key RENAULT KANGOO 1997 KC / 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 105

Page 4 of 105

Master cylinder

Brake servo

Air filter - Brake servo non-return

valve

Vacuum pump

Handbrake control lever

Handbrake control

Brake pipes

Braking compensator

Clutch control cable

Clutch automatic wear take-up

system

External gear control37-1

37-3

37-5

37-6

37-7

37-8

37-10

37-11

37-22

37-23

37-24

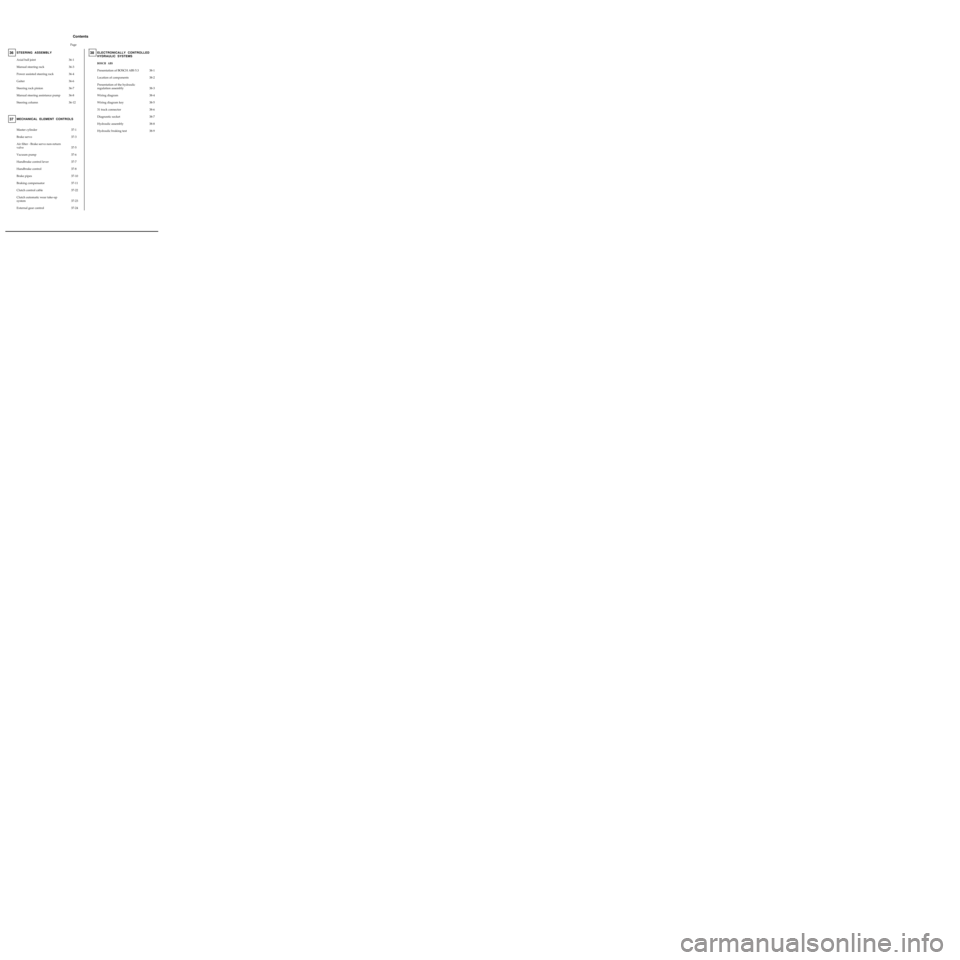

Contents

Page

MECHANICAL ELEMENT CONTROLS37

38-1

38-2

38-3

38-4

38-5

38-6

38-7

38-8

38-9

BOSCH ABS

Presentation of BOSCH ABS 5.3

Location of components

Presentation of the hydraulic

regulation assembly

Wiring diagram

Wiring diagram key

31 track connector

Diagnostic socket

Hydraulic assembly

Hydraulic braking test

ELECTRONICALLY CONTROLLED

HYDRAULIC SYSTEMS38STEERING ASSEMBLY

Axial ball joint

Manual steering rack

Power assisted steering rack

Gaiter

Steering rack pinion

Manual steering assistance pump

Steering column

36-1

36-3

36-4

36-6

36-7

36-8

36-12

36

Page 14 of 105

FRONT AXLE

Lower wishbone

31

85875R2

12992R

Wheel bolts 9

Lower wishbone nut on sub-frame 9

Key nut on stub-axle carrier 5.5

Anti-roll bar bearing nut 1.5

TIGHTENING TORQUES (in daN.m)

REMOVAL

Put the vehicle on a two post lift.

Remove both wheels.

Remove the mounting nuts for the anti-roll bar on

the lower wishbones.

Release the anti-roll bar downwards.

Remove:

- the nut and key on the stub-axle carrier,

- the two mounting bolts for the wishbone on

the sub-frame,

- the wishbone.

REFITTING

NOTE :

ensure the plastic protective washer ( A ) is

present on the lower ball joint shaft.

Refit:

- the wishbone,

- the two bolts, without tightening them,

- the ball joint shaft in the stub-axle carrier and

tighten the key nut.

Refit the anti-roll bar and fit the mounting nuts

using tool Sus. 1414 (see method in anti-roll bar

section).

This tool allows the rubber mounting to be

compressed to fit the nut.

NOTE : bounce the suspension and tighten the

wishbone and anti-roll bar bearing nuts to the re-

commended torque (tightening position: vehicle

unladen).

31-1

Page 20 of 105

FRONT AXLE

Stub axle carrier bearing

31

SPECIAL TOOLING REQUIRED

Rou. 15 -01 Shaft protector

Rou. 604 -01 Hub locking tool

T.Av.476 Ball joint extractor

T.Av. 1050-02 Tool for pushing driveshaft back

Driveshaft nut 28

Wheel bolts 9

Shock absorber base nut 18

Brake caliper mounting bolt 10

Track rod end nut 3.7

Key nut on stub axle carrier 5.5

83348G

REMOVAL

Disconnect the battery.

Remove:

- the wheel,

- the brake caliper and attach it to the spring so

the pipe is not damaged,

- the track rod end using tool

T.Av. 476,

- the driveshaft nut.

Push back the driveshaft using tool :

T. Av. 1050-02.

Remove:

- the brake disc,

- the lower ball joint nut and key,

- the two shock absorber base bolts,

- the hub / stub axle carrier / bearing assembly.

TIGHTENING TORQUES (in daN.m)Remove the hub on the press.

Remove the lower bush from the hub using an ex-

tractor with jaws and tool Rou. 15-01.

Remove the locking spring ring from the stub axle

carrier.

On the press remove the remainder of the bea-

ring, taking care to take the weight on the inner

bush using a tube of the same diameter.

31-7

Page 25 of 105

FRONT AXLE

Engine sub-frame

Remove:

- the two nuts for the steering rack heat shield,

- the mounting nuts for the steering rack and

attach it to the exhaust manifold.

31

12988R

SPECIAL TOOLING REQUIRED

Mot. 1040 -01 Dummy sub-frame for removing/refitting engine/transmission assembly

T. Av. 476 Ball joint extractor

REMOVAL

Disconnect the battery.

Put the vehicle on a two post lift.

Remove the wheels.

Disconnect the track rod ends using tool T. Av.

476.

Remove the key on the stub axle carrier.

Release but do not remove the mudguards to

reach the upper bolt on the sub-frame - side mem-

ber tie rod and remove it.

Remove:

- the exhaust downpipe and attach the catalytic

converter,

- the bolt (engine side) for the engine tie bar.

- the gear control by removing the two bolts at

the ends of the control. To do this, the cataly-

tic converter heat shield must be removed and

the gaiter on the gearbox side must also be re-

moved.

TIGHTENING TORQUES (in daN.m)

Wheel bolts 9

Track rod end nut 3.7

Steering universal joint bolt 2.5

Sub-frame mounting bolt front Ø10 6

rear Ø 12 10.5

Sub-frame - side member tie rod nut 3

Key nut on stub axle carrier 5.5

Engine tie bar 6.5

Steering box mounting bolt 5

Fit tool Mot. 1040-01 under the engine sub-frame.

12993-1R1

31-12

Page 100 of 105

WIRING DIAGRAM KEY

104Ignition switch

118 ABS computer

150Rear right wheel sensor

151Rear left wheel sensor

152Front right wheel sensor

153Front left wheel sensor

160Stop switch

225Diagnostic socket

247Instrument panel

260Fuse box

777Power feed fuse board

R2Dashboard / rear left

R36ABS / Dashboard

R101Right hand side member / Right hand

headlight

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEMS

BOSCH ABS

38

38-5