brake RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 5 of 208

ENGINE AND ENGINE PERIPHERALS

Consumables

10

Identification

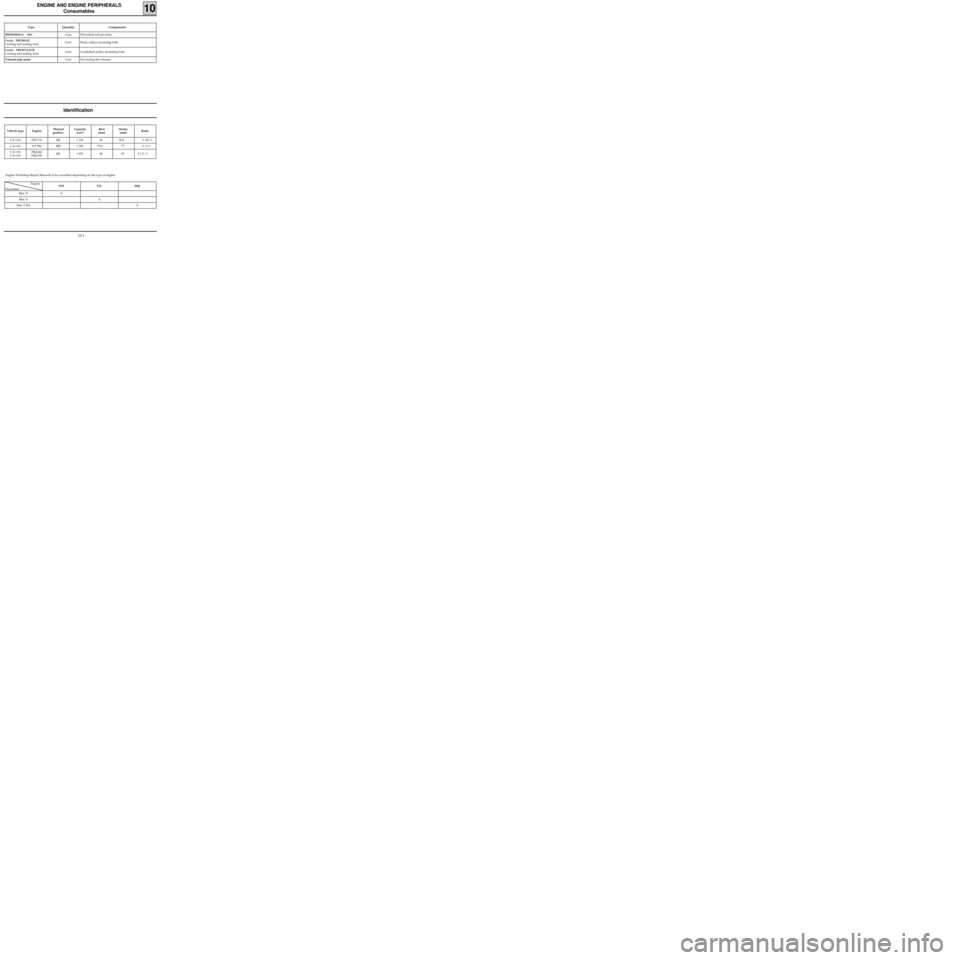

Type Quantity Components

RHODORSEAL 5661Coat Driveshaft roll pin holes

Loctite FRENBLOC

Locking and sealing resinCoat Brake caliper mounting bolts

Loctite FRENETANCH

Locking and sealing resinCoat Crankshaft pulley mounting bolts

Exhaust pipe pasteCoat For sealing the exhaust

Vehicle type EngineManual

gearboxCapacity

(cm3)Bore

(mm)Stroke

(mm)Ratio

F/K C0AD7F 710 JB1 1 149 69 76.8 9 .65/1

F/K C0CE7J 780 JB3 1 390 75.8 77 9 .5/1

F/K C0D

F/K C0EF8Q 662

F8Q 630JB1 1 870 80 93 2 1.5 /1

Engine Workshop Repair Manuals to be consulted depending on the type of engine:

D7F E7J F8Q

Mot. D X

Mot. E X

Mot. F (D)XEngine

Document

10-1

Page 8 of 208

ENGINE AND ENGINE PERIPHERALS

Engine - Gearbox

10

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect:

- the battery,

- the electrical connectors from the engine

connection unit and its environment.

13034S

Drain:

- the cooling circuit (bottom hose of the

radiator),

- the gearbox oil,

- the engine oil if necessary.

Remove:

- the battery,

- the bonnet,

- the wheels,

- the air intake pipe,

- the expansion bottle and fix it to the engine. Brake caliper guide bolt 4

Shock absorber base bolts 18

Driveshaft gaiter mounting bolt 2.5

Wheel bolt 9

Left-hand suspended mounting bolt

on gearbox 6.2

Left-hand suspended mounting bolt

and nut on body 2.1

Right hand suspended

engine mounting bolt on engine 6.2

Right hand suspended

engine mounting bolt on body 6.2

TIGHTENING TORQUES (in daN.m)

D7F engine

SPECIAL TOOLING REQUIRED

B. Vi. 31-01 Set of three punches for roll

pins

Mot. 1202 Hose clip pliers

Mot. 1273 Tool for checking belt tension

Mot. 1311-06 Tool for removal of fuel pipe

Mot. 1379 Tool for retaining engine on

sub-frame

T. Av. 476 Ball joint extractor

EQUIPMENT REQUIRED

Load positioner

10-4

Page 9 of 208

ENGINE AND ENGINE PERIPHERALS

Engine - Gearbox

Left-hand side of the vehicle

Remove:

- the brake caliper mounting bolt, then fix it to

the shock absorber spring,

- the three driveshaft gaiter mounting bolts,

- the track rod end with the aid of tool

T.Av.476,

- the shock absorber base bolts.

Tilt the hub to disconnect the driveshaft from the

gearbox.

Right-hand side of the vehicle

Remove:

- the driveshaft roll pins with the punches

B.Vi.31-01,

- the brake caliper mounting bolt, then fix it to

the shock absorber spring,

- the track rod end with the aid of tool

T.Av.476,

- the shock absorber base bolts.

Tilt the hub to disconnect the driveshaft from the

gearbox.

Remove the earth strap mounting bolt (gearbox

side)

10D7F engine

10-5

Page 10 of 208

ENGINE AND ENGINE PERIPHERALS

Engine - Gearbox

- the heater hoses on the bulkhead side (with

plastic unions),

10

Disconnect the gear control at the position of the

gearbox output lever after releasing the gaiter.

93912R1

Slacken bolt (A) without removing it and remove

bolt (B) from the engine tie-bar.

92661R1

Disconnect:

- the accelerator cable,

- the canister pipe,

- the brake servo vacuum pipe,

- the hoses between the radiator and the

engine block, on the engine block side,

13085R

(with metal unions),

13084R

- the connectors of the oxygen sensor and fan,

- the fuel pipes. D7F engine

10-6

Page 12 of 208

ENGINE AND ENGINE PERIPHERALS

Engine - Gearbox

10

12924R3

Apply Rhodorseal 5661 to the driveshaft roll pin hole.

Press the brake pedal several times to bring the pistons into contact with the brake pads.

Refit the power assisted steering pump belt (see section 07).

Fill:

- the gearbox with oil,

- the engine with oil (if necessary),

- the cooling circuit and bleed it (see section 19).

REFITTING (special notes)

Refitting is the reverse of removal.

Tighten the suspended engine mounting bolts to the recommended torque.

NOTE : tighten the suspended engine mounting bolts on the body in the order recommended below:

-1⇒bolt A to a torque of 2.1 daNm.

-2⇒bolt B to a torque of 2.1 daNm.

-3⇒bolt C to a torque of 2.1 daNm. D7F engine

10-8

Page 14 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

Disconnect:

- the accelerator cable,

- the canister pipe,

- the brake servo pipe,

- the heater hoses,

- the oxygen sensor connector,

- the fuel pipes.

Remove:

- the shock absorber base bolts,

- the steering shaft yoke bolt.

10

97390-1R

SPECIAL NOTES FOR VEHICLES FITTED WITH

DRIVER’S AIR BAG

WARNING

In order to avoid any risk of damage to the rotary

switch beneath the steering wheel, the following

instructions should be followed:

• Before disconnecting the steering column from

the rack, the steering wheel MUST be immobi-

lised with the wheels straight with the aid of a

"steering wheel lock" throughout the opera-

tion.

• If there is any doubt about the rotary switch

being properly centred, the steering wheel

must be removed in order to apply the centring

method described in the Technical Note cove-

ring the 2nd generation air bag.

REMINDER: this kind of work must only be carried

out by properly trained and qualified staff.

Remove:

- both the sub-frame reinforcements,

- the earth strap mounting bolt on the body

side,

- the exhaust downpipe nuts. D7F engine

10-10

Page 17 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

12924R4

Apply Rhodorseal 5661 to the driveshaft roll pin hole.

Press the brake pedal several times to bring the pistons into contact with the brake pads.

Fill:

- the gearbox with oil (if necessary),

- the engine with oil (if necessary),

- the cooling circuit and bleed it (see section 19).

REFITTING (special notes)

Use tool T. Av. 1233-01 to position the engine and transmission assembly in relation to the body.

Refitting is the reverse of removal.

Tighten the suspended engine mounting bolts and nuts to the recommended torque.D7F engine

10-13

Page 18 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

Front sub-frame mounting bolt 6.2

Rear sub-frame mounting bolt 10.5

Mounting bolt for front right suspended

engine mounting cover on engine 6.2

Mounting nut for front right suspended

engine mounting cover 4.4

Mounting nut for rubber engine mounting pad

on front left-hand side member support 6.2

Shock absorber base bolt 18

Brake caliper mounting bolt 4

Steering shaft yoke bolt 3

Wheel bolt 9

TIGHTENING TORQUES (in daN.m)

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Drain:

- the cooling circuit through the bottom hose

of the radiator,

- the gearbox and the engine if necessary.

Remove:

- the bonnet,

- the front wheels,

- the tie-rods between sub-frame and body,- the mounting bolts (1); pull away the brake

calipers as shown in the diagram below and

attach them to the suspension springs,

12994R1

- the shock absorber base bolts, E7J engine

SPECIAL TOOLING REQUIRED

Mot. 1040-01 Dummy sub-frame for removing

and refitting engine and

transmission assembly

Mot. 1159 Tool for maintaining engine on

sub-frame

Mot. 1202

Mot. 1448

Mot. 1311-06 Tool for removing fuel pipe

Hose clip pliers

10-14

Page 19 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

13085R

- the exhaust heat shield and the gear control

on the lever and gearbox sides,

12988R

- the exhaust pipe clamp between the catalytic

converter and the expansion chamber,

- the earth strap on the gearbox,

- the front bumper,

- the air intake pipe from the air filter,

- the injection computer support after dis-

connecting the 55 track connector and that of

the impact switch.

13088R2

Disconnect:

- the wiring connections and the hoses on the

thermostat support,

- the hoses on the expansion bottle,

- the brake servo pipe,

- the heater hoses (there are two types of as-

sembly to be disconnected, as shown in the

diagrams below),

13084R

E7J engine

10-15

Page 22 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

REFITTING

The alignment of the sub-frame with the body

will be made easier by positioning two threaded

rods Mot. 1233-01 in the two front mountings of

the sub-frame on the body.

Tighten the sub-frame mounting bolts to a torque

of:

- 6.2 daN.m at the front,

-10.5 daN.m at the rear.

Refitting is the reverse of removal.

Fit the heat shields correctly.

Apply

Loctite FRENBLOC to the caliper mounting

bolts and tighten them to the recommended tor-

que.

Press the brake pedal several times to bring the

pistons into contact with the brake pads.

Fill:

- the engine and gearbox with oil, if necessary,

- the cooling circuit and bleed it (see section 19

"Filling - bleeding"). E7J engine

Fix tool Mot. 1040-01 underneath the sub-frame.

98755R1

Lower the lift until the tool touches the ground.

Remove the sub-frame mounting bolts and take

out the engine and transmission assembly by lif-

ting the body.

NOTE : for any operation requiring separation of

the engine, gearbox and sub-frame assembly,

take care to mark the position of Mot. 1159 on the

sub-frame.

10-18