cooling RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 175 of 208

COOLING

Specifications

19

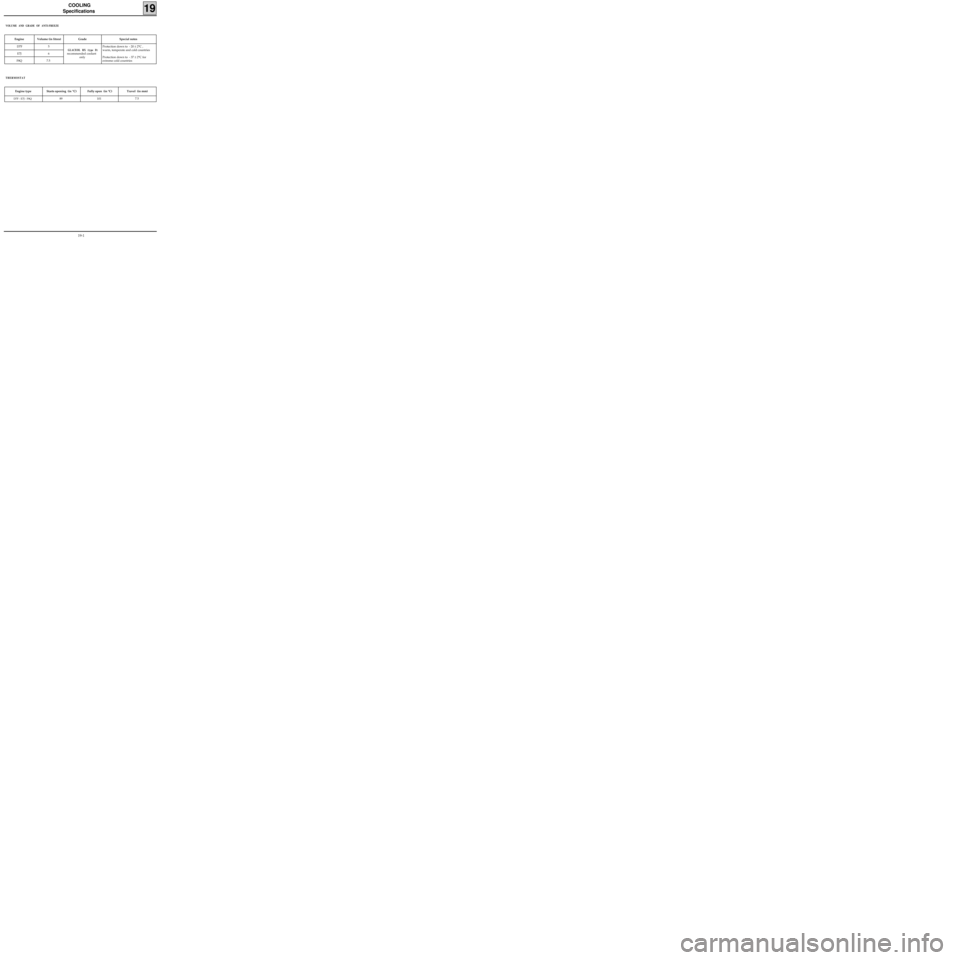

VOLUME AND GRADE OF ANTI-FREEZE

Engine Volume (in litres) Grade Special notes

D7F

E7J

F8Q5

6

7.5

GLACEOL RX (type D)

recommended coolant

onlyProtection down to - 20 ± 2°C ,

warm, temperate and cold countries

Protection down to - 37 ± 2°C for

extreme cold countries

THERMOSTAT

Engine type Starts opening (in °C) Fully open (in °C) Travel (in mm)

D7F - E7J - F8Q89 101 7.5

19-1

Page 176 of 208

COOLING

Filling and bleeding

19

There is no heater matrix water control valve.

Water flow is continuous in the heater matrix,

which contributes to the cooling of the engine.

FILLING

Check the tightening of the drain plug(s).

Open the two bleed screws.

Fill the circuit through the opening in the expan-

sion bottle.

Tighten the bleed screws as soon as the liquid

flows in a continuous jet.

Start the engine (2 500 rpm).

Adjust the level by overflow for a period of about

4 minutes .

Close the bottle.

BLEEDING

Allow the engine to run for about 10 minutes at

2 500 rpm, until the fan(s) operate (time necessary

for automatic degassing).

Check the liquid level is at the "Maximum" mar-

ker.

DO NOT OPEN THE BLEED SCREWS WHILST THE

ENGINE IS TURNING.

RE-TIGHTEN THE EXPANSION BOTTLE CAP WHILST

THE ENGINE IS WARM.

19-2

Page 177 of 208

COOLING

Testing

19

SPECIAL TOOLING REQUIRED

M.S.554-01 Adapter for M.S. 554-05

M.S.554-06 Adapter for M.S. 554-05

M.S.554-07 Kit for testing cooling circuit

sealing

97871R

Engine Colour of valve Valve rating (in

bars)

D7F-E7J-F8QBrown 1.2

1 - Testing the sealing of the circuit

Replace the expansion bottle valve with adapter

M.S. 554-01.

Connect this to tool M.S. 554-07.

Let the engine warm up then turn it off.

Pump to put the circuit under pressure.

Stop pumping at 0.1 bar less than the valve is

rated.

The pressure should not drop, otherwise look for

the leak.

Slowly unscrew the union of tool M.S. 554-07 to

decompress the cooling circuit, then remove tool

M.S. 554-01 and refit the expansion bottle valve

with a new seal.2 - Checking the rating of the valve.

If liquid passes through the expansion bottle

valve,the valve must be replaced.

On pump M.S. 554-07 fit tool M.S. 554-06 and fit

the assembly on the valve to be checked.

Increase the pressure which should stabilise at the

valve rating pressure with a test tolerance of

±

0.1 bar.

Valve rating :

19-3

Page 178 of 208

COOLING

Diagram

19

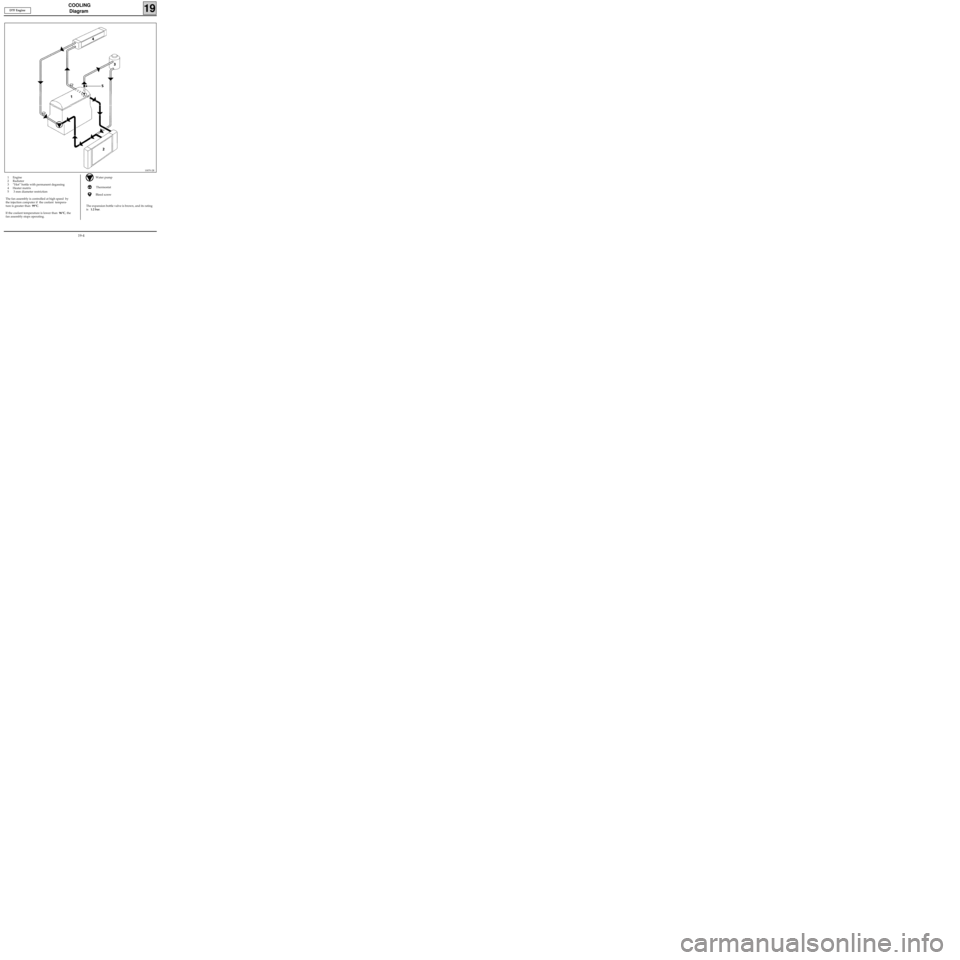

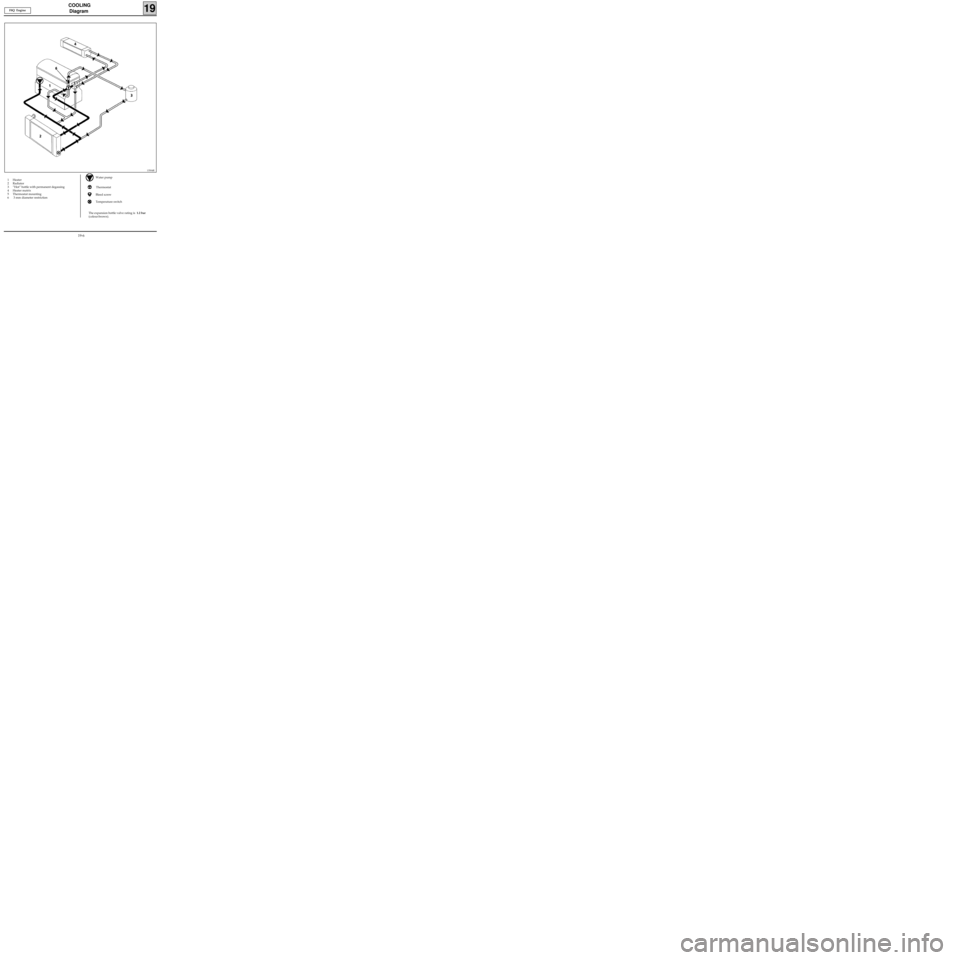

1 Engine

2 Radiator

3 ”Hot” bottle with permanent degassing

4 Heater matrix

5 3 mm diameter restriction

The fan assembly is controlled at high speed by

the injection computer if the coolant tempera-

ture is greater than 99°C.

If the coolant temperature is lower than 96°C, the

fan assembly stops operating.Water pump

Thermostat

Bleed screw

The expansion bottle valve is brown, and its rating

is 1.2 bar.

10070-2R

D7F Engine

19-4

Page 179 of 208

COOLING

Diagram

19

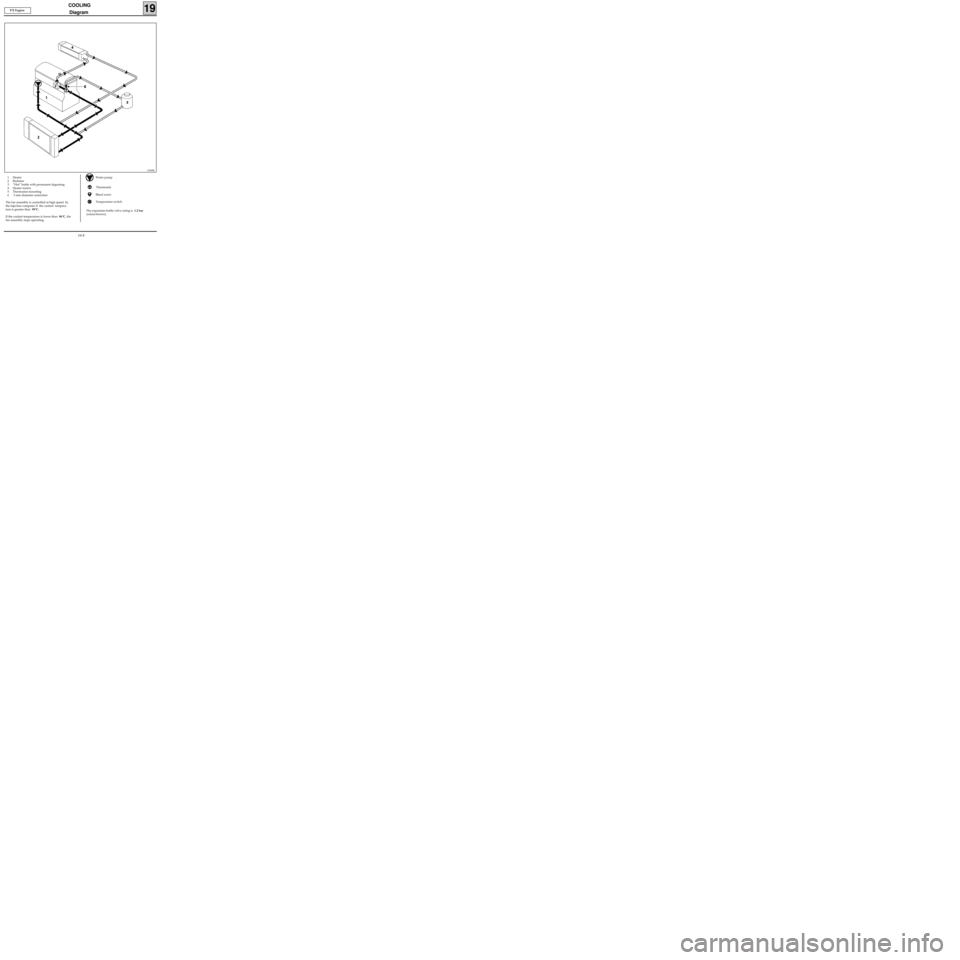

1 Heater

2 Radiator

3 ”Hot” bottle with permanent degassing

4 Heater matrix

5 Thermostat mounting

6 3 mm diameter restriction

The fan assembly is controlled at high speed by

the injection computer if the coolant tempera-

ture is greater than 99°C.

If the coolant temperature is lower than 96°C, the

fan assembly stops operating.Water pump

Thermostat

Bleed screw

Temperature switch

The expansion bottle valve rating is 1.2 bar

(colour:brown).

13508R

E7J Engine

19-5

Page 180 of 208

COOLING

Diagram

19

Water pump

Thermostat

Bleed screw

Temperature switch

13504R

F8Q Engine

1 Heater

2 Radiator

3 ”Hot” bottle with permanent degassing

4 Heater matrix

5 Thermostat mounting

6 3 mm diameter restriction

The expansion bottle valve rating is 1.2 bar

(colour:brown).

19-6

Page 181 of 208

COOLING

Water pump

CLEANING

It is very important not to scratch the gasket faces

of all aluminium components.

Use the product Décapjoint to dissolve the part

of the gasket which remains attached.

Apply the product to the part to be cleaned, wait

approximately 10 minutes, then remove it using a

wooden spatula.

The wearing of gloves is recommended during

this operation.

19

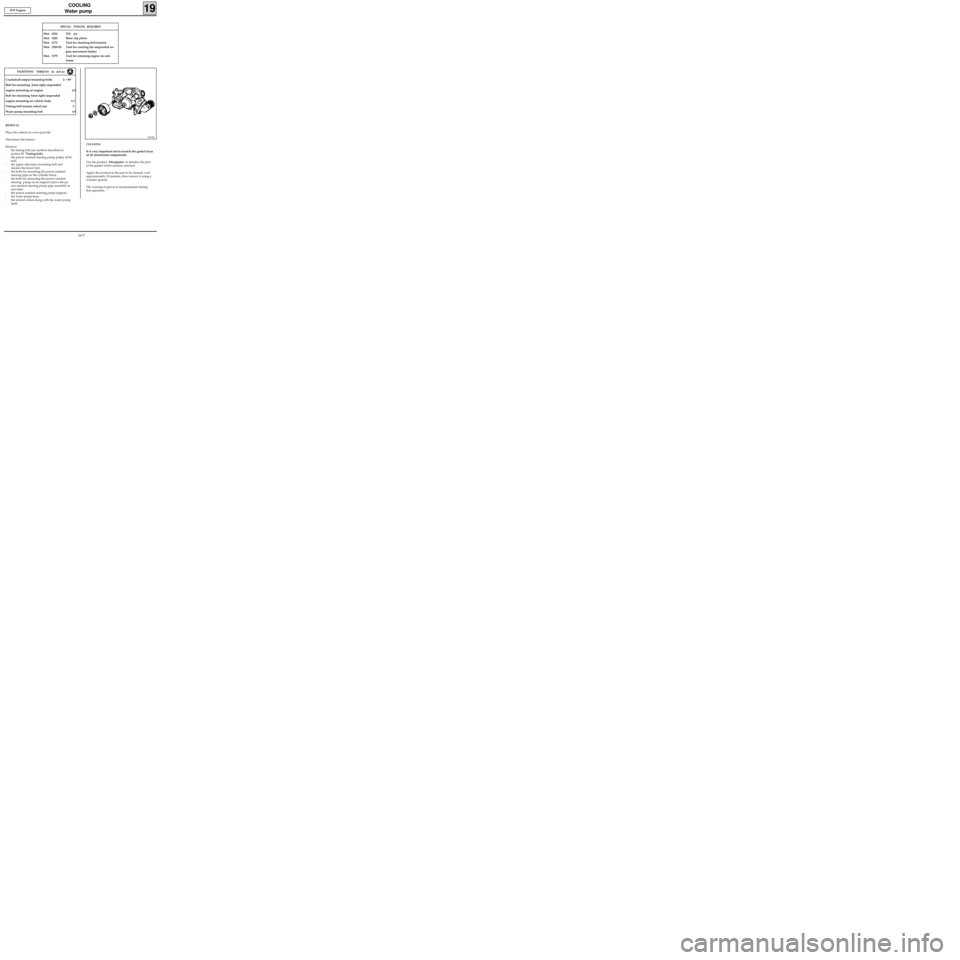

SPECIAL TOOLING REQUIRED

Mot. 1054TDC pin

Mot. 1202 Hose clip pliers

Mot. 1273 Tool for checking belt tension

Mot. 1289-03 Tool for centring the suspended en-

gine movement limiter

Mot. 1379 Tool for retaining engine on sub-

frame

10478S

D7F Engine

Crankshaft output mounting bolts 2 + 90°

Bolt for mounting front right suspended

engine mounting on engine 6.2

Bolt for mounting front right suspended

engine mounting on vehicle body 6.2

Timing belt tension wheel nut 5

Water pump mounting bolt 0.9

TIGHTENING TORQUES (in daN.m)

REMOVAL

Place the vehicle on a two post lift.

Disconnect the battery.

Remove:

- the timing belt (see method described in

section 11 "Timing belt),

- the power assisted steering pump pulley (if fit-

ted),

- the upper alternator mounting bolt and

slacken the lower bolt,

- the bolts for mounting the power assisted

steering pipe on the cylinder block,

- the bolts for mounting the power assisted

steering pump on its support (move the po-

wer assisted steering pump-pipe assembly to

one side),

- the power assisted steering pump support,

- the water pump hose,

- the tension wheel along with the water pump

itself.

19-7

Page 182 of 208

COOLING

Water pump

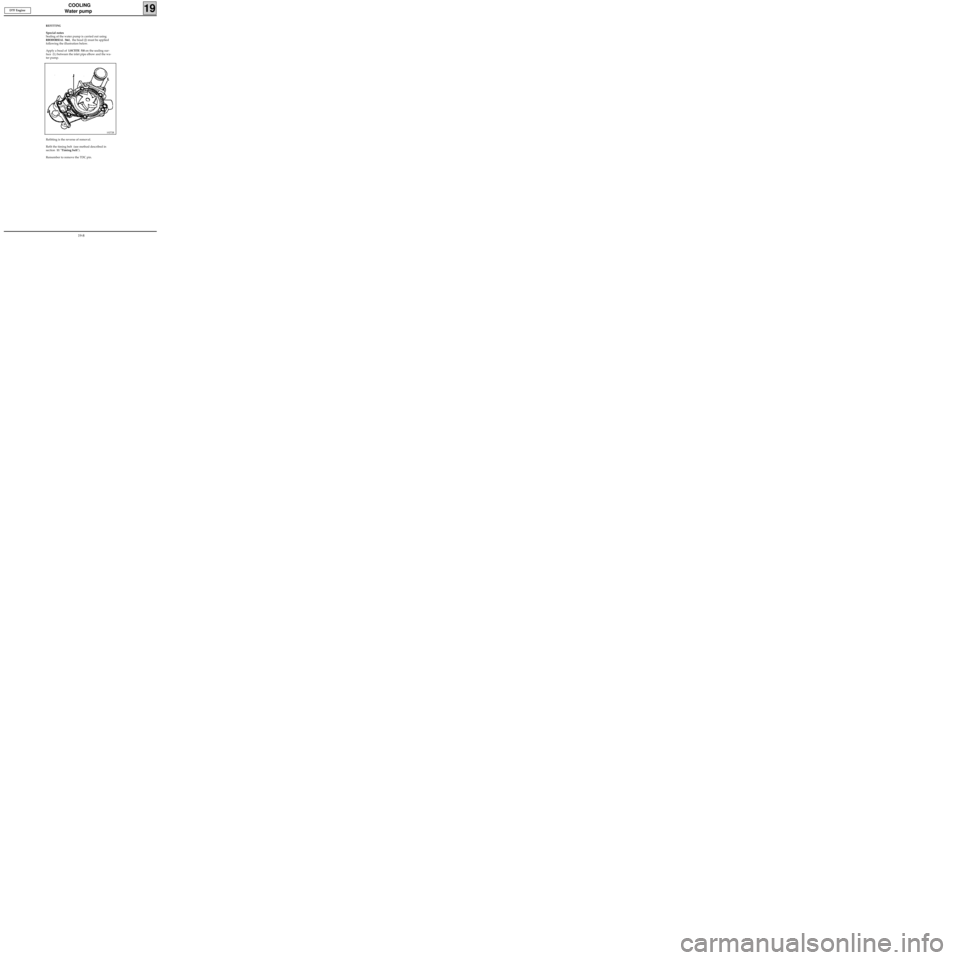

Refitting is the reverse of removal.

Refit the timing belt (see method described in

section 11 "Timing belt").

Remember to remove the TDC pin.

19

10272R

D7F Engine

REFITTING

Special notes

Sealing of the water pump is carried out using

RHODORSEAL 5661, the bead (J) must be applied

following the illustration below.

Apply a bead of

LOCTITE 518 on the sealing sur-

face (L) between the inlet pipe elbow and the wa-

ter pump.

19-8

Page 183 of 208

COOLING

Water pump

Refit the timing belt (see method described in

chapter 11 "Timing belt").

Fill and bleed the cooling circuit (see section 19

"Filling - Bleeding").

19

SPECIAL TOOLING REQUIRED

Mot. 591-02 Index

Mot. 591-04 Angle tightening wrench

Mot. 1135-01 Tool for tensioning the timing belt

Mot. 1202 Hose clip pliers

Mot. 1273 Tool for checking belt tension

92068R

E7J Engine

Tension wheel nut 5

Crankshaft pulley bolt 2 + 68° + 6°

Bolt for suspended engine mounting cover 6,2

Nut for suspended engine mounting cover 4,4

Water pump bolt 2,2

Water pump nut 1

Wheel bolts 9

TIGHTENING TORQUES (in daN.m)

EQUIPMENT REQUIRED

Engine support tool

REFITTING

The sealing of the water pump is carried out using

the product

LOCTITE 518; the bead (H) must be

applied following the diagram below.

REMOVAL

Place the vehicle on a two post lift.

Disconnect the battery.

Drain the cooling circuit from the lower radiator

hose.

Remove:

- the timing belt (see method described in

section 11 "Timing belt),

- the timing tension wheel,

- the water pump, and extract this from above.

CLEANING

It is very important not to scratch the gasket faces

of all aluminium components.

Use the product Décapjoint to dissolve the part

of the gasket which remains attached.

Apply the product to the part to be cleaned, wait

approximately 10 minutes, then remove it using a

wooden spatula.

The wearing of gloves is recommended during

this operation.

19-9

Page 184 of 208

COOLING

Water pump

19

SPECIAL TOOLING REQUIRED

Mot. 1202 Hose clip pliers

13090R

F8Q Engine

Water pump bolt 1.6

Bolt for water pump pulley 2

Bolt for crankshaft pulley 2 + 115° ± 15°

TIGHTENING TORQUES (in daN.m)

REMOVAL

Place the vehicle on a two post lift.

Disconnect the battery.

Drain the cooling circuit through the lower radia-

tor hose.

Fit the engine support tool.

Remove :

- the plastic protector for the suspended engine

mounting cover,

- the suspended engine mounting cover,

EQUIPMENT REQUIRED

Engine support tool

- the front right wheel arch,

- the accessories belt,

- the crankshaft pulley (A),

- the water pump pulley (B) , lowering the en-

gine as far as possible,

- the injection pump housing (C),

- the bolt at (1) and move the alternator to the

right.

13086R1

19-10