check engine RENAULT SCENIC 2008 J84 / 2.G Automatic Transmission Siemens TA2000 Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2008, Model line: SCENIC, Model: RENAULT SCENIC 2008 J84 / 2.GPages: 128, PDF Size: 0.43 MB

Page 116 of 128

AUTOMATIC TRANSMISSION

Fault finding – Fault Finding Chart23A

23A-116V4 MR-372-J84-23A050$924.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

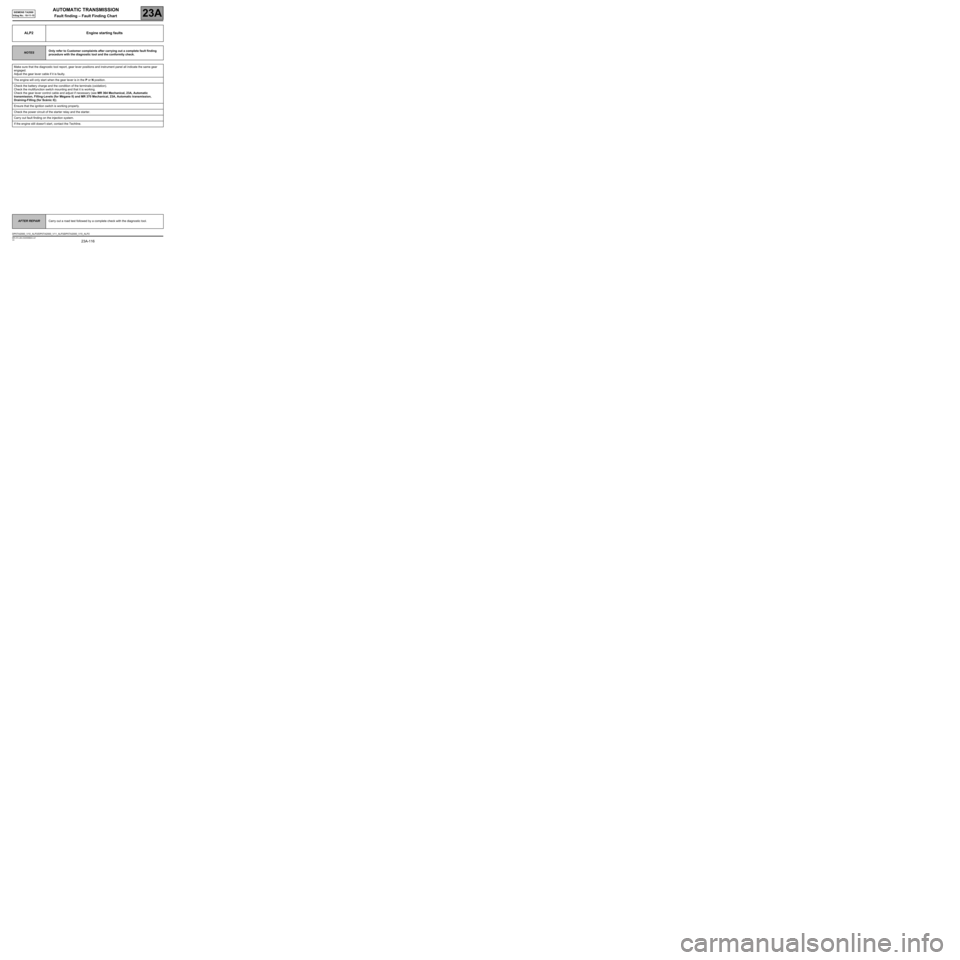

ALP2 Engine starting faults

NOTESOnly refer to Customer complaints after carrying out a complete fault finding

procedure with the diagnostic tool and the conformity check.

Make sure that the diagnostic tool report, gear lever positions and instrument panel all indicate the same gear

engaged.

Adjust the gear lever cable if it is faulty.

The engine will only start when the gear lever is in the P or N position.

Check the battery charge and the condition of the terminals (oxidation).

Check the multifunction switch mounting and that it is working.

Check the gear lever control cable and adjust if necessary (see MR 364 Mechanical, 23A, Automatic

transmission, Filling-Levels (for Mégane II) and MR 370 Mechanical, 23A, Automatic transmission,

Draining-Filling (for Scénic II)).

Ensure that the ignition switch is working properly.

Check the power circuit of the starter relay and the starter.

Carry out fault finding on the injection system.

If the engine still doesn't start, contact the Techline.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

DP0TA2000_V10_ALP2/DP0TA2000_V11_ALP2/DP0TA2000_V15_ALP2

Page 117 of 128

AUTOMATIC TRANSMISSION

Fault finding – Fault Finding Chart23A

23A-117V4 MR-372-J84-23A050$924.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

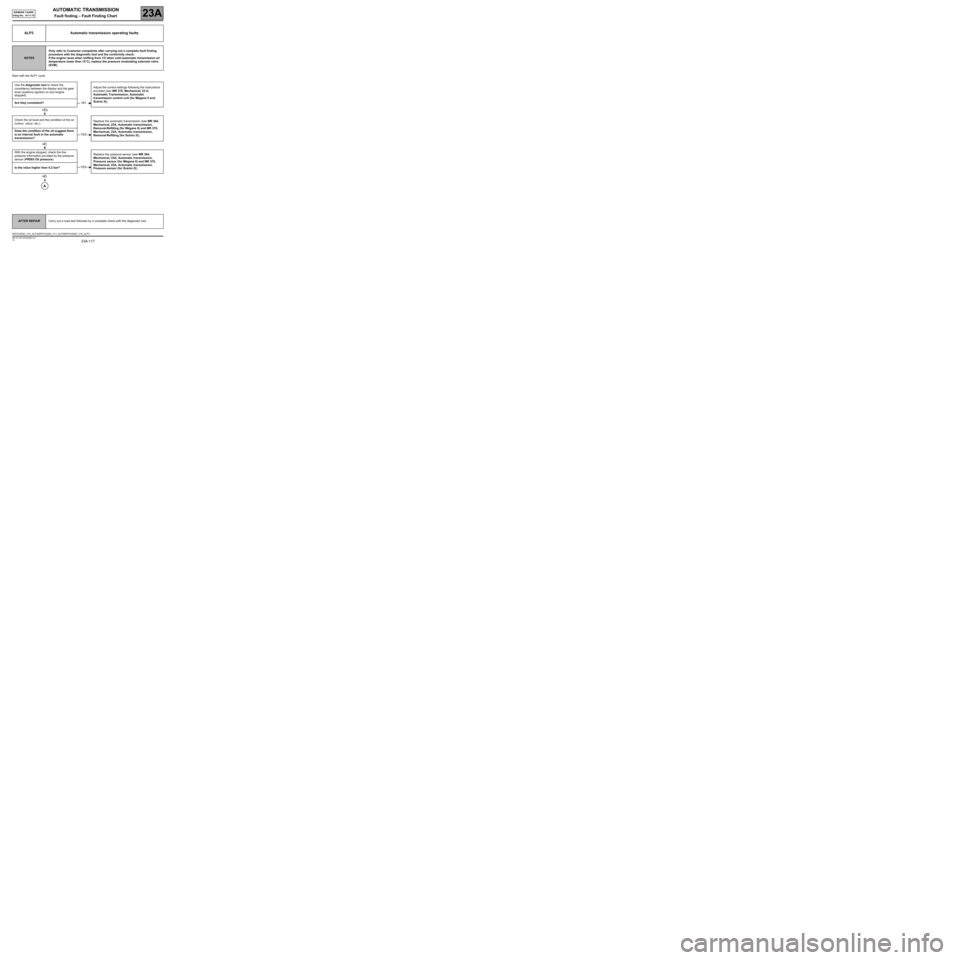

Start with the ALP1 cycle

ALP3 Automatic transmission operating faults

NOTESOnly refer to Customer complaints after carrying out a complete fault finding

procedure with the diagnostic tool and the conformity check.

If the engine races when shifting from 1/2 when cold (automatic transmission oil

temperature lower than 15˚C), replace the pressure modulating solenoid valve

(EVM).

Use the diagnostic tool to check the

consistency between the display and the gear

lever positions (ignition on and engine

stopped).Adjust the control settings following the instructions

provided (see MR 370, Mechanical, 23 A,

Automatic Transmission, Automatic

transmission control unit (for Mégane II and

Scénic II)).

Are they consistent?

Check the oil level and the condition of the oil

(colour, odour, etc.).Replace the automatic transmission (see MR 364,

Mechanical, 23A, Automatic transmission,

Removal-Refitting (for Mégane II) and MR 370,

Mechanical, 23A, Automatic transmission,

Removal-Refitting (for Scénic II)). Does the condition of the oil suggest there

is an internal fault in the automatic

transmission?

With the engine stopped, check the line

pressure information provided by the pressure

sensor (PR003 Oil pressure).Replace the pressure sensor (see MR 364,

Mechanical, 23A, Automatic transmission,

Pressure sensor (for Mégane II) and MR 370,

Mechanical, 23A, Automatic transmission,

Pressure sensor (for Scénic II)). Is the value higher than 0.2 bar?

NO

YES

YES

NO

YES

NO

A

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

DP0TA2000_V10_ALP3/DP0TA2000_V11_ALP3/DP0TA2000_V15_ALP3

Page 118 of 128

AUTOMATIC TRANSMISSION

Fault finding – Fault Finding Chart23A

23A-118V4 MR-372-J84-23A050$924.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

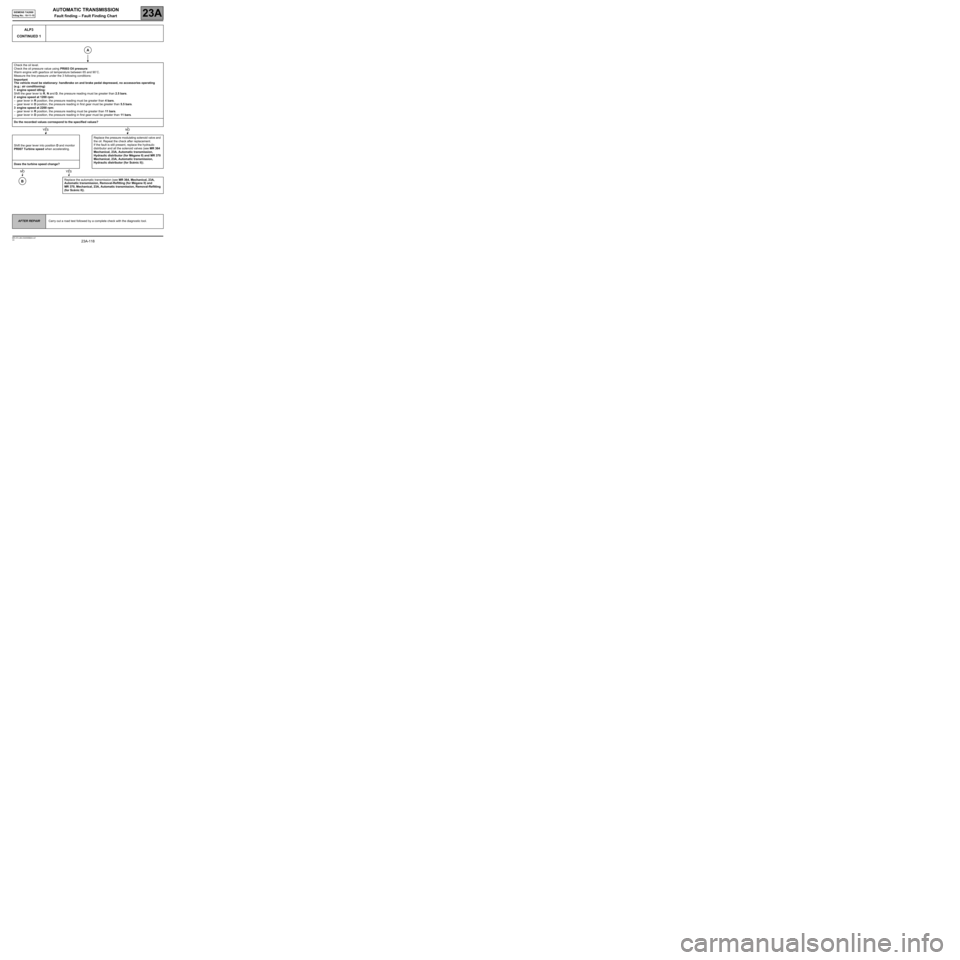

ALP3

CONTINUED 1

Check the oil level.

Check the oil pressure value using PR003 Oil pressure:

Warm engine with gearbox oil temperature between 65 and 90˚C.

Measure the line pressure under the 3 following conditions:

Important

The vehicle must be stationary: handbrake on and brake pedal depressed, no accessories operating

(e.g.: air conditioning)

1engine speed idling:

Shift the gear lever to R, N and D, the pressure reading must be greater than 2.5 bars.

2engine speed at 1200 rpm:

–gear lever in R position, the pressure reading must be greater than 4 bars.

–gear lever in D position, the pressure reading in first gear must be greater than 5.5 bars.

3engine speed at 2200 rpm:

–gear lever in R position, the pressure reading must be greater than 11 bars.

–gear lever in D position, the pressure reading in first gear must be greater than 11 bars.

Do the recorded values correspond to the specified values?

Shift the gear lever into position D and monitor

PR007 Turbine speed when accelerating.Replace the pressure modulating solenoid valve and

the oil. Repeat the check after replacement.

If the fault is still present, replace the hydraulic

distributor and all the solenoid valves (see MR 364

Mechanical, 23A, Automatic transmission,

Hydraulic distributor (for Mégane II) and MR 370

Mechanical, 23A, Automatic transmission,

Hydraulic distributor (for Scénic II)).

Does the turbine speed change?

Replace the automatic transmission (see MR 364, Mechanical, 23A,

Automatic transmission, Removal-Refitting (for Mégane II) and

MR 370, Mechanical, 23A, Automatic transmission, Removal-Refitting

(for Scénic II)).

A

YESNO

NOYES

B

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 119 of 128

AUTOMATIC TRANSMISSION

Fault finding – Fault Finding Chart23A

23A-119V4 MR-372-J84-23A050$924.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

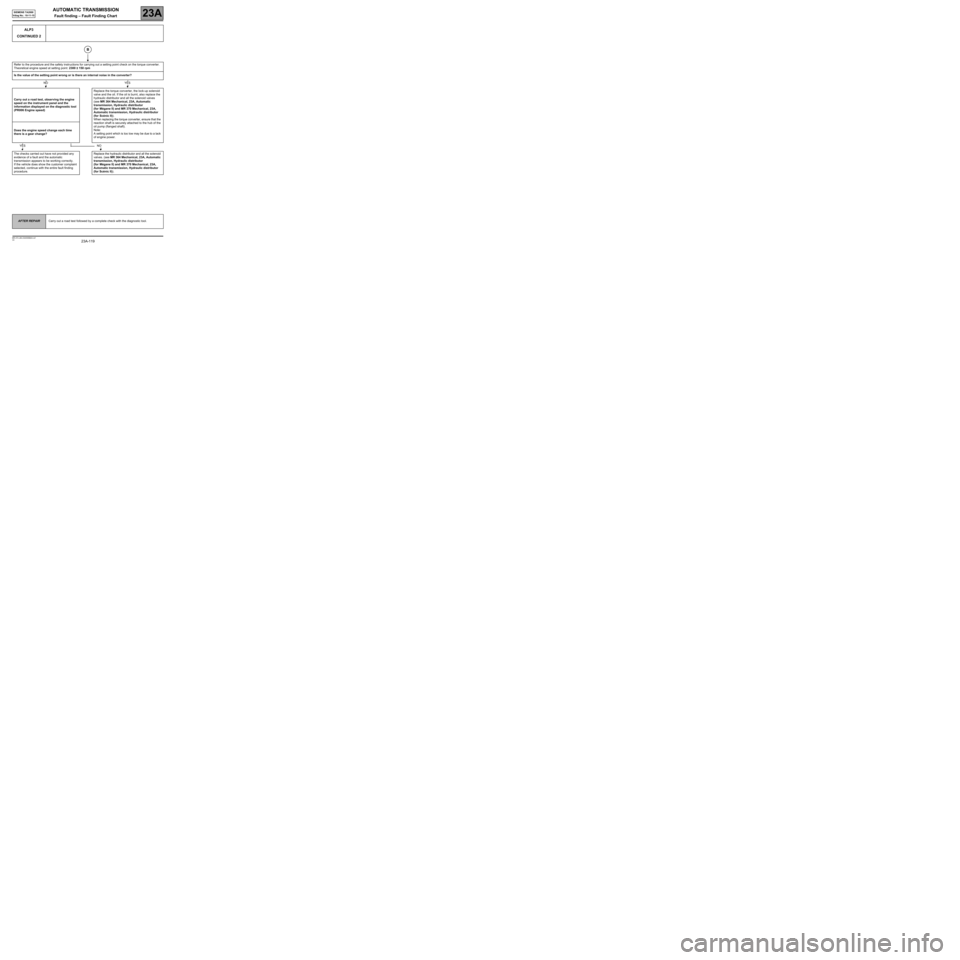

ALP3

CONTINUED 2

Refer to the procedure and the safety instructions for carrying out a setting point check on the torque converter.

Theoretical engine speed at setting point: 2300 ± 150 rpm

Is the value of the setting point wrong or is there an internal noise in the converter?

Carry out a road test, observing the engine

speed on the instrument panel and the

information displayed on the diagnostic tool

(PR006 Engine speed)Replace the torque converter, the lock-up solenoid

valve and the oil. If the oil is burnt, also replace the

hydraulic distributor and all the solenoid valves

(see MR 364 Mechanical, 23A, Automatic

transmission, Hydraulic distributor

(for Mégane II) and MR 370 Mechanical, 23A,

Automatic transmission, Hydraulic distributor

(for Scénic II)).

When replacing the torque converter, ensure that the

reaction shaft is securely attached to the hub of the

oil pump (flanged shaft).

Note:

A setting point which is too low may be due to a lack

of engine power. Does the engine speed change each time

there is a gear change?

The checks carried out have not provided any

evidence of a fault and the automatic

transmission appears to be working correctly.

If the vehicle does show the customer complaint

selected, continue with the entire fault finding

procedure. Replace the hydraulic distributor and all the solenoid

valves. (see MR 364 Mechanical, 23A, Automatic

transmission, Hydraulic distributor

(for Mégane II) and MR 370 Mechanical, 23A,

Automatic transmission, Hydraulic distributor

(for Scénic II)).

B

NOYES

YESNO

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 121 of 128

AUTOMATIC TRANSMISSION

Fault finding – Fault Finding Chart23A

23A -121V4 MR-372-J84-23A050$924.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

ALP5 Erratic gear changes

NOTESOnly refer to Customer complaints after carrying out a complete fault finding

procedure with the diagnostic tool and the conformity check.

Carry out a road test using the diagnostic tool, making sure that status ET013 Gear engaged operates normally.

If the customer complaint occurs with the brake pedal released, check that status ET004 Brake light switch

(Closed) is NO.

If not, adjust the brake light switch and the brake pedal.

Make sure that the instrument panel display of the gear engaged matches the gear lever position.

Check the automatic transmission wiring harness (sequence solenoid valve control).

Replace it if necessary.

Check that the gear lever cable is working properly and adjust it if necessary.

Check that the multifunction switch is working correctly.

If the fault is still present, replace the multifunction switch.

Carry out fault finding on the injection system.

Check engine speed signal PR006 during a road test at a steady speed.

If the signal is wrong, replace the engine speed sensor.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

DP0TA2000_V10_ALP5/DP0TA2000_V11_ALP5/DP0TA2000_V15_ALP5

Page 123 of 128

AUTOMATIC TRANSMISSION

Fault finding – Fault Finding Chart23A

23A -123V4 MR-372-J84-23A050$924.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

ALP7 Oil present under vehicle

NOTESOnly refer to Customer complaints after carrying out a complete fault finding

procedure with the diagnostic tool and the conformity check.

Check the colour of the oil under the vehicle to determine the source of the leak (automatic transmission fluid is

red).

Clean the engine and gearbox.

Check the oil level in the engine and gearbox.

Top up if necessary (see MR 364 Mechanical, 23A, Automatic transmission, Filling-levels (for Mégane II) and

MR 370 Mechanical, 23A, Automatic transmission, Draining-Filling (for Scénic II)).

If there is no gearbox leak, look for a leak in the engine compartment.

If the leak is from the gearbox side:

–Locate the source of the leak and carry out the necessary repairs.

–Replace any faulty parts.

–Check the oil level.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

DP0TA2000_V10_ALP7/DP0TA2000_V11_ALP7/DP0TA2000_V15_ALP7