RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Owner's Manual

Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 21 of 230

PETROL INJECTION

17B

17B - 21

17B

17B - 21V9 MR-372-J84-17B050$141.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Allocation of computer tracks

Connector (A), 32 tracks:

Track Description

A1 Not used

A2 Cruise control on/off button logical input

A3 CAN L1 passenger compartment multiplex connection

A4 CAN H1 passenger compartment multiplex connection

B1 Not used

B2 Not used

B3 Not used

B4 OBD diagnostic line K

C1 Not used

C2 Not used

C3 Speed limiter on/off button logical input

C4 + Clutch switch signal

D1 + after ignition feed via UPC

D2 Cruise control signal analogue input

D3 Cruise control signal earth

D4 Not used

E1 Not used

E2 Not used

E3 Not used

E4 Brake pedal normally closed switch no. 1 signal

F1 Not used

F2 + 5 V supply, accelerator pedal potentiometer gang 2

F3 Accelerator pedal potentiometer signal, gang 2

F4 Accelerator pedal potentiometer earth, gang 2

G1 Not used

G2 + 5 V supply, accelerator pedal potentiometer gang 1

G3 Not used

G4 Not used

H1 Not used

H2 Accelerator pedal potentiometer signal, gang 1

H3 Accelerator pedal potentiometer earth, gang 1

H4 Not used

MR-372-J84-17B050$141.mif

Page 22 of 230

PETROL INJECTION

Fault finding - Allocation of computer tracks17B

17B - 22

17B

17B - 22V9 MR-372-J84-17B050$141.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

Connector (B), 48 tracks:

Track Description

A1 Injector 1 - control

A2 Injector 2 - control

A3 Injector 3 - control

A4 Injector 4 - control

B1 Not used

B2 Pinking sensor screening earth

B3 Pinking sensor + signal

B4 Pinking sensor - signal

C1 Not used

C2 Not used

C3 Engine speed (LPG) TDC - signal

C4 Not used

D1 Not used

D2 Not used

D3 Motorised throttle valve potentiometer gang 2 signal

D4 + Power latch relay feed output

E1 Turbocharging pressure sensor earth (F4RT 774 and 776 only)

E2 Air temperature sensor signal

E3 Air temperature sensor earth

E4 Position and engine speed sensor - signal (tooth signal)

F1 Turbocharging pressure sensor + signal (F4RT 774 and 776 only)

F2 Coolant temperature sensor + signal

F3 Engine speed and position sensor + signal (tooth signal)

F4 Coolant temperature sensor earth

G1 + 5 V turbocharging pressure sensor (F4RT 774 and 776 only)

G2 Motorised throttle potentiometer + 5 V feed

G3 Motorised throttle valve potentiometer gang 1 signal

G4 Motorised throttle valve potentiometers common earth

H1 Not used

H2 Manifold pressure sensor + 5 V feed

H3 Manifold pressure sensor + signal

H4 Manifold pressure sensor earth

Page 23 of 230

PETROL INJECTION

Fault finding - Allocation of computer tracks17B

17B - 23

17B

17B - 23V9 MR-372-J84-17B050$141.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

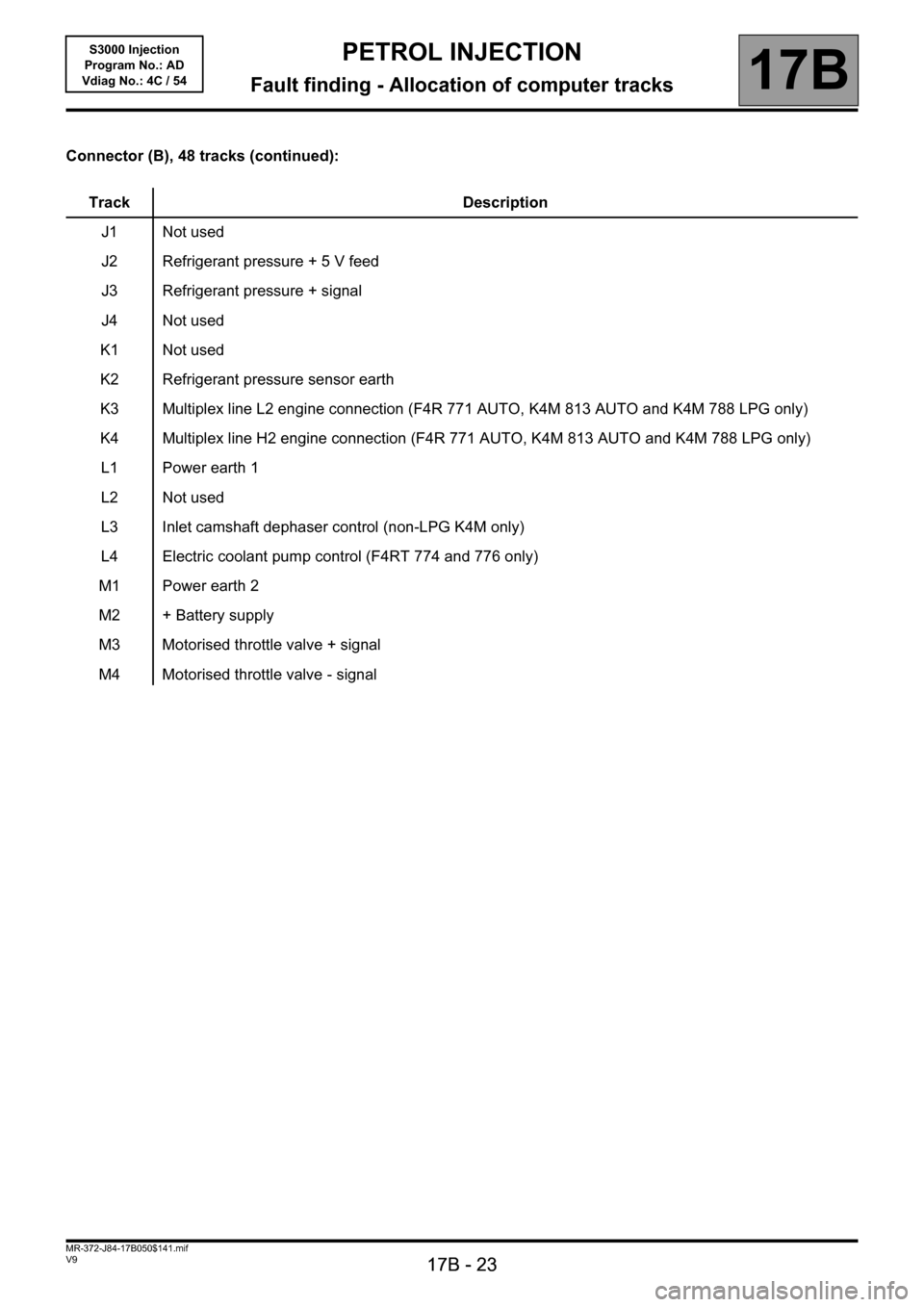

Connector (B), 48 tracks (continued):

Track Description

J1 Not used

J2 Refrigerant pressure + 5 V feed

J3 Refrigerant pressure + signal

J4 Not used

K1 Not used

K2 Refrigerant pressure sensor earth

K3 Multiplex line L2 engine connection (F4R 771 AUTO, K4M 813 AUTO and K4M 788 LPG only)

K4 Multiplex line H2 engine connection (F4R 771 AUTO, K4M 813 AUTO and K4M 788 LPG only)

L1 Power earth 1

L2 Not used

L3 Inlet camshaft dephaser control (non-LPG K4M only)

L4 Electric coolant pump control (F4RT 774 and 776 only)

M1 Power earth 2

M2 + Battery supply

M3 Motorised throttle valve + signal

M4 Motorised throttle valve - signal

Page 24 of 230

PETROL INJECTION

Fault finding - Allocation of computer tracks17B

17B - 24

17B

17B - 24V9 MR-372-J84-17B050$141.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

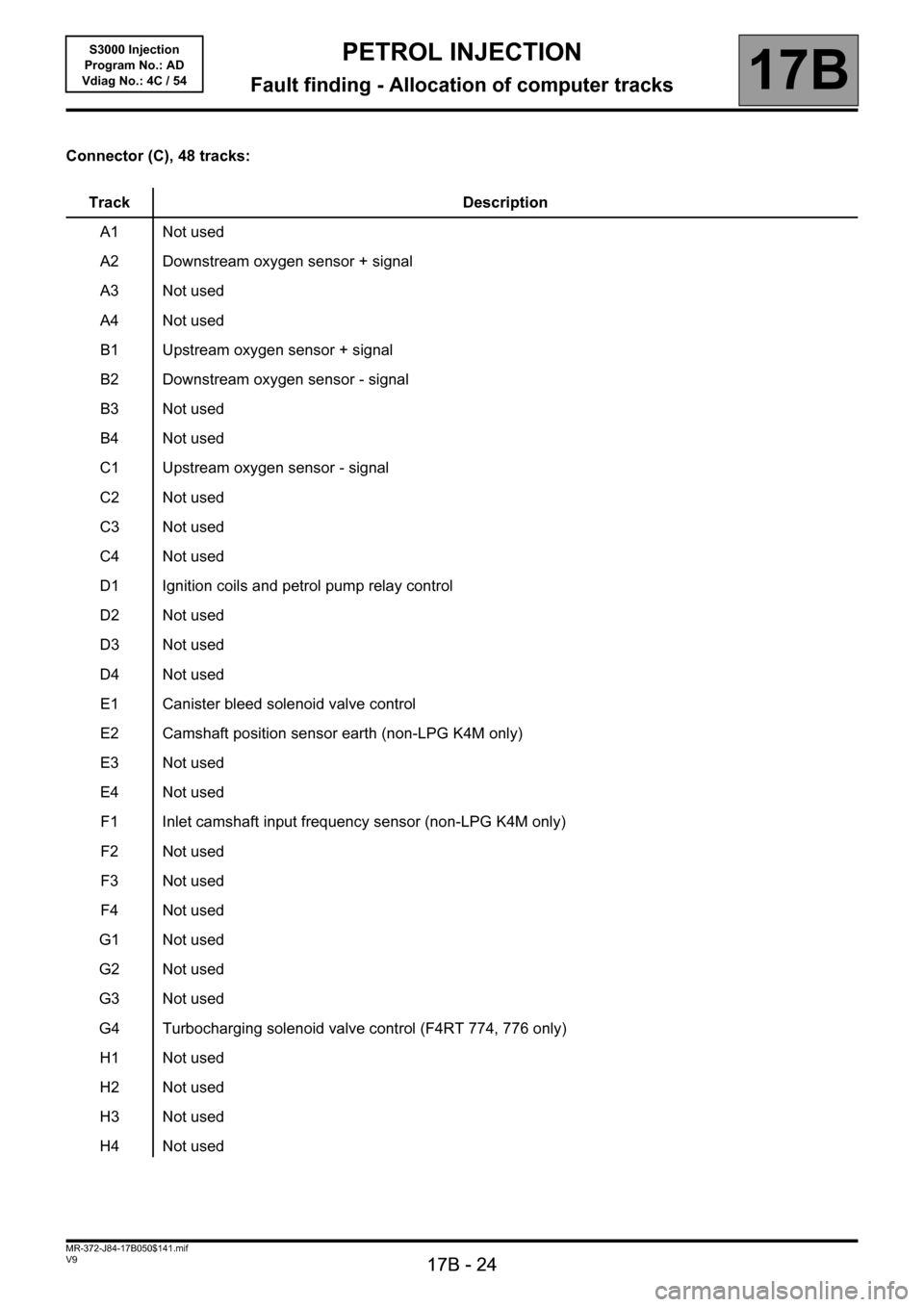

Connector (C), 48 tracks:

Track Description

A1 Not used

A2 Downstream oxygen sensor + signal

A3 Not used

A4 Not used

B1 Upstream oxygen sensor + signal

B2 Downstream oxygen sensor - signal

B3 Not used

B4 Not used

C1 Upstream oxygen sensor - signal

C2 Not used

C3 Not used

C4 Not used

D1 Ignition coils and petrol pump relay control

D2 Not used

D3 Not used

D4 Not used

E1 Canister bleed solenoid valve control

E2 Camshaft position sensor earth (non-LPG K4M only)

E3 Not used

E4 Not used

F1 Inlet camshaft input frequency sensor (non-LPG K4M only)

F2 Not used

F3 Not used

F4 Not used

G1 Not used

G2 Not used

G3 Not used

G4 Turbocharging solenoid valve control (F4RT 774, 776 only)

H1 Not used

H2 Not used

H3 Not used

H4 Not used

Page 25 of 230

PETROL INJECTION

Fault finding - Allocation of computer tracks17B

17B - 25

17B

17B - 25V9 MR-372-J84-17B050$141.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

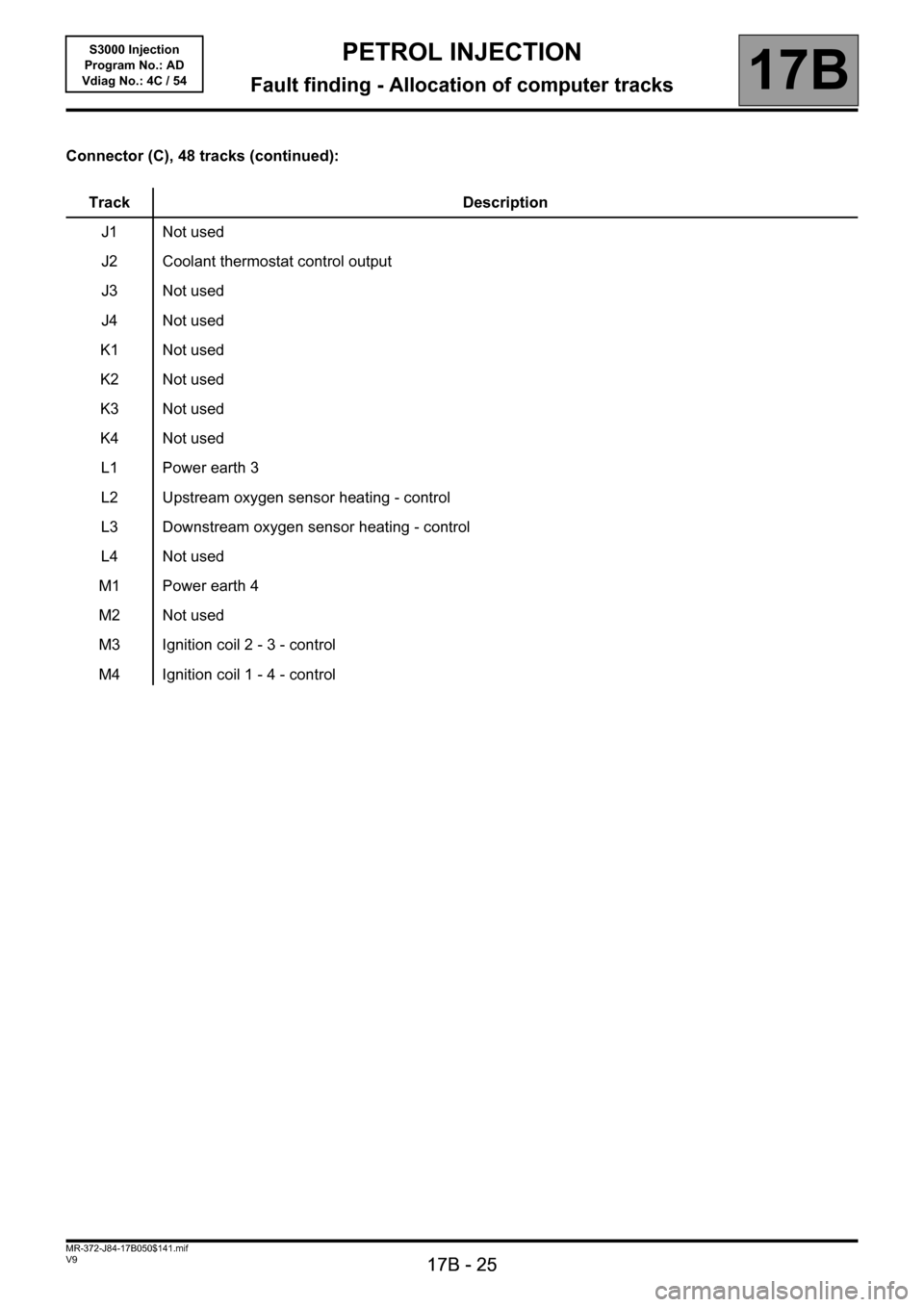

Connector (C), 48 tracks (continued):

Track Description

J1 Not used

J2 Coolant thermostat control output

J3 Not used

J4 Not used

K1 Not used

K2 Not used

K3 Not used

K4 Not used

L1 Power earth 3

L2 Upstream oxygen sensor heating - control

L3 Downstream oxygen sensor heating - control

L4 Not used

M1 Power earth 4

M2 Not used

M3 Ignition coil 2 - 3 - control

M4 Ignition coil 1 - 4 - control

Page 26 of 230

PETROL INJECTION

Fault finding - Replacement of components

17B

17B-26

PETROL INJECTION

Fault finding - Replacement of components

17B

17B-26V9 MR-372-J84-17B050$188.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Replacement of components

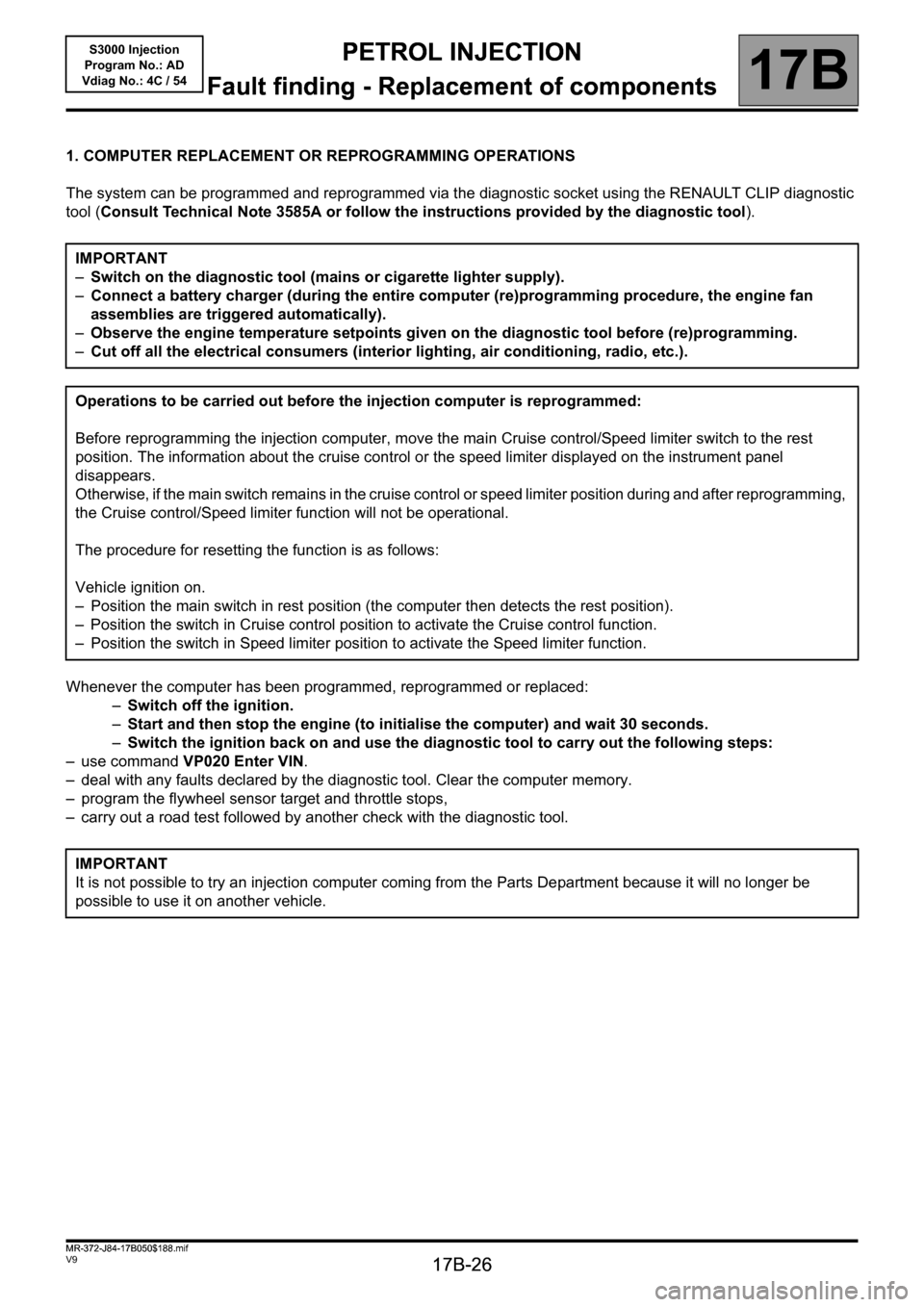

1. COMPUTER REPLACEMENT OR REPROGRAMMING OPERATIONS

The system can be programmed and reprogrammed via the diagnostic socket using the RENAULT CLIP diagnostic

tool (Consult Technical Note 3585A or follow the instructions provided by the diagnostic tool).

Whenever the computer has been programmed, reprogrammed or replaced:

–Switch off the ignition.

–Start and then stop the engine (to initialise the computer) and wait 30 seconds.

–Switch the ignition back on and use the diagnostic tool to carry out the following steps:

– use command VP020 Enter VIN.

– deal with any faults declared by the diagnostic tool. Clear the computer memory.

– program the flywheel sensor target and throttle stops,

– carry out a road test followed by another check with the diagnostic tool. IMPORTANT

–Switch on the diagnostic tool (mains or cigarette lighter supply).

–Connect a battery charger (during the entire computer (re)programming procedure, the engine fan

assemblies are triggered automatically).

–Observe the engine temperature setpoints given on the diagnostic tool before (re)programming.

–Cut off all the electrical consumers (interior lighting, air conditioning, radio, etc.).

Operations to be carried out before the injection computer is reprogrammed:

Before reprogramming the injection computer, move the main Cruise control/Speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the Cruise control/Speed limiter function will not be operational.

The procedure for resetting the function is as follows:

Vehicle ignition on.

– Position the main switch in rest position (the computer then detects the rest position).

– Position the switch in Cruise control position to activate the Cruise control function.

– Position the switch in Speed limiter position to activate the Speed limiter function.

IMPORTANT

It is not possible to try an injection computer coming from the Parts Department because it will no longer be

possible to use it on another vehicle.

MR-372-J84-17B050$188.mif

Page 27 of 230

PETROL INJECTION

Fault finding - Replacement of components

17B

17B-27

PETROL INJECTION

Fault finding - Replacement of components

17B

17B-27V9 MR-372-J84-17B050$188.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Replacement of components

2. REPLACING OR REMOVING THE TDC SENSOR

When replacing or removing the TDC sensor, program the flywheel target (see17B, Petrol injection,

Configuration and programming).

3. REPLACING THE MOTORISED THROTTLE VALVE

When replacing the throttle valve, the throttle stops are automatically programmed.

–PR058 Air temperature between 0°C and 105°C,

– wait for the end of power latch for the programming to be stored in the computer memory.

Check the programming using status ET051 Throttle stop programming is DONE.

When replacing the throttle valve, reinitialise the programming using command RZ005 Programming. IMPORTANT

– The injection computer retains the immobiliser code for life,

– the system has no security code,

– it is forbidden to perform tests with computers borrowed from the Parts Department or from another vehicle which

must then be returned. These computers are hard-coded.

IMPORTANT

Never drive the vehicle without having programmed the throttle stops.

Page 28 of 230

PETROL INJECTION

17B

17B - 28

17B

17B - 28V9 MR-372-J84-17B050$235.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Configurations and programming

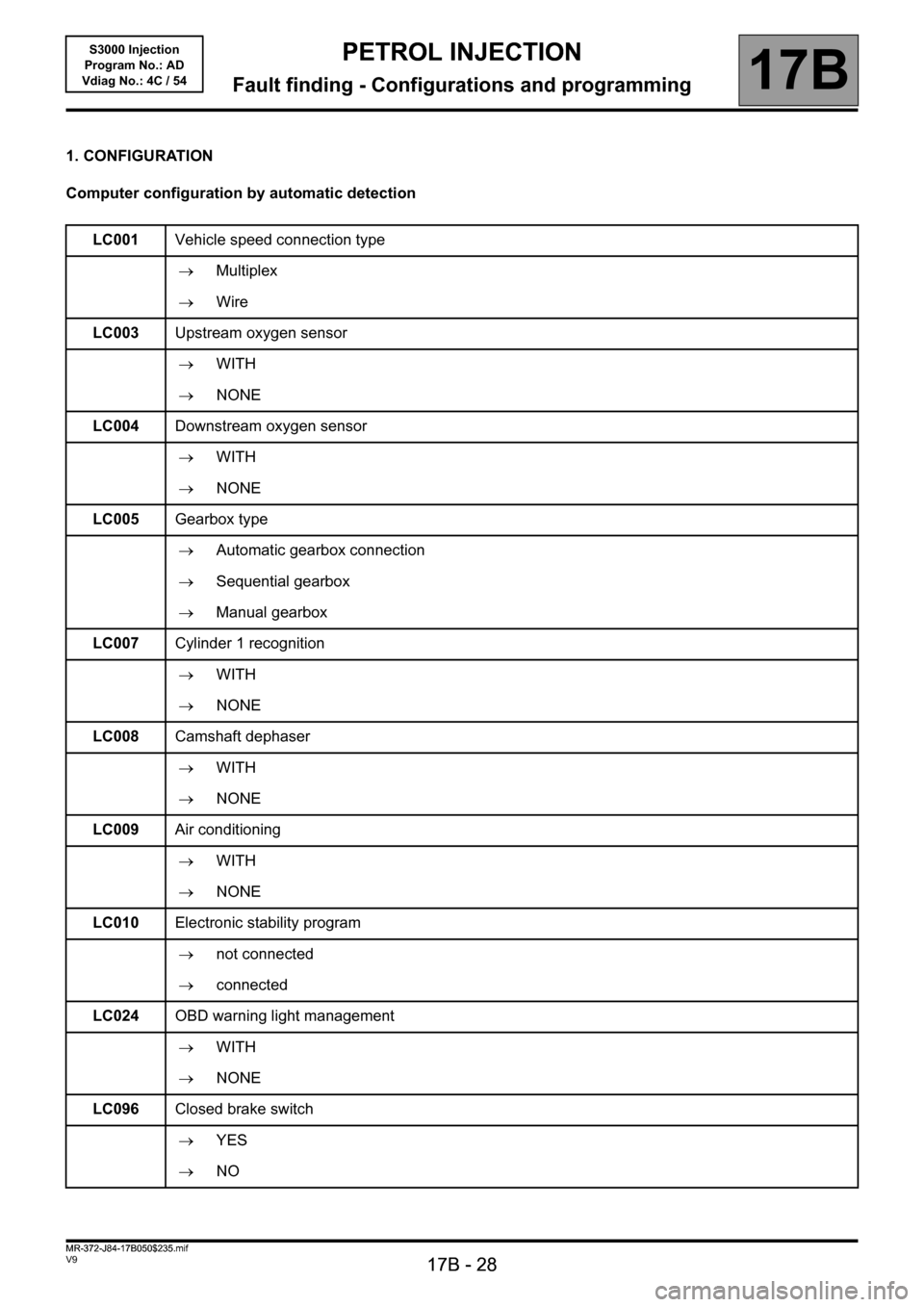

1. CONFIGURATION

Computer configuration by automatic detection

LC001Vehicle speed connection type

→Multiplex

→Wire

LC003Upstream oxygen sensor

→WITH

→NONE

LC004Downstream oxygen sensor

→WITH

→NONE

LC005Gearbox type

→Automatic gearbox connection

→Sequential gearbox

→Manual gearbox

LC007Cylinder 1 recognition

→WITH

→NONE

LC008Camshaft dephaser

→WITH

→NONE

LC009Air conditioning

→WITH

→NONE

LC010Electronic stability program

→not connected

→connected

LC024OBD warning light management

→WITH

→NONE

LC096Closed brake switch

→YES

→NO

MR-372-J84-17B050$235.mif

Page 29 of 230

PETROL INJECTION

Fault finding - Configurations and programming17B

17B - 29

17B

17B - 29V9 MR-372-J84-17B050$235.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

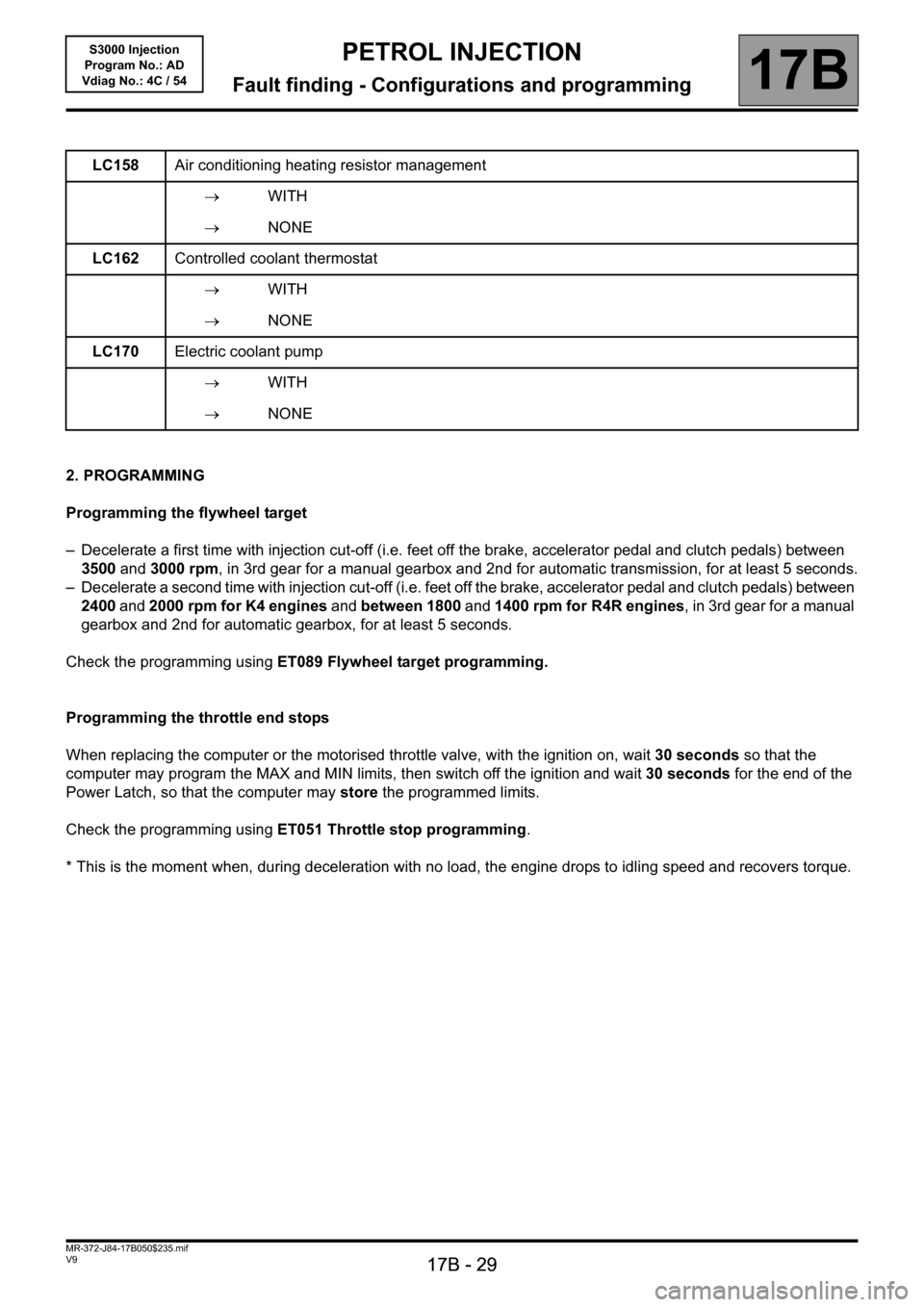

2. PROGRAMMING

Programming the flywheel target

– Decelerate a first time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

3500 and 3000 rpm, in 3rd gear for a manual gearbox and 2nd for automatic transmission, for at least 5 seconds.

– Decelerate a second time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

2400 and 2000 rpm for K4 engines and between 1800 and 1400 rpm for R4R engines, in 3rd gear for a manual

gearbox and 2nd for automatic gearbox, for at least 5 seconds.

Check the programming using ET089 Flywheel target programming.

Programming the throttle end stops

When replacing the computer or the motorised throttle valve, with the ignition on, wait 30 seconds so that the

computer may program the MAX and MIN limits, then switch off the ignition and wait 30 seconds for the end of the

Power Latch, so that the computer may store the programmed limits.

Check the programming using ET051 Throttle stop programming.

* This is the moment when, during deceleration with no load, the engine drops to idling speed and recovers torque. LC158Air conditioning heating resistor management

→WITH

→NONE

LC162Controlled coolant thermostat

→WITH

→NONE

LC170Electric coolant pump

→WITH

→NONE

Page 30 of 230

PETROL INJECTION

17B

17B-30

PETROL INJECTION

17B

17B-30V9 MR-372-J84-17B050$282.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

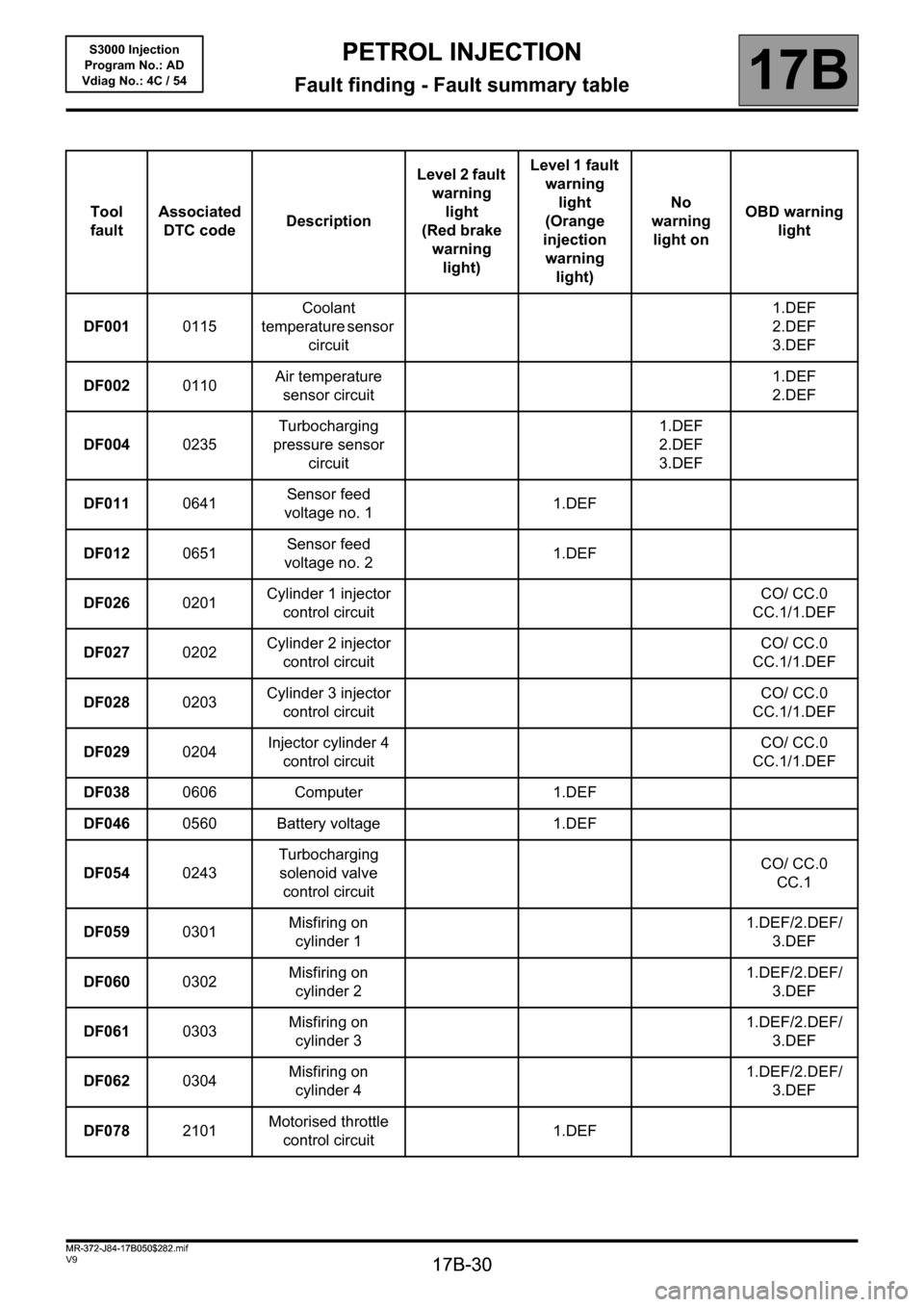

Fault finding - Fault summary table

Tool

faultAssociated

DTC codeDescriptionLevel 2 fault

warning

light

(Red brake

warning

light)Level 1 fault

warning

light

(Orange

injection

warning

light)No

warning

light onOBD warning

light

DF0010115Coolant

temperature sensor

circuit1.DEF

2.DEF

3.DEF

DF0020110Air temperature

sensor circuit1.DEF

2.DEF

DF0040235Turbocharging

pressure sensor

circuit1.DEF

2.DEF

3.DEF

DF0110641Sensor feed

voltage no. 11.DEF

DF0120651Sensor feed

voltage no. 21.DEF

DF0260201Cylinder 1 injector

control circuitCO/ CC.0

CC.1/1.DEF

DF0270202Cylinder 2 injector

control circuitCO/ CC.0

CC.1/1.DEF

DF0280203Cylinder 3 injector

control circuitCO/ CC.0

CC.1/1.DEF

DF0290204Injector cylinder 4

control circuitCO/ CC.0

CC.1/1.DEF

DF0380606 Computer 1.DEF

DF0460560 Battery voltage 1.DEF

DF0540243Turbocharging

solenoid valve

control circuitCO/ CC.0

CC.1

DF0590301Misfiring on

cylinder 11.DEF/2.DEF/

3.DEF

DF0600302Misfiring on

cylinder 21.DEF/2.DEF/

3.DEF

DF061

0303Misfiring on

cylinder 31.DEF/2.DEF/

3.DEF

DF0620304Misfiring on

cylinder 41.DEF/2.DEF/

3.DEF

DF0782101Motorised throttle

control circuit1.DEF

MR-372-J84-17B050$282.mif