cooling RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 38 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

Fault finding - Checking conformity

13

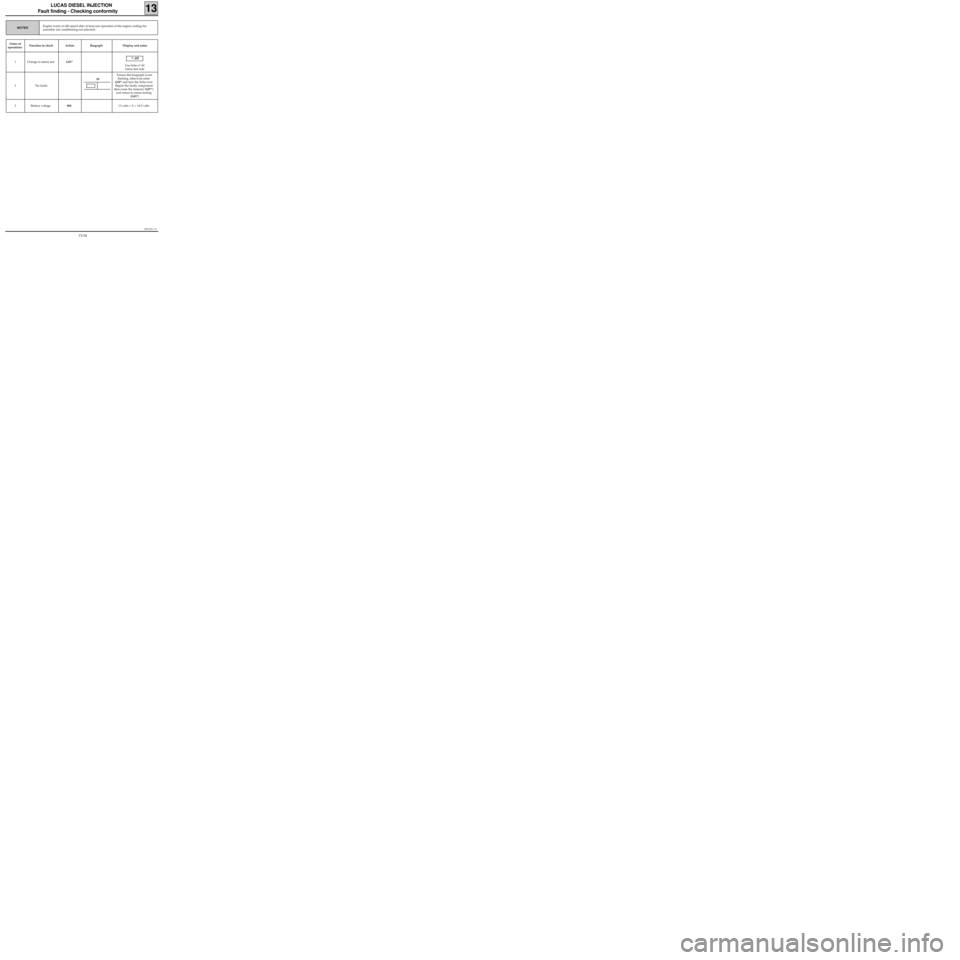

Order of

operationsFunction to check Action Bargraph Display and notes

1 Change to status testG01* 7. dlE

Use fiche n° 60

status test side

2 No faultsEnsure this bargraph is not

flashing, otherwise enter

G02* and turn the fiche over.

Repair the faulty component

then erase the memory (G0**)

and return to status testing

(G01*)

3 Battery voltage#04 13 volts < X < 14.5 volts

Engine warm at idle speed after at least one operation of the engine cooling fan

assembly (air conditioning not selected).NOTES

20

13-34

Page 39 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

Fault finding - Checking conformity

13

Engine warm at idle speed after at least one operation of the engine cooling fan

assembly (air conditioning not selected).NOTES

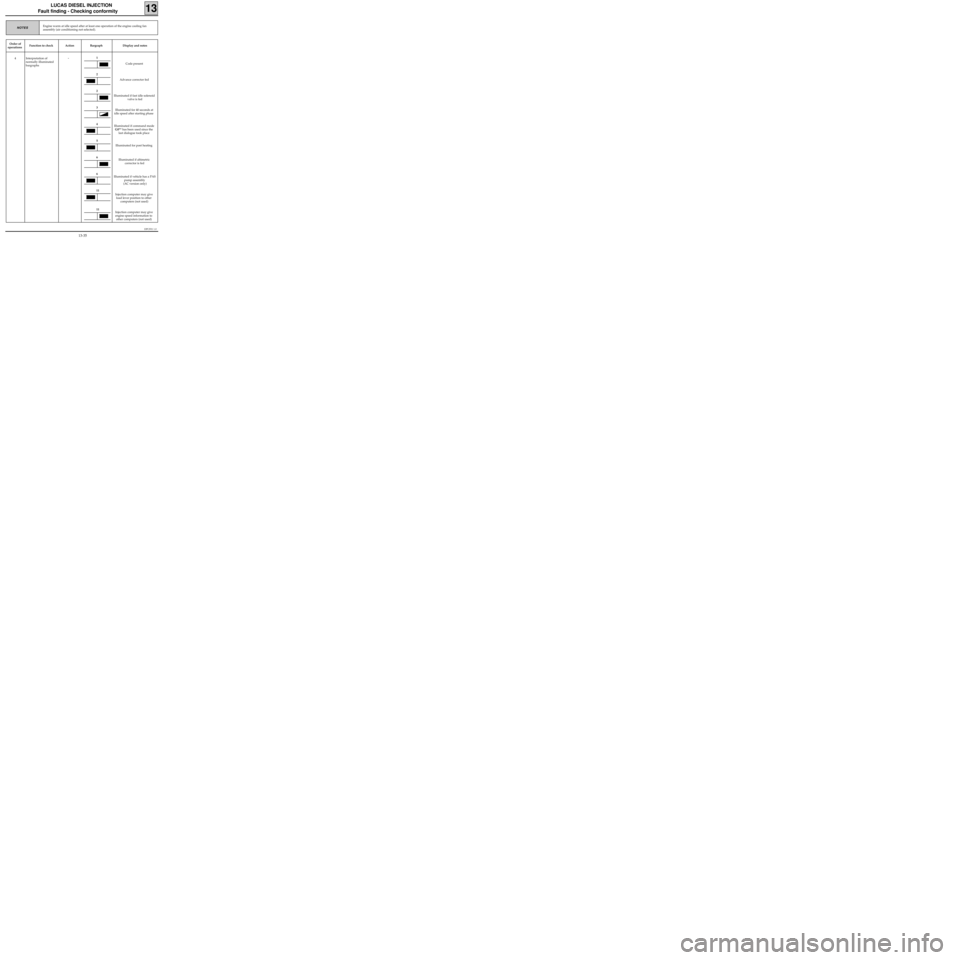

Order of

operationsFunction to check Action Bargraph Display and notes

4 Interpretation of

normally illuminated

bargraphs

-

Code present

Advance corrector fed

Illuminated if fast idle solenoid

valve is fed

Illuminated for 40 seconds at

idle speed after starting phase

Illuminated if command mode

G0** has been used since the

last dialogue took place

Illuminated for post heating

Illuminated if altimetric

corrector is fed

Illuminated if vehicle has a PAS

pump assembly

(AC version only)

Injection computer may give

load lever position to other

computers (not used)

Injection computer may give

engine speed information to

other computers (not used)1

2

2

3

4

5

6

6

11

11

13-35

Page 40 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

Fault finding - Checking conformity

13

Engine warm at idle speed after at least one operation of the engine cooling fan

assembly (air conditioning not selected).NOTES

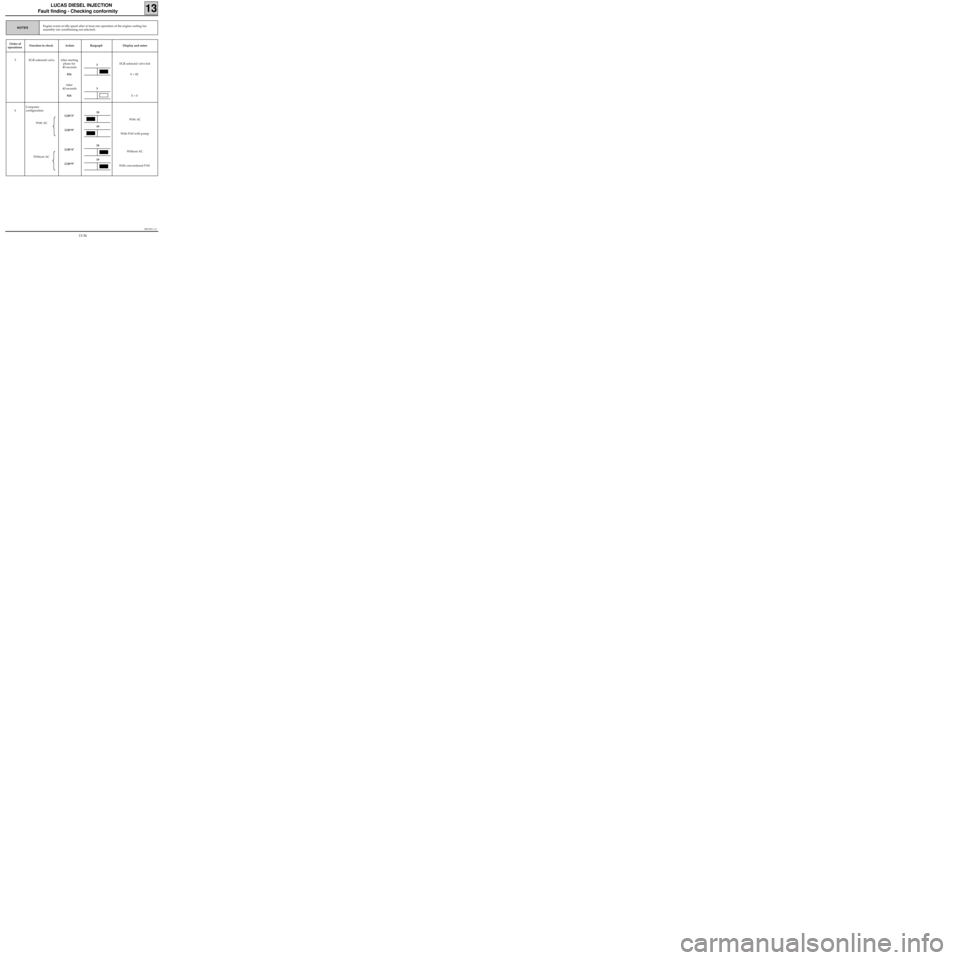

Order of

operationsFunction to check Action Bargraph Display and notes

5 EGR solenoid valve After starting

phase for

40 seconds

#24

After

40 seconds

#24EGR solenoid valve fed

X = 82

X = 0

6Computer

configuration

With AC

Without ACG50*3*

G50*8*

G50*4*

G50*9*With AC

With PAS with pump

Without AC

With conventional PAS

3

3

18

18

19

19

13-36

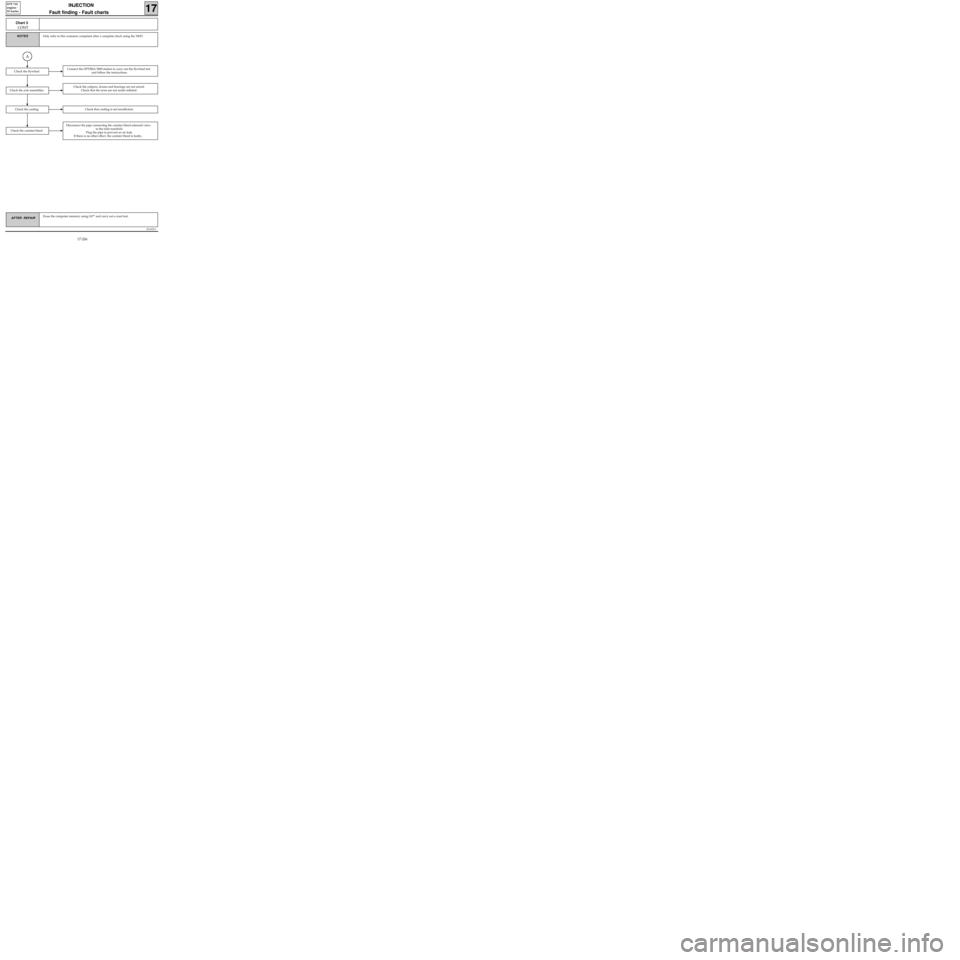

Page 109 of 363

JF5111.0

INJECTION

Fault finding - Fault charts

17

E7J 780

engine

AFTER REPAIRErase the computer memory using G0** and carry out a road test.

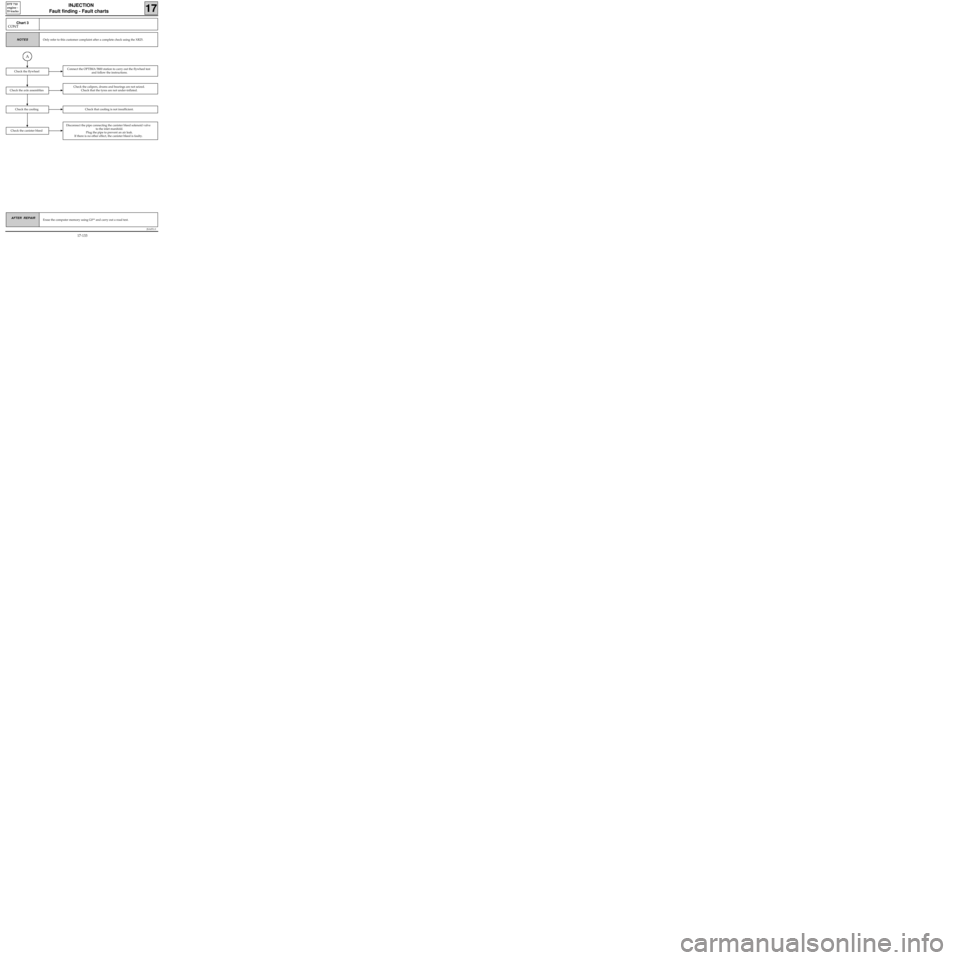

Chart 3

SUITE

Only refer to this customer complaint after a complete check using the XR25.NOTES

Check the calipers, drums and bearings are not seized.

Check that the tyres are not under-inflated.

Check the coolingCheck that cooling is not insufficient.

Check the canister bleed

Disconnect the pipe connecting the canister bleed solenoid valve

to the inlet manifold.

Plug the pipe to prevent an air leak.

If there is no other effect, the canister bleed is faulty.

Check the axle assemblies

A

Connect the OPTIMA 5800 station to carry out the flywheel test

and follow the instructions.Check the flywheel

17-61

Page 178 of 363

JSA051.0

INJECTION

Fault finding - Fault charts

17

D7F 710

engine -

35 tracks

AFTER REPAIRErase the computer memory using G0** and carry out a road test.

Chart 3

CONT

Only refer to this customer complaint after a complete check using the XR25.NOTES

Check the calipers, drums and bearings are not seized.

Check that the tyres are not under-inflated.

Check the coolingCheck that cooling is not insufficient.

Check the canister bleed

Disconnect the pipe connecting the canister bleed solenoid valve

to the inlet manifold.

Plug the pipe to prevent an air leak.

If there is no other effect, the canister bleed is faulty.

Check the axle assemblies

A

Connect the OPTIMA 5800 station to carry out the flywheel test

and follow the instructions.Check the flywheel

17-133

Page 249 of 363

JSA052.0

INJECTION

Fault finding - Fault charts

17

D7F 710

engine -

55 tracks

AFTER REPAIRErase the computer memory using G0** and carry out a road test.

Chart 3

CONT

Only refer to this customer complaint after a complete check using the XR25.NOTES

Check the calipers, drums and bearings are not seized.

Check that the tyres are not under inflated.

Check the coolingCheck that cooling is not insufficient.

Check the canister bleed

Disconnect the pipe connecting the canister bleed solenoid valve

to the inlet manifold.

Plug the pipe to prevent an air leak.

If there is no other effect, the canister bleed is faulty..

Check the axle assemblies

A

Connect the OPTIMA 5800 station to carry out the flywheel test

and follow the instructions.Check the flywheel

17-206