ECU RENAULT SCENIC 2008 J84 / 2.G Engine Compartment Connection Unit Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2008, Model line: SCENIC, Model: RENAULT SCENIC 2008 J84 / 2.GPages: 94, PDF Size: 0.28 MB

Page 4 of 94

ENGINE COMPARTMENT CONNECTION UNIT

Fault finding - Introduction87G

87G - 4V7 MR-372-J84-87G050$055.mif

UPC

Vdiag No.: 48, 4C

Conformity check

The aim of the conformity check is to check data that does not produce a fault on the diagnostic tool because the

data is inconsistent. Therefore, this stage is used to:

–carry out fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint.

–check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section gives the fault finding procedures for statuses and parameters and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Customer complaints - Fault finding chart

If the test with the diagnostic tool is OK but the customer complaint is still present, the fault should be dealt with by

Customer complaints.

A summary of the overall procedure to follow is provided on the following page in

the form of a flow chart.

Page 23 of 94

ENGINE COMPARTMENT CONNECTION UNIT

Fault finding - Interpretation of faults87G

87G-23V7 MR-372-J84-87G050$330.mif

UPC

Vdiag No.: 4C

DF009

CONTINUED

Check the connection and condition of the passenger compartment fuse and relay box, the gear lever display,

the steering column top control module, the additional heater relay 1 and 2, the diagnostic socket, the

parking distance control ECU, the right and left-hand rear electric window switch, the radio, the electric

door mirror control, the front and rear electric window locking controls and the passenger electric window

switch, component codes 260, 1129, 1546, 1067, 1068, 225, 1222, 130, 131, 261, 134, 135, 1511, 1512

and 133.

Check for a voltage on connection AP43 to the connectors for the passenger compartment fuse and relay box,

the gear lever display, the steering column top control module, the additional heater relay 1 and 2, the

diagnostic socket, the parking distance control ECU, the right and left-hand rear electric window switch,

the radio, the electric door mirror control, the front and rear electric window locking controls, the

passenger electric window switch, component codes 260, 1129, 1546, 1067, 1068, 225, 1222, 130, 131, 261,

134, 135, 1511, 1512 and 133.

If the connection or connections are faulty and if there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–AP31 between components 1337 and 997,

–AP11 between components 1337, 485, 155 and 1109,

–APCB between components 1337 and 645,

–AP15 between components 1337 and 1088,

–AP44 between components 1337, 756 and 1232,

–AP43 between components 1337, 260, 1129, 1546, 1067, 1068, 225, 1222, 130, 131, 261, 134, 135, 1511, 1512

and 133.

If the connections are faulty and if there is a repair procedure (see Technical Note 6015A, Electrical wiring

repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the connection and condition of the Protection and Switching Unit, component code 1337.

If the connector is faulty and if there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the connector.

If the fault is still present, contact the Techline.

AFTER REPAIRErase the faults from the computer memory, switch the + after ignition supply off and

back on again and run another check using the diagnostic tool.

Page 93 of 94

ENGINE COMPARTMENT CONNECTION UNIT

Fault finding - Tests87G

87G-93V7 MR-372-J84-87G050$935.mif

UPC

Vdiag No.: 48, 4C

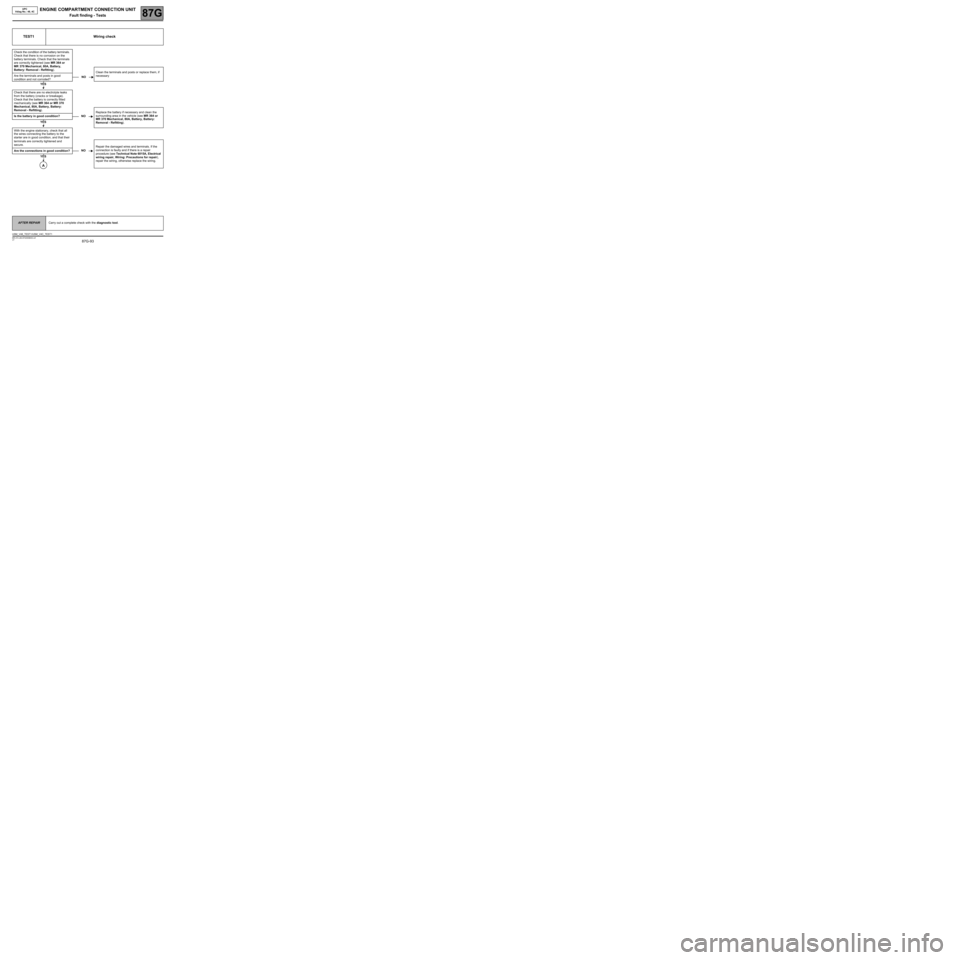

TEST1 Wiring check

Check the condition of the battery terminals.

Check that there is no corrosion on the

battery terminals. Check that the terminals

are correctly tightened (see MR 364 or

MR 370 Mechanical, 80A, Battery,

Battery: Removal - Refitting).

Clean the terminals and posts or replace them, if

necessary Are the terminals and posts in good

condition and not corroded?

Check that there are no electrolyte leaks

from the battery (cracks or breakage).

Check that the battery is correctly fitted

mechanically (see MR 364 or MR 370

Mechanical, 80A, Battery, Battery:

Removal - Refitting).

Replace the battery if necessary and clean the

surrounding area in the vehicle (see MR 364 or

MR 370 Mechanical, 80A, Battery, Battery:

Removal - Refitting). Is the battery in good condition?

With the engine stationary, check that all

the wires connecting the battery to the

starter are in good condition, and that their

terminals are correctly tightened and

secure.

Repair the damaged wires and terminals. If the

connection is faulty and if there is a repair

procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair),

repair the wiring, otherwise replace the wiring. Are the connections in good condition?

NO

YES

NO

YES

NO

YES

A

AFTER REPAIRCarry out a complete check with the diagnostic tool.

USM_V48_TEST1/USM_V4C_TEST1