RENAULT SCENIC 2008 J84 / 2.G Automatic Transmission Siemens TA2000 Owners Manual

Manufacturer: RENAULT, Model Year: 2008, Model line: SCENIC, Model: RENAULT SCENIC 2008 J84 / 2.GPages: 128, PDF Size: 0.43 MB

Page 91 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of statuses23A

23A-91V4 MR-372-J84-23A050$594.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

ET071

TORQUE CONVERTER

NOTESThere must be no present or stored faults.

This indicates the status of the torque converter.

The status should be ACTIVE when the vehicle is driven with a gear engaged.

The status should be INACTIVE when starting, changing gears, or if the vehicle is stopped.

If the status does not function as specified, apply the interpretation of fault DF016 Converter lockup solenoid

valve circuit.

If the fault is still present, contact your Techline.

AFTER REPAIRRepeat the conformity check from the start.

Make sure that shifting up and down through each gear works properly.

DP0TA2000_V10_ET071/DP0TA2000_V11_ET071/DP0TA2000_V15_ET071

Page 92 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of statuses23A

23A-92V4 MR-372-J84-23A050$594.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

ET097

MANUAL MODE

NOTESThere must be no present or stored faults.

This status indicates the gear lever position.

This status displays ACTIVE when the gear lever is in position M, M+ or M-.

This status displays INACTIVE when the gear lever is in positions P, R, N or D.

If the correct status is not displayed, use the interpretation of fault DF093 Manual sequential controls circuits.

If the fault is still present, replace the sequential lever module.

If the fault is still present, contact your Techline.

AFTER REPAIRRepeat the conformity check from the start.

Make sure that shifting up and down through each gear works properly.

DP0TA2000_V10_ET097/DP0TA2000_V11_ET097/DP0TA2000_V15_ET097

Page 93 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of statuses23A

23A-93V4 MR-372-J84-23A050$594.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

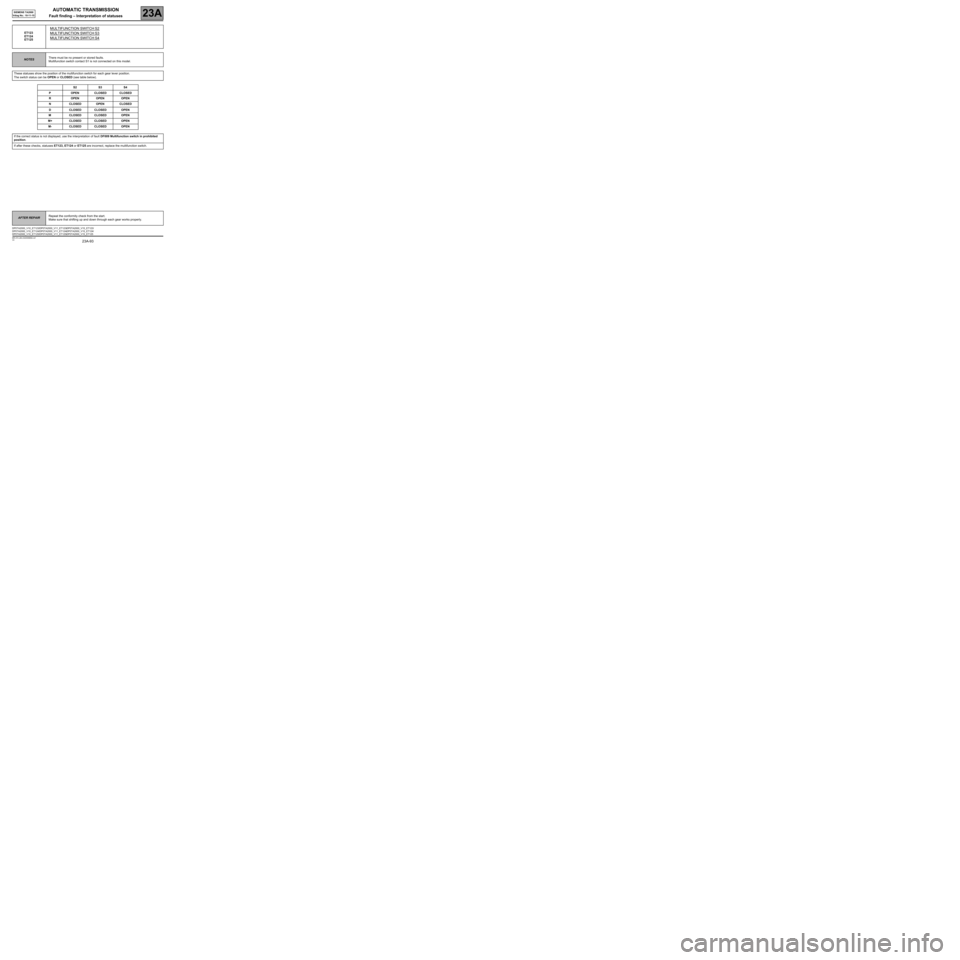

ET123

ET124

ET125

MULTIFUNCTION SWITCH S2

MULTIFUNCTION SWITCH S3

MULTIFUNCTION SWITCH S4

NOTESThere must be no present or stored faults.

Multifunction switch contact S1 is not connected on this model.

These statuses show the position of the multifunction switch for each gear lever position.

The switch status can be OPEN or CLOSED (see table below).

S2 S3 S4

POPEN CLOSED CLOSED

ROPEN OPEN OPEN

NCLOSED OPEN CLOSED

DCLOSED CLOSED OPEN

MCLOSED CLOSED OPEN

M+ CLOSED CLOSED OPEN

M- CLOSED CLOSED OPEN

If the correct status is not displayed, use the interpretation of fault DF009 Multifunction switch in prohibited

position.

If after these checks, statuses ET123, ET124 or ET125 are incorrect, replace the multifunction switch.

AFTER REPAIRRepeat the conformity check from the start.

Make sure that shifting up and down through each gear works properly.

DP0TA2000_V10_ET123/DP0TA2000_V11_ET123/DP0TA2000_V15_ET123/

DP0TA2000_V10_ET124/DP0TA2000_V11_ET124/DP0TA2000_V15_ET124/

DP0TA2000_V10_ET125/DP0TA2000_V11_ET125/DP0TA2000_V15_ET125

Page 94 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of statuses23A

23A-94V4 MR-372-J84-23A050$594.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

ET126

MULTIFUNCTION SWITCH P/N

NOTESThere must be no present or stored faults.

These indicate the status of the P/N multifunction switch contact for each gearshift position.

The switch status is "OPEN" or "CLOSED".

The status should be OPEN when the gear lever is in any position except P.

The status should be CLOSED when the gear lever is in position P.

If this status does not operate as indicated above, use the interpretation of fault DF054 Multifunction switch P/N

contact signal.

If the fault is still present, contact your Techline.

AFTER REPAIRRepeat the conformity check from the start.

Make sure that shifting up and down through each gear works properly.

DP0TA2000_V10_ET126/DP0TA2000_V11_ET126/DP0TA2000_V15_ET126

Page 95 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of statuses23A

23A-95V4 MR-372-J84-23A050$594.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

ET127

LOWER SEQUENTIAL LEVER SWITCH

NOTESThere must be no present or stored faults.

This indicates the status of the lower sequential lever switch.

This status displays ACTIVE with the gear lever in position M-.

This status displays INACTIVE with the gear lever in a position other than M-.

Check the sequential lever supply on the following connections:

●Check for + 12 V on connection AP43 of component 129.

●Check for the vehicle earth on connection N of component 129.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

With the gear lever in position M, measure the voltage of the following connections:

●Check for the vehicle earth on connection 5H of component 129.

●Check for the vehicle earth on connection 5FM of component 129.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If any of the measured values is + 12 V, replace the sequential lever

If the values are 0 V, check that the selector lever positions match those displayed on the instrument panel.

Repair if necessary.

If the correct status is not displayed, use the interpretation of fault DF093 Manual sequential controls circuits.

If the fault is still present, contact the Techline.

AFTER REPAIRRepeat the conformity check from the start.

DP0TA2000_V10_ET128

Page 96 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of statuses23A

23A-96V4 MR-372-J84-23A050$594.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

ET128

UPPER SEQUENTIAL LEVER SWITCH

NOTESThere must be no present or stored faults.

This indicates the status of the lower sequential lever switch.

This status displays ACTIVE with the gear lever in position M+.

This status displays INACTIVE with the gear lever in a position other than M+.

Check the sequential lever supply on the following connections:

●Check for + 12 V on connection AP43 of component 129.

●Check for the vehicle earth on connection N of component 129.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

With the gear lever in position M, measure the voltage of the following connections:

●Check for the vehicle earth on connection 5H of component 129.

●Check for the vehicle earth on connection 5FM of component 129.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If any of the measured values is + 12 V, replace the sequential lever

If the values are 0 V, check that the selector lever positions match those displayed on the instrument panel.

If the correct status is not displayed, use the interpretation of fault DF093 Manual sequential controls circuits.

If the fault is still present, contact the Techline.

AFTER REPAIRRepeat the conformity check from the start.

DP0TA2000_V10_ET128/DP0TA2000_V11_ET128/DP0TA2000_V15_ET128

Page 97 of 128

AUTOMATIC TRANSMISSION

Fault finding – Parameter summary table23A

23A - 97V4 MR-372-J84-23A050$660.mif

SIEMENS TA2000

Vdiag No.: 10-11-15AUTOMATIC TRANSMISSION

Fault finding – Parameter summary table

ET142

BRAKE PEDAL DEPRESSED

NOTESThere must be no present or stored faults.

This status indicates the position of the brake pedal

The status is YES when the brake pedal is pressed.

The status is NO when the brake pedal is not pressed.

If the status does not function as specified above, use the interpretation of fault DF119 Brake pedal position.

Disconnect the computer.

Check the cleanliness and condition of the connections.

Check the continuity, insulation and the absence of interference resistance on the following connections:

●Connection code 5A between components 119 and 160.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the brake sensor.

If the fault is still present, contact the Techline.

DP0TA2000_V10_ET142/DP0TA2000_V11_ET142/DP0TA2000_V15_ET142

MR-372-J84-23A050$660.mif

Page 98 of 128

AUTOMATIC TRANSMISSION

Fault finding – Parameter summary table23A

23A - 98V4 MR-372-J84-23A050$660.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

ET155

FIXED THIRD CONTACT

NOTESThe vehicle does not have a fixed 3rd (D3).

Ignore ET155 "Fixed third contact".

DP0TA2000_V10_ET155/DP0TA2000_V11_ET155/DP0TA2000_V15_ET155

Page 99 of 128

AUTOMATIC TRANSMISSION

Fault finding – Parameter summary table23A

23A - 99V4 MR-372-J84-23A050$660.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

ET157

GEAR LEVER UNLOCKING

NOTESThere must be no present or stored faults.

This status indicates whether or not the gear lever is unlocked.

Lever in position P.

The status is YES when the brake pedal is pressed.

The status is NO when the brake pedal is not pressed.

Lever in any position except P.

The status is YES whether or not the brake pedal is pressed.

Check that the instrument panel indicates that the lever is in position P.

Check that, when the brake pedal is pressed, the "Press brake pedal" message disappears from the instrument

panel.

Check the gear lever operation up to the multifunction switch.

Adjust the cable if necessary.

Check that statuses ET154, ET123, ET124 and ET125 Multifunction switch are correct.

If the correct status is not displayed, use the interpretation of fault DF095 Gear lever locking electromagnet

circuit.

If the fault is still present, contact the Techline.

DP0TA2000_V10_ET157/DP0TA2000_V11_ET157/DP0TA2000_V15_ET157

Page 100 of 128

AUTOMATIC TRANSMISSION

Fault finding – Parameter summary table23A

23A - 100V4 MR-372-J84-23A050$660.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

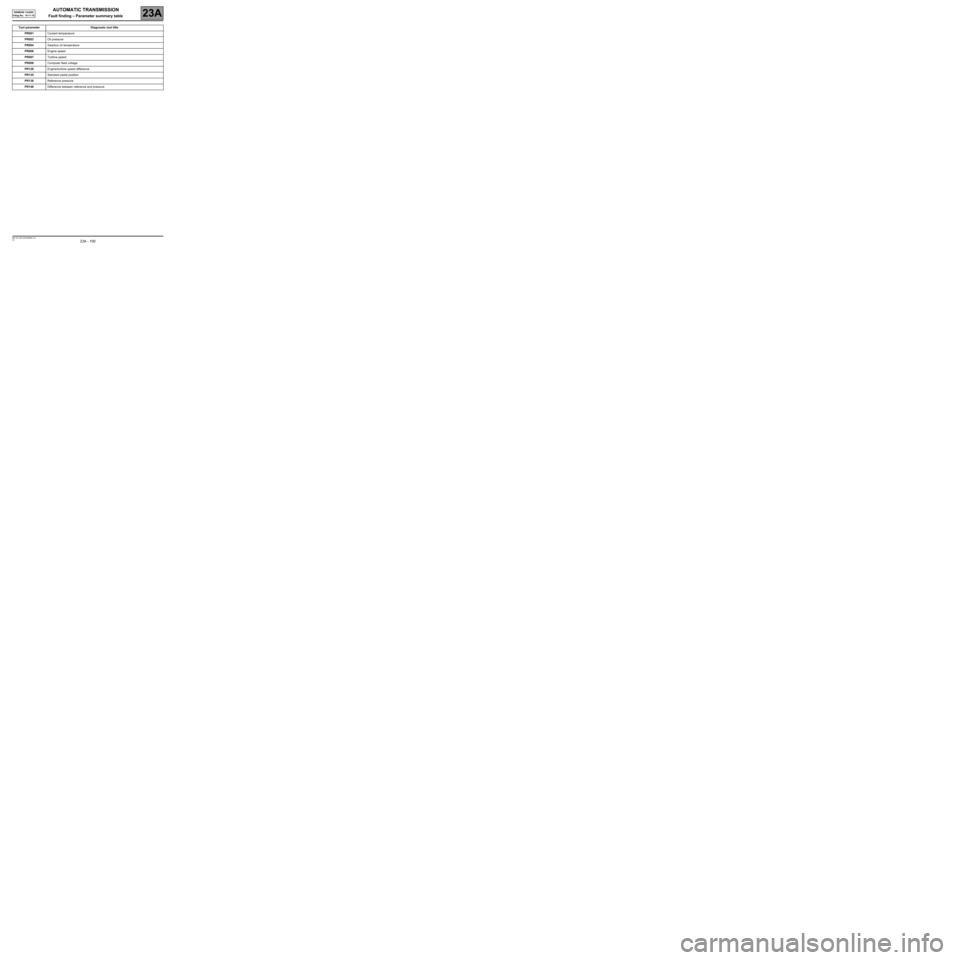

Tool parameter Diagnostic tool title

PR001Coolant temperature

PR003Oil pressure

PR004Gearbox oil temperature

PR006Engine speed

PR007Turbine speed

PR008Computer feed voltage

PR128Engine/turbine speed difference

PR135Standard pedal position

PR138Reference pressure

PR146Difference between reference and pressure