wheel bolt torque RENAULT KANGOO 1997 KC / 1.G Chassis Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 105

Page 56 of 105

STEERING ASSEMBLY

Power assisted steering rack

36

SPECIAL TOOLING REQUIRED

Mot. 453-01 Hose clamp pliers

T.Av. 476 Ball joint extractor

Wheel bolts 9

Track rod end nut 3.7

Steering rack mounting bolt 5

Universal joint eccentric bolt 2.5

Engine tie bar bolt 6.5

TIGHTENING TORQUES (in daN.m)

Put the vehicle on a two post lift.

REMOVAL

Remove the front wheels.

Fit a clamp Mot. 453-01 to each of the pipes from

the oil reservoir.

NOTE :never clamp the high pressure pipes.

Cut the rubber gaiter retaining clip and push the

gaiter back towards the bulkhead.

Disconnect the ball joints using tool T.Av. 476.

Remove the universal joint eccentric bolt.

Disconnect the oxygen sensor.

Remove the exhaust downpipe.

Remove the bolt (engine side) from the engine tie

bar and pivot the engine and transmission

assembly forwards.

Insert a retaining block.

Special notes for F8Q engine

Remove (from above) :

- the battery,

- the battery mounting,

- the high and low pressure pipes from the

steering valve.

13120S

36-4

Page 57 of 105

STEERING ASSEMBLY

Power assisted steering rack

36

Disconnect the high and low pressure pipes on the

steering rack (take precautions to catch the oil)

and the nut on the pipe retaining bracket.

Remove:

- the two nuts on the heat shield for the right

hand steering rack bearing,

- the steering rack mounting nuts and remove it

from the timing side.

NOTE :

- do not remove the pipes between the valve

and cylinder,

- fit plugs to the steering rack openings to

prevent the introduction of impurities.

12997R

REFITTING

Refitting is the reverse of removal. Observe the

recommended tightening torques.

Fill the circuit with oil.

Turn the wheels from left to right (engine not

running) to distribute the oil in the circuit.

Repeat the operation with the engine running

then top up the level.

If a new steering rack is being fitted, fit the track

rod ends in the position noted on removal.

To do this, slacken the bolt on the parallelism

adjustment sleeve and slacken the track rod end

while holding the axial ball joint using an open

wrench.

Make a mark or count the number of turns of

thread taken up so the parallelism can be pre-

adjusted on refitting.

Check the parallelism.

36-5

Page 64 of 105

STEERING ASSEMBLY

Steering column

36

TIGHTENING TORQUES (in daN.m)

REMOVAL

Disconnect the battery.

Set the vehicle wheels straight.

Remove the steering wheel in the following

manner.

Without airbag option

Remove the plastic cover.

Remove:

- the steering wheel bolt (this

MUST be renewed

on refitting),

- the steering wheel after noting its position.

With airbag option

REMOVAL

Disconnect the battery.

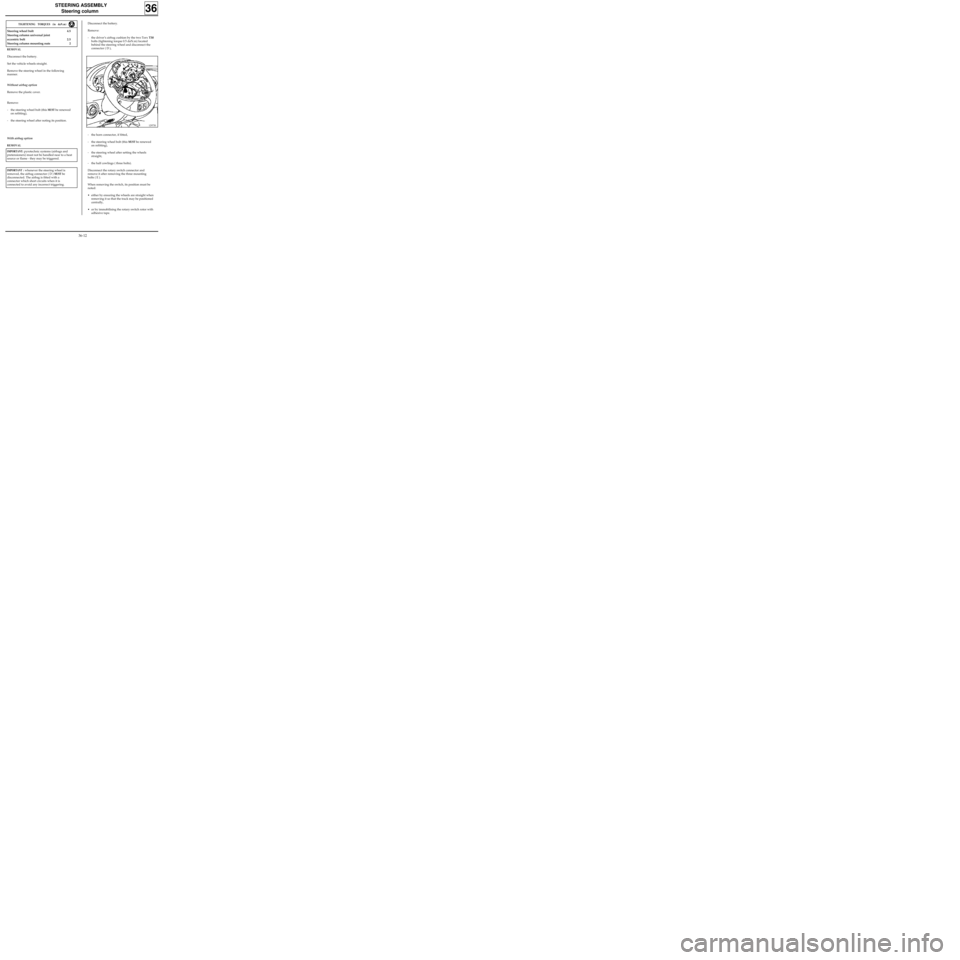

Remove:

- the driver’s airbag cushion by the two Torx T30

bolts (tightening torque 0.5 daN.m) located

behind the steering wheel and disconnect the

connector ( D ),

IMPORTANT: pyrotechnic systems (airbags and

pretensioners) must not be handled near to a heat

source or flame - they may be triggered.

IMPORTANT : whenever the steering wheel is

removed, the airbag connector ( D )

MUST be

disconnected. The airbag is fitted with a

connector which short circuits when it is

connected to avoid any incorrect triggering.

12973S

- the horn connector, if fitted,

- the steering wheel bolt (this

MUST be renewed

on refitting),

- the steering wheel after setting the wheels

straight,

- the half cowlings ( three bolts).

Disconnect the rotary switch connector and

remove it after removing the three mounting

bolts ( E ).

When removing the switch, its position must be

noted:

• either by ensuring the wheels are straight when

removing it so that the track may be positioned

centrally,

• or by immobilising the rotary switch rotor with

adhesive tape.

Steering wheel bolt 4.5

Steering column universal joint

eccentric bolt 2.5

Steering column mounting nuts 2

36-12

Page 68 of 105

STEERING ASSEMBLY

Steering column

36

IMPORTANT : if these instructions are not

followed exactly the system may not operate

normally and could even be triggered incorrectly.

IMPORTANT

Before reconnecting the driver’s airbag cushion,

check to see if the system is operating correctly as

follows:

•check the airbag warning light on the

instrument panel is illuminated when the

ignition is on,

•connect a dummy ignition module to the

driver’s airbag connector and check that the

warning light extinguishes,

•switch the ignition off, connect the airbag

cushion in place of the dummy ignition module

and secure the cushion to the steering wheel,

•switch the ignition on. Check the warning light

illuminates for three seconds when the ignition

is switched on then extinguishes and remains

extinguished.

If the warning light does not operate as described

above, refer to the fault finding section and check

the system using the

XRBAG (Elé. 1288).

SPECIAL NOTES FOR VEHICLES FITTED WITH A

DRIVER’S AIRBAG

Ensure that the wheels are still straight.

Check that the rotary switch is still immobilised

before refitting.

If it is not, follow the method for centring

described in section 88 "driver’s airbag".

Renew the steering wheel bolt each time it is

removed ( pre-bonded bolt).

Observe the correct tightening torque ( 4.5

daN.m).

36-16

Page 80 of 105

MECHANICAL ELEMENT CONTROLS

Braking compensator

37

NOTE

the braking compensators differ depending on the type of rear axle:

-standard load rear axle: red reference mark,

-increased load rear axle: green reference mark,

REMOVAL

Put the vehicle on a two post lift.

Disconnect the brake pipes.

Disconnect rod ( 2 ) from the compensator by

slackening bolt ( 1 ).

Remove the compensator (two bolts).

12865-1R

TIGHTENING TORQUES (in daN.m)

Hydraulic unions 1.7

Compensator mounting bolt 1.8

Rod adjustment bolt 1

NOTE : do not alter the position of nut (3).

REFITTING

Refitting is the reverse of removal.

Bleed and check the circuit (see section "Checking

- Adjusting").

SPECIAL TOOLING REQUIRED

Fre. 244 -03

or

Fre. 1085-01

CHECKING

Connect two pressure gauges Fre. 244-03 or

Fre. 1085-01 :

- one at the front right hand side,

- one at the rear left hand side.

Bleed the pressure gauges via screw (P).

98828R

Progressively press the brake pedal until the

pressure at the front wheels is the setting

pressure (see table of values). Read the

corresponding pressure at the rear wheels;

correct it if necessary.Pressure gauge for checking

compensator rating

37-12

Page 103 of 105

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEMS

BOSCH ABS

38

13138R

Pipe unions M10 × 100 1.7

M12 × 100 1.7

TIGHTENING TORQUES (in daN.m)

REMOVAL

Put the vehicle on a two post lift.

Disconnect the battery.

Remove the front right hand wheel.

Fit a pedal press to limit the amount of brake

fluid which will run out.

From above:

Disconnect the computer connector.

Remove the two earth bolts.

Disconnect the six pipes from the hydraulic assem-

bly, marking their position for refitting.

From below:

Remove:

- the exhaust downpipe,

- the exhaust manifold heat shield ( 3 bolts),

- the two lower mounting bolts for the hydraulic

assembly,HYDRAULIC ASSEMBLY

13139R

- the hydraulic assembly via the wheel arch.

Remove the upper hydraulic assembly mounting

bolt ( 1 ).

REFITTING

Refitting is the reverse of removal.

NOTE : the computer must not be removed. If

there is a fault, replace the complete hydraulic as-

sembly.

38-8