heating RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 24 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

Fault finding - Interpretation of XR25 bargraphs13

AFTER REPAIRErase the computer memory (G0**), switch the ignition off, then carry out a road

test.

Finish the operation by checking using the XR25.

Bargraph 8 LH illuminated (co.0) or flashing (cc.1)

Preheating relay N° 1 control circuit

XR25 aid:*08 :co.0 : Open circuit or short circuit to earth

cc.1 : Short circuit to 12 volts

8

Use bornier Elé. 1332 for any operations on the computer connector.NOTES

co.0

Ensure the continuity and insulation in relation to earth of the connection between track 14 on the

computer connector and track B1 on the relay unit connector.

Ensure the presence of + after ignition feed on track A1 on the relay unit connector.

Test the connections on the 2 connectors.

None NOTES

If the fault persists after these tests, replace the relay unit.

If the "preheating relay No. 1 control circuit" fault reappears, replace the computer (consult the "Aid"

section for this operation).

cc.1

Ensure insulation in relation to 12 volts of the connection between track 14 on the computer connector

and track B1 on the relay unit connector.

Test the connections on the 2 connectors.

Even if present at the moment of testing, this fault is still declared

by a flashing BG 8LH side. To confirm its presence and the necessity

of following the fault finding below, erase the computer memory

then start command mode G10*1*.

The fault is present if the bargraph flashes again.

NOTES

If the fault persists after these tests, replace the relay unit.

If the "preheating relay No. 1 control circuit" fault reappears, replace the computer (consult the "Aid"

section for this operation).

Fiche n° 60 1/2

13-20

Page 27 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

Fault finding - Interpretation of XR25 bargraphs13

AFTER REPAIRErase the computer memory (G0**), switch the ignition off, then carry out a road

test.

Finish the operation by checking using the XR25.

Bargraph 10 RH illuminated (Co.0) or flashing (cc.1)

Preheating warning light circuit

XR25 aid:*30 :cc.0 : Open circuit or short circuit to earth

cc.1 : Short circuit to 12 volts

10Fiche n° 60 1/2

co.0

Check the condition of the preheating warning light bulb then the presence of +after ignition feed at

the warning light.

Ensure the continuity and insulation in relation to earth of the connection between track 9 of the

computer connector and the instrument panel preheating warning light (track 5 on CY connector).

Test the connections on the computer connector.

None NOTES

cc.1

Ensure insulation in relation to 12 volts of the connection between track 9 of the computer connector

and the instrument panel preheating warning light (track 5 on connector CY).

Test at the preheating warning light bulb (bulb in short circuit).

Use bornier Elé. 1332 for any operations on the computer connector.NOTES

Even if present at the moment of testing, this fault is still declared

by a flashing BG 10RH side. To confirm its presence and the necessity

of following the fault finding below, erase the computer memory

then start command mode G21*2*.

The fault is present if the bargraph flashes again.

NOTES

13-23

Page 31 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

Fault finding - Interpretation of XR25 bargraphs13

AFTER REPAIR

Bargraphs 2 RH and LH sides and bargraph 3 RH side

Solenoid valve control2

None NOTES

These bargraphs visualise the control of the various solenoid valves:

- Advance solenoid valve (bargraph 2 LH side is always illuminated).

- Fast idle solenoid valve .

- EGR solenoid valve.

Fiche n° 60 2/2

3

Ensure the bargraphs operate correctly

Bargraph 4 LH side

Erase stored faults

XR25 aid :BG 4LH is illuminated if command mode G0** to erase the memory

has been used since the last XR25 dialogue began.

4Fiche n° 60 2/2

None

NOTES

Bargraph 4 RH side

Preheating prevented

XR25 aid :BG 4RH is illuminated if command mode G59*1* to prevent control

of the heater plugs has been used since the last XR25 dialogue be-

gan.

4Fiche n° 60 2/2

None

NOTES

13-27

Page 32 of 363

Bargraphs 9 RH and 9 LH side

Air conditioning

XR25 aid :BG 9LH illuminated if AC requested

BG 9RH illuminated if AC authorised

DPCF01 1.0

LUCAS DIESEL INJECTION

Fault finding - Interpretation of XR25 bargraphs13

AFTER REPAIR

Bargraphs 5 and 6 RH and LH sides

Relay control5

None NOTES

These bargraphs visualise the control of the various relays:

- Preheating relay N° 1.

- Preheating relay N° 2 (not used).

- Power assisted steering pump assembly relay (for AC + PAS).

- Altimetric corrector relay.

Fiche n° 60 2/2

6

Ensure the bargraphs operate correctly

9Fiche n° 60 2/2

If

BG 9LH is extinguished when AC is requested, ensure the continuity and insula-

tion of the connection between track 11 of the diesel computer connector and

track 20 of the AC computer connector.

NOTES

Bargraph 10 LH side

Warning light control

XR25 aid :BG 10LH is illuminated if the warning light on the instrument panel

is controlled. This bargraph is normally illuminated; it extinguishes

when the engine is running if there is no fault.

10Fiche n° 60 2/2

None

NOTES

13-28

Page 33 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

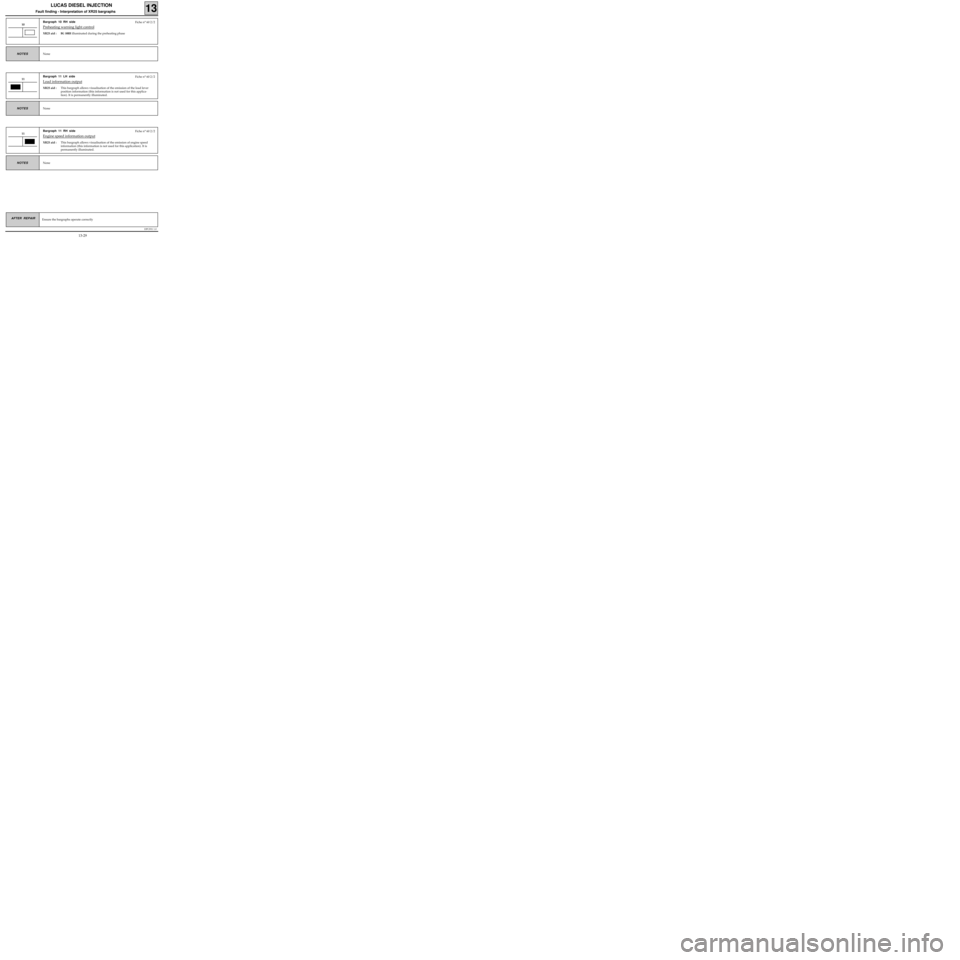

Fault finding - Interpretation of XR25 bargraphs13

AFTER REPAIREnsure the bargraphs operate correctly

Bargraph 10 RH side

Preheating warning light control

XR25 aid :BG 10RH illuminated during the preheating phase

10Fiche n° 60 2/2

None

NOTES

Fiche n° 60 2/2

Bargraph 11 LH side

Load information output

XR25 aid :This bargraph allows visualisation of the emission of the load lever

position information (this information is not used for this applica-

tion). It is permanently illuminated.

11Fiche n° 60 2/2

None

NOTES

Bargraph 11 RH side

Engine speed information output

XR25 aid :This bargraph allows visualisation of the emission of engine speed

information (this information is not used for this application). It is

permanently illuminated.

11Fiche n° 60 2/2

None NOTES

13-29

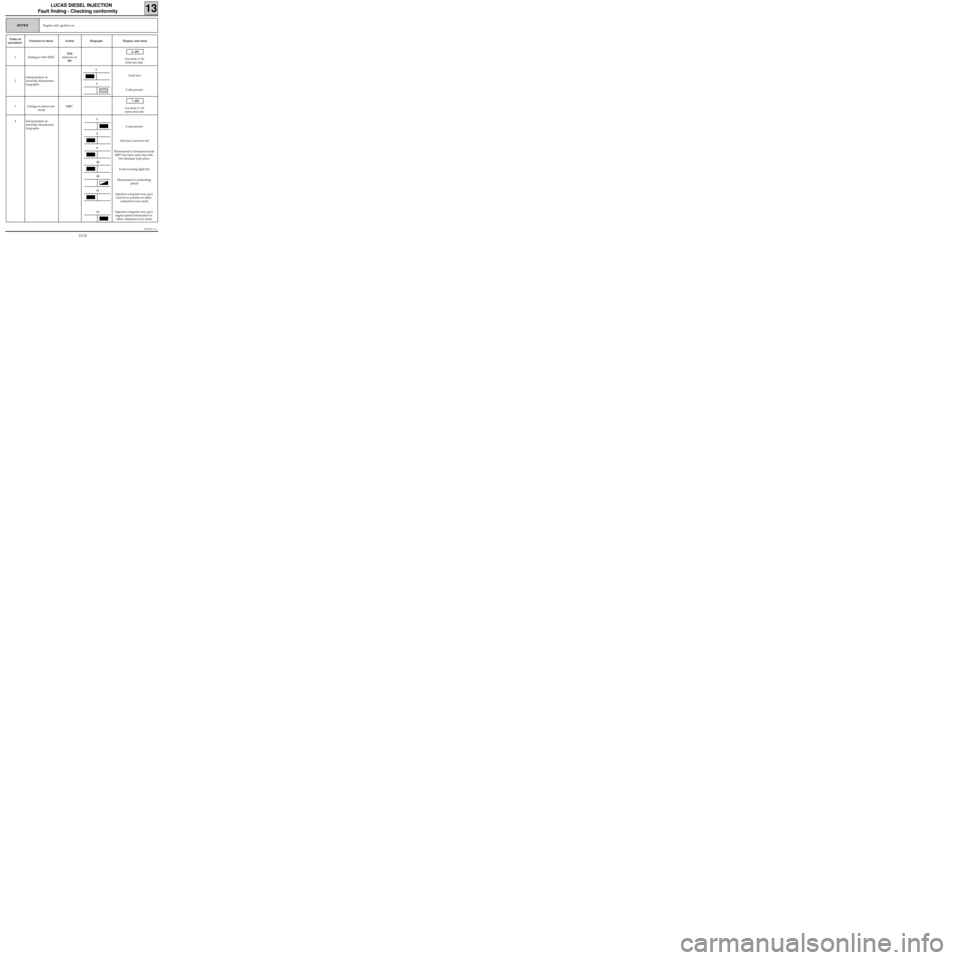

Page 36 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

Fault finding - Checking conformity

13

Engine cold, ignition onNOTES

Order of

operationsFunction to check Action Bargraph Display and notes

1 Dialogue with XR25D34

(selector on

S8) 6. dlE

Use fiche n° 60

fault test side

2Interpretation of

normally illuminated

bargraphs Fault test

Code present

3 Change to status test

modeG01* 7. dlE

Use fiche n° 60

status test side

4 Interpretation of

normally illuminated

bargraphs

Code present

Advance corrector fed

Illuminated if command mode

G0** has been used since the

last dialogue took place

Fault warning light fed

Illuminated in preheating

phase

Injection computer may give

load lever position to other

computers (not used)

Injection computer may give

engine speed information to

other computers (not used)

1

1

1

2

11

4

11

10

10

13-32

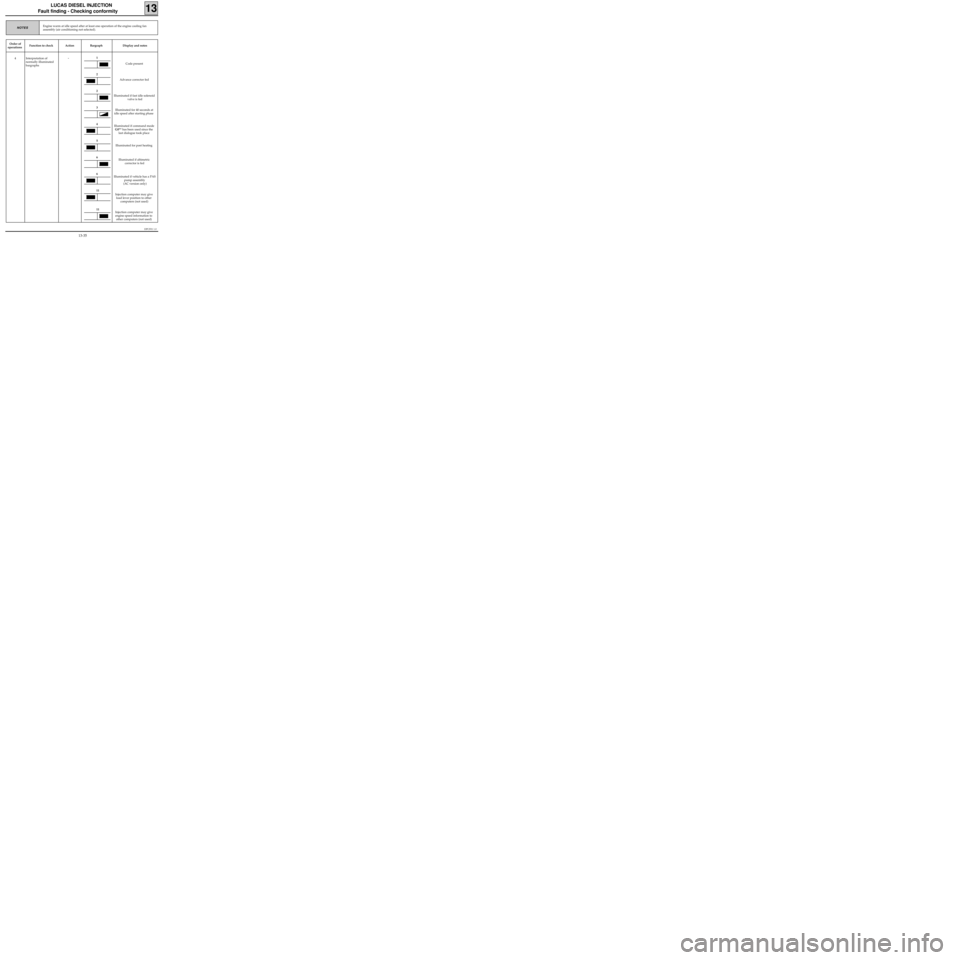

Page 39 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

Fault finding - Checking conformity

13

Engine warm at idle speed after at least one operation of the engine cooling fan

assembly (air conditioning not selected).NOTES

Order of

operationsFunction to check Action Bargraph Display and notes

4 Interpretation of

normally illuminated

bargraphs

-

Code present

Advance corrector fed

Illuminated if fast idle solenoid

valve is fed

Illuminated for 40 seconds at

idle speed after starting phase

Illuminated if command mode

G0** has been used since the

last dialogue took place

Illuminated for post heating

Illuminated if altimetric

corrector is fed

Illuminated if vehicle has a PAS

pump assembly

(AC version only)

Injection computer may give

load lever position to other

computers (not used)

Injection computer may give

engine speed information to

other computers (not used)1

2

2

3

4

5

6

6

11

11

13-35

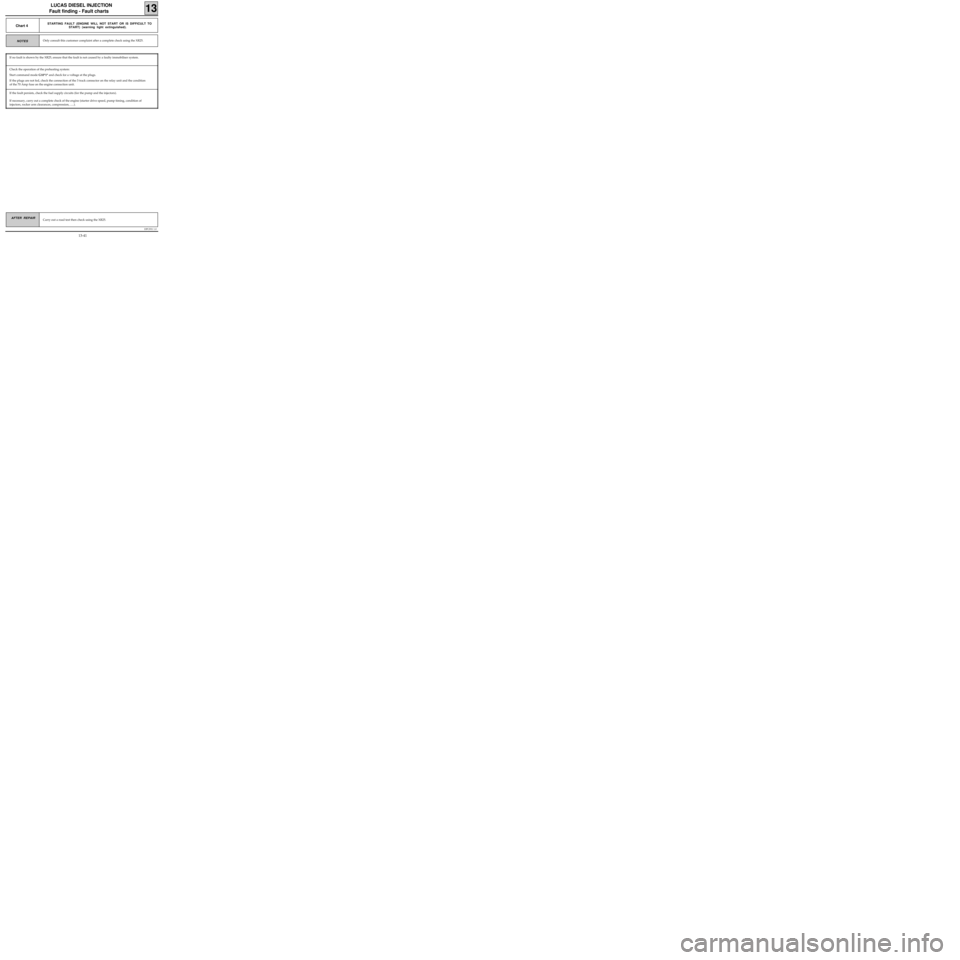

Page 45 of 363

DPCF01 1.0

LUCAS DIESEL INJECTION

Fault finding - Fault charts

13

Carry out a road test then check using the XR25.AFTER REPAIR

If the fault persists, check the fuel supply circuits (for the pump and the injectors).

If necessary, carry out a complete check of the engine (starter drive speed, pump timing, condition of

injectors, rocker arm clearances, compression, .....).NOTES

Chart 4STARTING FAULT (ENGINE WILL NOT START OR IS DIFFICULT TO

START) (warning light extinguished).

Only consult this customer complaint after a complete check using the XR25.

If no fault is shown by the XR25, ensure that the fault is not caused by a faulty immobiliser system.

Check the operation of the preheating system:

Start command mode G10*1* and check for a voltage at the plugs.

If the plugs are not fed, check the connection of the 3 track connector on the relay unit and the condition

of the 70 Amp fuse on the engine connection unit.

13-41

Page 98 of 363

JF5111.0

INJECTION

Fault finding - Status and parameter interpretation17

E7J 780

engine

AFTER REPAIRStart the status and parameter check again from the beginning.

NOTES

DIAG 15

Fiche n° 27

EMISSION OF POLLUTANTS

XR25 aid:None

No fault bargraphs should be illuminated.NOTES

0.97 ≤ λ ≤ 1.03

at 2500 rpm.The oxygen sensor loops correctly at 2500 rpm.

If CO > 0.3 % at 2500 rpm.

NOTES 0.97 ≤ λ ≤ 1.03

at 2500 rpm.The oxygen sensor does not loop correctly at 2500 rpm.

There is a fault with the injection or the sensor.

The catalytic converter is faulty.

NOTE : it is vital to determine the cause of the catalytic converter damage to

avoid a new converter also being damaged.

If λ < 0.97 or λ > 1.03 at idle speed

Check the sensor earth and heating.

Check there is no air leak at the manifold.

17-50

Page 110 of 363

JF5111.0

INJECTION

Fault finding -Aid

17

E7J 780

engine

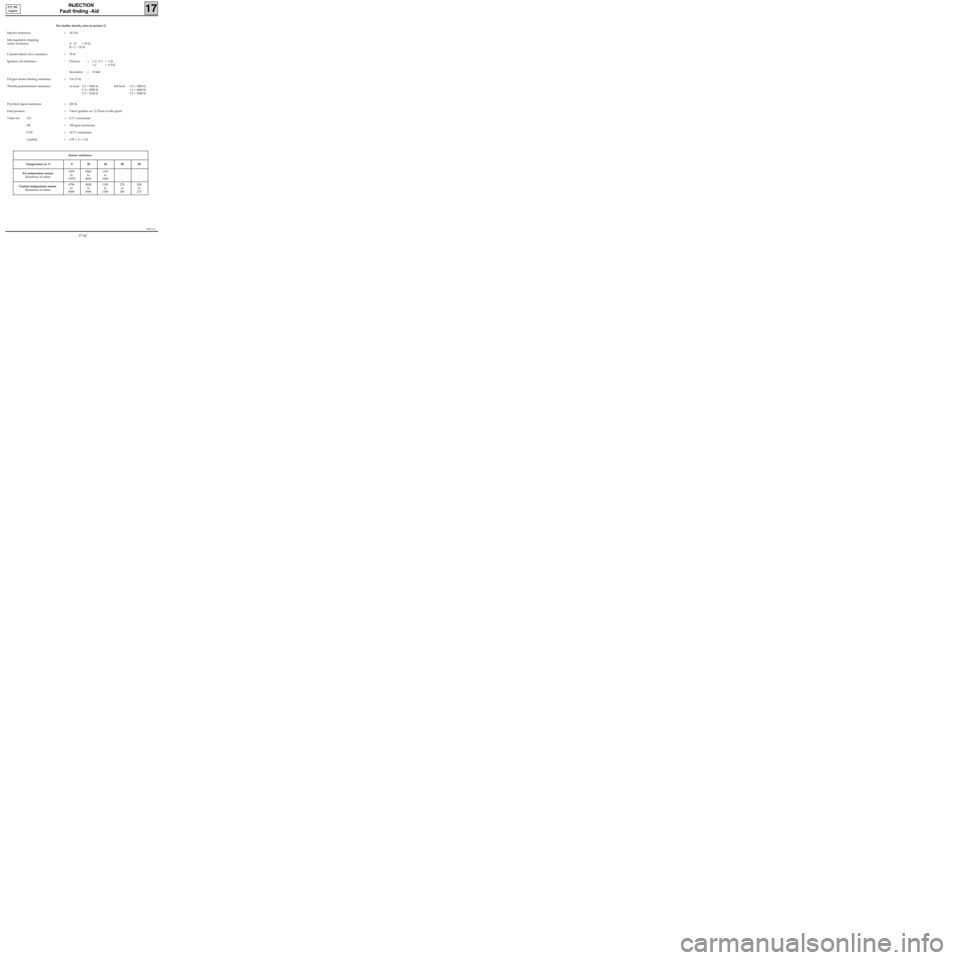

For further details, refer to section 12

Injector resistance = 14.5 Ω

Idle regulation stepping

motor resistance : A - D = 52 Ω

B - C = 52 Ω

Canister bleed valve resistance = 35 Ω

Ignition coil resistance : Primary = 1-3 ; 2-3 = 1 Ω

1-2 = 0.5 Ω

Secondary = 10 kΩ

Oxygen sensor heating resistance = 3 to 15 Ω

Throttle potentiometer resistance : no load 1-2 = 5440 Ωfull load 1-2 = 2200 Ω

1-3 = 4500 Ω1-3 = 4460 Ω

2-3 = 2160 Ω2-3 = 5340 Ω

Flywheel signal resistance = 220 Ω

Fuel pressure = 3 bars ignition on/ 2.5 bars at idle speed

Value for: CO = 0.3 % maximum

HC = 100 ppm maximum

CO2 = 14.5 % minimum

Lambda = 0.97 < λ < 1.03

Sensor resistance

Temperature in °C 0 20 40 80 90

Air temperature sensor

Resistance in ohms7470

to

119703060

to

40451315

to

1600--

Coolant temperature sensor

Resistance in ohms6700

to

80002600

to

30001100

to

1300270

to

300200

to

215

17-62