width PONTIAC FIERO 1988 Service User Guide

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 580 of 1825

DRIVEABILITY AND EMISSIONS - 5.OL (\/IN El 6EZ-CZ-5

sent to the ECM. The ECM then increases the injector

base pulse width, permitting increased fuel flow.

As the throttle valve rotates in response to

movement of the accelerator pedal, the throttle shaft

transfers this rotational movement to the

'I'PS. A

potentiometer (variable resistor) within the TPS

assembly changes its resistance (and voltage drop) in

proportion to throttle movement.

By applying a reference voltage (5.0 volts) to the

TPS input, a varying voltage (reflecting throttle

position) is available at the TPS output. For example,

approximately 2.5 volts results from a 50% throttle

valve opening (depending on TPS calibration). The

voltage output from the TPS assembly is routed to the

ECM for use in determining throttle position.

FUEL PUMP

The fuel pump is a turbine type, low pressure

electric pump, mounted in the fuel tank. Fuel

is

pumped at a positive pressure (above 62

kPa or 9 psi)

from the fuel pump through the in-line filter to the

pressure regulator in the TBI assembly Excess

fuel is

returned to the fuel tank through the fuel return line.

The fuel pump is attached to the fuel gage sender

assembly. A fuel strainer is attached to the fuel pump

inlet line and prevents dirt particles from entering the

fuel line and tends to separate

water from the fuel

Vapor lock problems are reduced when using an

electric

pump because the fuel is pushed from the tank

under pressure rather than being pulled

under

vacuum, a condition that produces vapor.

An inoperative fuel pump would cause

a. no start

condition. A fuel pump which does not provide enough

pressure can result in poor performance. (See "Fuel

System Pressure Test" procedure).

FUEL PUMP ELECTRICAL CIRCUIT

When the key is first turned "ON" without the

engine running, the ECM turns the

Fuel pump relay

"ON" for two seconds. This builds

up the fuel pressure

quickly. If the engine is not started within two

seconds, the

ECM shuts the fuel pump "OFF" and

waits until the engine starts. As soon as the engine is

cranked, the ECM turns the relay

"ON" and runs the

fuel pump.

As a backup system to the fuel pump relay, the

fuel pump can also be turned on

by the oil pressure

switch. The oil pressure sender has two circuits

internally. One operates the oil pressure indicator or

gage in the instrument cluster,

itnd the other is

anormally open switch which closes when oil pressure

reaches about 28

kPa (4 psi). If the fuel pump relay

fails, the oil pressure switch will run the fuel pump. An

inoperative fuel pump relay can result in long

cranking times, particularly if the engine is cold. The

oil pressure switch will turn on the fuel pump as soon

as oil pressure

reaches about 28 kPa (4 psi).

FUEL CONTROL

Always start with the "Diagnostic Circuit Check"

in Section

"6E2-A". This will reduce diagnosis time

and prevents unnecessary replacement of parts. The

information in this check will direct diagnosis

concerning "Engine

Crunlis But Won't Run" and the

"Fuel Control System," Section

"6E2-C2", including

diagnosis of an injector, pressure regulator,

fuel pump,

fuel

pump relay, and oil pressure switch.

Idle Air Control (IAC) Valve

A "Scan" tool reads IAC position in steps, calletl

"Counts." "0" steps indicates the ECM is commanding

the

IAC to be driven in, to a fully seiltetl position

(minimum idle air).

The higher the number steps, the

more idle air being allowed to pass

by the IAC valve.

cnose Refer to CHART C-2C for information to cliil,

the function of the IAC valve.

Driva bility

Refer to Section "B" for driveability symptoms

related to the fuel control.

ON-VEHICLE SERVICE

GENERAL SEWVICE INFORMATION

CAUTION:

e To prevent personal injury or damage to the

vehicle

as the result sf an accidental start,

disconnect and reconnect the negative

battery cable before and after service is

performed.

@ Also, catch any fuel that leaks out when

disconnecting the fuel lines, by covering the

fittings with

a shop cloth. Place the cloth in

an approved container when work is

complete.

The 'FBI unit repair procedures cover component

replacement with the unit on the vehicle,

tIowever,

throttle body replacement requires that the complete

unit

be removed from the enginc.

Page 620 of 1825

DRIVEABILITY AND EMISSIONS - 5.OL (VIN E) 6E2-C7-1

SECTION C7

EXHAUST GAS RECIRCULAVON (EGR) SYSEENO

GENERAL DESCRIPTION ...............

........................ PURPOSE

OPERATION

......................

EGR CONTROL .....................

...... NEGATIVE BACKPRESSURE VALVE

.......... EGR VALVE IDENTIFICATION

RESULTS OF INCORRECT OPERATION

. . , .

CONTENTS

......................... C7-1 DIAGNOSIS C7-2

..................... C7-1 ON-CAR SERVICE C7-2

....................... C7-1 EGRVALVE C7-2

............. C7-1 EGR Manifold Passage C7-2

C7-1

EGR CONTROL SOLENOID ............. C7-3

C7-2 PARTS INFORMATION

................. C7-3

C7-2

GENERAL DESCRIPTION

PURPOSE

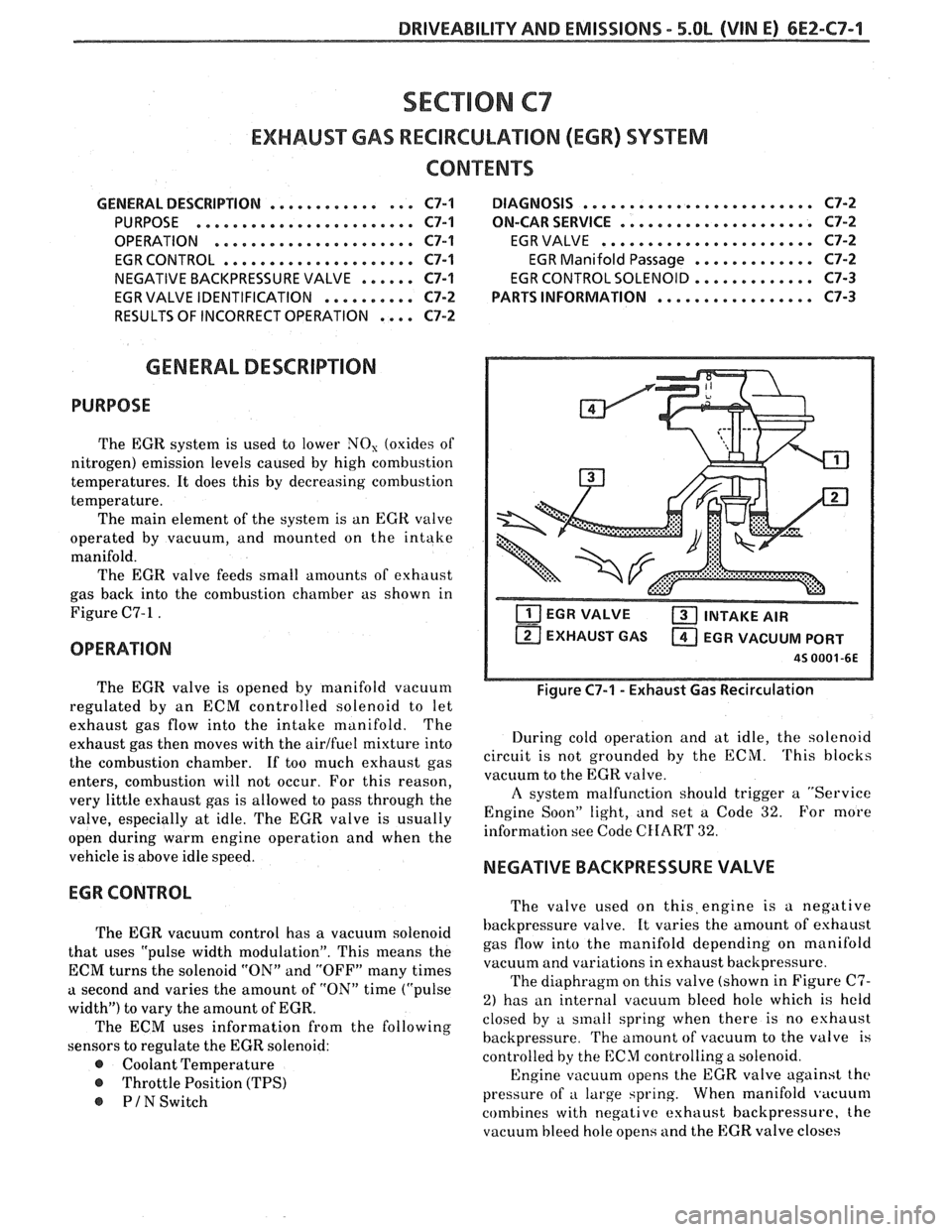

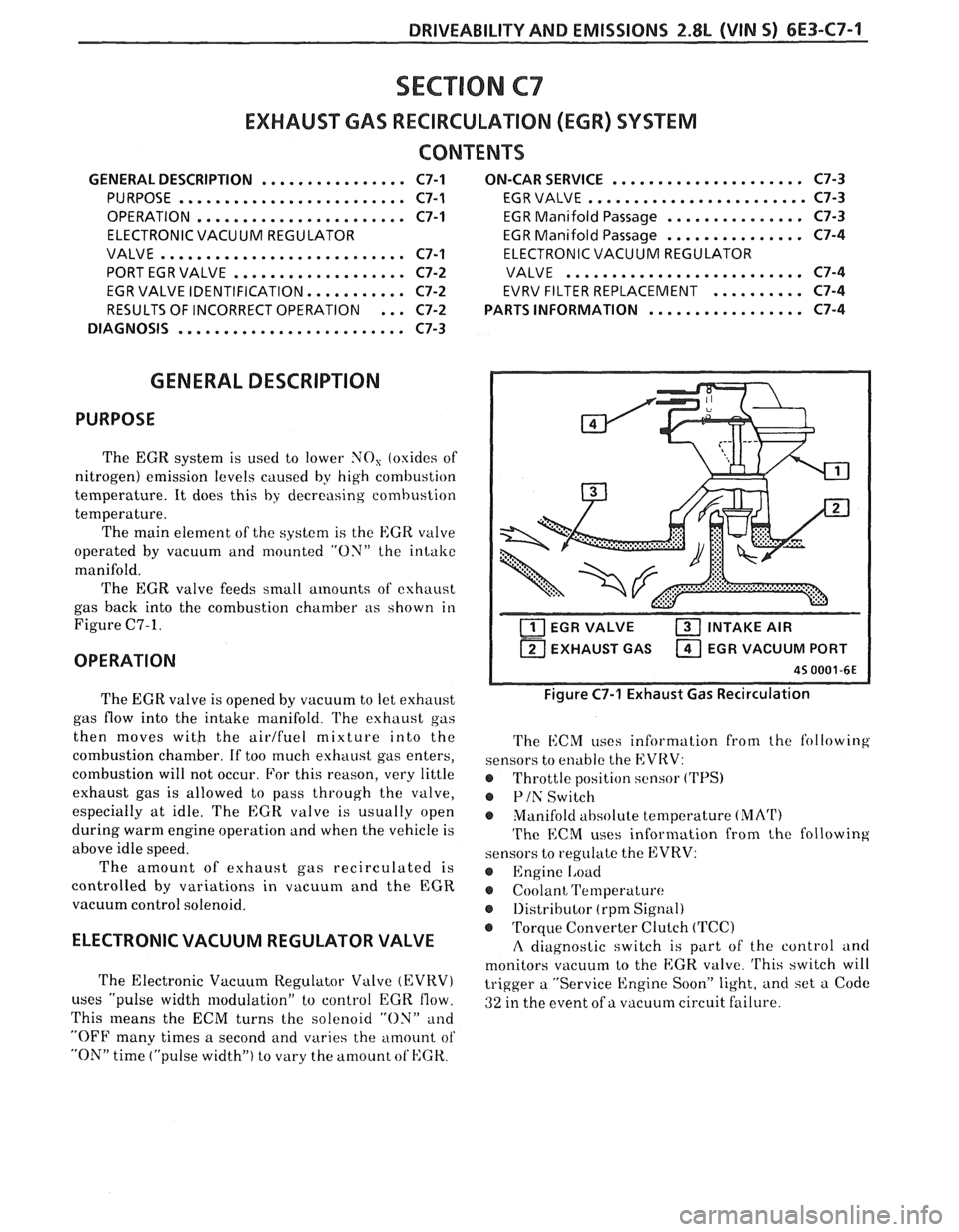

The EGR system is used to lower NO, (oxides of

nitrogen) emission levels caused by high combustion

temperatures.

It does this by decreasing combustion

temperature. The main element of the system is an

EGR valve

operated by vacuum, and mounted on the intake

manifold. The EGR valve feeds small amounts of exhaust

gas back into the combustion chamber as shown in

Figure C7-1

.

OPERATION

The EGR valve is opened by manifold vacuum

regulated by an ECM controlled solenoid to let

exhaust gas flow into the intake manifold. The

exhaust gas then moves with the

airlfuel mixture into

the combustion chamber.

If too much exhaust gas

enters, combustion will not occur. For this reason,

very little exhaust gas is allowed to pass through the

valve, especially at idle. The EGR valve is usually

open during warm engine operation and when the

vehicle is above idle speed.

EGR CONTROL

The EGR vacuum control has a vacuum solenoid

that uses "pulse width modulation". This means the

ECM turns the solenoid "ON" and "OFF" many times

a second and varies the amount of "ON" time ("pulse

width") to vary the amount of EGR.

The ECM uses information from the following

sensors to regulate the EGR solenoid:

@ Coolant Temperature

@ Throttle Position (TPS)

PIN Switch

T'IT] EGR VALVE a INTAKE AIR

EXHAUST GAS

a EGR VACUUM PORT

45 0001 -6E

Figure C7-1 - Exhaust Gas Recirculation

During cold operation and at idle, the solenoid

circuit is not grounded by the ECM.

'I'his blocks

vacuum to the EGR valve.

A system malfunction should trigger a "Service

Engine Soon" light, and set a Code

32. For more

information see Code

CHAR'I' 32.

NEGATIVE BACKPRESSURE VALVE

The valve used on this,engine is a negative

backpressure valve. It varies the amount of eshaust

gas flow into the manifold depending on manifold

vacuum and variations in exhaust backpressure.

The diaphragm on this valve (shown in Figure

C7-

2) has an internal vacuum bleed hole which is held

closed by a sinall spring when there is no eshaust

backpressure.

The amount of vacuum to the valve is

controlled

by the ECM controlling a solenoid.

Engine vacuum opens the EGR valve against

the

pressure of a large spring. When manifold vacuum

combines with negative exhaust backpressure, the

vacuum bleed hole opens and the EGR valve closes

Page 661 of 1825

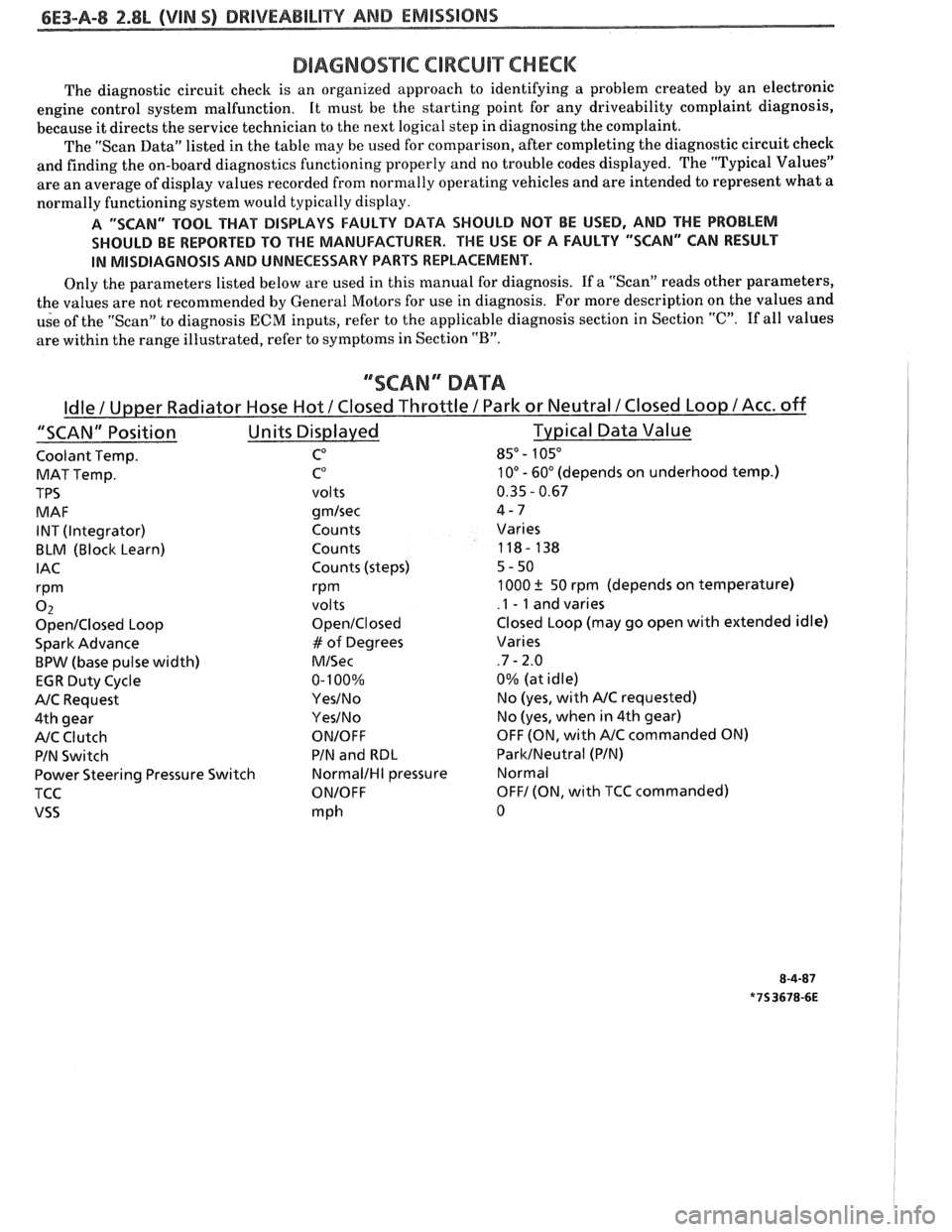

DIAGNOSTIC CIRCUIT CHECK

The diagnostic circuit check is an organized approach to identifying a problem created by an electronic

engine control system malfunction. It

must be the starting point for any driveability complaint diagnosis,

because it directs the service technician to the next logical step in diagnosing the complaint.

The "Scan Data" listed in the table may be used for comparison, after completing the diagnostic circuit check

and finding the on-board diagnostics functioning properly and no trouble codes displayed. The "Typical Values"

are an average of display values recorded from normally operating vehicles and are intended to represent what a

normally functioning system would typically display.

A "SCAN" TOOL THAT BiSPLAYS FAULTY DATA SHOULD NOT BE USED, AND THE PROBLEM

SHOULD BE REPORTED

TO THE MANUFACTURER. THE USE OF A FAULTY "SCAN" CAN RESULT

IN MISDIAGNOSIS AND UNNECESSARY PARTS REPLACEMENT.

Only the parameters listed below are used in this manual for diagnosis. If a "Scan" reads other parameters,

the values are not recommended by General Motors for use in diagnosis. For more description on the values and

use of the "Scan" to diagnosis

ECM inputs, refer to the applicable diagnosis section in Section "C". If all values

are within the range illustrated, refer to symptoms in Section

"B".

""SCAN" DATA

Coolant Temp. CO 85" - 105"

MAT Temp. C0 10" - 60" (depends on underhood temp.)

TPS

volts 0.35 - 0.67

MAF

gmlsec 4-7

INT (Integrator) Counts Varies

BLM (Block Learn) Counts 118- 138

IAC Counts (steps) 5-50

rPm rPm 1000 ? 50 rpm (depends on temperature)

0 2 volts .I - 1 and varies

OpenIClosed Loop OpenIClosed Closed Loop (may go open with extended idle)

Spark Advance

# of Degrees Varies

BPW (base pulse width) MISec .7 - 2.0

EGR Duty Cycle 0-

100% 0%

(at idle)

NC Request YesINo No (yes, with NC requested)

4th gear

YesINo No (yes, when in 4th gear)

NC Clutch ONIOFF OFF (ON, with NC commanded ON)

PIN Switch PIN

and

RBL ParkINeutral (PIN)

Power Steering Pressure Switch

NormalIHI pressure Normal

TCC

ONIOFF OFF1 (ON, with TCC commanded)

VSS mph 0

Page 740 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (VIN 5) 6E3-C2-5

As a backup system to the fuel pump relay, the

fuel pump can also be turned "ON" by the oil pressure

switch. The oil pressure switch is a normally open

switch which closes when oil pressure reaches about

28

kPa (4 psi). If the fuel pump relay fails, the oil

pressure switch will close and run the fuel pump.

An inoperative fuel pump relay can result in long

cranking times, particularly if the engine is cold.

An inoperative fuel pump would cause a no start

condition. A fuel pump which does not provide enough

pressure can result in poor performance.

FUEL CONTROL SYSTEM

Some failures of this system will result in an

"Engine Cranks But Won't Run". If

this condition

exists, see CHART A-3. This chart will determine if

the problem is caused by the ignition system, ECM or

fuel pump circuit. If

it's determined to be a fuel

problem, CHART

A-7 will be used. This includes the

injectors, pressure regulator, fuel pump and fuel pump

relay. The fuel system wiring schematic is covered on

the facing page of Code CHART

54.

If a malfunction occurs in the fuel control system

it usually results in either a rich or a lean exhaust

condition. This condition is sensed by the oxygen

sensor and the ECM will change the fuel calculation

(injector pulse width) based on the

02 sensor reading.

The change made to the fuel calculation will be

indicated by a change in the block learn values which

can be monitored by a "Scan" tool. The normal block

learn values are around 128 and if the

O2 sensor is

sensing a lean condition, the ECM will add fuel and

this will result in a block learn value above 128. If the

02 sensor is sensing a rich exhaust the ECM will

reduce fuel to the engine and this will result in block

learn values below 128. Some variations in block

learn values are normal because all engines are not

exactly the same. However, if the block learn values

are

+ 10 counts from 128, a system problem exists. If

the block learn values are greater than 138, see Code

44 for items which can cause a lean system.

If the block learn values are less than 118, see

Code

45 for items which can cause the system to run

rich. If a driveability symptom exists, refer to the

particular symptom in Section

"B" for additional

items to check.

IDLE AIR CONTROL VALVE

A "Scan" tool will read IAC position in steps

(counts).

"0" steps indicates the ECM is commanding

the IAC to be driven all the way in, to a fully seated

position, and this is usually caused by a vacuum leak.

The higher the number of counts the more air being

allowed to pass the IAC valve. CHART C-2C can be

used to diagnosis the IAC valve. Also refer to "Rough, Unstable,

or Incorrect Idle, Stalling" in "Symptoms,"

Section

"B" for other possibilities for the cause of idle

problems.

ON-CAR SERVICE

PORT FUEL INJECTION COMPONENTS

CAUTION:

Before servicing an injector, fuel

rail, or pressure regulator, it is

necessary to relieve the pressure in

the fuel system, to minimize the risk

of fire and personal injury. (See

"Fuel Pressure Relief Procedure"

below). To reduce the chance of

personal injury, cover the fuel line

with a shop cloth to collect the fuel,

and then place the cloth in an

approved container.

FUEL PRESSURE RELIEF PROCEDURE

Connect fuel gage J 34730-1 or equivalent to fuel

pressure valve. Wrap a shop towel around fitting

while connecting gage to avoid spillage.

Install bleed hose into an approved container and

open valve to bleed system pressure.

Plenum

Remove or Disconnect

1. Negative battery cable.

2. Air

inlet duct at throttle body.

3. Throttle body retaining bolts

(2).

4. EGR pipe bolts (2).

5. Throttle cable bracket.

6. Plenum bolts (8).

Install or Connect

I. Plenum and gaskets.

2. Plenum bolts. See Figure C2-6.

3. Throttle cable bracket.

4. EGR pipe bolts.

5. Throttle body and bolts.

6. Air inlet duct

7. Negative battery cable.

Fuel Rail and Pressure Regulator Assembly

Important

When servicing the fuel rail assembly,

precautions must be taken to prevent dirt and

other contaminants from entering the fuel

passages. It is recommended that fittings

he

capped and holes be plugged during servicing.

Page 778 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (VIN 5) 6E3-C7-1

SECTION C7

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

CONTENTS

GENERAL DESCRIPTION ................ C7-1

PURPOSE

......................... C7-1

OPERATION

....................... C7-1

ELECTRONIC VACUUM REGULATOR

VALVE

........................... C7-1

PORT EGR VALVE

................... C7-2

EGR VALVE IDENTIFICATION..

......... C7-2

RESULTS OF INCORRECT OPERATION

... C7-2

DIAGNOSIS

......................... C7-3

GENERAL DESCRIPTION

PURPOSE

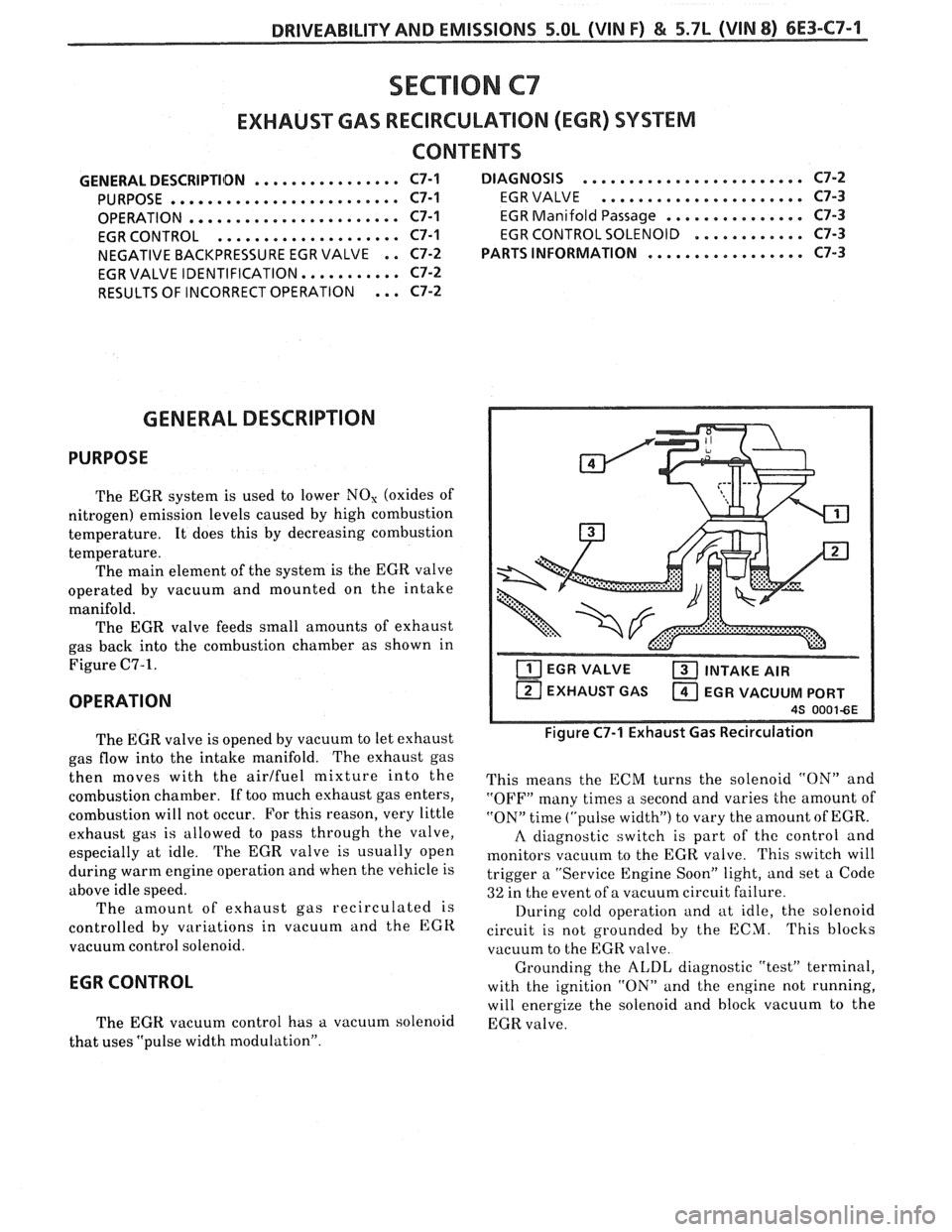

The EGR system is used to lower NO, (oxides of

nitrogen) emission levels caused by high combustion

temperature. It does this

by decreasing combustion

temperature.

The main element of the system is the

EGR valve

operated by vacuum and mounted

"ON" the intake

manifold.

The EGR valve feeds small

amounts of exhaust

gas back into the combustion chamber as shown in

Figure C7-1.

OPERATION

..................... ON-CAR SERVICE C7-3

EGR VALVE

........................ C7-3

EGR Manifold Passage

............... C7-3

EGR Manifold Passage

............... C7-4

ELECTRONIC VACUUM REGULATOR

VALVE

.......................... C7-4

EVRV FILTER REPLACEMENT

.......... C7-4

................. PARTS INFORMATION C7-4

EGR VALVE INTAKE AIR

1 EXHAUST GAS EGR VACUUM PORT I

The EGR valve is opened by vacuum to let exhaust

gas flow into the intake manifold.

l'he exhaust gas

then moves

witb the airlfuel mixture into the

combustion chamber. If too much exhaust gas enters,

combustion will not occur. For this reason, very little

exhaust gas is allowed to pass through the valve,

especially at idle. The

EGR valve is usually open

during warm engine operation and when the vehicle is

above idle speed.

The amount of exhaust gas recirculated is

controlled by variations in vacuum and the EGR

vacuum control solenoid.

ELECTRONIC VACUUM REGULATOR VALVE

The Electronic Vacuum Regulator Valve (EVRV)

uses "pulse width modulation" to control EGK flow.

This

means the ECM turns the solenoid "ON" and

"OFF many times a second and varies the amount of

"ON" time ("pulse width") to vary the amount ot'HGK.

Figure C7-1 Exhaust Gas Recirculation

The i1:CM uses information from the following

sensors to enable the EVRV:

@ Throttle position sensor ('I'PS)

@ Plh' Switch

Manifold

ahsolute temperature (MArI')

The ECM uses information from the following

sensors to regulate the EVRV:

@ Engine 1,oad

Coolant Temperature

@ 1)istributor (rpm Signal)

@ Torque Converter Clutch (TCC)

A diagnostic switch is part of the control and

monitors vacuum to the

EGK. valve. 'I'his switch will

trigger a "Service Engine Soon" light, and set a Code

ai ure. 32 in the event of a vacuum circuit f 'I

Page 811 of 1825

6E3-A-8 5.OL (VIN F) & 5.7L(VIN 8) DRIVEABILITY AND EMISSIONS

DIAGNOSIC CIRCUIXCHECK

The Diagnostic Circuit Checlc is an organized approach to identifying a problem created by an Electronic

Engine Control System malfunction. It

must be the starting point for any driveability complaint diagnosis,

because it directs the Service Technician to the next logical step in diagnosing the complaint.

The "Scan Data" listed in the table may be used for comparison, after completing the Diagnostic Circuit

Check and finding the on-board diagnostics functioning properly and no trouble codes displayed. The "Typical

Values" are an average of display values recorded from normally operating vehicles and are intended to

represent what a normally functioning system would typically display.

A "SCAN" TOOL THAT DISPLAYS FAULTY DATA SHOULD NOT BE USED, AND THE PROBLEM

SHOULD BE REPORTED TO THE MANUFACTURER. THE USE OF A FAULTY "SCAN" CAN RESULT

IN MISDIAGNOSIS AND UNNECESSARY PARTS REPLACEMENT.

Only the parameters listed below are used in this manual for diagnosing. If a "Scan" reads other parameters,

the values are not recommended by General Motors for use in diagnosing. For more description on the values

and use of the "Scan" to diagnosis ECM inputs, refer to the applicable diagnosis section in Section C.

If all values

are within the range illustrated, refer to symptoms in Section

B.

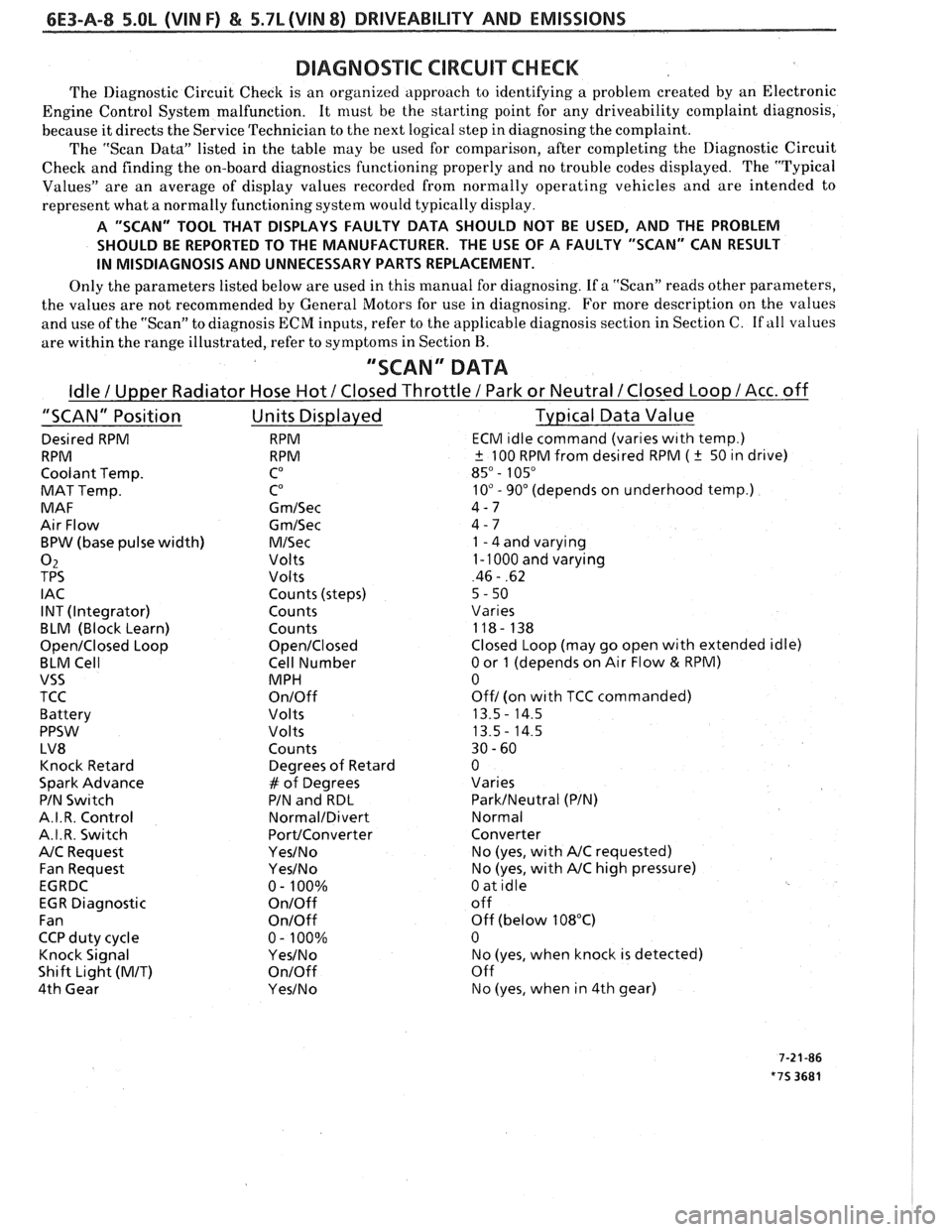

"SCAN" DATA

Idle / Upper Radiator Hose Hot / Closed Throttle / Park or Neutral /Closed Loop /Acc. off

"SCAN" Position Units Displayed Typical Data Value

Desired RPM RPM ECM ~dle command (vanes w~th temp.)

RPM RPM

+ 100 RPM from desired RPM ( k 50 ~n drive)

Coolant Temp.

CO 85" - 105"

MAT Temp. CO 10" - 90" (depends on underhood temp.)

MAF G

m/Sec 4-7

Air Flow

Gm/Sec 4 - 7

BPW (base pulse width)

M/Sec 1 - 4 and varying

02 Volts 1 - 1000 and varying

TPS Volts 46 - .62

I AC Counts (steps)

5 - 50

INT (Integrator) Counts

Vanes

BLM (Block Learn) Counts 118- 138

Open/Closed Loop Open/Closed Closed Loop (may go open with extended idle)

BLM Cell Cell Number

0 or 1 (depends on Air Flow & RPM)

VSS MPH 0

TCC

On/Off Off/ (on wlth TCC commanded)

Battery Volts 13.5

- 14.5

PPSW

Volts 13.5- 14.5

LV8 Counts 30

- 60

Knock Retard Degrees

of Retard 0

Spark Advance

# of Degrees Varies

PIN

Swltch PIN and RDL ParkINeutral (PIN)

A.I. R. Control

Normal/Divert Normal

A.I.R. Switch

PortIConverter Converter

NC Request Yes/No No (yes, wlth NC requested)

Fan Request

Yes/No No (yes, with NC high pressure)

EGRDC 0- 100%

0 at idle

EGR Diagnostic

On/Off off

Fan

OnIOff Off (below 108°C)

CCP duty cycle 0

- 100% 0

Knock Signal

YesINo No (yes, when knock is detected)

Shift Light

(MIT) On/Off Off

4th Gear

Yes/No No (yes, when in 4th gear)

Page 892 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-C2-5

Fuel Pump Electrical Circuit

When the ignition is first turned "ON", without

the engine running, the ECM will turn the fuel pump

relay "ON" for two seconds.

This builds up the fuel

pressure quickly. If the engine is not started within

two seconds, the ECM will shut the fuel pump "OFF"

and wait until the engine is cranking. As soon as the

engine is cranked, the ECM will turn the relay "ON"

and run the fuel pump.

As

a backup system to the fuel pump relay, the

fuel pump can also be turned "ON" by the oil pressure

switch. The oil pressure switch is a normally open

switch which closes when oil pressure reaches about

28

kPa (4 psi). If the fuel pump relay fails, the oil

pressure switch will close, and run the fuel pump.

An inoperative fuel pump relay can result in long

cranking times, particularly if the engine is cold but

should result in

a Code 54.

An inoperative fuel pump would cause a no start

condition. A fuel pump which does not provide enough

pressure can result in poor performance.

DIAGNOSIS

FUEL CONTROL SYSTEM

Some failures of this system will result in an

"Engine Cranks But Won't Run". If

this condition

exists see CHART A-3. This chart will determine if

the problem is caused by the ignition system, ECM, or

fuel pump circuit. If

it's determined to be a fuel

problem CHART A-7 will be used. This includes the

injectors, pressure regulator, fuel pump, and fuel

pump relay. The fuel system wiring schematic is

covered on the facing page of Code CHART 54.

If a malfunction occurs in the fuel control system,

it usually results in either a rich or

a lean exhaust

condition. This condition is sensed by the oxygen

sensor and the ECM will change the fuel calculation

(injector pulse width) based on the

O2 sensor reading.

The change

made to the fuel calculation will be

indicated by a change in the block learn values, which

can be monitored by a "Scan" tool.

The normal block

learn values are around 128, and if the

O2 sensor is

sensing a lean condition, the EC

M will add fuel which

will result in a block learn value above 128.

If the O2

sensor is sensing a rich exhaust the ECM will reduce

fuel to the engine and this will result in block learn

values below 128. Some variations in block

learn

values are normal because all engines are not exactly

the same. However, if the block learn values are

+ 10

counts from 128 a system problem exists. If the block

learn values are greater than 138 see Code 44, for

items which can cause a lean system.

If the block learn values are less than 118 see Code

45 for items which can cause the system to run rich. If

a driveability symptom exists, refer to the

particular symptom in Section

"B" for additional

items to check.

IDLE AIR CONTROL VALVE

AUScan" tool will read IAC position in steps (counts).

"0" steps indicates the ECM is commanding the IAC to

be driven all the way in, to a fully seated position, and

this is usually caused by a vacuum leak. The higher

the number of counts the more air being allowed to

pass the IAC valve. CHART C-2C can be used to

diagnosis the IAC valve. Also refer to "Rough,

Unstable, or Incorrect Idle, Stalling" in symptoms,

Section "B" for other possibilities for the cause

of idle

problems.

FUEL SYSTEM PRESSURE TEST

A fuel system pressure test is part of several of the

diagnostic charts and symptom checks. To perform

this test, use the procedure in CHART A-7.

ON-CAR SERVICE

PORT FUEL INJECTION COMPONENTS

CAUTION:

Before servicing an injector, fuel

rail, or pressure regulator,

it is

necessary to relieve the pressure in

the fuel system, to minimize the

risk of fire and personal injury.

(See "Fuel Pressure Relief

Procedure" below). To reduce the

chance of personal injury, cover

the fuel line with

a shop cloth to

collect the fuel, and then place the

cloth in an approved container.

FUEL PRESSURE RELIEF PROCEDURE

1. Connect fuel gage J 34730-1 or equivalent to fuel

pressure valve. Wrap a shop towel around fitting

while connecting gage to avoid spillage.

2. Install bleed hose into an approved container and

open valve to bleed system pressure.

Plenum

(Figure

C2-6)

Remove or Disconnect

1. Negative battery cable.

2. Throttle, 'F.V., and cruise control cable.

3. Cable retaining bracket.

4.

'I'hrottle body retaining bolts (4).

5. 'L'l'S and IAC valve electrical connectors.

6. Vacuum hoses.

Page 936 of 1825

DRIVEABILITY AND EMISSIONS 5.0L (VIN F) €4 5.7L (VIN 8) 6E3-C7-1

SECTION C7

EXHAUST GAS REClRCULATlON (EGR) SYSTEM

CONTENTS

................ GENERAL DESCRIPTIlDN C7-1 DIAGNOSIS ........................ C7-2

PURPOSE

......................... C7-1 EGR VALVE ...................... C7-3

....................... OPERATION C7-1 EGR Manifold Passage ............... C7-3

.................... EGR CONTROL C7-1

EGR CONTROL SOLENOID ............ C7-3

NEGATIVE BACKPRESSURE EGR VALVE

. . C7-2 PARTS INFORMATION ................. C7-3

......... EGR VALVE IDENTIFICATION.. C7-2

... RESULTS OF INCORRECT OPERATION C7-2

GENERAL DESCRIPTION

PURPOSE

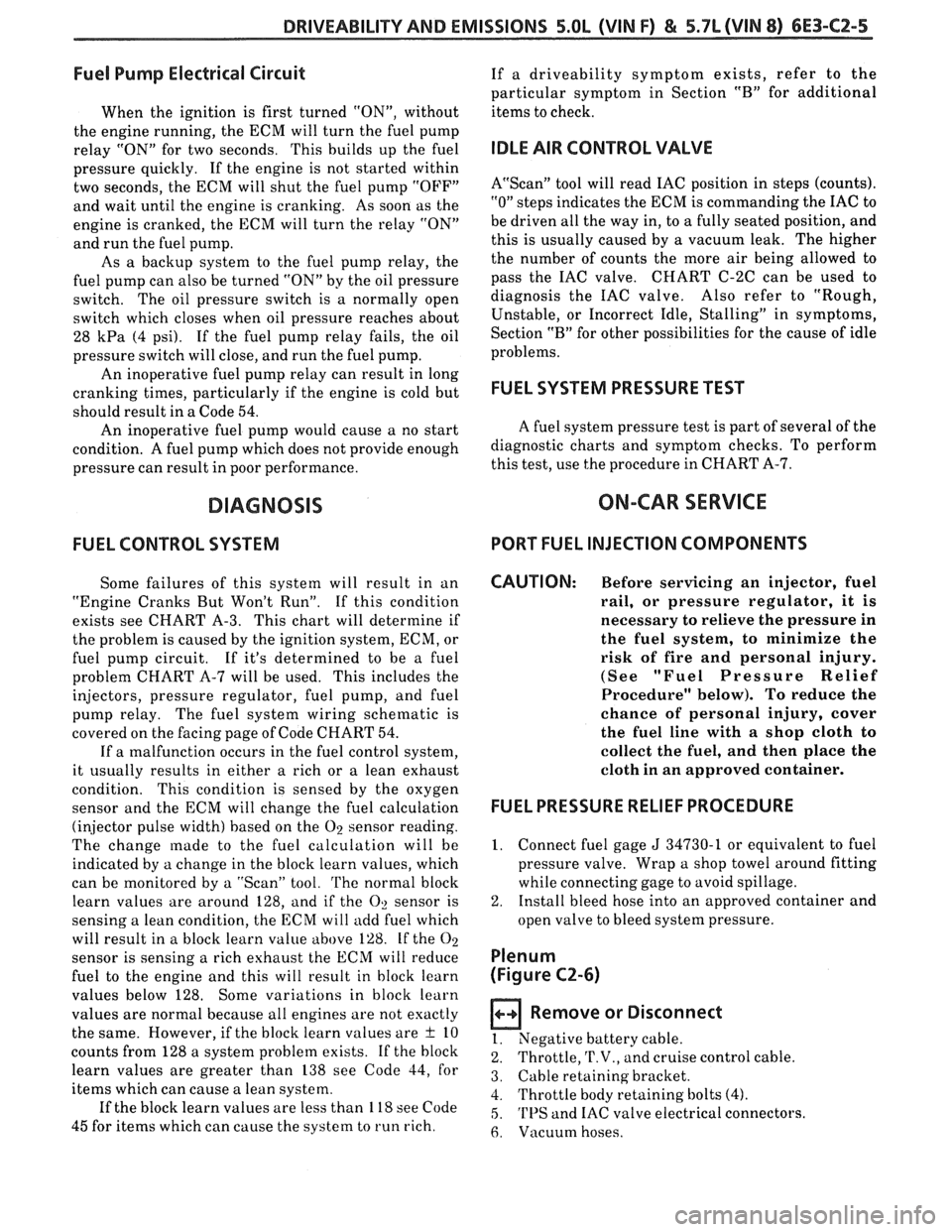

The EGR system is used to lower NO, (oxides of

nitrogen) emission levels caused by high combustion

temperature. It does this by decreasing combustion

temperature. The main element of the system is the EGR valve

operated by vacuum and mounted on the intake

manifold.

The EGR valve feeds small amounts of exhaust

gas back into the combustion chamber as shown in

Figure

C7-1.

OPERATION

The EGR valve is opened by vacuum to let exhaust

gas flow into the intake manifold. The exhaust gas

then moves with the

airlfuel mixture into the

combustion chamber.

If too much exhaust gas enters,

combustion will not occur. For this reason, very little

exhaust gas is allowed to pass through the valve,

especially at idle. The EGR valve is usually open

during warm engine operation and when the vehicle is

above idle speed. The amount of exhaust gas recirculated is

controlled by variations in vacuum and the

EGR

vacuum control solenoid.

EGR CONTROL

The EGR vacuum control has a vacuum solenoid

that uses "pulse width modulation".

EGR VALVE INTAKE AIR

EXHAUST GAS EGR VACUUM PORT

Figure C7-1 Exhaust Gas Recirculation

This means the ECM turns the solenoid "ON" and

"OFF" many times a second and varies the amount of

"ON" time ("pulse width") to vary the amount of EGR.

A diagnostic switch is part of the control and

monitors vacuum to the EGR valve. This switch will

trigger a "Service Engine Soon" light, and set a Code

32 in the event of a vacuum circuit failure.

During cold operation and at idle, the solenoid

circuit is not grounded by the ECM. This blocks

vacuum to the EGR valve.

Grounding the

ALDL diagnostic "test" terminal,

with the ignition "ON" and the engine not running,

will energize the solenoid and block vacuum to the

EGR valve.

Page 939 of 1825

6E3-C7-4 5.OL (VIN F) €4 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

CHART C-7

EXHAUST GAS RECIRCULATION CHECK

5.OL (VIN F) & 5.7L (VIN 8) "F" SERIES (PORT)

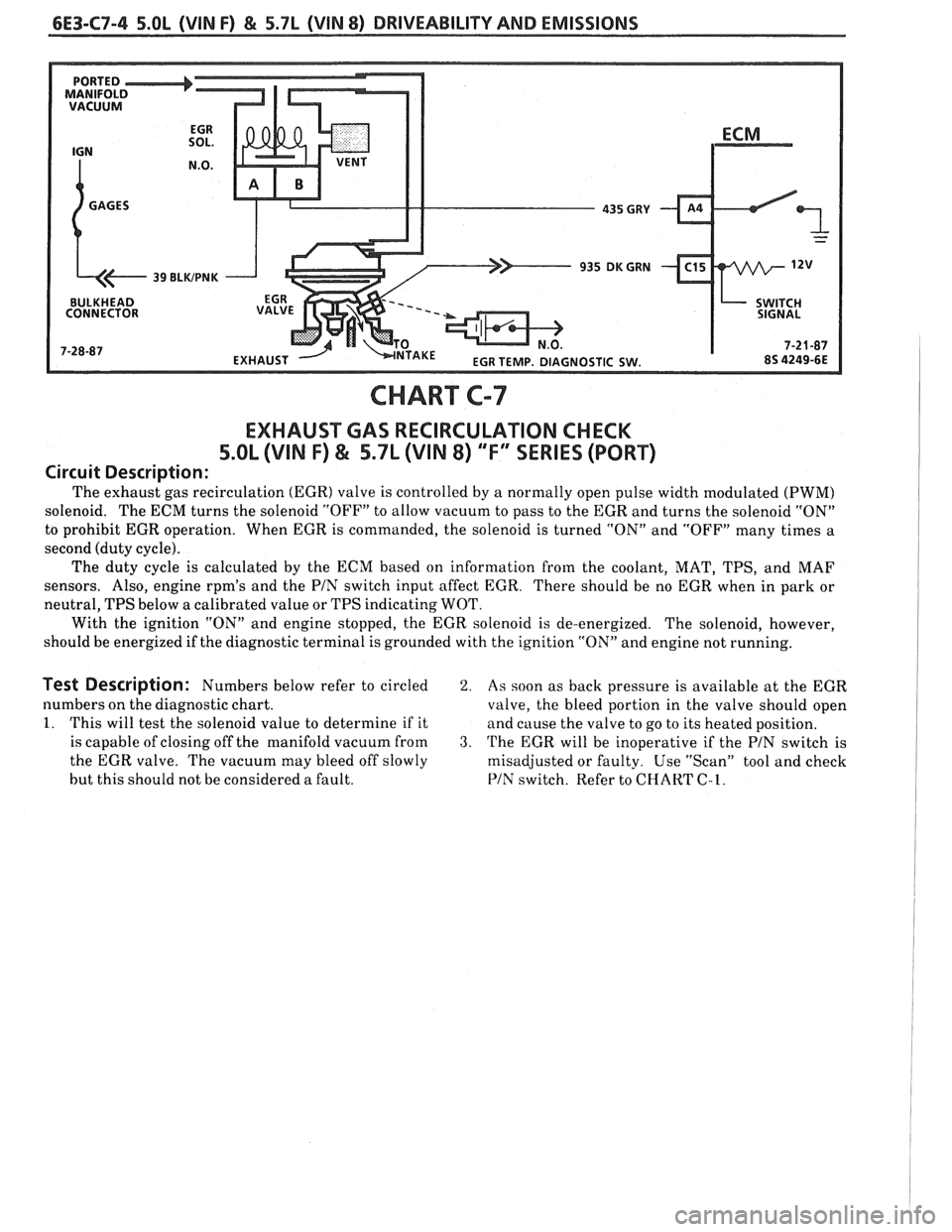

Circuit Description:

The exhaust gas recirculation (EGR) valve is controlled by a normally open pulse width modulated (PWM)

solenoid. The ECM turns the solenoid "OFF" to allow vacuum to pass to the EGR and turns the solenoid "ON"

to prohibit EGR operation. When EGR is commanded, the solenoid is turned "ON" and "OFF" many times a

second (duty cycle).

The duty cycle is calculated by the ECM based on information from the coolant, MAT, TPS, and MAF

sensors. Also, engine

rpm's and the PIN switch input affect EGR.

There should be no EGR when in park or

neutral, TPS below

a calibrated value or TPS indicating WOT.

With the ignition "ON" and engine stopped, the EGR solenoid is de-energized. The solenoid, however,

should be energized if the diagnostic terminal is grounded with the ignition "ON" and engine not running.

Test Description: Numbers below refer to circled 2. As soon as back pressure is available at the EGR

numbers on the diagnostic chart.

valve, the bleed portion in the valve should open

1. This will test the solenoid value to determine if it

and cause the valve to go to its heated position.

is capable of closing off the manifold vacuum from

3. 'I'he EGR will be inoperative if the PIN switch is

the EGR valve. The vacuum may bleed off slowly

misadjusted or faulty. Use "Scan" tool and check

but this should not be considered a fault.

PIN switch. Refer to CHART C-1.

Page 968 of 1825

DRIVEABILITY AND EMISSIONS - FUEL INJECTION 6E-7

On engines that can be monitored in the open

mode, it allows certain parameters to be obtained

without changing the engine operating

characteristics. The parameters capable of being read

vary from engine family to engine family. Most

"Scan" tools are programmed so that the system will

go directly into the special mode

if the "open" mode is

not available.

ALDL (7 OK, or Special) Mode

(not used on

all engines)

In this mode, all information incorporated into a

specific

engine and ECM is obtainable. However, in

this mode the system operating characteristics are

modified as follows.

@ "Closed Loop" timers are bypassed

EST (spark) is advanced

@ IAC will control engine idle to 1000 rpm I

50 rpm (if applicable)

@ On some engines, canister purge solenoid will

be enabled

@ P/N restrict functions will be disabled.

Factory Test (Back-up or 3.9 K) Mode

(TBI, Port)

In this mode, the ECM is operating on the fuel

back-up logic and is calibrated by the Calpak or Mem-

cal. These are used to control the fuel delivery

if the

ECM fails. This mode verifies that the back-up feature

is OK. The parameters that can be read on a

"Scan"

tool in this mode are not of much use for service.

"SCAN" TOOL LIMITATIONS AND USE

The "Scan" tool allows a quick check of sensors

and switches which are inputs to the ECM. However,

on some applications the data update rate makes the

tool less effective as a voltmeter when trying to detect

an intermittent which lasts for a very short time.

However, the "Scan" tool allows one to manipulate

wiring harnesses or components under the hood while

observing the "Scan" readout. This helps in locating

intermittents with the engine not running.

intermittent Conditions

for a period of time to see if there is any change in the

readings that indicates intermittent operation.

The "Scan" tool is also a useful and quick way of

comparing operating parameters of a poorly operating

engine with a known good one. For example;

A sensor

may shift in value but not set a code. Comparing with

a known good vehicle may uncover the problem.

The "Scan" tool has the ability to save time in

diagnosis and prevent the replacement of good parts.

The key to using the "Scan" tool successfully for

diagnosis lies in the technician's ability to understand

the system he is trying to diagnose as well as an

understanding of the "Scan" tool's limitations.

Therefore, the technician should read the tool

manufacturer's operating manual to become familiar

with the operation. The following information will

describe most of the "Scan" tool positions and how

they can be helpful in diagnosis.

"SCAN" TOOL POSITIONS

The following positions may not be applicable to

all engines. See the facing page

of the diagnostic

circuit check for a particular engine to decide which

positions apply to that engine.

Mode

Check with the manufacturer to determine what

the function of this mode is. In most cases it allows the

user to place the ECM in different operating modes.

Injector Pulse Width

In this position, the reading is given in

milliseconds, which is the

"ON" time that the ECM is

commanding to the

injector(s1.

Closed LoopIOpen Loop

This position will indicate whether the engine

control system is operating in "Open Loop" or "Closed

Loop". Most systems go "Closed Loop" after a certain

amount of running time, when coolant temperature is

high enough, and the oxygen sensor becomes active.

Exhaust (RichILean Indicator)

The "Scan" tool is helpful in cases of intermittent

This indicates the O2 sensor voltage at the instant operation' The can be in and observed that the data stream is sampled. If voltage is less than

while driving the vehicle under the condition where

350 mv, the value will be lean. If above 550 mv, a rich the light comes "ON" momentarily, or the engine exhaust is indicated. driveability is poor momentarily. If the problem

seems to be related to certain areas that can be

Codes checked on the "Scan" tool, then those are the

positions that should be checked while driving the

This will display any trouble codes stored in the

vehicle. If there does not seem to be any correlation

ECM memory. between the problem and any specific circuit, the

"Scan" tool can be checked on each position, watching