sensor RENAULT KANGOO 1997 KC / 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 105

Page 22 of 105

Spring compressor

FRONT AXLE

Spring and shock absorber assembly

31

Shock absorber base mounting bolt 18

Rebound stop nut 6

Wheel bolts 9

REMOVAL

Put the vehicle on a four post lift.

Remove:

- the wheels,

- the shock absorber base mounting bolts.

NOTE : release the ABS sensor wiring if this is

fitted on the base of the shock absorber.

Remove the upper shock absorber nut in the

engine compartment.

Remove the shock absorber and spring assembly.

TIGHTENING TORQUES (in daN.m)

EQUIPMENT REQUIRED

Replacing a shock absorber

When replacing a shock absorber, fit it in a vice

and compress the spring using the spring

compressor tool.

Remove the spring retaining nut.

Remove the spring and the intermediate parts.

If necessary, replace the shock absorber pad and

the rotating stop.

When refitting, ensure all components are

replaced in the correct location and then

decompress the spring.

NOTE : apply grease between the ends of the

spring and its stops.

REFITTING

Refitting is then the reverse of removal. Observe

the correct tightening torques.

31-9

Page 56 of 105

STEERING ASSEMBLY

Power assisted steering rack

36

SPECIAL TOOLING REQUIRED

Mot. 453-01 Hose clamp pliers

T.Av. 476 Ball joint extractor

Wheel bolts 9

Track rod end nut 3.7

Steering rack mounting bolt 5

Universal joint eccentric bolt 2.5

Engine tie bar bolt 6.5

TIGHTENING TORQUES (in daN.m)

Put the vehicle on a two post lift.

REMOVAL

Remove the front wheels.

Fit a clamp Mot. 453-01 to each of the pipes from

the oil reservoir.

NOTE :never clamp the high pressure pipes.

Cut the rubber gaiter retaining clip and push the

gaiter back towards the bulkhead.

Disconnect the ball joints using tool T.Av. 476.

Remove the universal joint eccentric bolt.

Disconnect the oxygen sensor.

Remove the exhaust downpipe.

Remove the bolt (engine side) from the engine tie

bar and pivot the engine and transmission

assembly forwards.

Insert a retaining block.

Special notes for F8Q engine

Remove (from above) :

- the battery,

- the battery mounting,

- the high and low pressure pipes from the

steering valve.

13120S

36-4

Page 96 of 105

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEMS

BOSCH ABS

38

This vehicle is fitted with BOSCH ABS 5.3 of the four channel additional type; the conventional braking

equipment and the ABS equipment are separate.

SPECIAL NOTES

The system comprises four speed sensors. Each hydraulic braking channel is associated with a sensor at each

wheel. The front wheels are therefore regulated separately. The rear wheels however are regulated at the

same time and in the same way according to the select low principle (the first wheel which tends to lock

causes immediate regulation on the complete axle assembly). The compensator fulfils its normal function.

38-1

Page 100 of 105

WIRING DIAGRAM KEY

104Ignition switch

118 ABS computer

150Rear right wheel sensor

151Rear left wheel sensor

152Front right wheel sensor

153Front left wheel sensor

160Stop switch

225Diagnostic socket

247Instrument panel

260Fuse box

777Power feed fuse board

R2Dashboard / rear left

R36ABS / Dashboard

R101Right hand side member / Right hand

headlight

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEMS

BOSCH ABS

38

38-5

Page 101 of 105

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEMS

BOSCH ABS

38

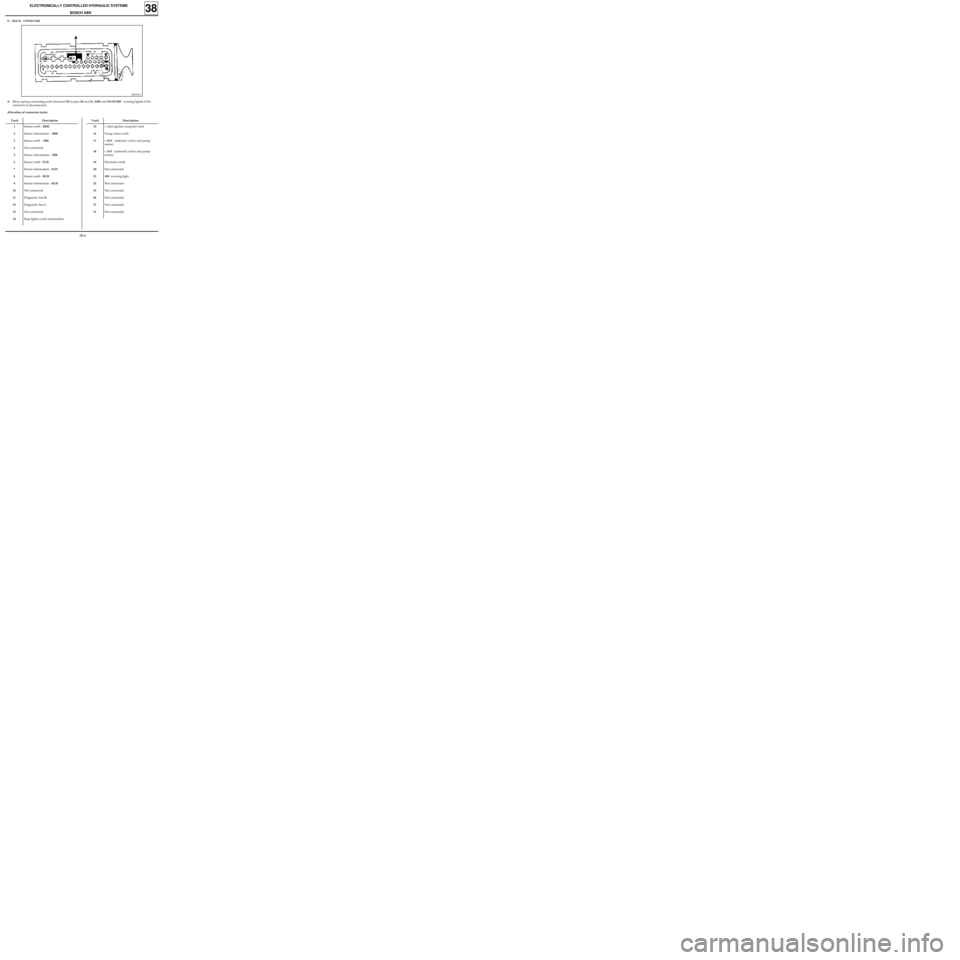

PRN3813

31 TRACK CONNECTOR

Track Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14Sensor earth - RRH

Sensor information -

RRH

Sensor earth - FRH

Not connected

Sensor information -

FRH

Sensor earth - FLH

Sensor information - FLH

Sensor earth - RLH

Sensor information - RLH

Not connected

Diagnostic line K

Diagnostic line L

Not connected

Stop lights switch information

AMicro-spring connecting earth (terminal 19) to pins 20 and 21 (ABS and NIVOCODE warning lights) if the

connector is disconnected.

Allocation of connector tracks

Track Description

15

16

17

18

19

20

21

22

25

26

27

31+ after ignition computer feed

Pump motor earth

+ BAT (solenoid valves and pump

motor)

+ BAT (solenoid valves and pump

motor)

Electronic earth

Not connected

ABS warning light

Not connected

Not connected

Not connected

Not connected

Not connected

38-6

Page 105 of 105

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEMS

BOSCH ABS

38

2)Bleeding the hydraulic assembly.

IMPORTANT : the bleeding order must be observed, beginning with the rear right , then the rear left, front

left and then front right.

a)Bleed the rear right brake by bleeding the hydraulic assembly secondary circuit using the XR25:

- position the bleed container and the hose, open the brake bleed screw,

- pump the brake pedal (approximately ten times),

- start the bleed command on the

XR25,

- pump the brake pedal during the diagnostic bleed phase,

- at the end of the bleed cycle on the

XR25, continue to pump the brake pedal and close the brake

bleed screw.

b)Carry out the procedure described at a) for the rear left, front left and front right brakes.

c)Check the pedal travel and if it is incorrect, restart the bleeding procedure.

IMPORTANT : ensure there is sufficient brake fluid in the reservoir.

CHECKING THE WHEEL SPEED SENSORS

a)Check the resistance of the sensor connections (from the computer connector to the 2 track speed sensor

connector).

b)Visually inspect the teeth ( 26 teeth) on the target and if they are faulty, replace the target.

c)Check the air gap using a set of shims. Only the front sensors can be checked.

PRN3820

Front: 0.13 < Z < 1.96 mm

38-10