sensor RENAULT SCENIC 2007 J84 / 2.G Automatic Transmission Siemens TA2005 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2007, Model line: SCENIC, Model: RENAULT SCENIC 2007 J84 / 2.GPages: 139, PDF Size: 0.43 MB

Page 44 of 139

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A-44V5 MR-372-J84-23A100$348.mif

SIEMENS TA2005

Vdiag No.: 14-18

DF113

CONTINUED

If the line pressure recorded under one of these 3 conditions is incorrect, replace the line pressure sensor.

If the line pressures recorded under these 3 conditions are good, then the pressure sensor is operating correctly.

Replace the pressure regulating solenoid valve.

If the fault is still present after the pressure regulating solenoid valve has been replaced, replace the hydraulic

distributor and during refitting, take into account Technical Note 4194A Automatic transmission indicator strip

flashing for the adjustment of the ball detent blade

If the fault is still present, contact the Techline

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

Page 45 of 139

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A-45V5 MR-372-J84-23A100$348.mif

SIEMENS TA2005

Vdiag No.: 14-18

DF131

PRESENT

OR

STOREDSLIPPAGE

1.DEF: Permanent low level

NOTESDeal with all other faults first.

Conditions for applying the fault finding procedure to stored faults:

Safe mode is triggered after a fault, not by the driver.

In particular, check that there are no faults on:

–the turbine speed sensor, DF244 Turbine speed sensor signal.

–the vehicle speed signal, DF230 Invalid vehicle speed multiplex signal.

Check that PR003 “Oil pressure” equals 21 bar. (forced setpoint)

Possible defective components:

Slave cylinder (brakes, clutch) or computer.

Then check cleanliness and condition of the gearbox oil.

If the fault is still present, contact Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

DP0TA2005_V14_DF131/DP0TA2005_V18_DF131

Page 48 of 139

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A-48V5 MR-372-J84-23A100$348.mif

SIEMENS TA2005

Vdiag No.: 14-18

DF177

PRESENT

OR

STOREDAUTOMATIC TRANSMISSION OVERHEATING

NOTESIf the following faults are present or stored, deal with them first:

–DF003 Analogue sensor supply.

–DF005 Oil pressure sensor circuit.

–DF016 Lock-up solenoid valve circuit.

–DF017 Exchanger flow solenoid valve circuit.

–DF023 Gearbox oil temperature sensor circuit.

–DF036 Pressure modulating solenoid valve circuit.

–DF131 Slipping.

–DF226 Automatic transmission internal pressure.

–DF237 Invalid coolant temperature signal.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after a road test.

Check gearbox oil grade and level.

If an operation is necessary (see MR 364 Mechanical, 23A, Automatic transmission, Filling - levels

(for Mégane II) and MR 370 Mechanical, 23A, Automatic transmission, Oil change (for Scenic II)).

Check that the water-oil exchanger is not blocked.

Measure the resistance of component 754 between the following connections:

●connection code 5BC,

●connection code 5BB.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring. Otherwise replace the wiring.

The resistance should be between:

2660 Ω < R < 2360 Ω at 20˚C and 327 Ω < R < 290 Ω at 80˚C.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

DP0TA2005_V14_DF177/DP0TA2005_V18_DF177

Page 52 of 139

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A-52V5 MR-372-J84-23A100$406.mif

SIEMENS TA2005

Vdiag No.: 14-18

DF226

PRESENT

OR

STOREDAUTOMATIC TRANSMISSION INTERNAL PRESSURE

NOTESIf the following faults are present or stored, deal with them first:

–DF003 Sensor feeds.

–DF005 Oil pressure sensor circuit.

–DF023 Gearbox oil temperature sensor circuit.

–DF036 Pressure modulating solenoid valve circuit.

–DF244 Turbine speed sensor signal

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after a road test.

Check the gearbox oil grade and level (see MR 364 Mechanical, 23A, Automatic transmission, Filling - levels

(for Mégane II) and MR 370 Mechanical, 23A, Automatic transmission, Oil change (for Scénic II)).

Check that the gearbox is not leaking oil

To locate the cap position, consult MR 364, Mechanical, 23A, Automatic transmission, Line pressure

measurement (for Mégane II) and MR 370, Mechanical, 23A, Automatic transmission, Line pressure

measurement (for Scénic II)).

Check the oil pressure with the engine switched off using PR003 Oil pressure: if the pressure is greater than

0.2 bars, replace the pressure sensor.

●Warm engine with gearbox oil temperature between 65 and 90˚C.

●Measure the line pressure under the 3 following conditions:

IMPORTANT

The vehicle must be stationary: handbrake on and brake pedal depressed, no accessories operating (e.g.:

air conditioning)

1engine speed idling:

Shift the gear lever to R, N and D, the pressure reading must be greater than 2.5 bar.

2engine speed at 1200 rpm:

–gear lever in R position, the pressure reading must be greater than 4 bar.

–gear lever in D position, the pressure reading in first gear must be greater than 5.5 bar.

3engine speed at 2200 rpm:

–gear lever in R position, the pressure reading must be greater than 11 bar.

–gear lever in D position, the pressure reading in first gear must be greater than 11 bar.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

DP0TA2005_V14_DF226/DP0TA2005_V18_DF226

Page 53 of 139

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A-53V5 MR-372-J84-23A100$406.mif

SIEMENS TA2005

Vdiag No.: 14-18

DF226

CONTINUED

If the line pressure recorded under one of these 3 conditions is incorrect, replace the line pressure sensor.

If the line pressures recorded under these 3 conditions are good, then the pressure sensor is operating correctly.

Replace the pressure regulating solenoid valve.

If the fault is still present after the pressure regulating solenoid valve has been replaced, replace the hydraulic

distributor and during refitting, take into account Technical Note 4194A Automatic transmission indicator strip

flashing for the adjustment of the ball detent blade

If the fault is still present, contact the Techline

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

1

Page 71 of 139

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A-71V5 MR-372-J84-23A100$406.mif

SIEMENS TA2005

Vdiag No.: 14-18

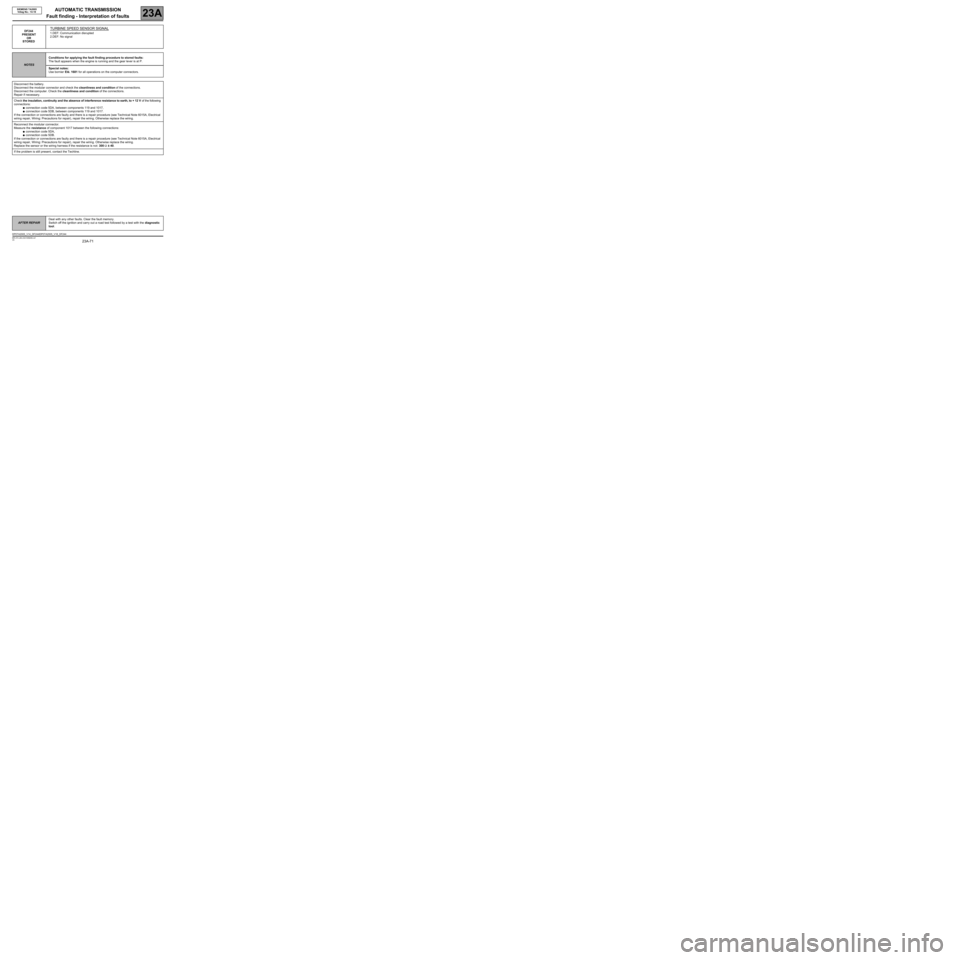

DF244

PRESENT

OR

STOREDTURBINE SPEED SENSOR SIGNAL

1.DEF: Communication disrupted

2.DEF: No signal

NOTESConditions for applying the fault finding procedure to stored faults:

The fault appears when the engine is running and the gear lever is at P.

Special notes:

Use bornier Elé. 1681 for all operations on the computer connectors.

Disconnect the battery.

Disconnect the modular connector and check the cleanliness and condition of the connections.

Disconnect the computer. Check the cleanliness and condition of the connections.

Repair if necessary.

Check the insulation, continuity and the absence of interference resistance to earth, to + 12 V of the following

connections:

●connection code 5DA, between components 119 and 1017,

●connection code 5DB, between components 119 and 1017.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring. Otherwise replace the wiring.

Reconnect the modular connector.

Measure the resistance of component 1017 between the following connections:

●connection code 5DA,

●connection code 5DB.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring. Otherwise replace the wiring.

Replace the sensor or the wiring harness if the resistance is not: 300 Ω ± 40.

If the problem is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

DP0TA2005_V14_DF244/DP0TA2005_V18_DF244

Page 79 of 139

AUTOMATIC TRANSMISSION

Fault finding - Conformity check

23A

23A - 79V5 MR-372-J84-23A100$464.mif

SIEMENS TA2005

Vdiag No.: 14-18

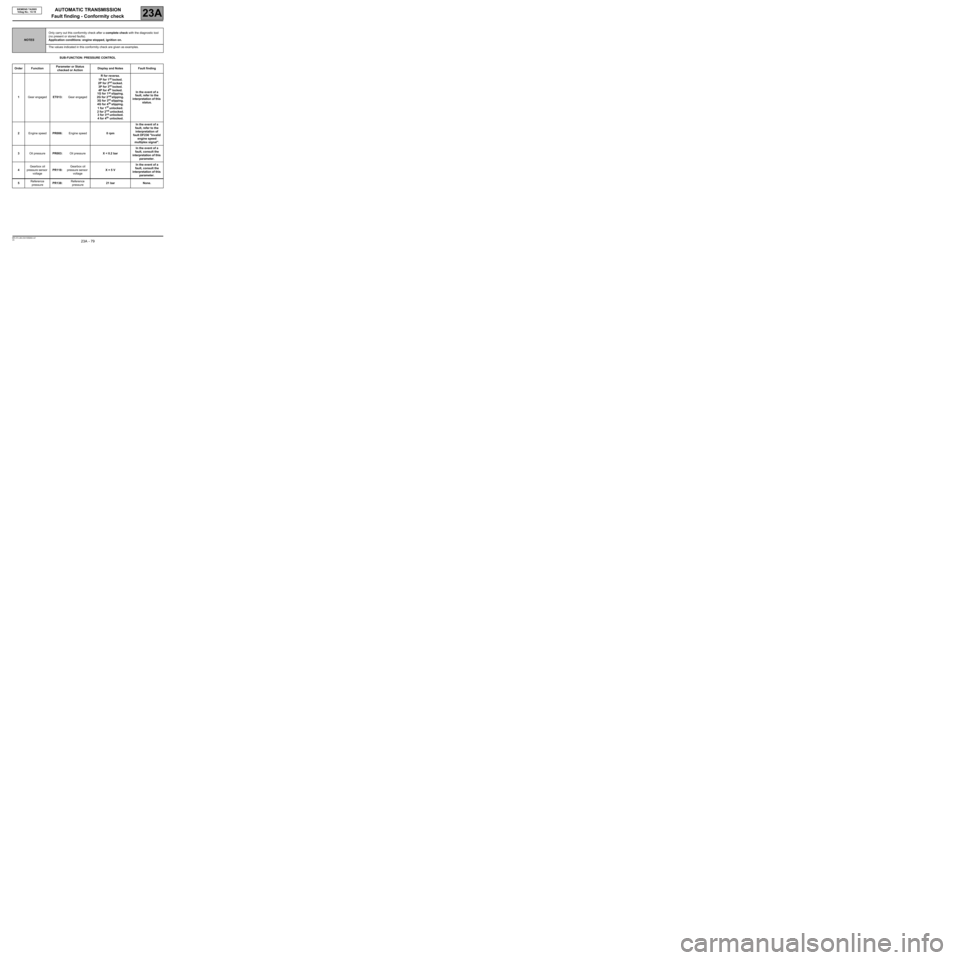

SUB-FUNCTION: PRESSURE CONTROL

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(no present or stored faults).

Application conditions: engine stopped, ignition on.

The values indicated in this conformity check are given as examples.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Gear engagedET013:Gear engagedR for reverse.

1P for 1

st locked.

2P for 2nd locked.

3P for 3rd locked.

4P for 4th locked.

1G for 1st slipping.

2G for 2nd slipping.

3G for 3rd slipping.

4G for 4th slipping.

1 for 1st unlocked.

2 for 2nd unlocked.

3 for 3rd unlocked.

4 for 4th unlocked.In the event of a

fault, refer to the

interpretation of this

status.

2Engine speedPR006:Engine speed0 rpmIn the event of a

fault, refer to the

interpretation of

fault DF236 "Invalid

engine speed

multiplex signal".

3Oil pressurePR003:Oil pressureX < 0.2 barIn the event of a

fault, consult the

interpretation of this

parameter.

4Gearbox oil

pressure sensor

voltagePR118:Gearbox oil

pressure sensor

voltageX = 5 VIn the event of a

fault, consult the

interpretation of this

parameter.

5Reference

pressurePR138:Reference

pressure21 bar None.

Page 83 of 139

AUTOMATIC TRANSMISSION

Fault finding - Conformity check

23A

23A - 83V5 MR-372-J84-23A100$464.mif

SIEMENS TA2005

Vdiag No.: 14-18

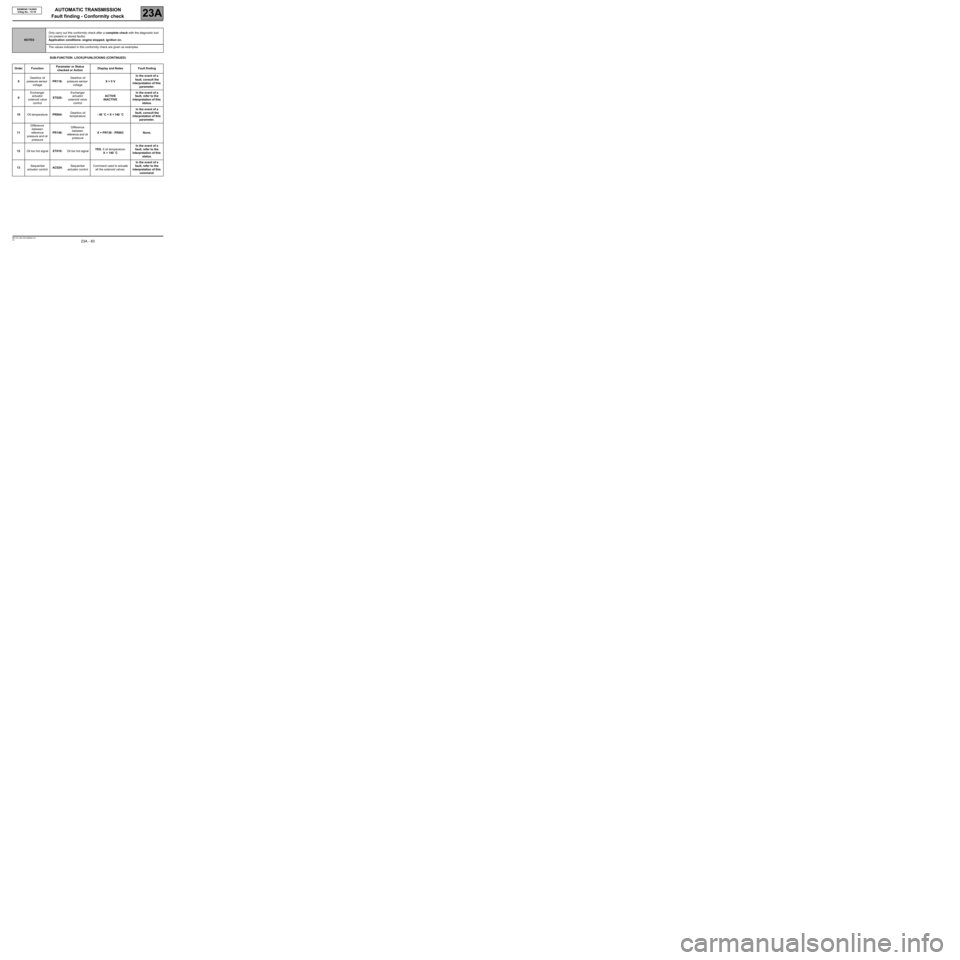

SUB-FUNCTION: LOCKUP/UNLOCKING (CONTINUED)

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(no present or stored faults).

Application conditions: engine stopped, ignition on.

The values indicated in this conformity check are given as examples.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

8Gearbox oil

pressure sensor

voltagePR118:Gearbox oil

pressure sensor

voltageX = 5 VIn the event of a

fault, consult the

interpretation of this

parameter.

9Exchanger

actuator

solenoid valve

control ET020:Exchanger

actuator

solenoid valve

controlACTIVE

INACTIVEIn the event of a

fault, refer to the

interpretation of this

status.

10Oil temperaturePR004:Gearbox oil

temperature- 40 ˚C < X < 140 ˚CIn the event of a

fault, consult the

interpretation of this

parameter.

11Difference

between

reference

pressure and oil

pressurePR146:Difference

between

reference and oil

pressureX = PR138 - PR003 None.

12Oil too hot signalET010:Oil too hot signalYES, if oil temperature:

X > 140 ˚CIn the event of a

fault, refer to the

interpretation of this

status.

13Sequential

actuator controlAC024:Sequential

actuator controlCommand used to actuate

all the solenoid valves.In the event of a

fault, refer to the

interpretation of this

command.

Page 108 of 139

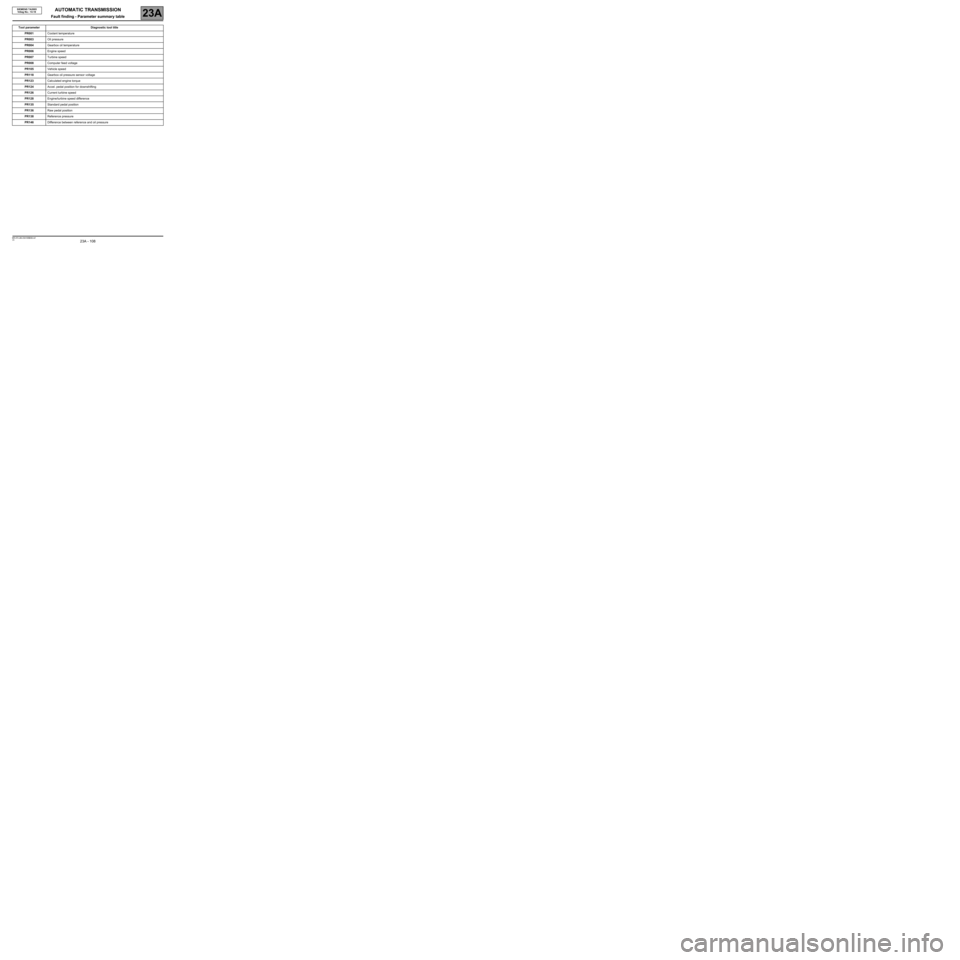

Fault finding - Parameter summary table23A

23A - 108V5 MR-372-J84-23A100$638.mif

SIEMENS TA2005

Vdiag No.: 14-18AUTOMATIC TRANSMISSION

Fault finding - Parameter summary table

Tool parameter Diagnostic tool title

PR001Coolant temperature

PR003Oil pressure

PR004Gearbox oil temperature

PR006Engine speed

PR007Turbine speed

PR008Computer feed voltage

PR105Vehicle speed

PR118Gearbox oil pressure sensor voltage

PR123Calculated engine torque

PR124Accel. pedal position for downshifting

PR126Current turbine speed

PR128Engine/turbine speed difference

PR135Standard pedal position

PR136Raw pedal position

PR138Reference pressure

PR146Difference between reference and oil pressure

MR-372-J84-23A100$638.mif

Page 116 of 139

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of parameters23A

23A - 116V5 MR-372-J84-23A100$696.mif

SIEMENS TA2005

Vdiag No.: 14-18

PR118

GEARBOX OIL PRESSURE SENSOR VOLTAGE

NOTESNo faults should be present or stored.

ELECTRICAL CONFORMITY OF THE SENSOR:

Check for continuity and absence of interference resistance on the following connections:

●connection code 5U, between components 119 and 781,

●connection code 5W, between components 119 and 781,

●connection code 5V, between components 119 and 781.

If any of the connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring

repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If all the connections are correct, check for + 5 V on connection 5U of component 781.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If all the connections are correct, check for earth on connection 5V of component 781.

If any of the connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring

repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRRepeat the conformity check from the start.

DP0TA2005_V14_PR118/DP0TA2005_V18_PR118