lock Ram 2500 2020 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 314 of 553

312STARTING AND OPERATING

(Continued)

ENGINE RUNAWAY — DIESEL ENGINE

Diesel engine runaway is a rare condition

affecting diesel engines, where the engine

consumes its own lubrication oil and runs at

higher and higher RPM until it overspeeds to a

point where it destroys itself due to either

mechanical failure or engine seizure through

lack of lubrication.

REFUELING THE VEHICLE — GAS ENGINE

The fuel filler cap (gas cap) is located behind the

fuel filler door, on the left side of the vehicle.

Open the fuel door and remove the fuel filler cap

by turning it counter-clockwise.

Fuel Filler Cap

NOTE:

When removing the fuel filler cap, lay the cap

tether in the hook, located on the fuel filler door.

WARNING!

In case of engine runaway due to flammable

fumes from fuel spills or turbocharger oil

leaks being sucked into the engine, do the

following to help avoid personal injury and/or

vehicle damage:

1. Turn the ignition switch to the OFF position.

2. Using a CO2 or dry chemical type fire

extinguisher, direct the spray from the fire

extinguisher into the grille on the driver side

so that the spray enters the engine air intake.

The inlet for the engine air intake is located

behind the drivers side headlamp and

receives air through the grille.

WARNING!

Never have any smoking materials lit in or

near the vehicle when the gas cap is

removed or the tank is being filled.

Never add fuel to the vehicle when the

engine is running.

A fire may result if gasoline is pumped into

a portable container that is inside of a

vehicle. You could be burned. Always place

gas containers on the ground while filling.

CAUTION!

Damage to the fuel system or emissions

control system could result from using an

improper fuel tank filler tube cap.

A poorly fitting fuel filler cap could let impu -

rities into the fuel system.

A poorly fitting fuel filler cap may cause the

“Malfunction Indicator Light (MIL)” to turn

on.

To avoid fuel spillage and overfilling, do not

“top off” the fuel tank after filling. When the

fuel nozzle “clicks” or shuts off, the fuel

tank is full.

WARNING! (Continued)

20_DJD2_OM_EN_USC_t.book Page 312

Page 326 of 553

324STARTING AND OPERATING

(Continued)

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h) when towing while using a full size spare tire.

Proper tire inflation pressures are essential

to the safe and satisfactory operation of your

vehicle. Refer to “Tires” in “Servicing And

Maintenance” for proper tire inflation proce -

dures.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer. Refer to

“Tires” in “Servicing And Maintenance” for

the proper inspection procedure.

When replacing tires, refer to “Tires” in

“Servicing And Maintenance” for the proper

tire replacement procedures. Replacing tires

with a higher load carrying capacity will not

increase the vehicle's GVWR and GAWR

limits.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake

system or vacuum system of your vehicle

with that of the trailer. This could cause inad -

equate braking and possible personal injury.

An electronically actuated trailer brake

controller is required when towing a trailer

with electronically actuated brakes. When

towing a trailer equipped with a hydraulic

surge actuated brake system, an electronic

brake controller is not required.

Trailer brakes are recommended for trailers

over 1,000 lbs (453 kg) and required for

trailers in excess of 2,000 lbs (907 kg).

When hauling cargo or towing a trailer, do

not overload your vehicle or trailer. Over -

loading can cause a loss of control, poor

performance or damage to brakes, axle,

engine, transmission, steering, suspension,

chassis structure or tires.

Safety chains must always be used

between your vehicle and trailer. Always

connect the chains to the hook retainers of

the vehicle hitch. Cross the chains under

the trailer tongue and allow enough slack

for turning corners.

Vehicles with trailers should not be parked

on a grade. When parking, apply the

parking brake on the tow vehicle. Put the

tow vehicle transmission in PARK. For

four-wheel drive vehicles, make sure the

transfer case is not in NEUTRAL. Always,

block or "chock" the trailer wheels.

GCWR must not be exceeded.

WARNING! (Continued)

Total weight must be distributed between

the tow vehicle and the trailer such that the

following four ratings are not exceeded :

GVWR

GTW

GAWR

Tongue weight rating for the trailer

hitch utilized.

WARNING! (Continued)

20_DJD2_OM_EN_USC_t.book Page 324

Page 328 of 553

326STARTING AND OPERATING

GAIN

The GAIN setting is used to set the trailer brake

control for the specific towing condition and

should be changed as towing conditions

change. Changes to towing conditions include

trailer load, vehicle load, road conditions and

weather.

Adjusting GAIN

NOTE:

This should only be performed in a traffic free

environment at speeds of approximately

20–25 mph (30–40 km/h).

1. Make sure the trailer brakes are in good

working condition, functioning normally

and properly adjusted. See your trailer

dealer if necessary.

2. Hook up the trailer and make the electrical connections according to the trailer manu -

facturer's instructions. 3. When a trailer with electric/EOH brakes is

plugged in, the trailer connected message

should appear in the instrument cluster

display (if the connection is not recognized

by the ITBM, braking functions will not be

available), the GAIN setting will illuminate

and the correct type of trailer must be

selected from the instrument cluster display

options.

4. Push the UP or DOWN button on the steering wheel until “TRAILER TOW”

appears on the screen.

5. Push the RIGHT arrow on the steering wheel to enter “TRAILER TOW”.

6. Push the UP or DOWN buttons until the Trailer Brake Type appears on the screen. 7. Push the RIGHT arrow and then push the UP

or DOWN buttons until the proper Trailer

Brake Type appears on the screen.

8. In a traffic-free environment, tow the trailer on a dry, level surface at a speed of

20–25 mph (30–40 km/h) and squeeze

the manual brake control lever completely.

9. If the trailer wheels lockup (indicated by squealing tires), reduce the GAIN setting; if

the trailer wheels turn freely, increase the

GAIN setting.

Repeat steps 8 and 9 until the GAIN setting is at

a point just below trailer wheel lockup. If towing

a heavier trailer, trailer wheel lockup may not be

attainable even with the maximum GAIN setting

of 10.

20_DJD2_OM_EN_USC_t.book Page 326

Page 338 of 553

336STARTING AND OPERATING

(Continued)

Off-Road Driving Tips

Care should be taken when attempting to climb

steep hills or driving diagonally across a hill or

slope. If natural obstacles force you to travel

diagonally up or down a hill, choose a mild angle

and keep as little side tilt as possible. Keep the

vehicle moving and make turns slowly and

cautiously. If you must back down a hill, back straight down

using REVERSE gear. Never back down in

NEUTRAL or diagonally across the hill.

When driving over sand, mud, and other soft

terrain, shift to low gear and drive steadily.

Apply the accelerator slowly to avoid spinning

the wheels.

Do not reduce the tire pressures for this type of

driving.

After Driving Off-Road

Off-road operation puts more stress on your

vehicle than does most on-road driving. After

going off-road, it is always a good idea to check

for damage. That way you can get any problems

taken care of right away and have your vehicle

ready when you need it.

Completely inspect the underbody of your

vehicle. Check tires, body structure, steering,

suspension, and exhaust system for damage.

Inspect the radiator for mud and debris and

clean as required.

Driving through standing water limits your

vehicle’s braking capabilities, which

increases stopping distances. Therefore,

after driving through standing water, drive

slowly and lightly press on the brake pedal

several times to dry the brakes.

Failure to follow these warnings may result

in injuries that are serious or fatal to you,

your passengers, and others around you.

CAUTION!

Always check the depth of the standing

water before driving through it. Never drive

through standing water that is deeper than

the bottom of the tire rims mounted on the

vehicle.

Determine the condition of the road or the

path that is under water and if there are any

obstacles in the way before driving through

the standing water.

Do not exceed 5 mph (8 km/h) when

driving through standing water. This will

minimize wave effects.

WARNING!

(Continued)

Driving through standing water may cause

damage to your vehicle’s drivetrain compo -

nents. Always inspect your vehicle’s fluids

(i.e., engine oil, transmission, axle, etc.) for

signs of contamination (i.e., fluid that is

milky or foamy in appearance) after driving

through standing water. Do not continue to

operate the vehicle if any fluid appears

contaminated, as this may result in further

damage. Such damage is not covered by

the New Vehicle Limited Warranty.

Getting water inside your vehicle’s engine

can cause it to lock up and stall out, and

cause serious internal damage to the

engine. Such damage is not covered by the

New Vehicle Limited Warranty.

CAUTION! (Continued)

20_DJD2_OM_EN_USC_t.book Page 336

Page 345 of 553

IN CASE OF EMERGENCY343

NOTE:

If your vehicle is equipped with an air suspen -

sion system, there is a feature which allows the

automatic leveling to be disabled to assist with

changing a tire.

This feature can be activated through the Ucon -

nect system.

Refer to “Uconnect Settings” in “Multimedia”

for further information.

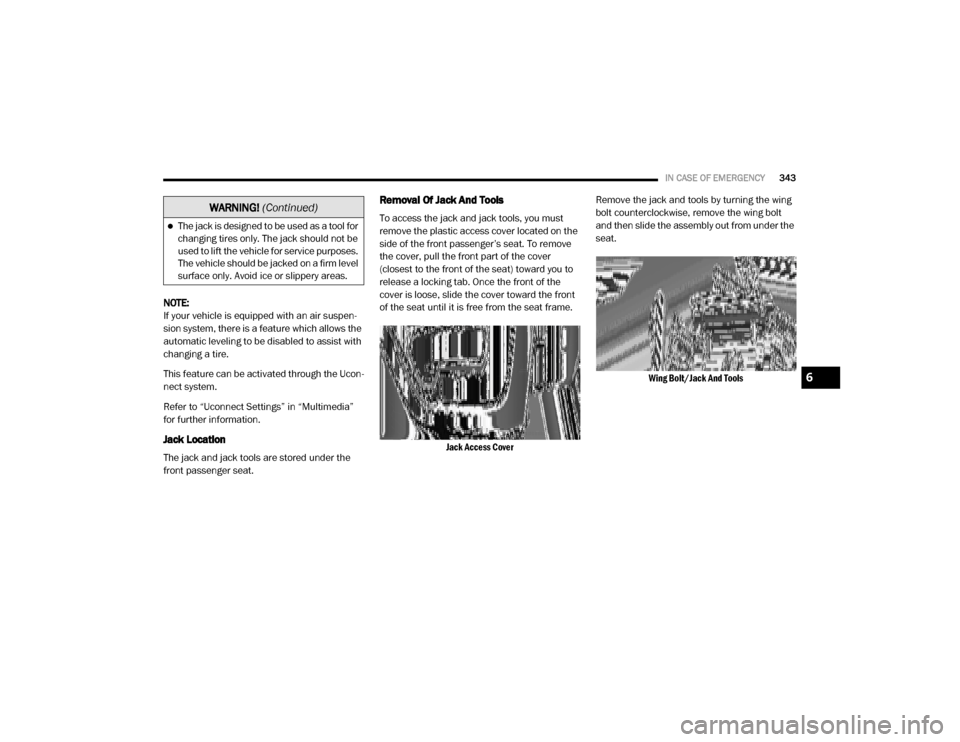

Jack Location

The jack and jack tools are stored under the

front passenger seat.

Removal Of Jack And Tools

To access the jack and jack tools, you must

remove the plastic access cover located on the

side of the front passenger’s seat. To remove

the cover, pull the front part of the cover

(closest to the front of the seat) toward you to

release a locking tab. Once the front of the

cover is loose, slide the cover toward the front

of the seat until it is free from the seat frame.

Jack Access Cover

Remove the jack and tools by turning the wing

bolt counterclockwise, remove the wing bolt

and then slide the assembly out from under the

seat.

Wing Bolt/Jack And Tools

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

WARNING! (Continued)

6

20_DJD2_OM_EN_USC_t.book Page 343

Page 346 of 553

344IN CASE OF EMERGENCY

(Continued)

Remove the jack and tools from the bracket

assembly. Turn the jack turn-screw counter-

clockwise to release jack from bracket

assembly.

Jack And Tools Bracket AssemblyJacking Tools

There are two ways to assemble the tools:

Assembled For Spare Tire Lowering/Raising

Assembled For Spare Tire Lowering/Raising

Assembled For Jack Operation

Assembled For Jack Operation

1 — Lug Wrench

2 — Extension 2

3 — Extension 3

4 — Extension 4

CAUTION!

The lug wrench can only be attached to

extension two (2).

When attaching the tool to the winch mech -

anism be sure the large flared end opening

on extension four (4) is positioned correctly

over the winch mechanism adjusting nut.

Damage to the lug wrench, extensions and

winch mechanism may occur from

improper tool assembly.

1 — Lug Wrench

2 — Extension 2

3 — Extension 3

4 — Extension 4

5 — Jack Driver

CAUTION! (Continued)

20_DJD2_OM_EN_USC_t.book Page 344

Page 347 of 553

IN CASE OF EMERGENCY345

Removing The Spare Tire

1. Remove the spare tire before attempting to

jack up the truck. Attach the lug wrench to

the extension tubes with the curved angle

facing away from the vehicle. Insert the

extension tube through the access hole

between the lower tailgate and the top of

the bumper and into the winch mechanism

tube.

Winch Mechanism Tube

Inserting The Extension Tubes Into The Access Hole

2. Rotate the lug wrench handle counterclock -

wise until the spare tire is on the ground

with enough cable slack to allow you to pull

it out from under the vehicle.

Rotating The Lug Wrench Handle

3. Pull the spare tire out from under the vehicle to gain access to the spare tire

retainer.

Pulling The Spare Tire Out

WARNING!

After using the jack and tools, always reinstall

them in the original carrier and location.

While driving you may experience abrupt

stopping, rapid acceleration or sharp turns. A

loose jack, tools, bracket or other objects in

the vehicle may move around with force,

resulting in serious injury.

6

20_DJD2_OM_EN_USC_t.book Page 345

Page 348 of 553

346IN CASE OF EMERGENCY

4. Lift the spare tire with one hand to give

clearance to tilt the retainer at the end of

the cable.

Gaining Access To The Retainer

5. Pull the retainer through the center of the wheel.

Pulling The Retainer Through The Center Of The Wheel

NOTE:

The winch mechanism is designed for use with

the extension tubes only. Use of an air wrench

or other power tools is not recommended and

can damage the winch.

Preparations For Jacking

1. Park the vehicle on a firm, level surface.

Avoid ice or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the parking brake.

4. Shift the transmission into Park (P).

5. Turn the ignition OFF. 6. Block both the front and rear of the wheel

diagonally opposite the jacking position. For

example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.

Wheel Blocked

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being raised or lifted.

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

20_DJD2_OM_EN_USC_t.book Page 346

Page 349 of 553

IN CASE OF EMERGENCY347

(Continued)

Jacking Instructions

Jack Warning Label Lug Wrench Adapter Shown In Jack And Tools Assembly

1. Remove the spare wheel, jack, and tools

from storage.

2. Using the lug wrench, loosen, but do not remove, the wheel nuts by turning them

counterclockwise one turn while the wheel

is still on the ground. Changing a dually tire

requires the lug wrench adapter.

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the

wheel to be raised.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when it

is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or inflated,

are securely stowed, spares must be

stowed with the valve stem facing the

ground.

WARNING! (Continued)

CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

6

20_DJD2_OM_EN_USC_t.book Page 347

Page 351 of 553

IN CASE OF EMERGENCY349

under the axle between the spring and the

shock absorber with the extension tubes ex -

tending to the rear.

Rear Lifting Point

Rear Jacking Location

Connect the extension tubes and lug

wrench. NOTE:

If the bottle jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary to

use the jack driver in order to lower the jack.

4. By rotating the lug wrench clockwise, raise

the vehicle until the wheel just clears the

surface.

5. Remove the lug nuts and pull the wheel off. On Single Rear Wheel (SRW) trucks, install

the spare wheel and lug nuts with the cone

shaped end of the wheel nuts toward the

wheel. On 3500 Dual Rear Wheel models

(DRW) trucks, if the outer tire is being replaced then leave the inner wheel on the

vehicle. If the inner wheel is being replaced

remove the outer wheel and replace the

inner wheel. The wheel nuts are a two-piece

assembly with a flat face. Lightly tighten the

lug nuts. To avoid the risk of forcing the

vehicle off the jack, do not fully tighten the

lug nuts until the vehicle has been lowered.

Rear Inner Wheel Proper Placement (Dual Rear Wheel Equipped)

CAUTION!

Before raising the wheel off the ground, make

sure that the jack will not damage

surrounding truck parts and adjust the jack

position as required.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

6

20_DJD2_OM_EN_USC_t.book Page 349