooves

by inserting feeler gages between each ring and its

lower land because any wear that occurs forms a step

at inner portion of the lower land.

If the piston grooves have worn to the extent that

relatively high steps exist on the lower lands, the piston

should be replaced because the steps will interfere with

the operation of new rings and the ring clearances will

be excessive. Piston rings are not furnished in oversize

widths to compensate for ring groove wear.

All compression rings are marked on the upper

side of the ring. When installing compression rings,

make sure the marked side is toward the top of the

piston. The top ring is treated with molybdenum for

maximum life.

The oil control rings are of three piece type,

consisting of two segments (rails) and a spacer.

Page 378 of 1825

COMPRESSION Groove Clearance

............................................................................................................................ Top .030..070

................................................................................ Second .................................... .... .040.. 095

Gap ................................................................................................................................. Top .25..50

............................................................................................................................ Second .25..50

OIL

...................................................................................................... . Groove Clearance 0 199 Max

Gap

................................................................................................................................ 0.51-1.40

Piston Pin

DIAMETER ....................................................................................................... 22.9937-23.0015

........................................................................................................... CLEARANCE .0065-.009 1

FIT IN ROD

..................................................................................................... .0187-. 0515 Press

Camshaft

LIFT

Intake

................................................................................................................................... 6.67

Exhaust

.................................................................................................................................. 6.94

............................................................. ............................ JOURNAL DIAMETER .. 47.44-47.49

............................................................................................. JOURNAL CLEARANCE .026- . 101

Crankshaft

MAIN JOURNAL

Diameter All

67.241-67.265mm

............................................................................................................................. Taper 005 Max .

................................................................................................................ Out of Round 005

Max .

.................................................................................. MAIN BEARING CLEARANCE 04

1-.08 1

................................................................ MAIN THRUST BEARING CLEARANCE .054..084

...................................................................................... CRANKSHAFT END PLAY .06-. 2 1mm

CRANK PIN

Diameter

..................................... ... ......................................................................... 50.784-50.758

............................................................................................................................. Taper 005 Max .

............................................................................................................ Out of Round 005

Max .

.................................................... ROD BEARING CLEARANCE ......................... .. 03 5..095

................................................................................................ ROD SIDE CLEARANCE .16-. 44

Valve System

LIFTER ......................... .. ........................................................................................... Hydraulic

......................................................................................................... ROCKER ARM RATIO 1.5. 1

............................................................................... VALVE LASH 1- 1/2 Turns From Zero Lash

FACE ANGLE

........................................................................................................................... 45"

SEAT ANGLE ......................................................................................................................... 46"

....................................................................................................................... SEAT RUNOUT 05"

SEAT WIDTH

Intake

........................................................................................................................ 1.25-1.50

......................................................................................................................... Exhaust 1.60- 1.90

............................................................... STEM CLEARANCE ..................................... ... .026-. 068

VALVE SPRING

Free Length

......................................................................................................................... 48.5

Pressure N

. m

Closed

....................... .. .......................................................................................... 391 @40

Open

......................................................................................................................... 867 @30

Installed Height

........................................................................................................................ 40

DAMPER

........................................................................................................................... Free Length 47.2

Page 399 of 1825

6A3-20 V-8 ENGINE

PLASTIC GAGE

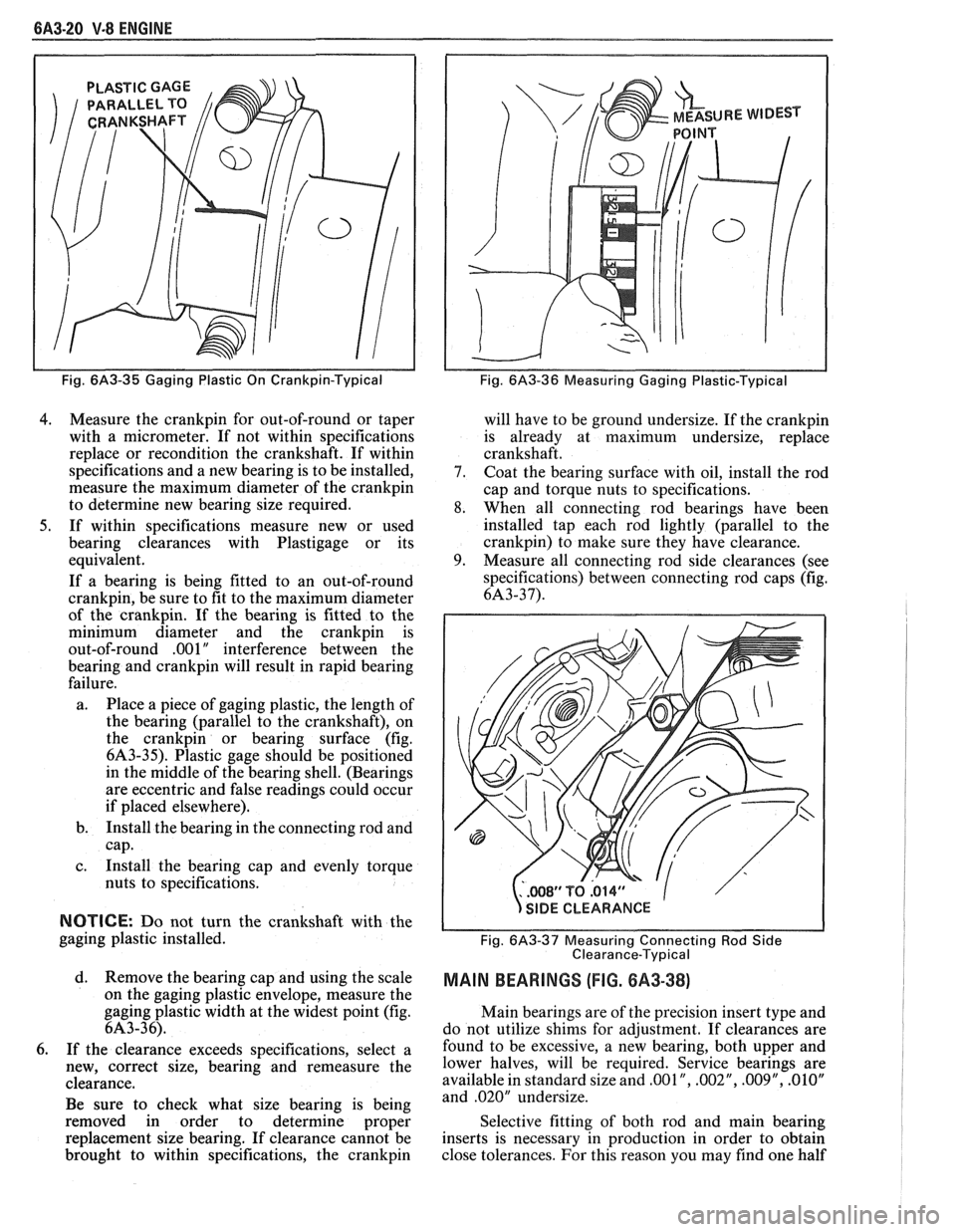

Fig. 6A3-35 Gaging Plastic On Crankpin-Typical

4. Measure the crankpin for out-of-round or taper

with a micrometer. If not within specifications

replace or recondition the crankshaft. If within

specifications and a new bearing is to be installed,

measure the maximum diameter of the

crankpin

to determine new bearing size required.

5. If within specifications measure new or used

bearing clearances with Plastigage or its

equivalent.

If a bearing is being fitted to an out-of-round

crankpin, be sure to fit to the maximum diameter

of the crankpin. If the bearing is fitted to the

minimum diameter and the

crankpin is

out-of-round .OO 1

" interference between the

bearing and

crankpin will result in rapid bearing

failure.

a. Place a piece of gaging plastic, the length of

the bearing (parallel to the crankshaft), on

the

crankpin or bearing surface (fig.

6A3-35). Plastic gage should be positioned

in the middle of the bearing shell. (Bearings

are eccentric and false readings could occur

if placed elsewhere).

b. Install the bearing in the connecting rod and

cap.

c. Install the bearing cap and evenly torque

nuts to specifications.

NOTICE: Do not turn the crankshaft with the

gaging plastic installed.

d. Remove the bearing cap and using the scale

on the gaging plastic envelope, measure the

gaging plastic width at the widest point (fig.

6A3-36).

6. If the clearance exceeds specifications, select a

new, correct size, bearing and remeasure the

clearance.

Be sure to check what size bearing is being

removed in order to determine proper

replacement size bearing. If clearance cannot be

brought to within specifications, the

crankpin

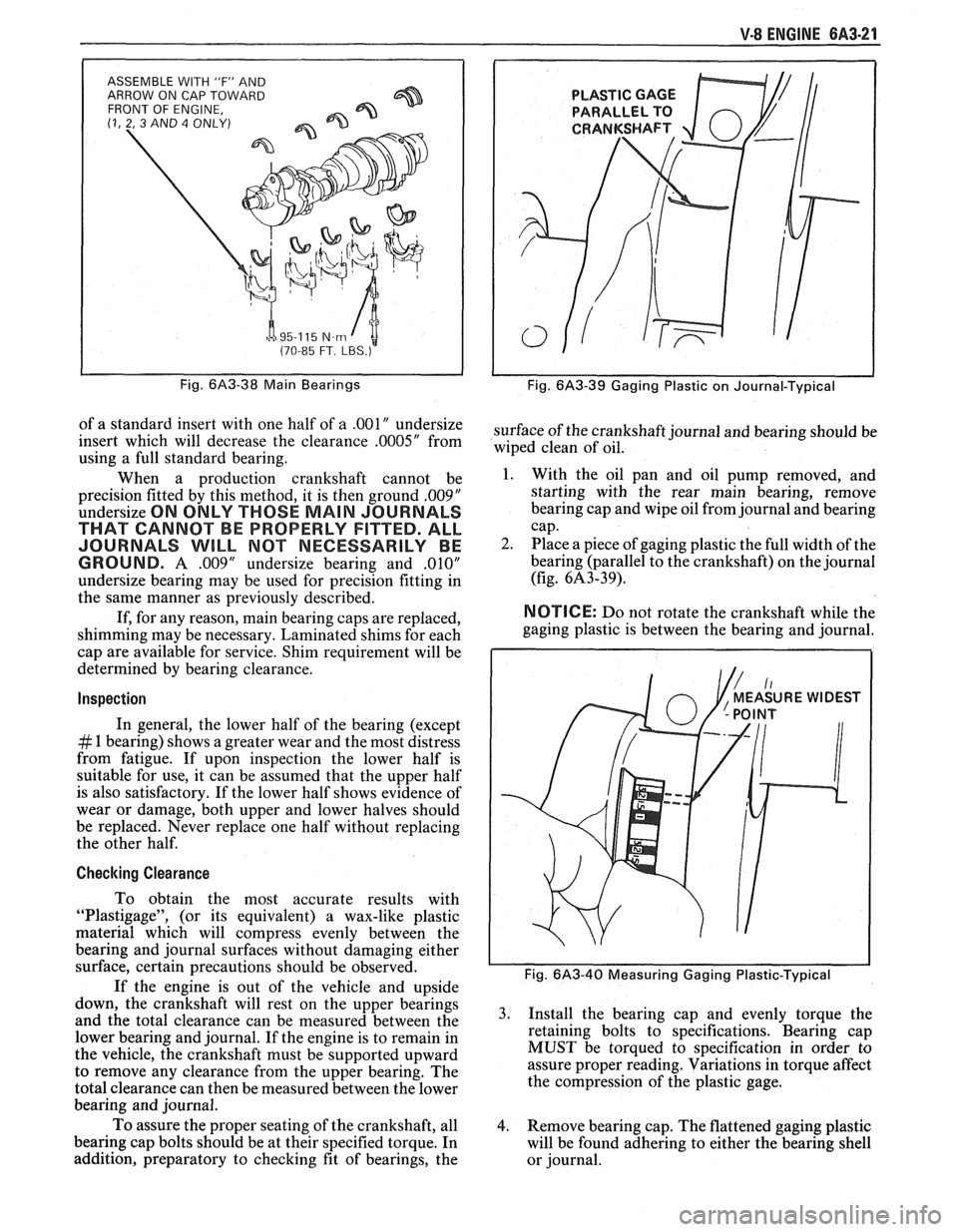

Fig. 6A3-36 Measuring Gaging Plastic-Typical

will have to be ground undersize. If the crankpin

is already at maximum undersize, replace

crankshaft.

7. Coat the bearing surface with oil, install the rod

cap and torque nuts to specifications.

8. When all connecting rod bearings have been

installed tap each rod lightly (parallel to the

crankpin) to make sure they have clearance.

9. Measure all connecting rod side clearances (see

specifications) between connecting rod caps (fig.

6A3-37).

..WS1'TQ.014" 1

s

/

SIDE CLEARANCE

Fig.

6A3-37 Measuring Connecting Rod Side

Clearance-Typical

MAIN BEARINGS (FIG. 8A3-38)

Main bearings are of the precision insert type and

do not utilize shims for adjustment. If clearances are

found to be excessive, a new bearing, both upper and

lower halves, will be required. Service bearings are

available in standard size and

,001 ", .002", .009", .01OV

and .020" undersize.

Selective fitting of both rod and main bearing

inserts is necessary in production in order to obtain

close tolerances. For this reason you may find one half

Page 400 of 1825

V-8 ENGINE 6A3-21

ASSEMBLE WITH 'IF" AND

ARROW ON CAP TOWARD

FRONT OF ENGINE,

(1, 2, 3 AND 4 ONLY)

h a 95-1 15 N.m I t (70-85 FT. LBS.)

Fig. 6A3-38 Main Bearings

of a standard insert with one half of a .00lU undersize

insert which will decrease the clearance

.0005" from

using a full standard bearing.

When a production crankshaft cannot be

precision fitted by this method, it is then ground

.00$"

undersize ON ONLY THOSE MAIN JOURNALS

THAT CANNOT BE PROPERLY FITTED. ALL

JOURNALS

WILL MOT NECESSARILY BE

GROUND.

A .009" undersize bearing and ,010"

undersize bearing may be used for precision fitting in

the same manner as previously described.

If, for any reason, main bearing caps are replaced,

shimming may be necessary. Laminated shims for each

cap are available for service. Shim requirement will be

determined by bearing clearance.

Inspection

In general, the lower half of the bearing (except

# 1 bearing) shows a greater wear and the most distress

from fatigue. If upon inspection the lower half is

suitable for use, it can be assumed that the upper half

is also satisfactory. If the lower half shows evidence of

wear or damage, both upper and lower halves should

be replaced. Never replace one half without replacing

the other half.

Checking Clearance

To obtain the most accurate results with

"Plastigage", (or its equivalent) a wax-like plastic

material which will compress evenly between the

bearing and journal surfaces without damaging either

surface, certain precautions should be observed.

If the engine is out of the vehicle and upside

down, the crankshaft will rest on the upper bearings

and the total clearance can be measured between the

lower bearing and journal. If the engine is to remain in

the vehicle, the crankshaft must be supported upward

to remove any clearance from the upper bearing. The

total clearance can then be measured between the lower

bearing and journal.

To assure the proper seating of the crankshaft, all

bearing cap bolts should be at their specified torque. In

addition, preparatory to checking fit of bearings, the

Fig. 6A3-39 Gaging Plastic on Journal-Typical

surface of the crankshaft journal and bearing should be

wiped clean of oil.

1. With the oil pan and oil pump removed, and

starting with the rear main bearing, remove

bearing cap and wipe oil from journal and bearing

cap.

2. Place a piece of gaging plastic the full width of the

bearing (parallel to the crankshaft) on the journal

(fig. 6A3-39).

NOTICE: Do not rotate the crankshaft while the

gaging plastic is between the bearing and journal.

Fig. 6A3-40 Measuring Gaging Plastic-Typical

3. Install the bearing cap and evenly torque the

retaining bolts to specifications. Bearing cap

MUST be torqued to specification in order to

assure proper reading. Variations in torque affect

the compression of the plastic gage.

4. Remove bearing cap. The flattened gaging plastic

will be found adhering to either the bearing shell

or journal.

Page 401 of 1825

BA3-22 V-8 ENGINE

5. On the edge of gaging plastic envelope there is a

graduated scale which is correlated in

thousandths of an inch. Without removing the

gaging plastic, measure its compressed width (at

the widest point) with the graduations on the

gaging plastic envelope (fig. 6A3-40).

Normally main bearing journals wear evenly and

are not out-of-round. However, if a bearing is

being fitted to an out-of-round journal

(.00lU

max.), be sure to fit to the maximum diameter of

the journal: If the bearing is fitted to the

minimum diameter and the journal is

out-of-round

.001", interference between the

bearing and journal will result in rapid bearing

failure. If the flattened gaging plastic tapers

toward the middle or ends, there is a difference

in clearance indicating taper, low spot or other

irregularity of the bearing or journal. Be sure to

measure the journal with a micrometer if the

flattened gaging plastic indicates more than

.00lV

difference.

6. If the bearing clearance is within specifications,

the bearing insert is satisfactory. If the clearance'

is not within specifications, replace the insert.

Always replace both upper and lower inserts as

a unit.

If a new bearing cap is being installed and

clearance is less than

.00 1 ", inspect for burrs or

nicks; if none are found then install shims as

required.

I MEASURE END PLAY

Fig. 6A3-4 1 Measuring Crankshaft End Play - Typical

7. A standard, .001" or .002" undersize bearing may

produce the proper clearance. If not, it will be

necessary to regrind the crankshaft journal for

use with the next undersize bearing.

After selecting new bearing, recheck clearance.

8. Proceed to the next bearing. After all bearings

have been checked rotate the crankshaft to see

that there is no excessive drag.

When checking

&t 1 main bearing, loosen

accessory drive belts so as to prevent tapered

reading with plastic gage.

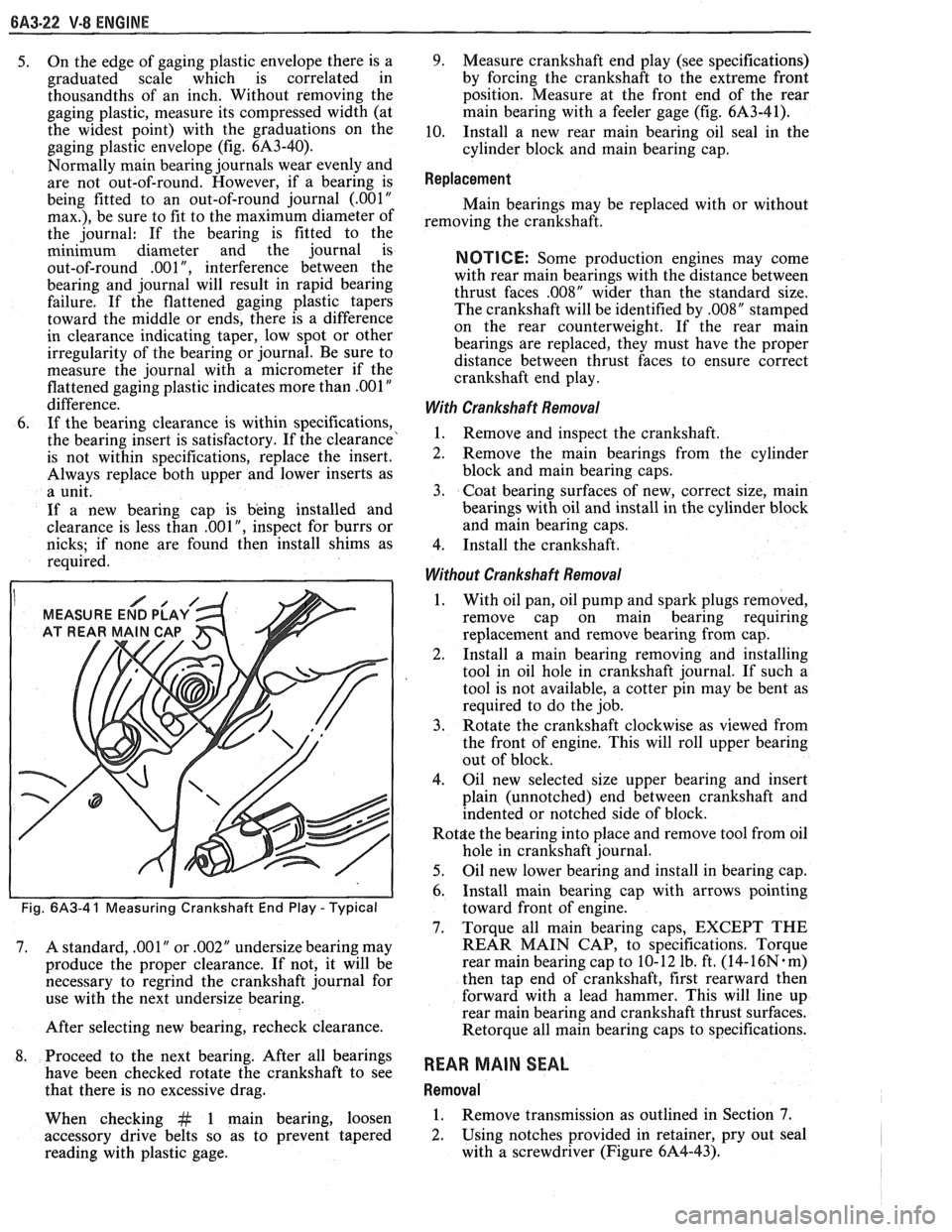

9. Measure crankshaft end play (see specifications)

by forcing the crankshaft to the extreme front

position. Measure at the front end of the rear

main bearing with a feeler gage (fig.

61\3-41),

10. Install a new rear main bearing oil seal in the

cylinder block and main bearing cap.

Replacement

Main bearings may be replaced with or without

removing the crankshaft.

NOTICE: Some production engines may come

with rear main bearings with the distance between

thrust faces

,008" wider than the standard size.

The crankshaft will be identified by

,008" stamped

on the rear counterweight. If the rear main

bearings are replaced, they must have the proper

distance between thrust faces to ensure correct

crankshaft end play.

With Crankshaft Removal

1. Remove and inspect the crankshaft.

2. Remove the main bearings from the cylinder

block and main bearing caps.

3. Coat bearing surfaces of new, correct size, main

bearings with oil and install in the cylinder block

and main bearing caps.

4. Install the crankshaft.

Without Crankshaft Removal

1. With oil pan, oil pump and spark plugs removed,

remove cap on main bearing requiring

replacement and remove bearing from cap.

2. Install a

main bearing removing and installing

tool in oil hole in crankshaft journal. If such a

tool is not available, a cotter pin may be bent as

required to do the job.

3. Rotate the crankshaft clockwise as viewed from

the front of engine. This will roll upper bearing

out of block.

4. Oil new selected size upper bearing and insert

plain (unnotched) end between crankshaft and

indented or notched side of block.

Rot$e the bearing into place and remove tool from oil

hole in crankshaft journal.

5. Oil new lower bearing and install in bearing cap.

6. Install main bearing cap with arrows pointing

toward front of engine.

7. Torque all main bearing caps, EXCEPT THE

REAR MAIN CAP, to specifications. Torque

rear main bearing cap to 10- 12 lb. ft. (14-

16N. m)

then tap end of crankshaft, first rearward then

forward with a lead hammer. This will line up

rear main bearing and crankshaft thrust surfaces.

Retorque all main bearing caps to specifications.

REAR MAIN SEAL

Removal

1. Remove transmission as outlined in Section 7.

2. Using notches provided

in retainer, pry out seal

with a screwdriver (Figure 6A4-43).

Page 409 of 1825

6A3-30 V-8 ENGINE

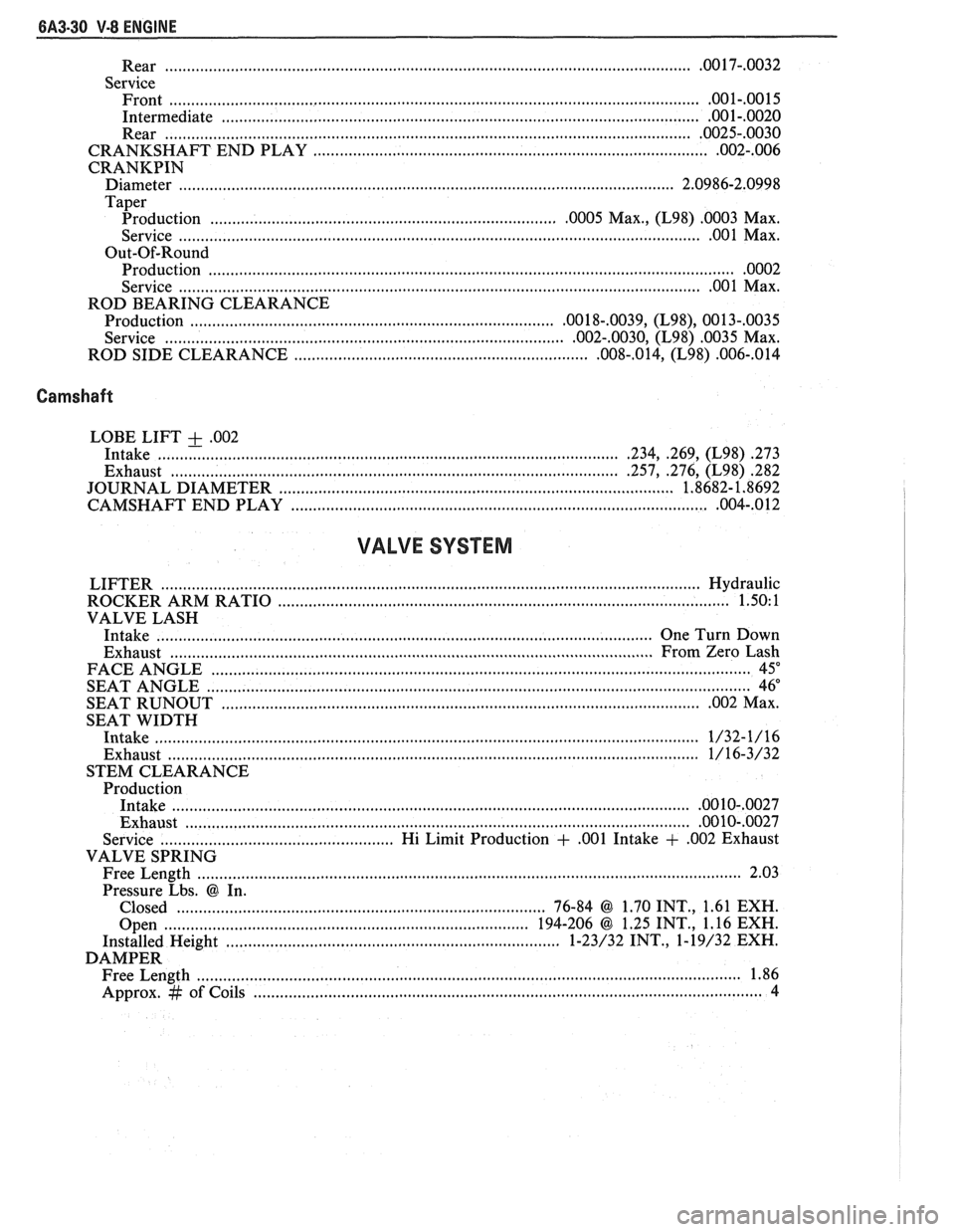

.............................................................................................. Rear ................... .. .OO 17-.0032

Service Front

......................................................................................................................... .001-.0015

Intermediate ............................................................................................................ .001-.0020

Rear ....................................................................................................................... .0025-.0030

............................................................. CRANKSHAFT END PLAY ....................... .. .002-.006

CRANKPIN

Diameter ........................... .. ................................................................................. 2.0986-2.0998

Taper

................................................ Production ....................... .. .0005 Max., (L98) .0003 Max.

............................................................................. Service ............................ .. ...... .... .OO 1 Max.

Out-Of-Round Production

....................................................................................................................... .0002

................................................................................... Service ............................ .. .00 1 Max.

ROD BEARING CLEARANCE

Production

................................................................................ ,0018-.0039, (L98), 0013-,0035

................................................... Service ................................. ....... .002-.0030, (L98) .0035 Max.

ROD SIDE CLEARANCE

............................................................... ,008-.014, (L98) .006-,014

Camshaft

LOBE LIFT + .002

Intake ..................... .. .......................................................................... .234, .269, (L98) .273

Exhaust ................................................................................................. .257, .276, (L98) 282

....................................................... JOURNAL DIAMETER .................... .... ... 1.8682- 1.8692

................................................................. CAMSHAFT END PLAY ...................... .. ,004-.012

VALVE SYSTEM

LIFTER ......................................................................................................................... Hydraulic

ROCKER ARM RATIO

................................................................................................. 1.50: 1

VALVE LASH

Intake

............................................................................................................. One Turn Down

Exhaust

..................................... ... ...................................................................... From Zero Lash

FACE ANGLE

..................... ... ............................................................................................. 45"

.......................................................................................................................... SEAT ANGLE 46"

SEAT

RUNOUT ............................................................................................................. .002 Max.

SEAT WIDTH

Intake

.................................... .... .................................................................................... 1/32-1/16

Exhaust ......................................................................................................................... 1/16-3/32

STEM CLEARANCE

Production

Intake

.................................................................................................................... .0010-,0027

Exhaust .................................................................................................................. .00 10-.0027

Service .................................................. Hi Limit Production + ,001 Intake + ,002 Exhaust

VALVE SPRING

Free Length

......................................................................................................................... 2.03

Pressure Lbs.

@ In.

Closed

.................................................................................... 76-84 @ 1.70 INT., 1.61 EXH.

Open

............................................................................... 194-206 @ 1.25 INT., 1.16 EXH.

Installed Height

....................... .. ............................................. 1-23/32 INT., 1-19/32 EXH.

DAMPER Free Length

................... .. ............................................................................................... 1.86

Approx.

# of Coils .................................................................................................................. 4