sensor RENAULT SCENIC 2007 J84 / 2.G Automatic Transmission Siemens TA2005 Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2007, Model line: SCENIC, Model: RENAULT SCENIC 2007 J84 / 2.GPages: 139, PDF Size: 0.43 MB

Page 119 of 139

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of parameters23A

23A - 119V5 MR-372-J84-23A100$696.mif

SIEMENS TA2005

Vdiag No.: 14-18

PR126

CURRENT TURBINE SPEED

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the turbine speed sensor and its connections.

Check the insulation, continuity and the absence of interference resistance to earth, to + 12 V and the

following connections:

●connection code 5DA, between components 119 and 1017,

●connection code 5DB, between components 119 and 1017.

If any of the connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring

repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the turbine speed on the diagnostic tool:

Gear lever position at N or P.

Oil temperature 43 ˚C: turbine speed ~ 681 rpm and engine speed: ~ 743 rpm.

Oil temperature 45 ˚C: turbine speed ~ 654 rpm and engine speed: ~ 743 rpm.

AFTER REPAIRRepeat the conformity check from the start.

DP0TA2005_V14_PR126/DP0TA2005_V18_PR126

Page 120 of 139

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of parameters23A

23A - 120V5 MR-372-J84-23A100$696.mif

SIEMENS TA2005

Vdiag No.: 14-18

PR128

ENGINE/TURBINE SPEED DIFFERENCE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the engine speed sensor and its connections.

Run a multiplex network test (see 88B, Multiplex).

After these checks, if parameter PR006 Engine speed is absent, refer to the interpretation of the parameter

(see 17B, Petrol injection or 13B, Diesel injection).

Check the cleanliness and condition of the turbine speed sensor and its connections.

This parameter is the difference between parameter PR006 Engine speed and parameter PR007 Turbine speed.

Check the engine/turbine speed difference with the diagnostic tool:

Engine idling:

Engine speed: ~ 743 rpm and turbine speed: ~ 654 rpmdifference = ~ 89 rpm.

AFTER REPAIRRepeat the conformity check from the start.

DP0TA2005_V14_PR128/DP0TA2005_V18_PR128

Page 128 of 139

Fault finding - Fault Finding Chart23A

23A -128V5 MR-372-J84-23A100$928.mif

SIEMENS TA2005

Vdiag No.: 14-18AUTOMATIC TRANSMISSION

Fault finding - Fault Finding Chart

ALP1 No dialogue with the computer

NOTESNone.

Try the diagnostic tool on another vehicle.

Check:

–the connection between the diagnostic tool and the diagnostic socket (connection and cable in good condition),

–the power supply to the computer,

–the engine and passenger compartment fuses.

Check that the CLIP sensor is supplied by connections BP32, MAN and NAM of component 225, displayed when

both red indicator lights on the sensor illuminate.

Make sure that the CLIP sensor is connected to the computer's USB port.

Make sure the CLIP sensor is communicating properly with the vehicle's computers; this can be seen by the two

green diodes on the sensor lighting up.

Check the following connections on component 225:

●connection code AP43 (+ after ignition feed),

●connection code BP32 (+ battery feed),

●connection code MAN (earth).

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring. Otherwise replace the wiring.

Disconnect the automatic transmission computer connector to check the insulation, continuity and the absence

of interference resistance of the following connections:

●connection code AP4, between components 119 and 1337,

●connection code BP42, between components 119 and 1337,

●connection code N, between components 119 and 107,

●connection code 3MT, between components 119 and 120,

●connection code 3MS, between components 119 and 120,

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring. Otherwise replace the wiring.

If the fault is still present, contact the Techline.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

DP0TA2005_V14_ALP01/DP0TA2005_V18_ALP01

MR-372-J84-23A100$928.mif

Page 130 of 139

AUTOMATIC TRANSMISSION

Fault finding - Fault Finding Chart23A

23A -130V5 MR-372-J84-23A100$928.mif

SIEMENS TA2005

Vdiag No.: 14-18

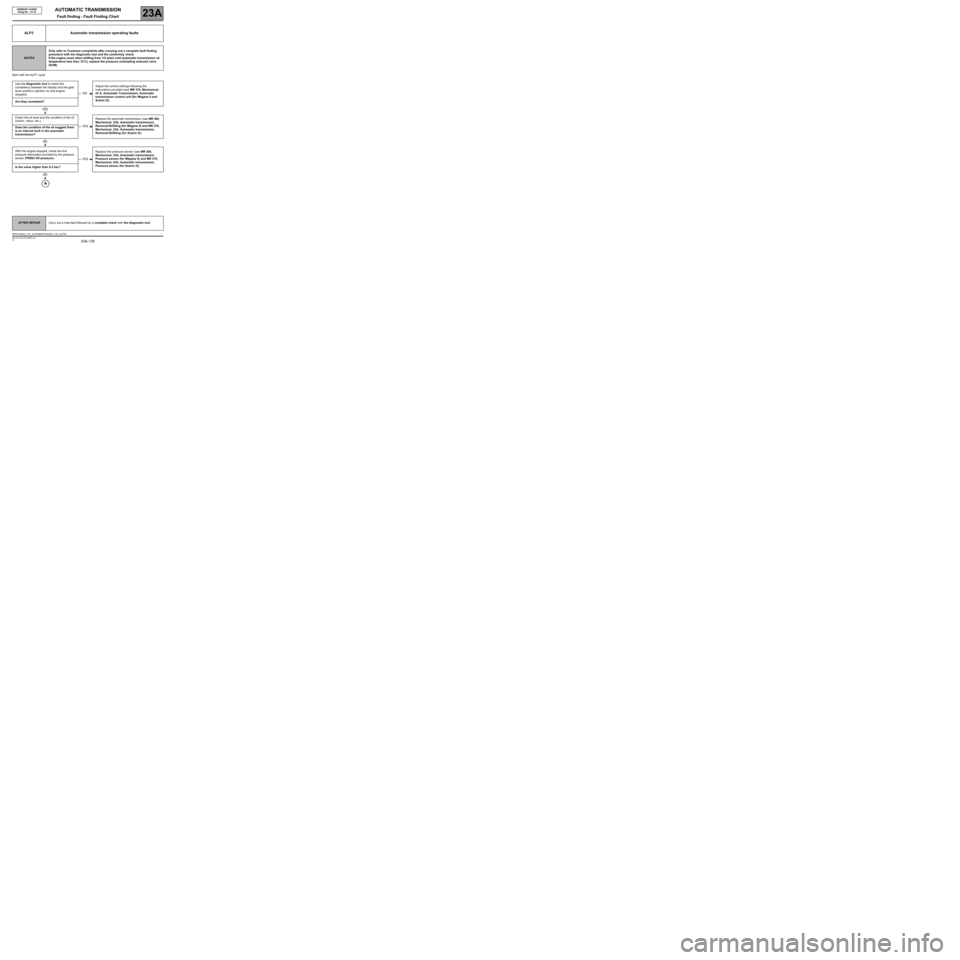

Start with the ALP1 cycle

ALP3 Automatic transmission operating faults

NOTESOnly refer to Customer complaints after carrying out a complete fault finding

procedure with the diagnostic tool and the conformity check.

If the engine races when shifting from 1/2 when cold (automatic transmission oil

temperature less than 15˚C), replace the pressure modulating solenoid valve

(EVM).

Use the diagnostic tool to check the

consistency between the display and the gear

lever positions (ignition on and engine

stopped).Adjust the control settings following the

instructions provided (see MR 370, Mechanical,

23 A, Automatic Transmission, Automatic

transmission control unit (for Mégane II and

Scénic II)).

Are they consistent?

Check the oil level and the condition of the oil

(colour, odour, etc.).Replace the automatic transmission (see MR 364,

Mechanical, 23A, Automatic transmission,

Removal-Refitting (for Mégane II) and MR 370,

Mechanical, 23A, Automatic transmission,

Removal-Refitting (for Scénic II)). Does the condition of the oil suggest there

is an internal fault in the automatic

transmission?

With the engine stopped, check the line

pressure information provided by the pressure

sensor (PR003 Oil pressure).Replace the pressure sensor (see MR 364,

Mechanical, 23A, Automatic transmission,

Pressure sensor (for Mégane II) and MR 370,

Mechanical, 23A, Automatic transmission,

Pressure sensor (for Scénic II)).

Is the value higher than 0.2 bar?

NO

YES

YES

NO

YES

NO

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

DP0TA2005_V14_ALP03/DP0TA2005_V18_ALP03