warning Ram 4500 Chassis Cab 2018 Manual Online

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 151 of 298

WARNING!

matic transmission is in PARK (or manual

transmission is in gear). The parking brake

should always be applied when the driver

is not in the vehicle.

CAUTION!

It is necessary to follow these steps to be

certain that the transfer case is fully in

NEUTRAL (N) before recreational towing

to prevent damage to internal parts.

1. Bring the vehicle to a complete stop on level ground, with the engine running.

Firmly apply the parking brake.

2. Shift the transmission to NEUTRAL.

3. Press and hold the brake pedal.

4. Depress the clutch pedal on a manual transmission.

5. Shift the transfer case into NEUTRAL: • With manual shift transfer case, shift

the transfer case lever into NEUTRAL

(N).

• With electronic shift transfer case, push and hold the transfer case NEU-

TRAL (N) button. Some models have a

small, recessed "N" button (at the cen-

ter of the transfer case switches) that

must be pressed using a ballpoint pen

or similar object. Other models have a

rectangular NEUTRAL switch, below

the rotary transfer case control knob.

The NEUTRAL (N) indicator light will

blink while the shift is in progress. The

light will stop blinking (stay on solid)

when the shift to NEUTRAL (N) is com-

plete. After the shift is completed and

the NEUTRAL (N) light stays on, re-

lease the NEUTRAL (N) button.

6. Release the parking brake.

7. Shift the transmission into REVERSE. 8. Release the brake pedal (and clutch pedal

on manual transmissions) for five seconds

and ensure that there is no vehicle

movement.

9. Repeat steps seven and eight with auto- matic transmission in DRIVE or manual

transmission in first gear.

10. Shift the transmission to NEUTRAL. Firmly apply the parking brake. Turn OFF

the engine. For vehicles with Keyless

Enter-N-Go, push and hold the ENGINE

START/STOP button until the engine

shuts off.

11. Shift the transmission into PARK or place manual transmission in gear (NOT

in NEUTRAL).

12. Place the ignition in the OFF mode, and remove the key fob.

13. Attach the vehicle to the tow vehicle using a suitable tow bar.

14. Release the parking brake.

149

Page 155 of 298

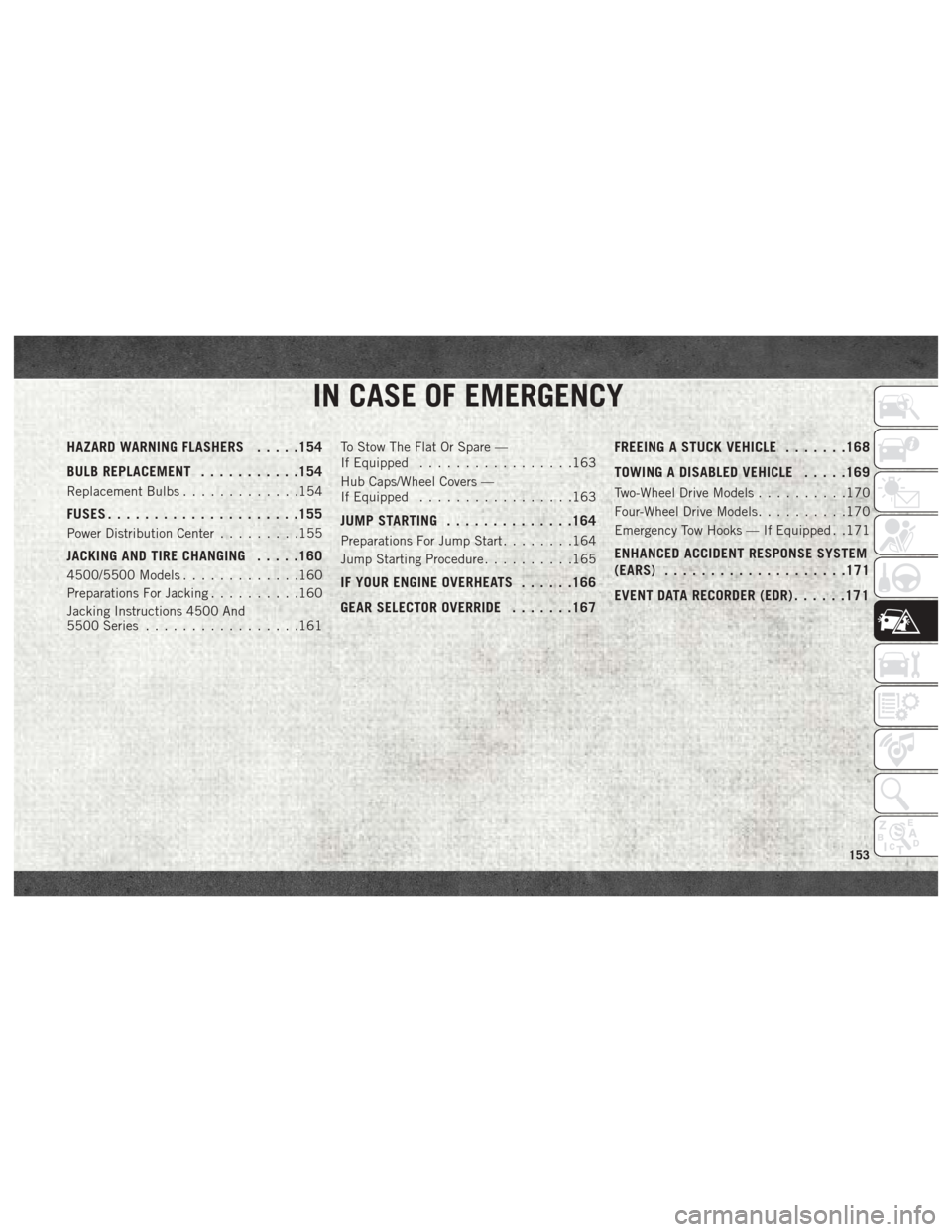

IN CASE OF EMERGENCY

HAZARD WARNING FLASHERS.....154

BULB REPLACEMENT ...........154

Replacement Bulbs.............154

FUSES.................... .155

Power Distribution Center.........155

JACKING AND TIRE CHANGING .....160

4500/5500 Models.............160

Preparations For Jacking ..........160

Jacking Instructions 4500 And

5500 Series .................161 To Stow The Flat Or Spare —

If Equipped

.................163

Hub Caps/Wheel Covers —

If Equipped .................163

JUMP STARTING ..............164

Preparations For Jump Start ........164

Jump Starting Procedure ..........165

IF YOUR ENGINE OVERHEATS ......166

GEAR SELECTOR OVERRIDE .......167FREEING A STUCK VEHICLE

.......168

TOWING A DISABLED VEHICLE .....169

Two-Wheel Drive Models..........170

Four-Wheel Drive Models ..........170

Emergency Tow Hooks — If Equipped . .171

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS) ................... .171

EVENT DATA RECORDER (EDR) ......171

IN CASE OF EMERGENCY

153

Page 156 of 298

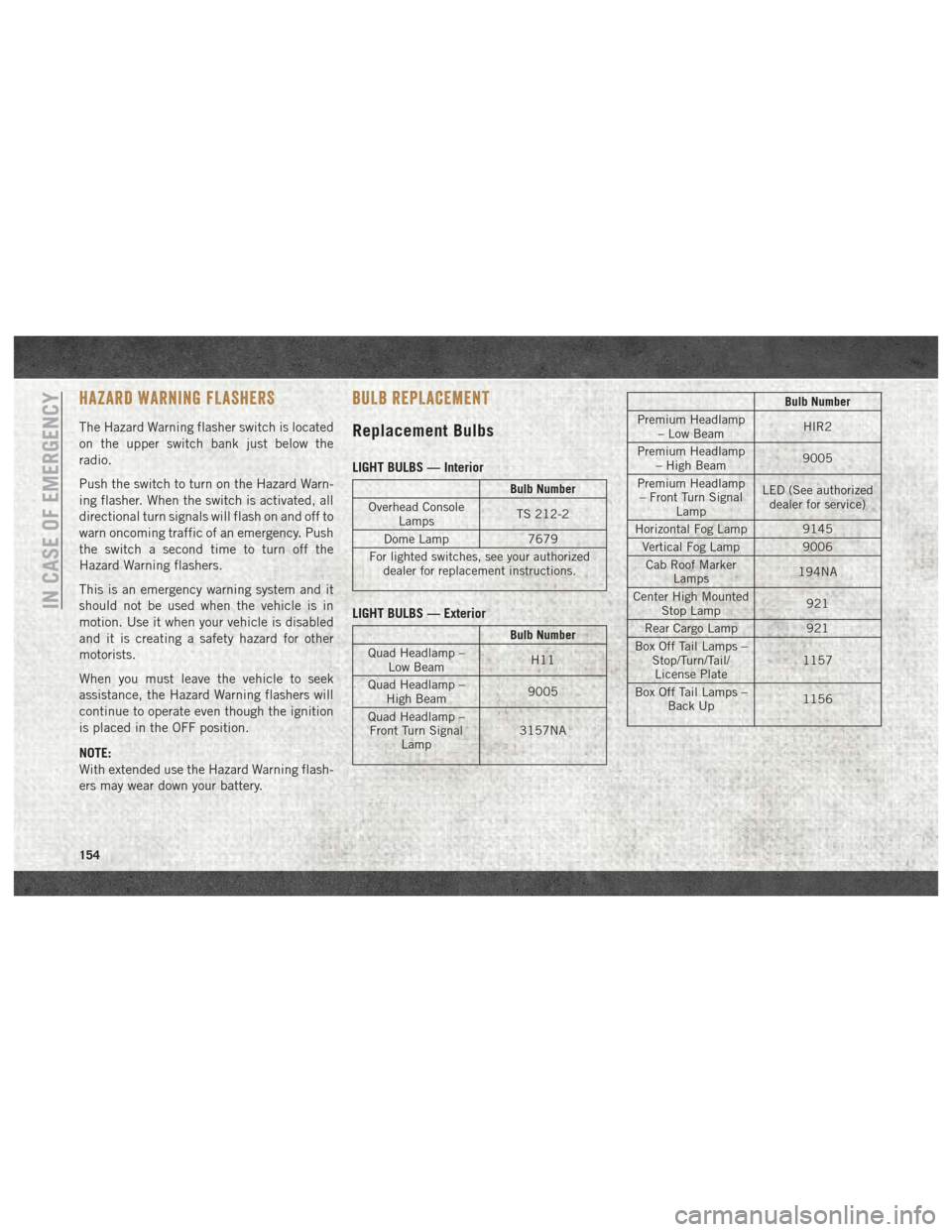

HAZARD WARNING FLASHERS

The Hazard Warning flasher switch is located

on the upper switch bank just below the

radio.

Push the switch to turn on the Hazard Warn-

ing flasher. When the switch is activated, all

directional turn signals will flash on and off to

warn oncoming traffic of an emergency. Push

the switch a second time to turn off the

Hazard Warning flashers.

This is an emergency warning system and it

should not be used when the vehicle is in

motion. Use it when your vehicle is disabled

and it is creating a safety hazard for other

motorists.

When you must leave the vehicle to seek

assistance, the Hazard Warning flashers will

continue to operate even though the ignition

is placed in the OFF position.

NOTE:

With extended use the Hazard Warning flash-

ers may wear down your battery.

BULB REPLACEMENT

Replacement Bulbs

LIGHT BULBS — Interior

Bulb Number

Overhead Console Lamps TS 212-2

Dome Lamp 7679

For lighted switches, see your authorized dealer for replacement instructions.

LIGHT BULBS — Exterior

Bulb Number

Quad Headlamp – Low Beam H11

Quad Headlamp – High Beam 9005

Quad Headlamp – Front Turn Signal Lamp 3157NA

Bulb Number

Premium Headlamp – Low Beam HIR2

Premium Headlamp – High Beam 9005

Premium Headlamp – Front Turn Signal Lamp LED (See authorized

dealer for service)

Horizontal Fog Lamp 9145 Vertical Fog Lamp 9006

Cab Roof Marker Lamps 194NA

Center High Mounted Stop Lamp 921

Rear Cargo Lamp 921

Box Off Tail Lamps – Stop/Turn/Tail/License Plate 1157

Box Off Tail Lamps – Back Up 1156

IN CASE OF EMERGENCY

154

Page 157 of 298

FUSES

WARNING!

• When replacing a blown fuse, always usean appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Do not place a fuse inside a

circuit breaker cavity or vice versa. Fail-

ure to use proper fuses may result in

serious personal injury, fire and/or prop-

erty damage.

WARNING!

• Before replacing a fuse, make sure thatthe ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

• If a general protection fuse for safety

systems (air bag system, braking sys-

tem), power unit systems (engine sys-

tem, transmission system) or steering

system blows, contact an authorized

dealer.

Power Distribution Center

The Power Distribution Center is located in

the engine compartment near the battery.

This center contains cartridge fuses, micro

fuses, relays, and circuit breakers. A descrip-

tion of each fuse and component may be

stamped on the inside cover, otherwise the

cavity number of each fuse is stamped on the

inside cover that corresponds to the following

chart.

Cavity Cartridge Fuse Micro Fuse Description

F01 80 Amp Black –Rad Fan Control Module – If Equipped

F03 60 Amp Yellow –Rad Fan – If Equipped

F05 40 Amp Green –Compressor for Air Suspension – If Equipped

F06 40 Amp Green –Antilock Brakes/Electronic Stability Control Pump

F07 40 Amp Green – Starter Solenoid

F08 20 Amp Blue (1500 LD/

Cummins Diesel) –

Emissions Diesel – If Equipped

155

Page 162 of 298

CAUTION!

• When installing the power distributioncenter cover, it is important to ensure

the cover is properly positioned and fully

latched. Failure to do so may allow water

to get into the power distribution center

and possibly result in an electrical sys-

tem failure.

• When replacing a blown fuse, it is impor-

tant to use only a fuse having the correct

amperage rating. The use of a fuse with

a rating other than indicated may result

in a dangerous electrical system over-

load. If a properly rated fuse continues

to blow, it indicates a problem in the

circuit that must be corrected.

JACKING AND TIRE CHANGING

WARNING!

• Do not attempt to change a tire on theside of the vehicle close to moving traf-

fic. Pull far enough off the road to avoid

the danger of being hit when operating

the jack or changing the wheel.

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

4500/5500 Models

These vehicles do not come equipped with a

jack.

NOTE:

Jacking and tire changing on 4500/

5500 models should be performed by an

authorized dealer, or knowledgeable service

personnel with the appropriate heavy duty

equipment, like a tire service company.

Preparations For Jacking

1. Park the vehicle on a firm, level surface.

Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic, pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

2. Place the gear selector into PARK. On four-wheel drive vehicles, shift the trans-

fer case to the 4L position.

3. Turn on the Hazard Warning flasher.

IN CASE OF EMERGENCY

160

Page 163 of 298

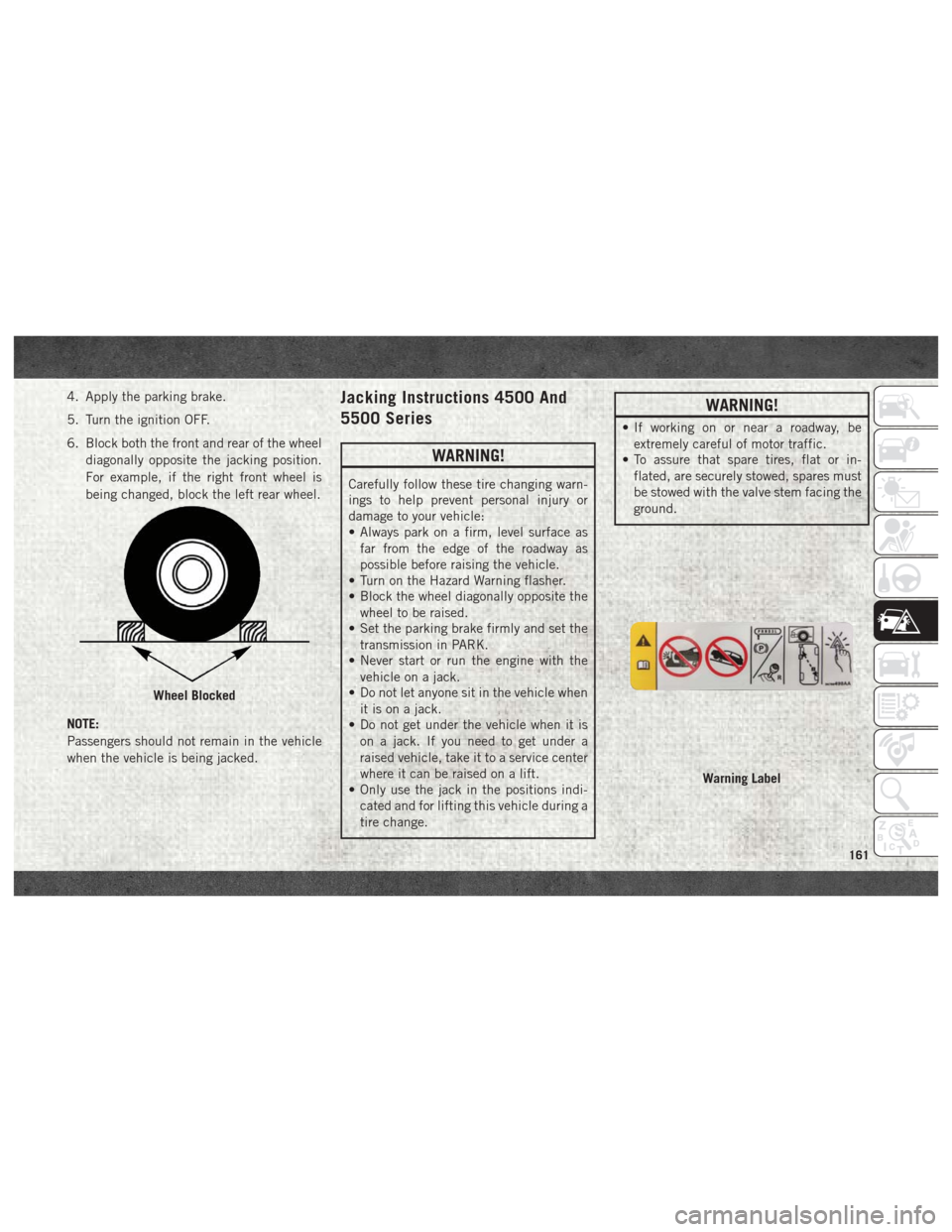

4. Apply the parking brake.

5. Turn the ignition OFF.

6. Block both the front and rear of the wheeldiagonally opposite the jacking position.

For example, if the right front wheel is

being changed, block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.Jacking Instructions 4500 And

5500 Series

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the

wheel to be raised.

• Set the parking brake firmly and set the

transmission in PARK.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

• Only use the jack in the positions indi-

cated and for lifting this vehicle during a

tire change.

WARNING!

• If working on or near a roadway, beextremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

Wheel Blocked

Warning Label

161

Page 165 of 298

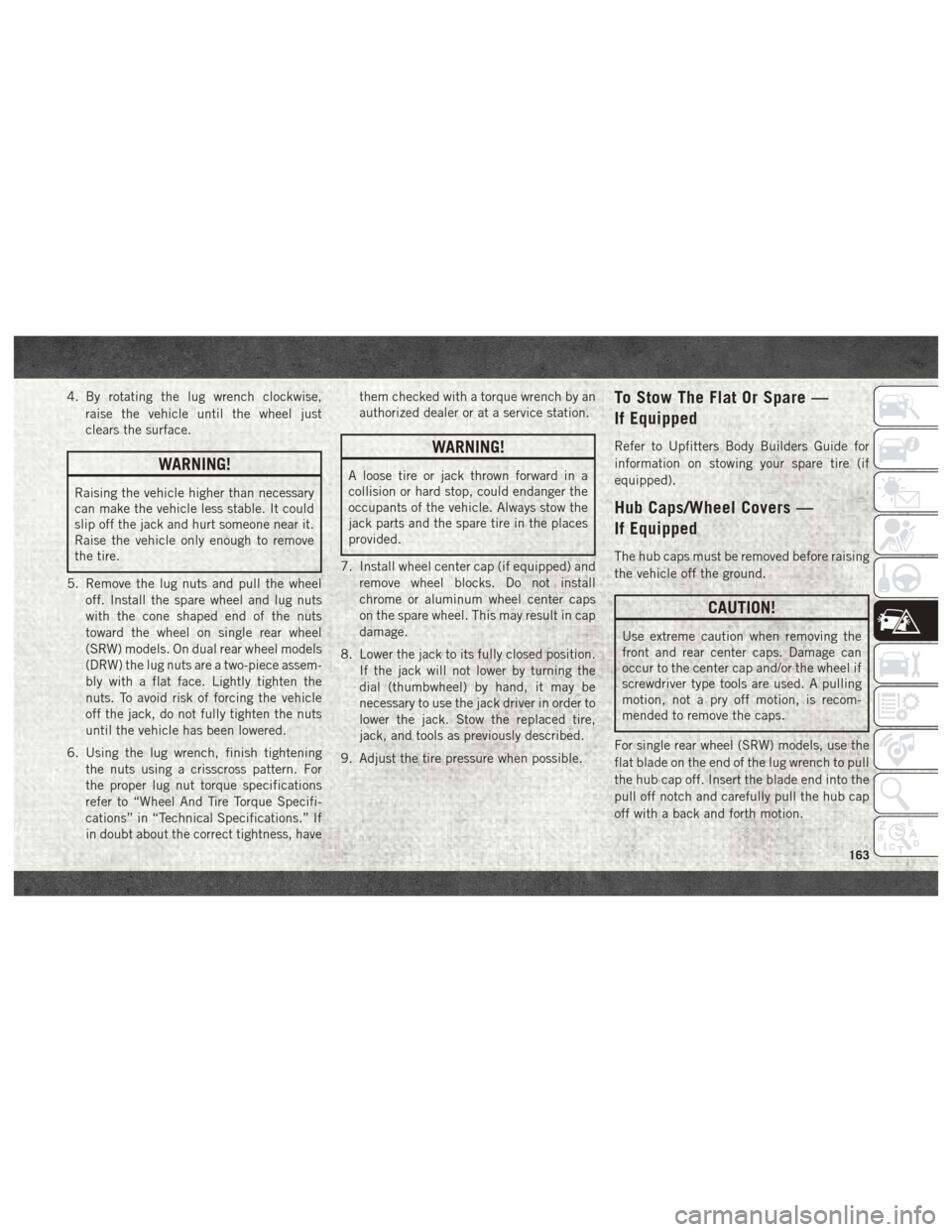

4. By rotating the lug wrench clockwise,raise the vehicle until the wheel just

clears the surface.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

5. Remove the lug nuts and pull the wheel off. Install the spare wheel and lug nuts

with the cone shaped end of the nuts

toward the wheel on single rear wheel

(SRW) models. On dual rear wheel models

(DRW) the lug nuts are a two-piece assem-

bly with a flat face. Lightly tighten the

nuts. To avoid risk of forcing the vehicle

off the jack, do not fully tighten the nuts

until the vehicle has been lowered.

6. Using the lug wrench, finish tightening the nuts using a crisscross pattern. For

the proper lug nut torque specifications

refer to “Wheel And Tire Torque Specifi-

cations” in “Technical Specifications.” If

in doubt about the correct tightness, have them checked with a torque wrench by an

authorized dealer or at a service station.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

7. Install wheel center cap (if equipped) and remove wheel blocks. Do not install

chrome or aluminum wheel center caps

on the spare wheel. This may result in cap

damage.

8. Lower the jack to its fully closed position. If the jack will not lower by turning the

dial (thumbwheel) by hand, it may be

necessary to use the jack driver in order to

lower the jack. Stow the replaced tire,

jack, and tools as previously described.

9. Adjust the tire pressure when possible.

To Stow The Flat Or Spare —

If Equipped

Refer to Upfitters Body Builders Guide for

information on stowing your spare tire (if

equipped).

Hub Caps/Wheel Covers —

If Equipped

The hub caps must be removed before raising

the vehicle off the ground.

CAUTION!

Use extreme caution when removing the

front and rear center caps. Damage can

occur to the center cap and/or the wheel if

screwdriver type tools are used. A pulling

motion, not a pry off motion, is recom-

mended to remove the caps.

For single rear wheel (SRW) models, use the

flat blade on the end of the lug wrench to pull

the hub cap off. Insert the blade end into the

pull off notch and carefully pull the hub cap

off with a back and forth motion.

163

Page 166 of 298

On 3500 models with dual rear wheels

(DRW), you must first remove the hub caps.

The jack handle driver has a hook at one end

that will fit in the pull off notch of the rear

hub caps. Position the hook and pull straight

out on the ratchet firmly. The hub cap should

pop off. The wheel skins can now be re-

moved. For the front hub cap, use the flat

blade on the end of the lug wrench to pull the

caps off. The wheel skin can now be removed.

CAUTION!

• Use a pulling motion to remove the hubcap. Do not use a twisting motion when

removing the hub cap, damage to the

hub cap; finish may occur.

• The rear hub caps on the dual rear wheel

has two pull off notches. Make sure that

the hook of the jack handle driver is

located squarely in the cap notch before

attempting to pull off.

You must use the flat end of the lug wrench to

pull off the wheel skins. Locate the hub cap

pull notches (2 notches on each cap). Insert the flat tip completely and using a back and

forth motion, loosen the wheel skin. Repeat

this procedure around the tire until the skin

pops off.

Replace the wheel skins first using a rubber

mallet. When replacing the hub caps, tilt the

cap retainer over the lug nut bolt circle and

strike the high side down with a rubber mal-

let. Be sure that the hub caps and wheel

skins are firmly seated around the wheel.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle, or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so

please follow the procedures in this section

carefully.

WARNING!

Do not attempt jump starting if the battery

is frozen. It could rupture or explode and

cause personal injury.

CAUTION!

Do not use a portable battery booster pack

or any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

NOTE:

When using a portable battery booster pack,

follow the manufacturer's operating instruc-

tions and precautions.

Preparations For Jump Start

The battery in your vehicle is located in the

front of the engine compartment, behind the

left headlight assembly.

IN CASE OF EMERGENCY

164

Page 167 of 298

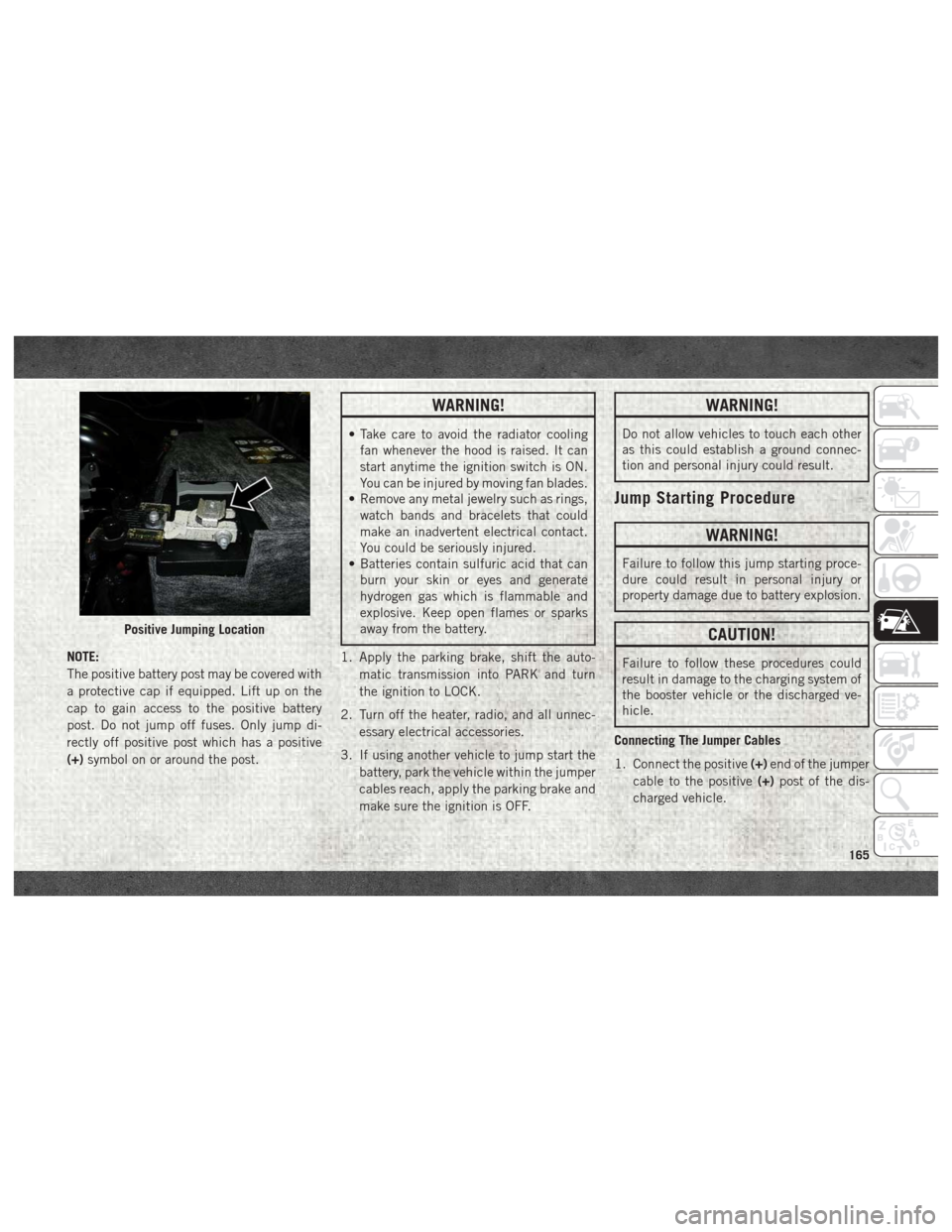

NOTE:

The positive battery post may be covered with

a protective cap if equipped. Lift up on the

cap to gain access to the positive battery

post. Do not jump off fuses. Only jump di-

rectly off positive post which has a positive

(+)symbol on or around the post.

WARNING!

• Take care to avoid the radiator cooling

fan whenever the hood is raised. It can

start anytime the ignition switch is ON.

You can be injured by moving fan blades.

• Remove any metal jewelry such as rings,

watch bands and bracelets that could

make an inadvertent electrical contact.

You could be seriously injured.

• Batteries contain sulfuric acid that can

burn your skin or eyes and generate

hydrogen gas which is flammable and

explosive. Keep open flames or sparks

away from the battery.

1. Apply the parking brake, shift the auto- matic transmission into PARK and turn

the ignition to LOCK.

2. Turn off the heater, radio, and all unnec- essary electrical accessories.

3. If using another vehicle to jump start the battery, park the vehicle within the jumper

cables reach, apply the parking brake and

make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other

as this could establish a ground connec-

tion and personal injury could result.

Jump Starting Procedure

WARNING!

Failure to follow this jump starting proce-

dure could result in personal injury or

property damage due to battery explosion.

CAUTION!

Failure to follow these procedures could

result in damage to the charging system of

the booster vehicle or the discharged ve-

hicle.

Connecting The Jumper Cables

1. Connect the positive (+)end of the jumper

cable to the positive (+)post of the dis-

charged vehicle.

Positive Jumping Location

165

Page 168 of 298

NOTE:

Do not jump off fuses. Only jump directly off

positive post.

2. Connect the opposite end of the positive (+) jumper cable to the positive (+)post of

the booster battery.

3. Connect the negative (-)end of the jumper

cable to the negative (-)post of the

booster battery.

4. Connect the opposite end of the negative (-)jumper cable to a good engine ground

(exposed metal part of the discharged

vehicle’s engine) away from the battery

and the fuel injection system.

WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause

the battery to explode and could result in

personal injury. Only use the specific

ground point, do not use any other exposed

metal parts. 5. Start the engine in the vehicle that has

the booster battery, let the engine idle a

few minutes, and then start the engine in

the vehicle with the discharged battery.

CAUTION!

Do not connect jumper cable to any of the

fuses on the positive battery terminal. The

resulting electrical current will blow the

fuse.

6. Once the engine is started, remove the jumper cables in the reverse sequence:

Disconnecting The Jumper Cables

1. Disconnect the negative (-)end of the

jumper cable from the engine ground of

the vehicle with the discharged battery.

2. Disconnect the opposite end of the nega- tive (-)jumper cable from the negative (-)

post of the booster battery.

3. Disconnect the positive (+)end of the

jumper cable from the positive (+)post of

the booster battery. 4. Disconnect the opposite end of the posi-

tive (+)jumper cable from the positive (+)

post of the vehicle with the discharged

battery.

If frequent jump starting is required to start

your vehicle you should have the battery and

charging system inspected at an authorized

dealer.

CAUTION!

Accessories plugged into the vehicle

power outlets draw power from the vehi-

cle’s battery, even when not in use (i.e.,

cellular devices, etc.). Eventually, if

plugged in long enough without engine

operation, the vehicle’s battery will dis-

charge sufficiently to degrade battery life

and/or prevent the engine from starting.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can

reduce the potential for overheating by taking

the appropriate action.

• On the highways — slow down.

IN CASE OF EMERGENCY

166