warning light RENAULT KANGOO 1997 KC / 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 105

Page 17 of 105

FRONT AXLE

Brake pads

31

REMOVAL

Disconnect the wear warning light wire (if fitted).

Push the piston back, sliding the caliper by hand.

Remove the lower brake caliper guide bolt.

SPECIAL TOOLING REQUIRED

Fre. 823 Tool for pushing piston back

Wheel bolts 9

Brake caliper guide bolt 4

12994R

REFITTING

Push back the caliper piston using tool Fre. 823.

Fit new brake pads.

The brake pad with the wear warning light wire

(if fitted) is fitted to the inside.

Refit the caliper into position and fit the lower

guide bolt.

Tighten the guide bolt to the recommended

torque 4 daN.m.

Reconnect the wear warning light wire (if fitted).

Press the brake pedal several times to bring the

piston into contact with the pads.

TIGHTENING TORQUES (in daN.m)

Pivot the caliper around the upper bolt.

Remove the brake pads.

Check:

- the condition and mounting of the piston dust

cover,

- the condition of the guide dust cover.

31-4

Page 68 of 105

STEERING ASSEMBLY

Steering column

36

IMPORTANT : if these instructions are not

followed exactly the system may not operate

normally and could even be triggered incorrectly.

IMPORTANT

Before reconnecting the driver’s airbag cushion,

check to see if the system is operating correctly as

follows:

•check the airbag warning light on the

instrument panel is illuminated when the

ignition is on,

•connect a dummy ignition module to the

driver’s airbag connector and check that the

warning light extinguishes,

•switch the ignition off, connect the airbag

cushion in place of the dummy ignition module

and secure the cushion to the steering wheel,

•switch the ignition on. Check the warning light

illuminates for three seconds when the ignition

is switched on then extinguishes and remains

extinguished.

If the warning light does not operate as described

above, refer to the fault finding section and check

the system using the

XRBAG (Elé. 1288).

SPECIAL NOTES FOR VEHICLES FITTED WITH A

DRIVER’S AIRBAG

Ensure that the wheels are still straight.

Check that the rotary switch is still immobilised

before refitting.

If it is not, follow the method for centring

described in section 88 "driver’s airbag".

Renew the steering wheel bolt each time it is

removed ( pre-bonded bolt).

Observe the correct tightening torque ( 4.5

daN.m).

36-16

Page 97 of 105

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEMS

BOSCH ABS

38

PRN3818

LOCATION OF THE BOSCH ABS COMPONENTS

1Hydraulic assembly

2Master cylinder

3Brake servo4Brake fluid level warning light

5Braking compensator

38-2

Page 101 of 105

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEMS

BOSCH ABS

38

PRN3813

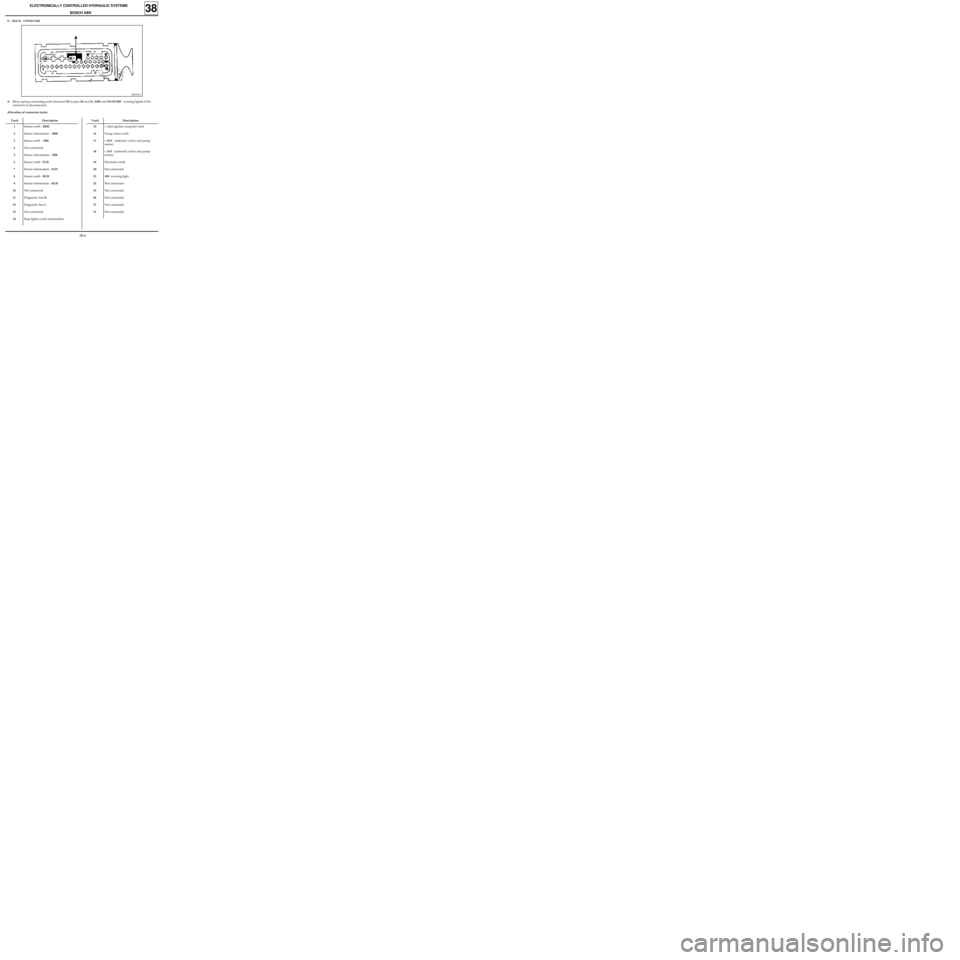

31 TRACK CONNECTOR

Track Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14Sensor earth - RRH

Sensor information -

RRH

Sensor earth - FRH

Not connected

Sensor information -

FRH

Sensor earth - FLH

Sensor information - FLH

Sensor earth - RLH

Sensor information - RLH

Not connected

Diagnostic line K

Diagnostic line L

Not connected

Stop lights switch information

AMicro-spring connecting earth (terminal 19) to pins 20 and 21 (ABS and NIVOCODE warning lights) if the

connector is disconnected.

Allocation of connector tracks

Track Description

15

16

17

18

19

20

21

22

25

26

27

31+ after ignition computer feed

Pump motor earth

+ BAT (solenoid valves and pump

motor)

+ BAT (solenoid valves and pump

motor)

Electronic earth

Not connected

ABS warning light

Not connected

Not connected

Not connected

Not connected

Not connected

38-6