display RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 94 of 431

13B-94V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF055

CONTINUED

1.DEF

2.DEFNOTESNone.

Check the condition of the turbocharging pressure sensor connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 1071).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Check the continuity and absence of interference resistance of the following connections:

– connection code 3LP between components 1071 and 120.

– connection code 3LQ, between components 1071 and 120.

– connection code 3LN between components 1071 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

With the engine stationary and ignition on, display parameters PR035 Atmospheric pressure and PR041

Turbocharging pressure.

If there is a difference of > 100 mbar, check that the atmospheric pressure read is consistent (by comparing the

value with that of another vehicle for example).

If atmospheric pressure is consistent, replace the turbocharging sensor.

If not, contact the Techline.

Apply test 4: Turbocharged air inlet circuit check.

If the fault is still present, refer to the interpretation of parameter PR041 Turbocharging pressure.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 132 of 431

13B-132

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF196

CONTINUED 3

1.DEFNOTESNone.

Check the condition of the pedal sensor connector (see Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2, component code 921).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance of the pedal sensor between the following connections:

– Connection code 3LR of component 921.

– Connection code 3LT of component 921.

Replace the sensor if the resistance is not 1.2 kΩ ± 0.48 kΩ.

Check for continuity and absence of interference resistance of the following connections:

– Connection code 3LR between components 921 and 120.

– Connection code 3LS between components 921 and 120.

– Connection code 3LT between components 921 and 120.

– Connection code 3LU between components 921 and 120.

– Connection code 3LV between components 921 and 120.

– Connection code 3LW between components 921 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Check the insulation between the following connections:

– Connection code 3LS between components 921 and 120.

– Connection code 3LW

between components 921 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

If the fault is still present, vary the pedal position and consult the interpretation of parameters to check the

operating values of the accelerator pedal sensor.

If the values displayed are inconsistent, replace the accelerator pedal sensor.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 136 of 431

13B-136

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF198

CONTINUED 3

1.DEFNOTESNone.

Check the condition of the pedal sensor connector (see Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2, component code 921).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance of the pedal sensor between the following connections:

– Connection code 3LU of component 921.

– Connection code 3LV of component 921.

Replace the sensor if the resistance is not 1.7 kΩ ± 0.68 kΩ.

Check for continuity and absence of interference resistance of the following connections:

– Connection code 3LR between components 921 and 120.

– Connection code 3LS between components 921 and 120.

– Connection code 3LT between components 921 and 120.

– Connection code 3LU between components 921 and 120.

– Connection code 3LV between components 921 and 120.

– Connection code 3LW between components 921 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Check the insulation between the following connections:

– Connection code 3LS of component 921.

– Connection code 3LW of component 921

.

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair) repair the wiring, otherwise replace it.

If the fault is still present, vary the pedal position and consult the interpretation of parameters to check the operating

values of the accelerator pedal sensor.

If the values displayed are inconsistent, replace the accelerator pedal sensor.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 161 of 431

13B-161

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

*diff: differential

*temp: temperature

DF308

PRESENT

OR

STOREDCLOGGED PARTICLE FILTER

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after the engine is started or following a road test.

Special notes:

If the fault is present:

– particle filter regeneration is inhibited,

– the EGR function is inhibited,

– the vehicle performance is reduced,

–the level 1 warning light is lit and a warning message (or light) is displayed on the

instrument panel.

Priorities when dealing with a number of faults:

Deal with the following faults first:

– DF315 Particle filter differential pressure sensor if it is present.

– DF308 if DF315 is stored.

– DF316 Particle filter diff* pressure sensor if it is present or stored.

– DF226 Damper valve circuit if it is present or stored.

– DF272 EGR valve control circuit if it is present or stored.

– DF647 EGR valve position regulation if it is present or stored.

– DF309 Particle filter downstream temperature sensor if it is present or stored.

– DF899 Regeneration temperature threshold exceeded if it is present or stored.

– DF310 Particle filter upstream temperature sensor if it is present or stored.

– DF778 Turbine upstream temperature regulation if it is present or stored.

– DF652 Turbine upstream temperature sensor circuit if it is present or stored.

EDC16C36_V48_DF308/EDC16C36_V50_DF308/EDC16C36_V58_DF308EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 170 of 431

13B-170

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

* diff: differential

DF312

PRESENT

OR

STOREDSPEED REQUEST

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after the engine is started or following a road test.

Special notes:

If the fault is present:

– the special regenerate particle filter warning light is lit or a warning message is

displayed on the instrument panel.

– The vehicle needs to be driven specially to activate particle filter regeneration during

driving.

Priorities when dealing with a number of faults:

Firstly, deal with the following faults:

– DF308 Particle filter clogged if it is present or stored.

– DF311 Failed regenerations limit exceeded if it is present.

– DF315 Particle filter diff* pressure sensor if it is present or stored.

The fault appears after:

– 7 failed regeneration attempts when driving and the weight of soot in the particle filter is greater than

21 g.

– the weight of soot in the particle filter is greater than 58 g.

PART A:

The flow chart on the following page can be used to analyse the driving profile and causes of the activation of this

fault.

EDC16C36_V48_DF312/EDC16C36_V58_DF312EDC16 C36

Program No.: 91

Vdiag No.: 48, 58

Page 183 of 431

13B-183

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

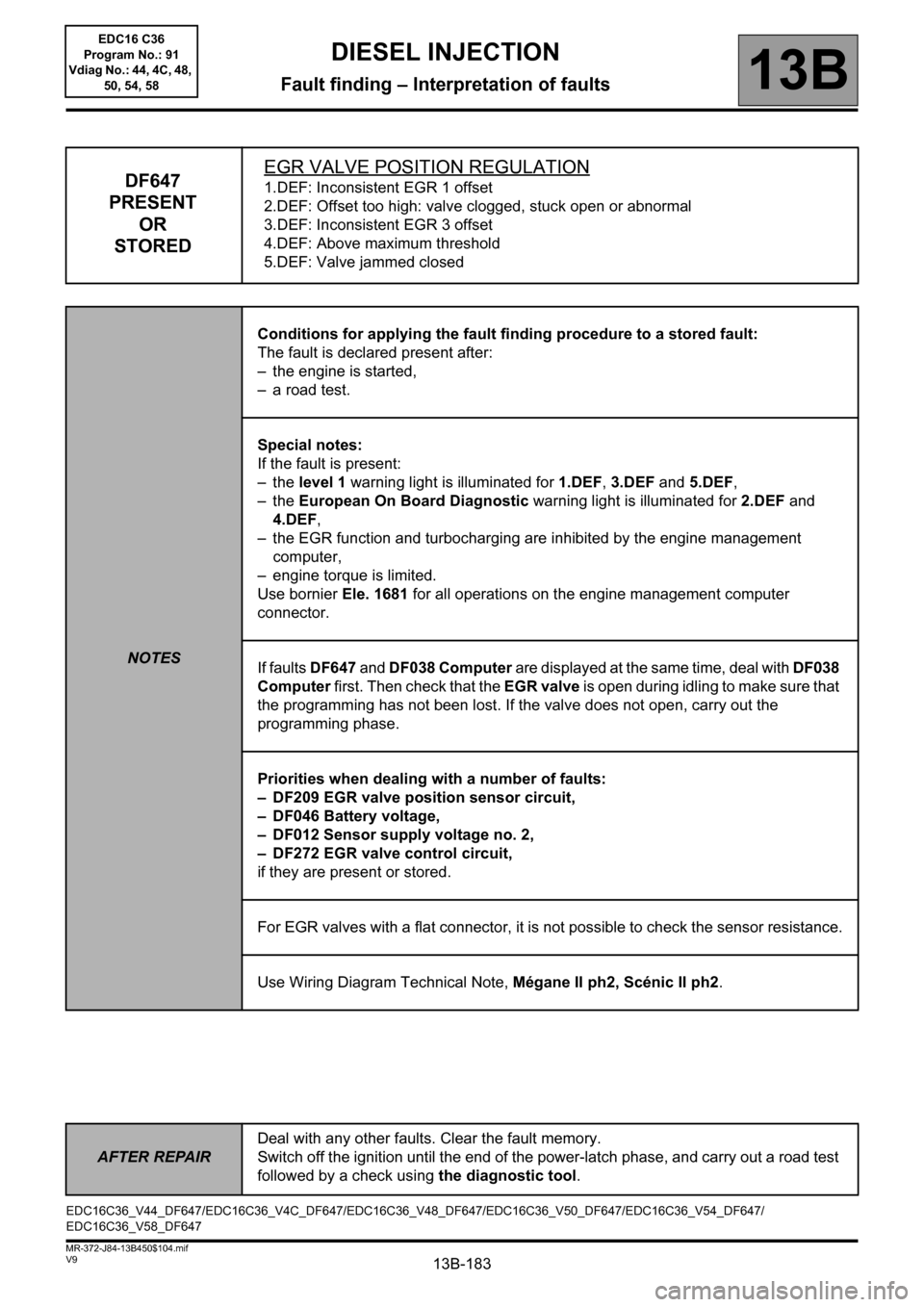

DF647

PRESENT

OR

STOREDEGR VALVE POSITION REGULATION1.DEF: Inconsistent EGR 1 offset

2.DEF: Offset too high: valve clogged, stuck open or abnormal

3.DEF: Inconsistent EGR 3 offset

4.DEF: Above maximum threshold

5.DEF: Valve jammed closed

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the engine is started,

– a road test.

Special notes:

If the fault is present:

–the level 1 warning light is illuminated for 1.DEF, 3.DEF and 5.DEF,

–the European On Board Diagnostic warning light is illuminated for 2.DEF and

4.DEF,

– the EGR function and turbocharging are inhibited by the engine management

computer,

– engine torque is limited.

Use bornier Ele. 1681 for all operations on the engine management computer

connector.

If faults DF647 and DF038 Computer are displayed at the same time, deal with DF038

Computer first. Then check that the EGR valve is open during idling to make sure that

the programming has not been lost. If the valve does not open, carry out the

programming phase.

Priorities when dealing with a number of faults:

– DF209 EGR valve position sensor circuit,

– DF046 Battery voltage,

– DF012 Sensor supply voltage no. 2,

– DF272 EGR valve control circuit,

if they are present or stored.

For EGR valves with a flat connector, it is not possible to check the sensor resistance.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V44_DF647/EDC16C36_V4C_DF647/EDC16C36_V48_DF647/EDC16C36_V50_DF647/EDC16C36_V54_DF647/

EDC16C36_V58_DF647EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 201 of 431

13B-201

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

*ADAC: Trip Computer

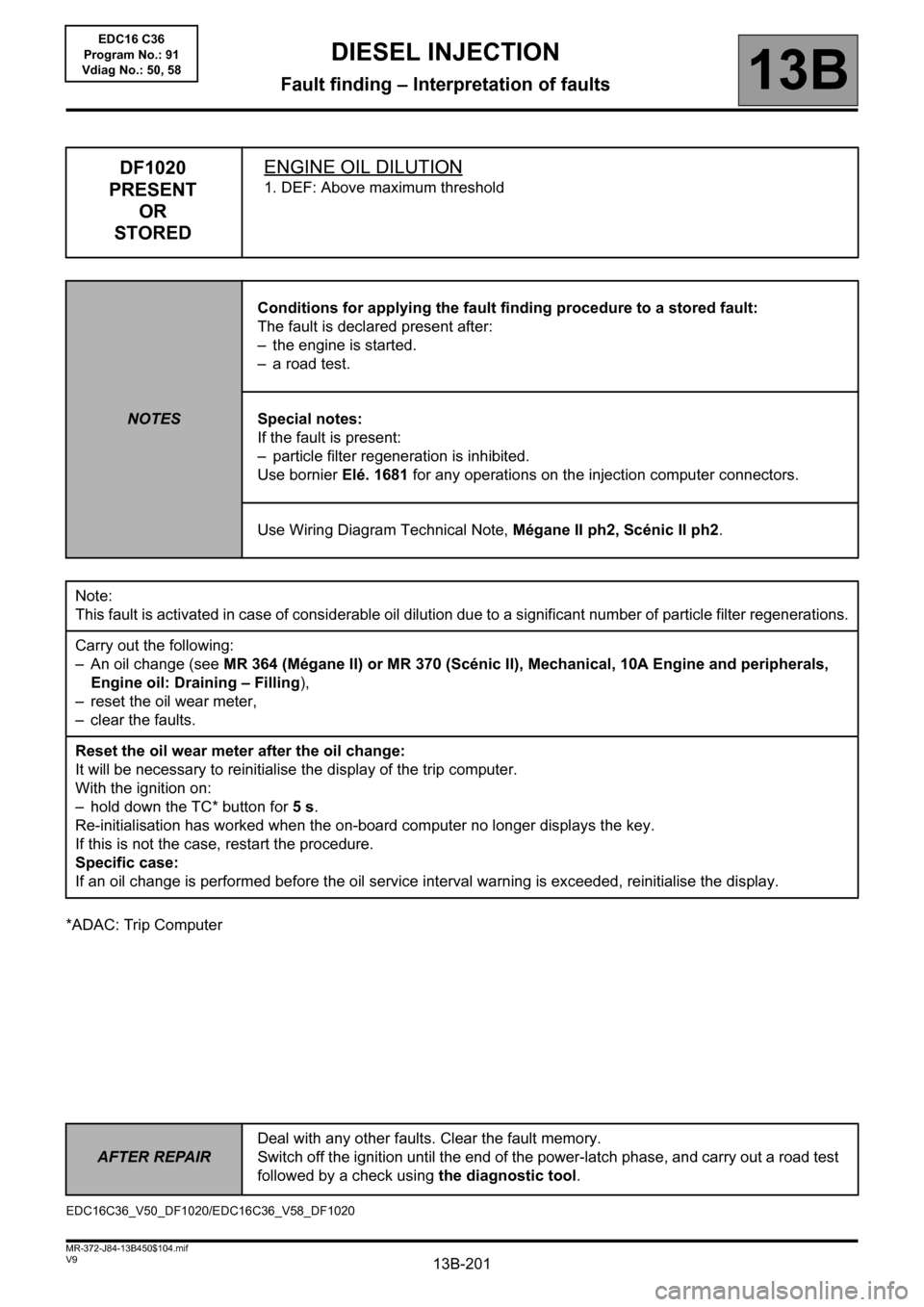

DF1020

PRESENT

OR

STOREDENGINE OIL DILUTION

1. DEF: Above maximum threshold

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the engine is started.

– a road test.

Special notes:

If the fault is present:

– particle filter regeneration is inhibited.

Use bornier Elé. 1681 for any operations on the injection computer connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Note:

This fault is activated in case of considerable oil dilution due to a significant number of particle filter regenerations.

Carry out the following:

– An oil change (see MR 364 (Mégane II) or MR 370 (Scénic II), Mechanical, 10A Engine and peripherals,

Engine oil: Draining – Filling),

– reset the oil wear meter,

– clear the faults.

Reset the oil wear meter after the oil change:

It will be necessary to reinitialise the display of the trip computer.

With the ignition on:

– hold down the TC* button for 5 s.

Re-initialisation has worked when the on-board computer no longer displays the key.

If this is not the case, restart the procedure.

Specific case:

If an oil change is performed before the oil service interval warning is exceeded, reinitialise the display.

EDC16C36_V50_DF1020/EDC16C36_V58_DF1020EDC16 C36

Program No.: 91

Vdiag No.: 50, 58

Page 218 of 431

13B-218V9 MR-372-J84-13B450$131.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

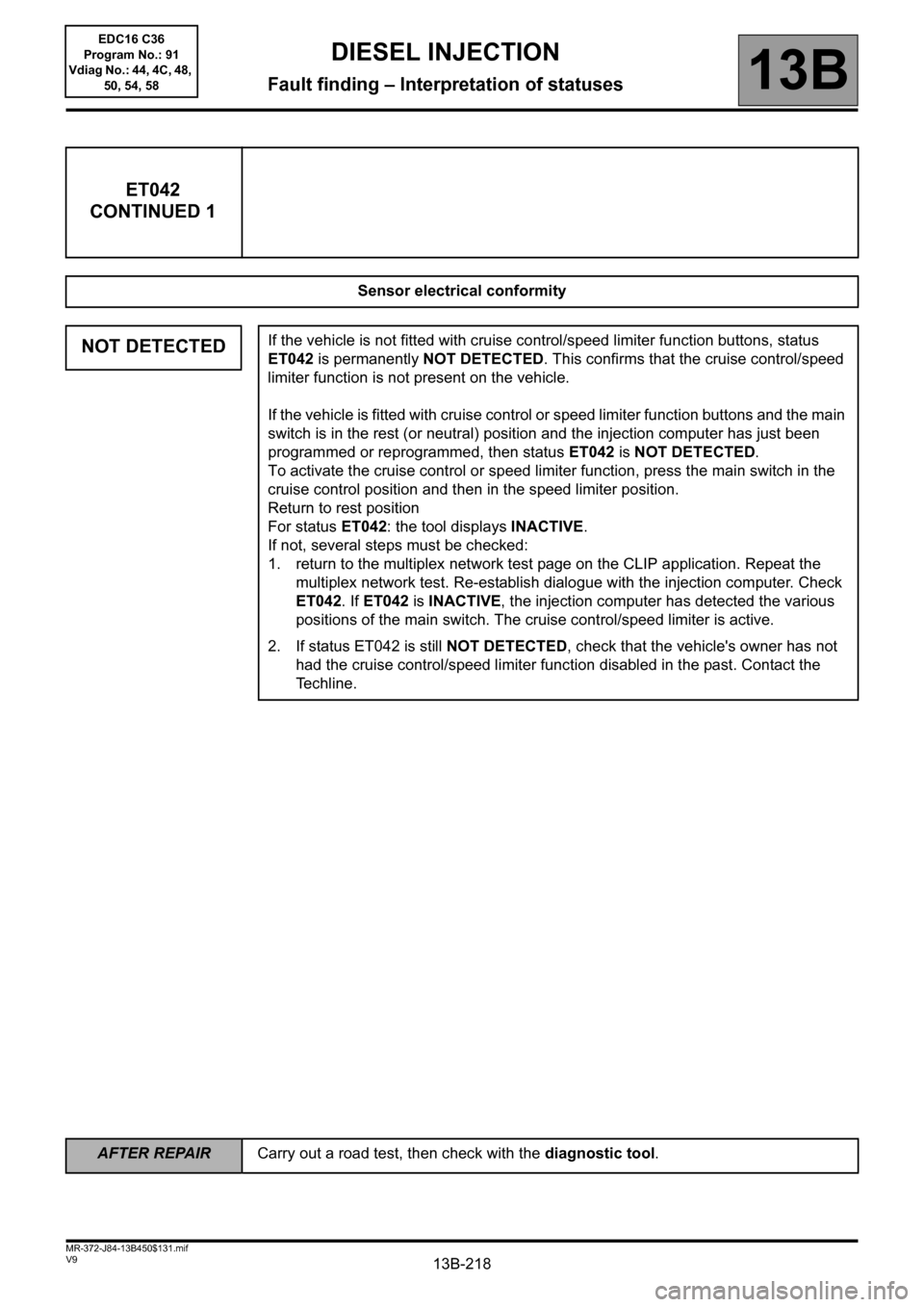

ET042

CONTINUED 1

Sensor electrical conformity

NOT DETECTEDIf the vehicle is not fitted with cruise control/speed limiter function buttons, status

ET042 is permanently NOT DETECTED. This confirms that the cruise control/speed

limiter function is not present on the vehicle.

If the vehicle is fitted with cruise control or speed limiter function buttons and the main

switch is in the rest (or neutral) position and the injection computer has just been

programmed or reprogrammed, then status ET042 is NOT DETECTED.

To activate the cruise control or speed limiter function, press the main switch in the

cruise control position and then in the speed limiter position.

Return to rest position

For status ET042: the tool displays INACTIVE.

If not, several steps must be checked:

1. return to the multiplex network test page on the CLIP application. Repeat the

multiplex network test. Re-establish dialogue with the injection computer. Check

ET042. If ET042 is INACTIVE, the injection computer has detected the various

positions of the main switch. The cruise control/speed limiter is active.

2. If status ET042 is still NOT DETECTED, check that the vehicle's owner has not

had the cruise control/speed limiter function disabled in the past. Contact the

Techline.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 241 of 431

13B-241V9 MR-372-J84-13B450$131.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

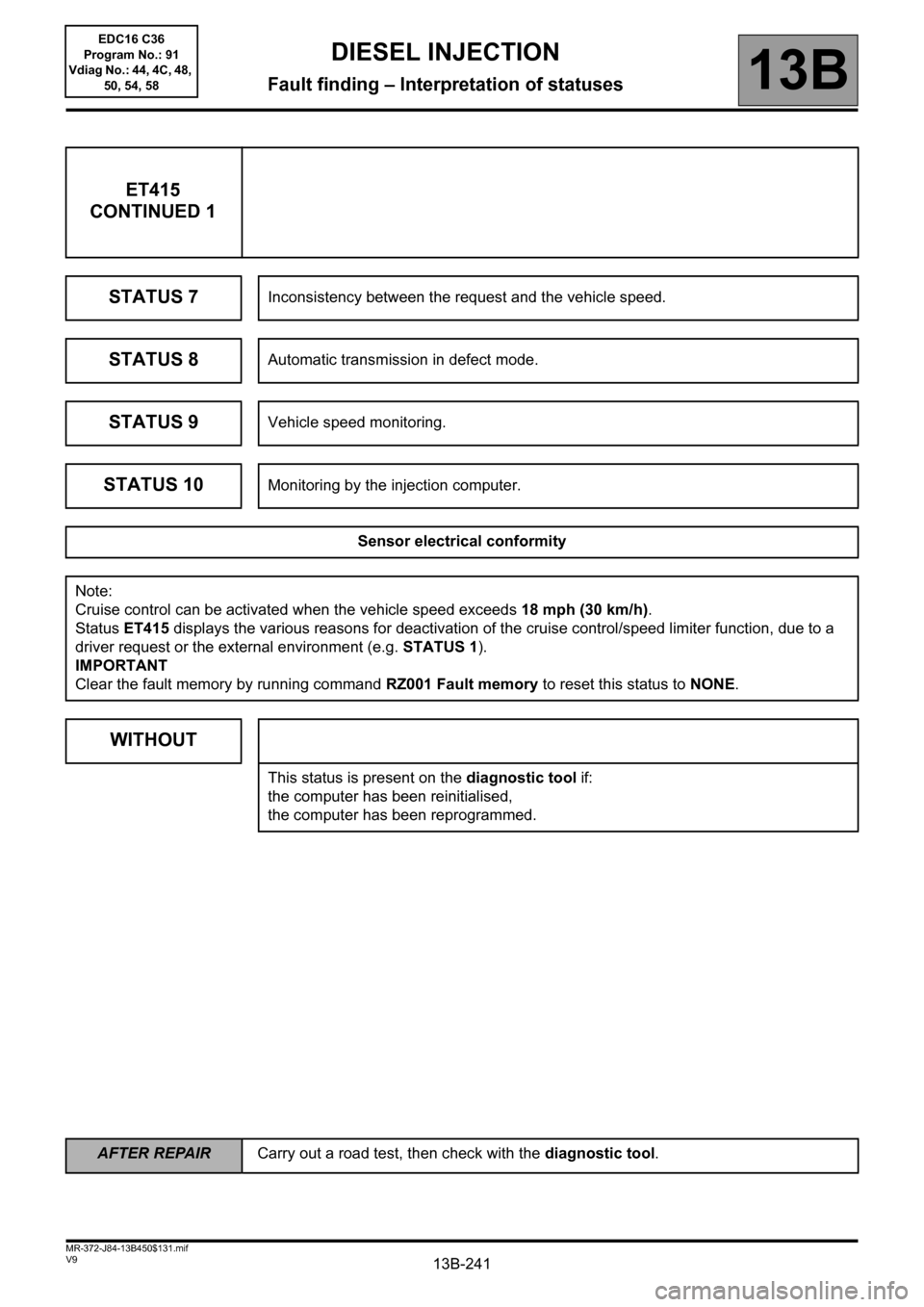

ET415

CONTINUED 1

STATUS 7

Inconsistency between the request and the vehicle speed.

STATUS 8Automatic transmission in defect mode.

STATUS 9Vehicle speed monitoring.

STATUS 10Monitoring by the injection computer.

Sensor electrical conformity

Note:

Cruise control can be activated when the vehicle speed exceeds 18 mph (30 km/h).

Status ET415 displays the various reasons for deactivation of the cruise control/speed limiter function, due to a

driver request or the external environment (e.g. STATUS 1).

IMPORTANT

Clear the fault memory by running command RZ001 Fault memory to reset this status to NONE.

WITHOUT

This status is present on the diagnostic tool if:

the computer has been reinitialised,

the computer has been reprogrammed.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 250 of 431

13B-250V9 MR-372-J84-13B450$132.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

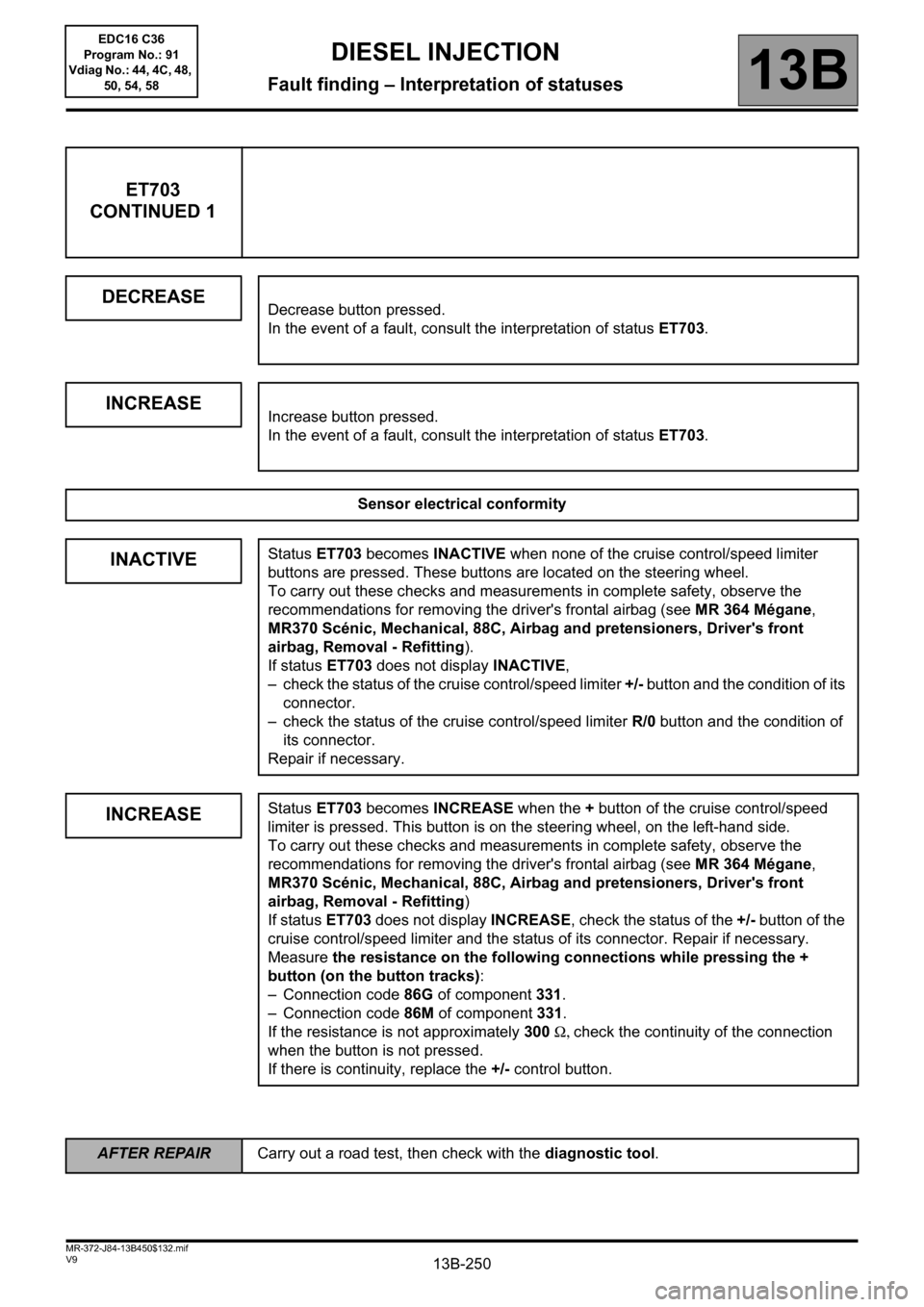

ET703

CONTINUED 1

DECREASE

Decrease button pressed.

In the event of a fault, consult the interpretation of status ET703.

INCREASEIncrease button pressed.

In the event of a fault, consult the interpretation of status ET703.

Sensor electrical conformity

INACTIVEStatus ET703 becomes INACTIVE when none of the cruise control/speed limiter

buttons are pressed. These buttons are located on the steering wheel.

To carry out these checks and measurements in complete safety, observe the

recommendations for removing the driver's frontal airbag (see MR 364 Mégane,

MR370 Scénic, Mechanical, 88C, Airbag and pretensioners, Driver's front

airbag, Removal - Refitting).

If status ET703 does not display INACTIVE,

– check the status of the cruise control/speed limiter +/- button and the condition of its

connector.

– check the status of the cruise control/speed limiter R/0 button and the condition of

its connector.

Repair if necessary.

INCREASEStatus ET703 becomes INCREASE when the + button of the cruise control/speed

limiter is pressed. This button is on the steering wheel, on the left-hand side.

To carry out these checks and measurements in complete safety, observe the

recommendations for removing the driver's frontal airbag (see MR 364 Mégane,

MR370 Scénic, Mechanical, 88C, Airbag and pretensioners, Driver's front

airbag, Removal - Refitting)

If status ET703 does not display INCREASE, check the status of the +/- button of the

cruise control/speed limiter and the status of its connector. Repair if necessary.

Measure the resistance on the following connections while pressing the +

button (on the button tracks):

– Connection code 86G of component 331.

– Connection code 86M of component 331.

If the resistance is not approximately 300 Ω, check the continuity of the connection

when the button is not pressed.

If there is continuity, replace the +/- control button.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58