tires Ram 4500 Chassis Cab 2018 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 162 of 298

CAUTION!

• When installing the power distributioncenter cover, it is important to ensure

the cover is properly positioned and fully

latched. Failure to do so may allow water

to get into the power distribution center

and possibly result in an electrical sys-

tem failure.

• When replacing a blown fuse, it is impor-

tant to use only a fuse having the correct

amperage rating. The use of a fuse with

a rating other than indicated may result

in a dangerous electrical system over-

load. If a properly rated fuse continues

to blow, it indicates a problem in the

circuit that must be corrected.

JACKING AND TIRE CHANGING

WARNING!

• Do not attempt to change a tire on theside of the vehicle close to moving traf-

fic. Pull far enough off the road to avoid

the danger of being hit when operating

the jack or changing the wheel.

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

4500/5500 Models

These vehicles do not come equipped with a

jack.

NOTE:

Jacking and tire changing on 4500/

5500 models should be performed by an

authorized dealer, or knowledgeable service

personnel with the appropriate heavy duty

equipment, like a tire service company.

Preparations For Jacking

1. Park the vehicle on a firm, level surface.

Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic, pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

2. Place the gear selector into PARK. On four-wheel drive vehicles, shift the trans-

fer case to the 4L position.

3. Turn on the Hazard Warning flasher.

IN CASE OF EMERGENCY

160

Page 163 of 298

4. Apply the parking brake.

5. Turn the ignition OFF.

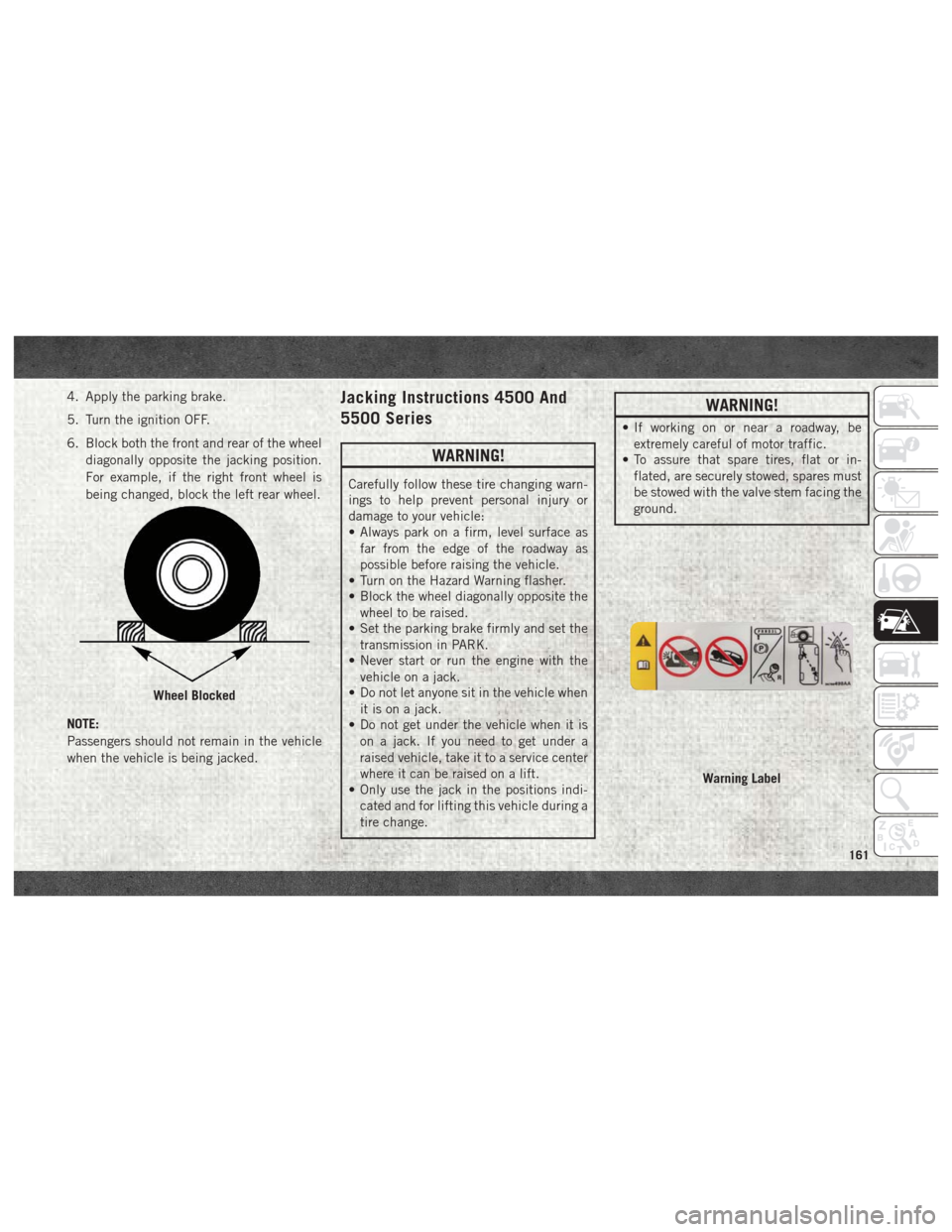

6. Block both the front and rear of the wheeldiagonally opposite the jacking position.

For example, if the right front wheel is

being changed, block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.Jacking Instructions 4500 And

5500 Series

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the

wheel to be raised.

• Set the parking brake firmly and set the

transmission in PARK.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

• Only use the jack in the positions indi-

cated and for lifting this vehicle during a

tire change.

WARNING!

• If working on or near a roadway, beextremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

Wheel Blocked

Warning Label

161

Page 164 of 298

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

1. If equipped, remove the spare wheel, jack, and tools from storage.

2. Using the lug wrench, loosen, but do not remove, the lug nuts by turning them

counterclockwise one turn while the

wheel is still on the ground.

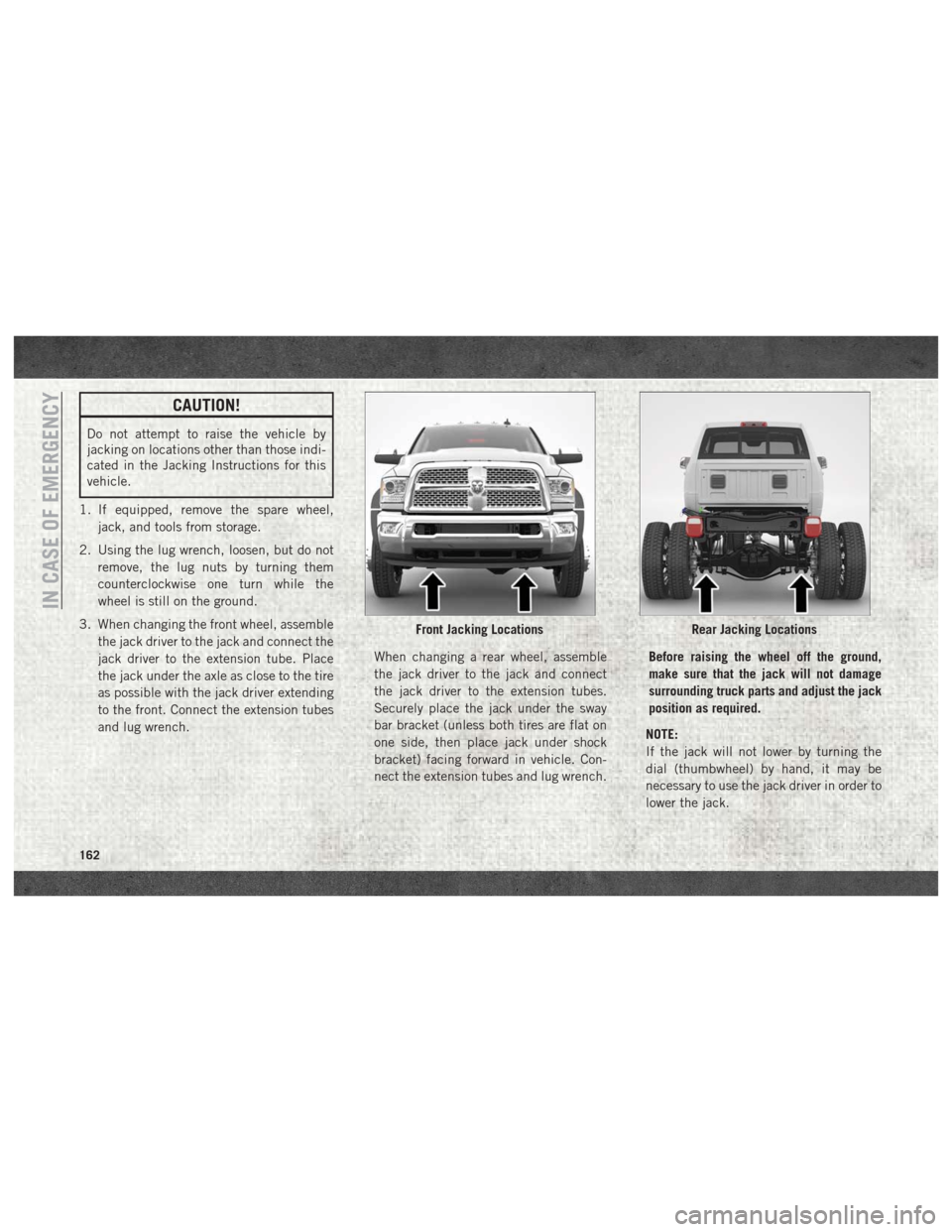

3. When changing the front wheel, assemble the jack driver to the jack and connect the

jack driver to the extension tube. Place

the jack under the axle as close to the tire

as possible with the jack driver extending

to the front. Connect the extension tubes

and lug wrench. When changing a rear wheel, assemble

the jack driver to the jack and connect

the jack driver to the extension tubes.

Securely place the jack under the sway

bar bracket (unless both tires are flat on

one side, then place jack under shock

bracket) facing forward in vehicle. Con-

nect the extension tubes and lug wrench.Before raising the wheel off the ground,

make sure that the jack will not damage

surrounding truck parts and adjust the jack

position as required.

NOTE:

If the jack will not lower by turning the

dial (thumbwheel) by hand, it may be

necessary to use the jack driver in order to

lower the jack.

Front Jacking LocationsRear Jacking Locations

IN CASE OF EMERGENCY

162

Page 170 of 298

6. Move the gear selector to the NEUTRALposition.

7. The vehicle may then be started in NEUTRAL.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand,

or snow, it can often be moved using a rock-

ing motion. Turn the steering wheel right and

left to clear the area around the front wheels.

Next, shift back and forth between DRIVE

and REVERSE (with automatic transmission)

or SECOND GEAR and REVERSE (with

manual transmission) while gently pressing

the accelerator. Use the least amount of ac-

celerator pedal pressure that will maintain

the rocking motion, without spinning the

wheels or racing the engine. NOTE:

Push the "ESC Off" switch, to place the Elec-

tronic Stability Control (ESC) system in "Par-

tial Off" mode, before rocking the vehicle.

Refer to “Electronic Brake Control System”

in “Safety” in the Owner’s Manual at

www.mopar.com/en-us/care/owners-manual.html

(U.S. Residents) or www.owners.mopar.ca

(Canadian Residents) for further information.

Once the vehicle has been freed, push the

"ESC Off" switch again to restore "ESC On"

mode.

WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause damage, or even failure,

of the axle and tires. A tire could explode

and injure someone. Do not spin your

vehicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping when you

are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

CAUTION!

• Racing the engine or spinning the

wheels may lead to transmission over-

heating and failure. Allow the engine to

idle with the transmission in NEUTRAL

for at least one minute after every five

rocking-motion cycles. This will mini-

mize overheating and reduce the risk of

clutch or transmission failure during

prolonged efforts to free a stuck vehicle.

• When “rocking” a stuck vehicle by shift-

ing between DRIVE/SECOND GEAR and

REVERSE, do not spin the wheels faster

than 15 mph (24 km/h), or drivetrain

damage may result.

• Revving the engine or spinning the

wheels too fast may lead to transmission

overheating and failure. It can also dam-

age the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear

(no transmission shifting occurring).

IN CASE OF EMERGENCY

168

Page 175 of 298

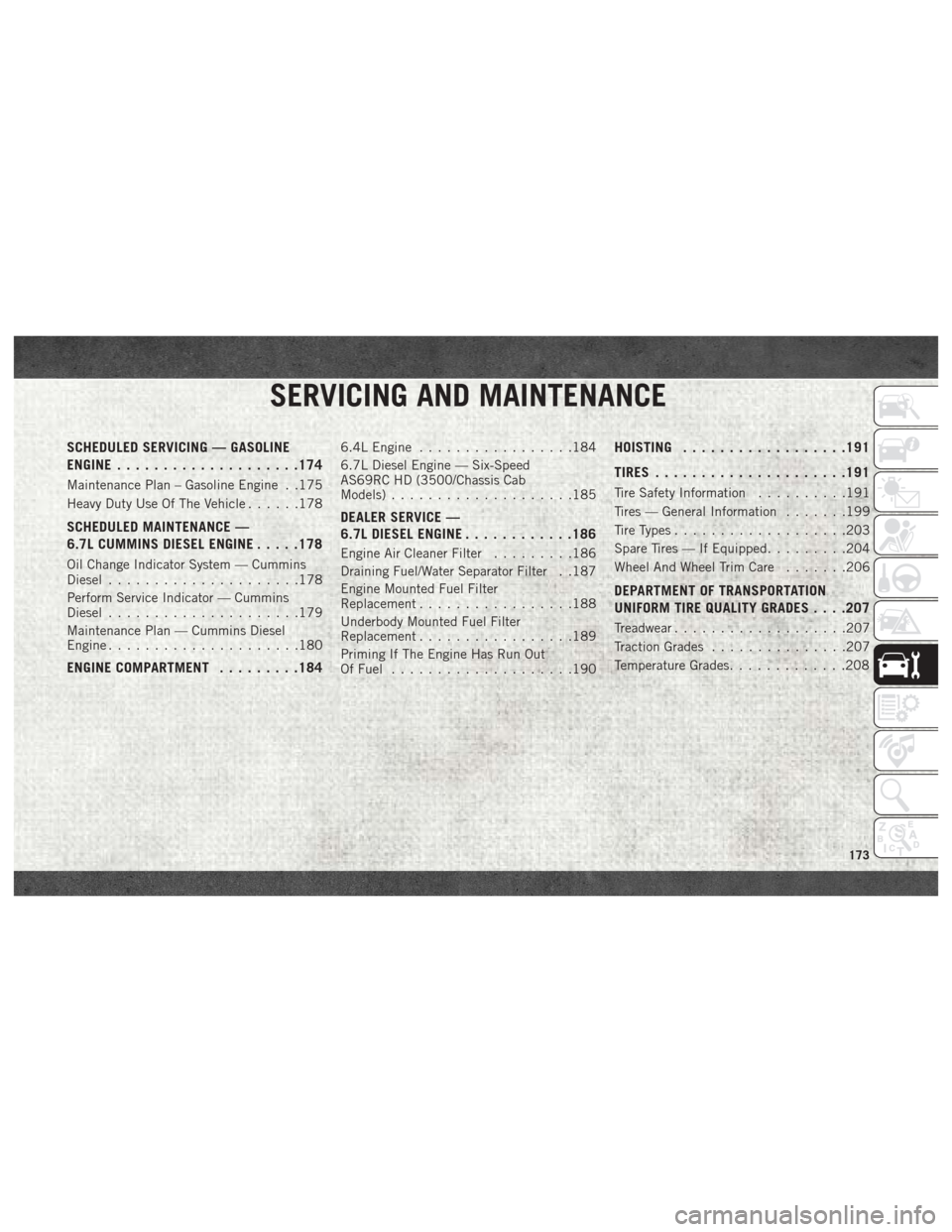

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GASOLINE

ENGINE................... .174

Maintenance Plan – Gasoline Engine . .175

Heavy Duty Use Of The Vehicle ......178

SCHEDULED MAINTENANCE —

6.7L CUMMINS DIESEL ENGINE.....178

Oil Change Indicator System — Cummins

Diesel.....................178

Perform Service Indicator — Cummins

Diesel .....................179

Maintenance Plan — Cummins Diesel

Engine .....................180

ENGINE COMPARTMENT .........184

6.4L Engine.................184

6.7L Diesel Engine — Six-Speed

AS69RC HD (3500/Chassis Cab

Models) ....................185

DEALER SERVICE —

6.7L DIESEL ENGINE ............186

Engine Air Cleaner Filter .........186

Draining Fuel/Water Separator Filter . .187

Engine Mounted Fuel Filter

Replacement .................188

Underbody Mounted Fuel Filter

Replacement .................189

Priming If The Engine Has Run Out

Of Fuel ....................190

HOISTING ................. .191

TIRES .................... .191

Tire Safety Information..........191

Tires — General Information .......199

Tire Types ...................203

Spare Tires — If Equipped .........204

Wheel And Wheel Trim Care .......206

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES . . . .207

Treadwear...................207

Traction Grades ...............207

Temperature Grades .............208

SERVICING AND MAINTENANCE

173

Page 177 of 298

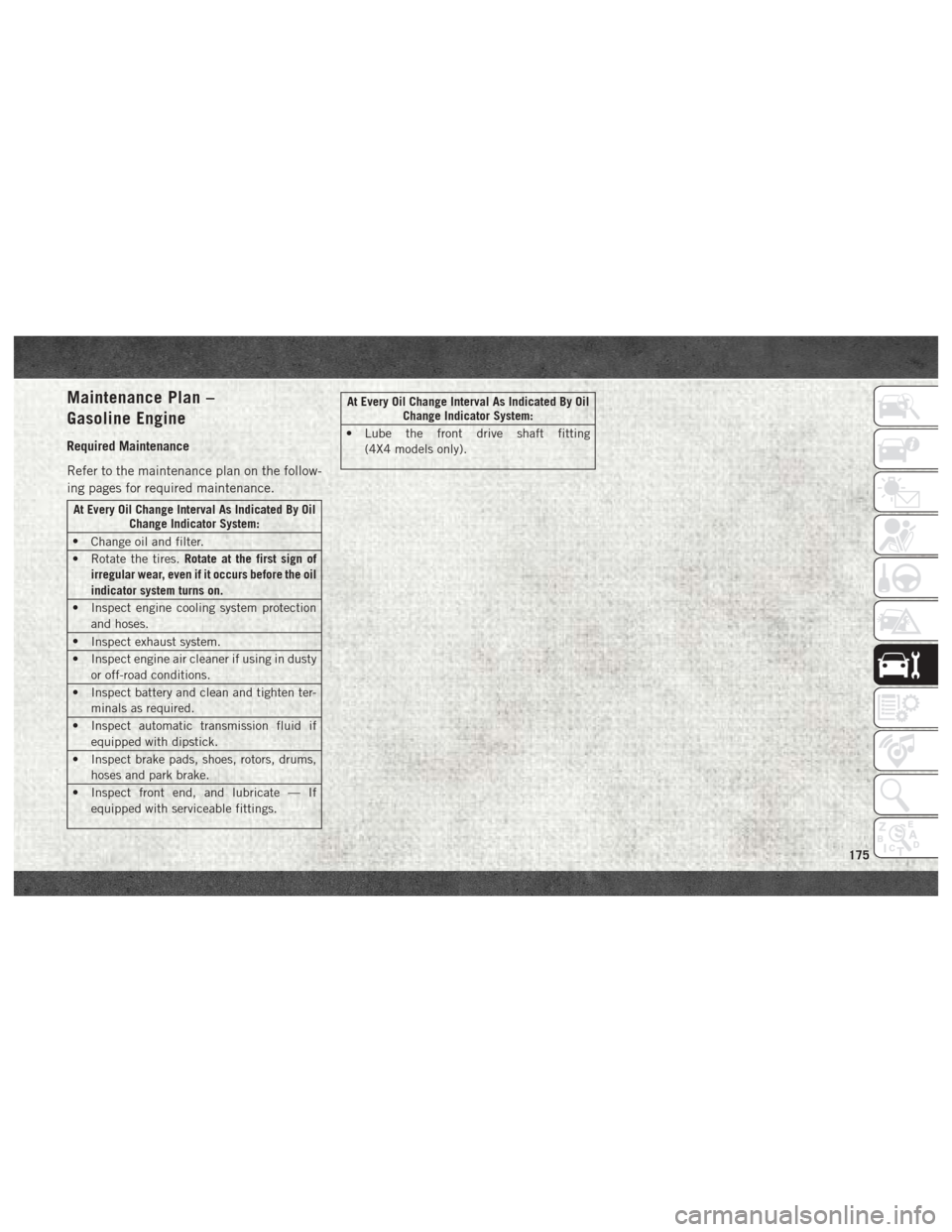

Maintenance Plan –

Gasoline Engine

Required Maintenance

Refer to the maintenance plan on the follow-

ing pages for required maintenance.

At Every Oil Change Interval As Indicated By OilChange Indicator System:

• Change oil and filter.

• Rotate the tires. Rotate at the first sign of

irregular wear, even if it occurs before the oil

indicator system turns on.

• Inspect engine cooling system protection and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or off-road conditions.

• Inspect battery and clean and tighten ter- minals as required.

• Inspect automatic transmission fluid if equipped with dipstick.

• Inspect brake pads, shoes, rotors, drums, hoses and park brake.

• Inspect front end, and lubricate — If equipped with serviceable fittings.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

• Lube the front drive shaft fitting (4X4 models only).

175

Page 182 of 298

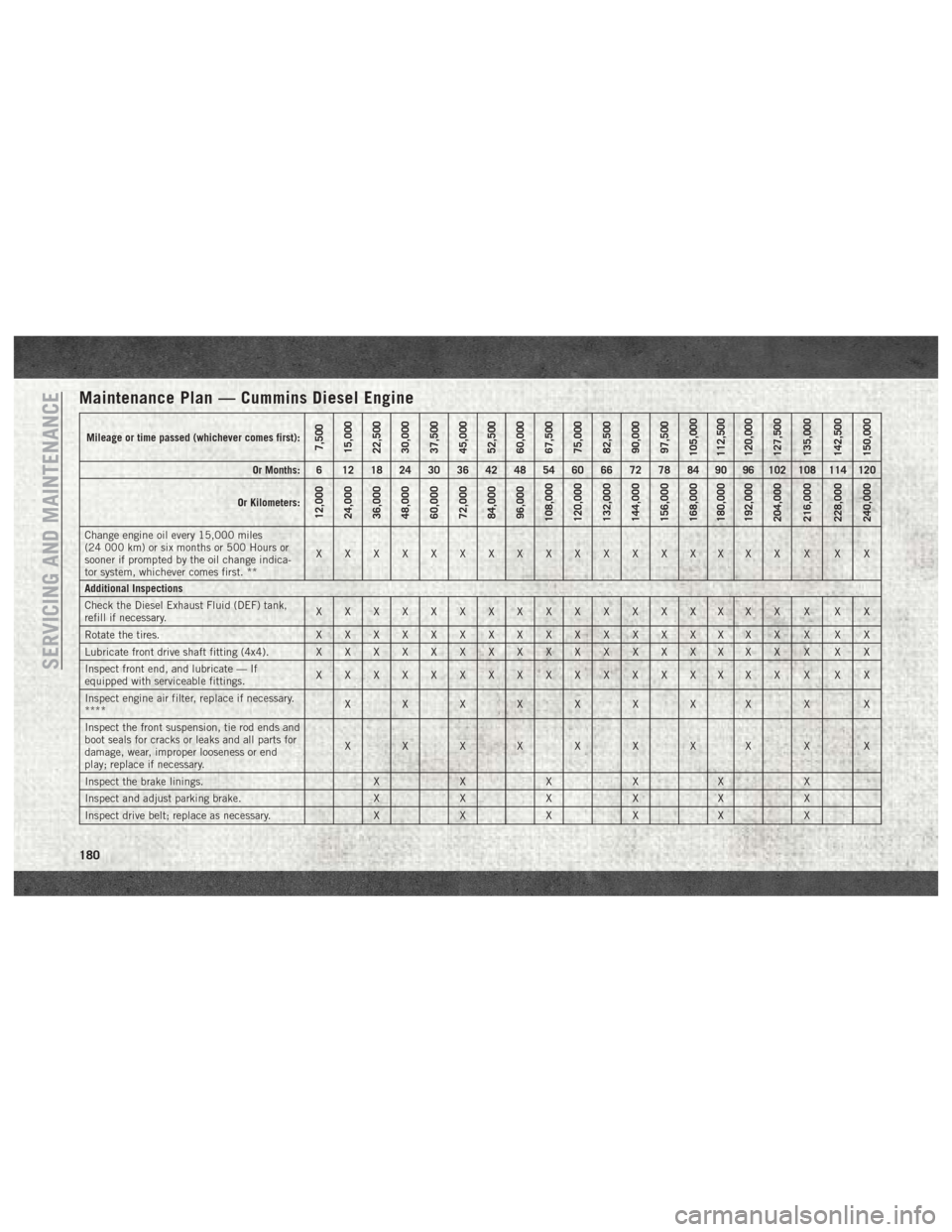

Maintenance Plan — Cummins Diesel Engine

Mileage or time passed (whichever comes first):7,500

15,000

22,500

30,000

37,500

45,000

52,500

60,000

67,500

75,000

82,500

90,000

97,500

105,000

112,500

120,000

127,500

135,000

142,500

150,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

Or Kilometers:

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

192,000

204,000

216,000

228,000

240,000

Change engine oil every 15,000 miles

(24 000 km) or six months or 500 Hours or

sooner if prompted by the oil change indica-

tor system, whichever comes first. ** XXXXXXXXXXXXXXXXX X XX

Additional Inspections

Check the Diesel Exhaust Fluid (DEF) tank,

refill if necessary. XXXXXXXXXXXXXXXXX X XX

Rotate the tires. X X X X X X X XXXXXXXXXX X XX

Lubricate front drive shaft fitting (4x4). X X X X X X X XXXXXXXXXX X XX

Inspect front end, and lubricate — If

equipped with serviceable fittings. XXXXXXXXXXXXXXXXX X XX

Inspect engine air filter, replace if necessary.

**** XX XX X X XX X X

Inspect the front suspension, tie rod ends and

boot seals for cracks or leaks and all parts for

damage, wear, improper looseness or end

play; replace if necessary. XX XX X X XX X X

Inspect the brake linings. XXX XX X

Inspect and adjust parking brake. XXX XX X

Inspect drive belt; replace as necessary. XXX XX X

SERVICING AND MAINTENANCE

180

Page 193 of 298

HOISTING

A conventional floor jack may be used at the

jacking locations. Refer to the graphics that

show jacking locations. However, a floor jack

or frame hoist must never be used on any

other parts of the underbody.

CAUTION!

Never use a floor jack directly under the

differential housing of a loaded truck or

damage to your vehicle may result.

TIRES

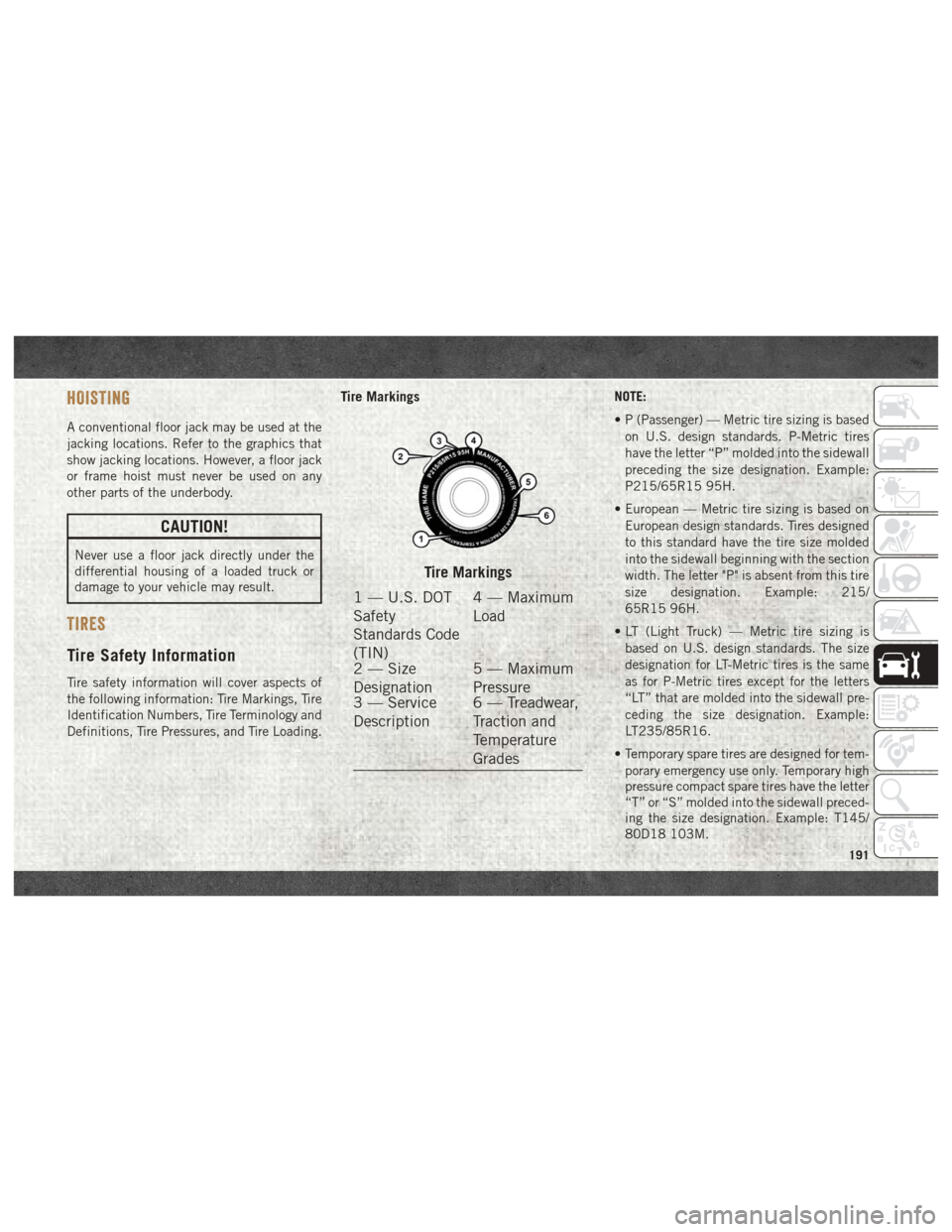

Tire Safety Information

Tire safety information will cover aspects of

the following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

Tire MarkingsNOTE:

• P (Passenger) — Metric tire sizing is basedon U.S. design standards. P-Metric tires

have the letter “P” molded into the sidewall

preceding the size designation. Example:

P215/65R15 95H.

• European — Metric tire sizing is based on European design standards. Tires designed

to this standard have the tire size molded

into the sidewall beginning with the section

width. The letter "P" is absent from this tire

size designation. Example: 215/

65R15 96H.

• LT (Light Truck) — Metric tire sizing is based on U.S. design standards. The size

designation for LT-Metric tires is the same

as for P-Metric tires except for the letters

“LT” that are molded into the sidewall pre-

ceding the size designation. Example:

LT235/85R16.

• Temporary spare tires are designed for tem- porary emergency use only. Temporary high

pressure compact spare tires have the letter

“T” or “S” molded into the sidewall preced-

ing the size designation. Example: T145/

80D18 103M.

Tire Markings

1 — U.S. DOT

Safety

Standards Code

(TIN) 4 — Maximum

Load

2 — Size

Designation 5 — Maximum

Pressure

3 — Service

Description 6 — Treadwear,

Traction and

Temperature

Grades

191

Page 196 of 298

Tire Identification Number (TIN)

The TIN may be found on one or both sides of

the tire; however, the date code may only be

on one side. Tires with white sidewalls will

have the full TIN, including the date code,located on the white sidewall side of the tire.

Look for the TIN on the outboard side of black

sidewall tires as mounted on the vehicle. If

the TIN is not found on the outboard side,

then you will find it on the inboard side of the

tire.

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

• This symbol certifies that the tire is in compliance with the U.S. Department of Transportation tire safety standards and is approved for highway

use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

03 = Number representing the week in which the tire was manufactured (two digits)

• 03 means the 3rd week

01 = Number representing the year in which the tire was manufactured (two digits)

• 01 means the year 2001

• Prior to July 2000, tire manufacturers were only required to have one number to represent the year in which the tire was manufactured. Example:

031 could represent the 3rd week of 1981 or 1991

SERVICING AND MAINTENANCE

194

Page 198 of 298

Tire Loading And Tire Pressure

NOTE:

The proper cold tire inflation pressure is

listed on the driver’s side B-Pillar or the rear

edge of the driver's side door.

Check the inflation pressure of each tire,

including the spare tire (if equipped), at least

monthly and inflate to the recommended

pressure for your vehicle.Tire And Loading Information Placard This placard tells you important information

about the:

1. Number of people that can be carried in

the vehicle.

2. Total weight your vehicle can carry.

3. Tire size designed for your vehicle.

4. Cold tire inflation pressures for the front, rear, and spare tires.

Loading

The vehicle maximum load on the tire must

not exceed the load carrying capacity of the

tire on your vehicle. You will not exceed the

tire's load carrying capacity if you adhere to

the loading conditions, tire size, and cold tire

inflation pressures specified on the Tire and

Loading Information placard in “Vehicle

Loading” in the “Starting And Operating”

section of this manual.

NOTE:

Under a maximum loaded vehicle condition,

gross axle weight ratings (GAWRs) for the

front and rear axles must not be exceeded.

Example Tire Placard Location (Door)

Example Tire Placard Location (B-Pillar)

Tire And Loading Information Placard

SERVICING AND MAINTENANCE

196