Ram ProMaster City 2018 Owners Manual

Manufacturer: RAM, Model Year: 2018, Model line: ProMaster City, Model: Ram ProMaster City 2018Pages: 180, PDF Size: 7.52 MB

Page 91 of 180

FUSES

WARNING!

• When replacing a blown fuse, always usean appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Do not place a fuse inside a

circuit breaker cavity or vice versa. Fail-

ure to use proper fuses may result in

WARNING!

serious personal injury, fire and/or prop-

erty damage.

• Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

• If a general protection fuse for safety

systems (air bag system, braking sys-

tem), power unit systems (engine sys-

tem, transmission system) or steering

WARNING!

system blows, contact an authorized

dealer.

Underhood Fuses

The Front Distribution Unit is located on the

right side of the engine compartment, next to

the battery. To access the fuses, remove fas-

teners and remove the cover.

The ID number of the electrical component

corresponding to each fuse can be found on

the back of the cover.

Cavity Maxi Fuse Mini Fuse Description

F01 60 Amp Blue –Body Controller

F02 40 Amp Orange –Rear Power Windows, Fog Lamps, Front Heated Seats

(If Equipped)

F02 30 Amp Green –Rear Power Windows, Front Heated Seats (If

Equipped)

F02 30 Amp Green –Fog Lamps, Front Heated Seats (If Equipped)

F02 20 Amp Yellow –Front Heated Seats

F03 20 Amp Yellow –Ignition Switch

F04 40 Amp Orange –BSM System Module

F06 20 Amp Yellow –Radiator Fan - Low Speed

89

Page 92 of 180

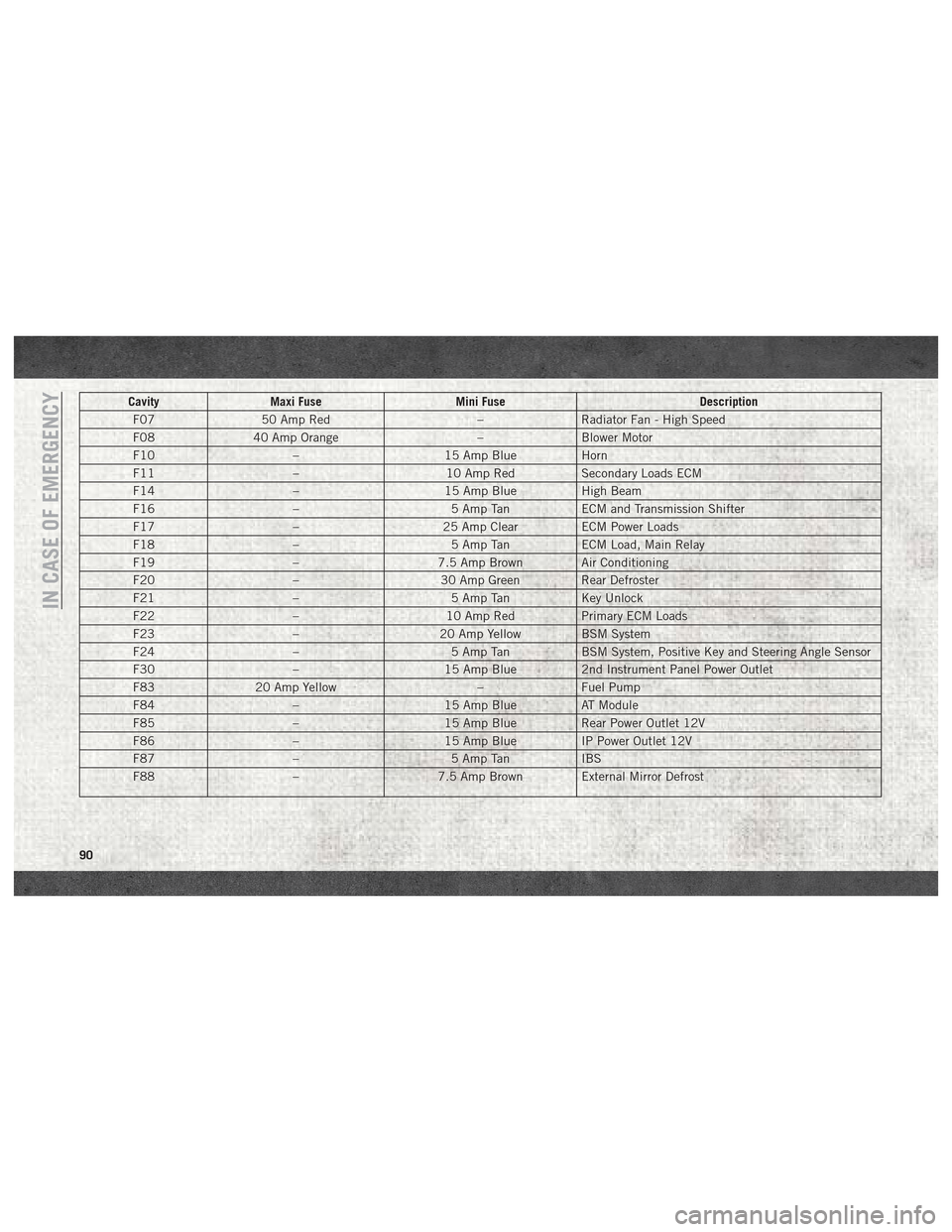

CavityMaxi Fuse Mini Fuse Description

F07 50 Amp Red –Radiator Fan - High Speed

F08 40 Amp Orange –Blower Motor

F10 –15 Amp BlueHorn

F11 –10 Amp RedSecondary Loads ECM

F14 –15 Amp BlueHigh Beam

F16 –5 Amp TanECM and Transmission Shifter

F17 –25 Amp ClearECM Power Loads

F18 –5 Amp TanECM Load, Main Relay

F19 –7.5 Amp Brown Air Conditioning

F20 –30 Amp Green Rear Defroster

F21 –5 Amp TanKey Unlock

F22 –10 Amp RedPrimary ECM Loads

F23 –20 Amp Yellow BSM System

F24 –5 Amp TanBSM System, Positive Key and Steering Angle Sensor

F30 –15 Amp Blue2nd Instrument Panel Power Outlet

F83 20 Amp Yellow –Fuel Pump

F84 –15 Amp BlueAT Module

F85 –15 Amp BlueRear Power Outlet 12V

F86 –15 Amp BlueIP Power Outlet 12V

F87 –5 Amp TanIBS

F88 –7.5 Amp Brown External Mirror Defrost

IN CASE OF EMERGENCY

90

Page 93 of 180

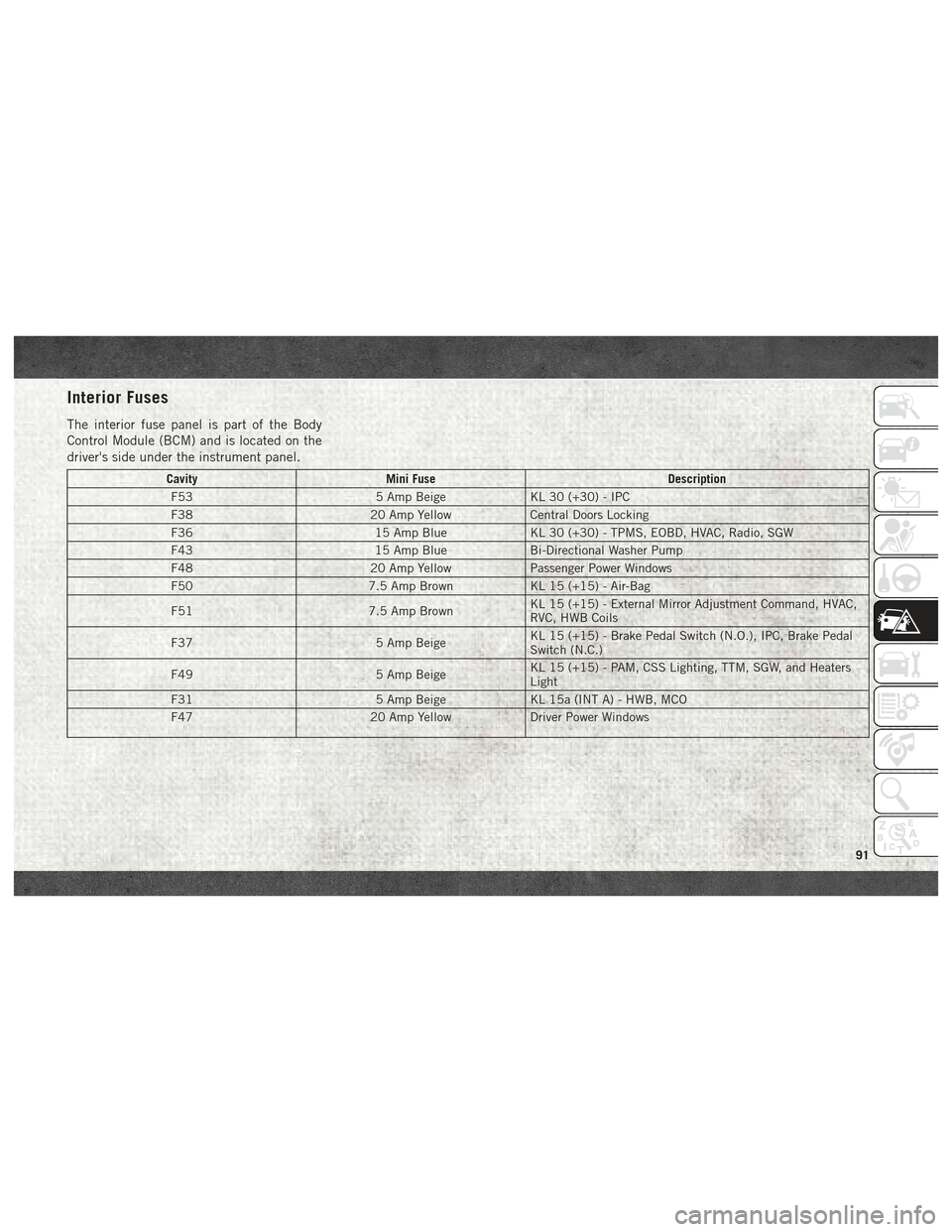

Interior Fuses

The interior fuse panel is part of the Body

Control Module (BCM) and is located on the

driver's side under the instrument panel.

CavityMini Fuse Description

F53 5 Amp BeigeKL 30 (+30) - IPC

F38 20 Amp YellowCentral Doors Locking

F36 15 Amp BlueKL 30 (+30) - TPMS, EOBD, HVAC, Radio, SGW

F43 15 Amp BlueBi-Directional Washer Pump

F48 20 Amp YellowPassenger Power Windows

F50 7.5 Amp BrownKL 15 (+15) - Air-Bag

F51 7.5 Amp BrownKL 15 (+15) - External Mirror Adjustment Command, HVAC,

RVC, HWB Coils

F37 5 Amp BeigeKL 15 (+15) - Brake Pedal Switch (N.O.), IPC, Brake Pedal

Switch (N.C.)

F49 5 Amp BeigeKL 15 (+15) - PAM, CSS Lighting, TTM, SGW, and Heaters

Light

F31 5 Amp BeigeKL 15a (INT A) - HWB, MCO

F47 20 Amp YellowDriver Power Windows

91

Page 94 of 180

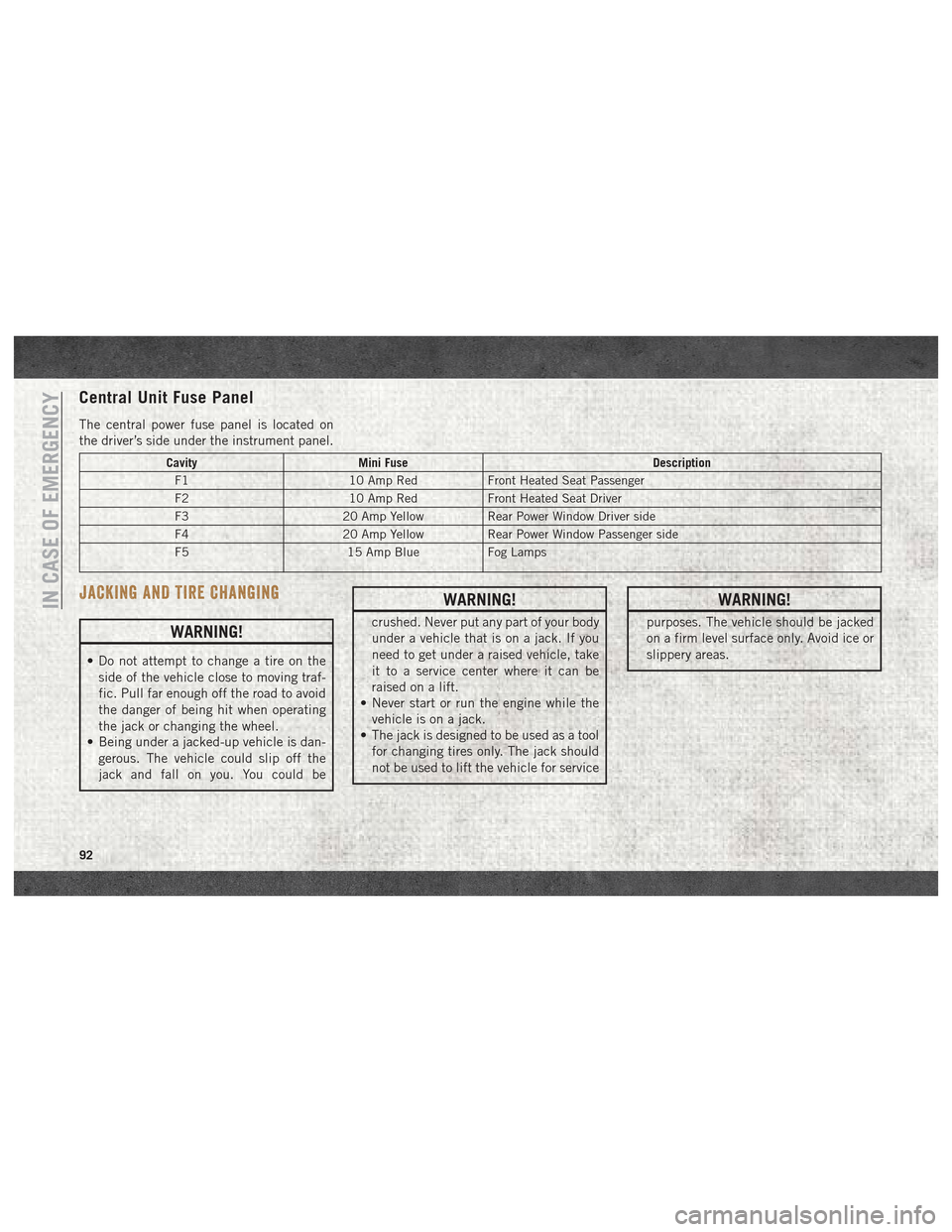

Central Unit Fuse Panel

The central power fuse panel is located on

the driver’s side under the instrument panel.

CavityMini Fuse Description

F1 10 Amp RedFront Heated Seat Passenger

F2 10 Amp RedFront Heated Seat Driver

F3 20 Amp YellowRear Power Window Driver side

F4 20 Amp YellowRear Power Window Passenger side

F5 15 Amp BlueFog Lamps

JACKING AND TIRE CHANGING

WARNING!

• Do not attempt to change a tire on the

side of the vehicle close to moving traf-

fic. Pull far enough off the road to avoid

the danger of being hit when operating

the jack or changing the wheel.

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

WARNING!

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

WARNING!

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

IN CASE OF EMERGENCY

92

Page 95 of 180

Jack Location

The jack and tools are stowed under the

driver’s front seat.

Removing The Spare Tire

1. Remove the spare tire before attemptingto jack up the vehicle. Attach the wrench

handle to the winch extension. 2. To access the winch mechanism open the

rear doors of the vehicle to expose the winch mechanism access cover. Remove

the access cover and install the winch

extension into the winch mechanism.

Jack/Tools Location

Jack Tools

1 — Wrench Handle

2 — Winch Extension

3 — Emergency Screwdriver

4 — Bolt Install Wrench

5 — Wheel Chock

6 — Jack

Jack Tools

1 — Wrench Handle

2 — Winch Extension

93

Page 96 of 180

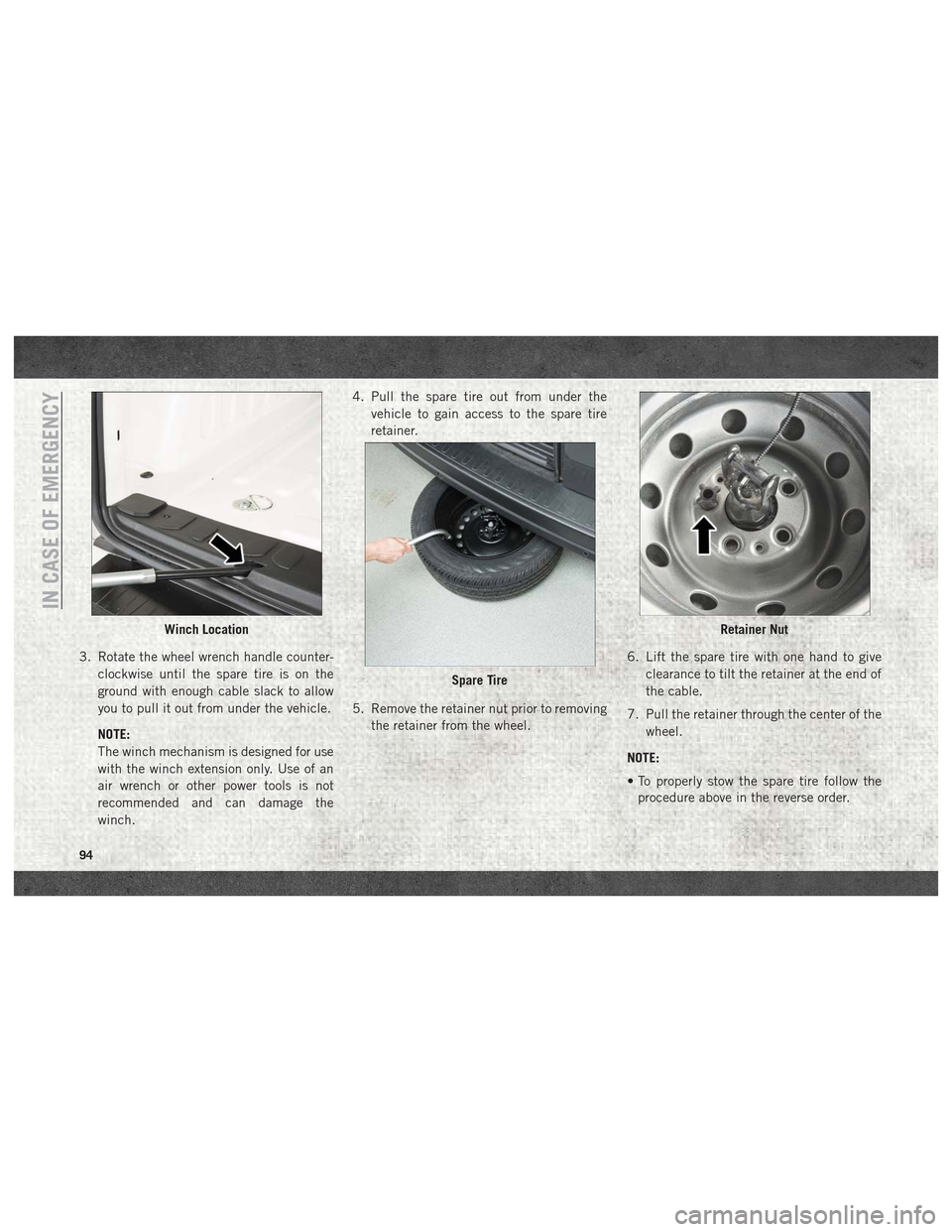

3. Rotate the wheel wrench handle counter-clockwise until the spare tire is on the

ground with enough cable slack to allow

you to pull it out from under the vehicle.

NOTE:

The winch mechanism is designed for use

with the winch extension only. Use of an

air wrench or other power tools is not

recommended and can damage the

winch. 4. Pull the spare tire out from under the

vehicle to gain access to the spare tire

retainer.

5. Remove the retainer nut prior to removing the retainer from the wheel. 6. Lift the spare tire with one hand to give

clearance to tilt the retainer at the end of

the cable.

7. Pull the retainer through the center of the wheel.

NOTE:

• To properly stow the spare tire follow the procedure above in the reverse order.

Winch Location

Spare Tire

Retainer Nut

IN CASE OF EMERGENCY

94

Page 97 of 180

• When winching the tire back into place, thewinch will make three audible noises once

secure. Reach underneath and shake tire

by hand to confirm that it is secure. The tire

should not move. If tire is still loose and/or

three audible noises are not heard, place

and secure damaged wheel into the vehicle

and seek dealer assistance for the winch

mechanism.

Preparations For Jacking

1. Park the vehicle on a firm level surface as

far from the edge of the roadway as pos-

sible. Avoid icy or slippery areas.

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic, pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

2. Turn on the Hazard Warning flasher.

3. Apply the parking brake. 4. Place the gear selector into PARK.

5. Turn the ignition off to the LOCK position.

6. Chock both the front and rear of the wheel

diagonally opposite of the jacking posi-

tion. For example, if changing the right

front tire, chock the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Jacking Instructions

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the

wheel to be raised.

• Set the parking brake firmly and set an

automatic transmission in PARK; a

manual transmission in REVERSE.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

• Only use the jack in the positions indi-

cated and for lifting this vehicle during a

tire change.

95

Page 98 of 180

WARNING!

• If working on or near a roadway, beextremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

• The stowed spare tire should always be

checked for security by pushing on it

with your hand , at the location under

the rear bumper, behind the vehicle. The

spare tire should not move when fully

secured by the winch under the vehicle.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

1. Loosen (but do not remove) the wheel lug bolts with the wrench handle by turning

them to the left one turn while the wheel

is still on the ground. 2. There are two jack engagement locations

on each side of the vehicle body.

NOTE:

Place the jack underneath the jack engage-

ment location that is closest to the flat tire.

WARNING!

Being under a jacked-up vehicle is danger-

ous. The vehicle could slip off the jack and

fall on you. You could be crushed. Never

get any part of your body under a vehicle

that is on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

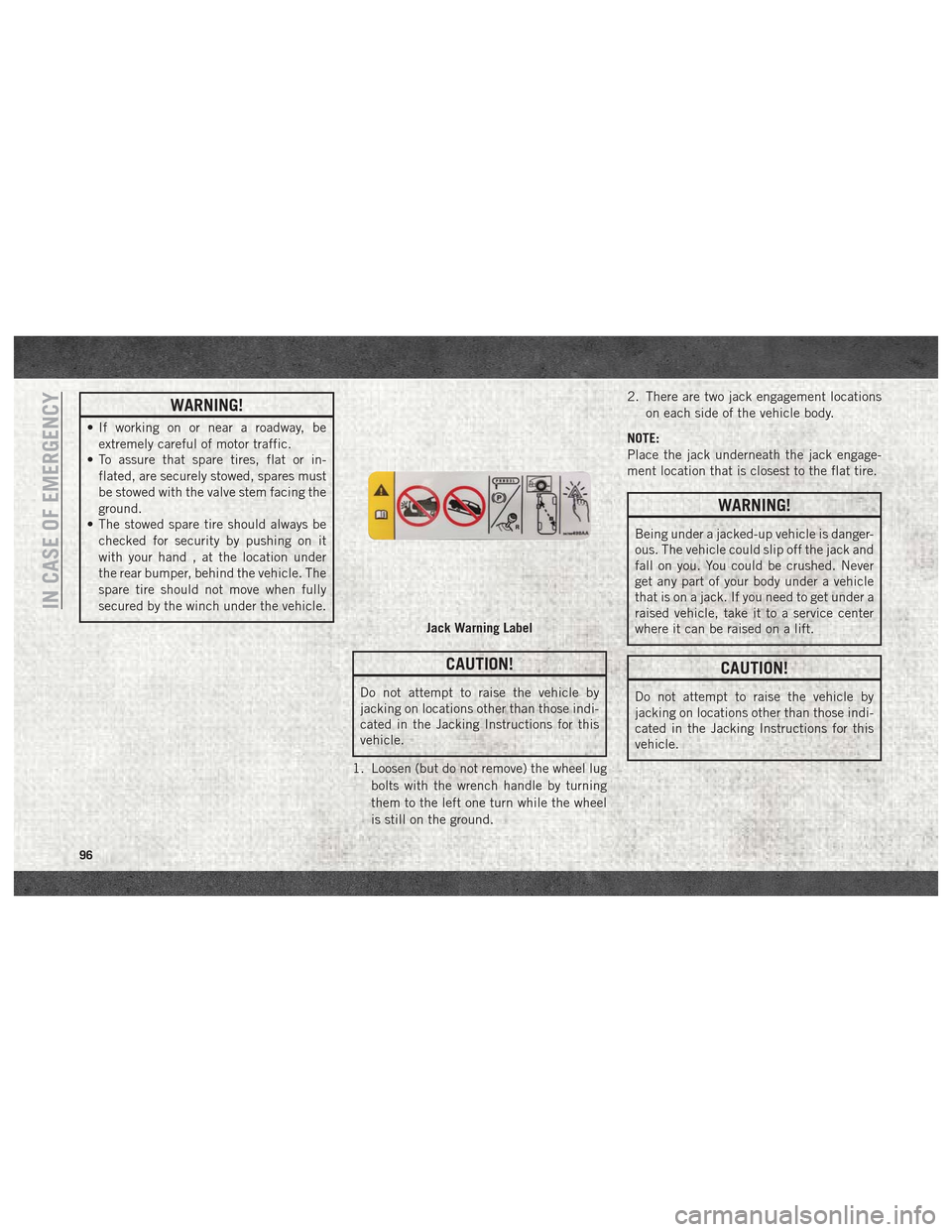

Jack Warning Label

IN CASE OF EMERGENCY

96

Page 99 of 180

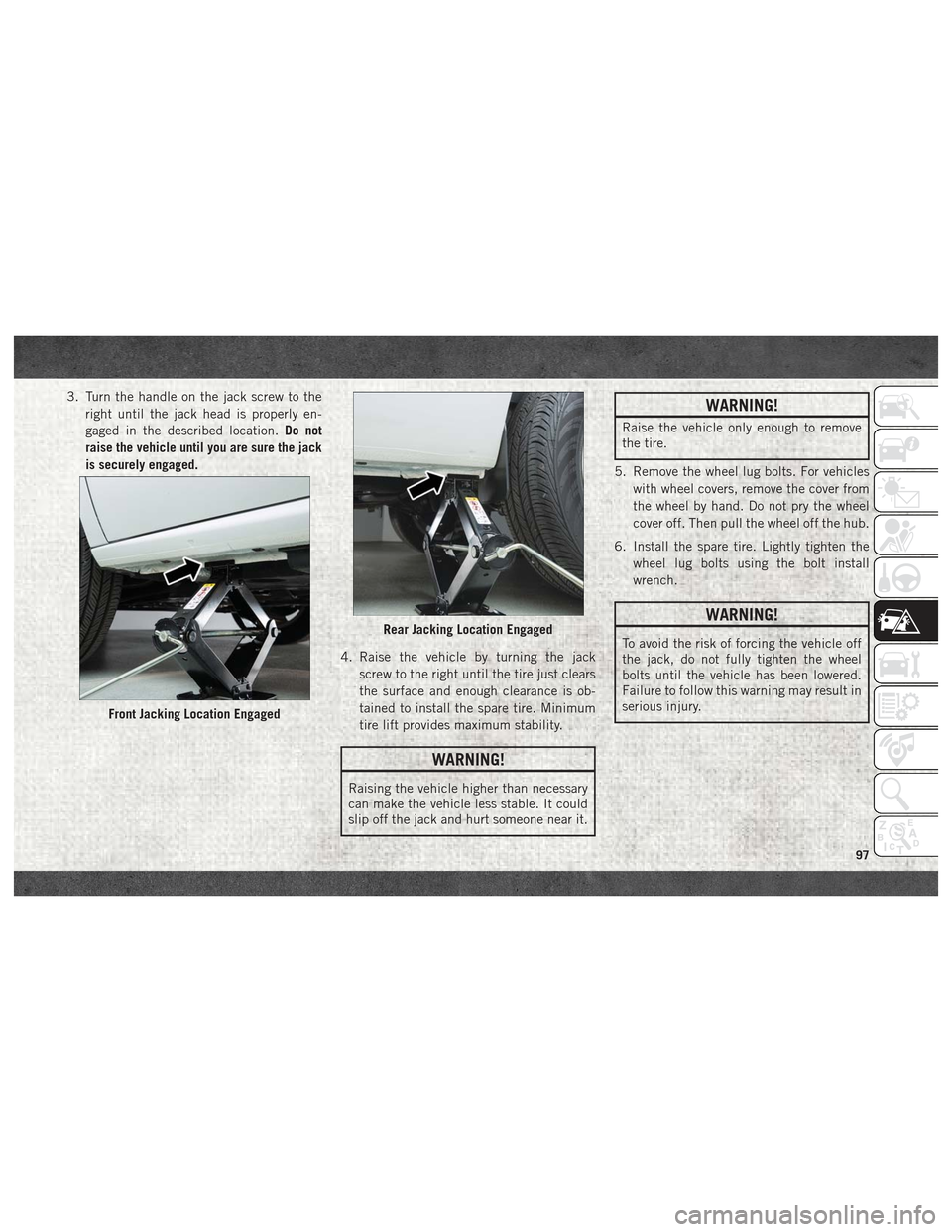

3. Turn the handle on the jack screw to theright until the jack head is properly en-

gaged in the described location. Do not

raise the vehicle until you are sure the jack

is securely engaged.

4. Raise the vehicle by turning the jackscrew to the right until the tire just clears

the surface and enough clearance is ob-

tained to install the spare tire. Minimum

tire lift provides maximum stability.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

WARNING!

Raise the vehicle only enough to remove

the tire.

5. Remove the wheel lug bolts. For vehicles with wheel covers, remove the cover from

the wheel by hand. Do not pry the wheel

cover off. Then pull the wheel off the hub.

6. Install the spare tire. Lightly tighten the wheel lug bolts using the bolt install

wrench.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not fully tighten the wheel

bolts until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

Front Jacking Location Engaged

Rear Jacking Location Engaged

97

Page 100 of 180

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.

7. Lower the vehicle by turning the jack screw to the left. 8. Refer to “Torque Specifications” in

“Technical Specifications” for proper

wheel lug bolt torque.

9. Lower the jack to its fully-closed position.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

10. Stow the cable and wheel spacer before driving the vehicle. Refer to “Vehicles

With Alloy Wheels” in this section for

instructions on stowing alloy wheels.

11. Stow the jack and tools under the driv- er’s seat.

12. Check the spare tire pressure as soon as possible. Correct the tire pressure, as

required.

13. When you place the spare tire back on the winch or if you carry the tire in need

of repair on the winch, always check that

the tire is properly secured under the vehicle by pushing on the stowed tire

under the rear bumper at the back of the

vehicle. If the tire has motion when

pushed, use the tools to retighten the

winch until a loud click is heard.

Vehicles With Alloy Wheels

For stowing a damaged tire on vehicles with

alloy wheels, remove the adapter bracket and

bolts from the storage bag in the glove com-

partment and follow the steps below:

1. Take the adapter and fit the plastic spacer

between the spring and the flange of the

bracket (The adapter bracket is sold sepa-

rately through the dealer).

2. The plastic fin must be directed down- wards and perfectly coincide with the

flange cut part; fit the bracket in the

adapter, fold the bracket up and secure it

to the adapter with the fastening knob.

3. Position the tire vertically and lay the mounted adapter on the inner part of the

rim, using the supplied bolts fasten the

wheel to the adapter using the bolt install

wrench.

4. Tighten the bolts with the wrench handle.

Mounting Spare Tire

IN CASE OF EMERGENCY

98