fuel RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 51 of 431

13B-51V9 MR-372-J84-13B450$101.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF007

CONTINUED 3

1.DEF

2.DEFNOTESThe fault is declared present or stored after an attempt to

start or after starting, with the engine cold, several hours

after the last trip (the difference in the coolant temperature

from the last engine stop and the present attempt to start

must be at least 60°C).

The level 1 warning light is on.

Check the condition of the rail pressure sensor connector (see Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2, component code 1032).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check that there are no external diesel leaks from the high pressure fuel circuit.

Check the continuity and for the absence of interference resistance on the following connections:

– connection code 3LZ between components 120 and 1032,

– connection code 3LX between components 120 and 1032,

– connection code 3LY between components 120 and 1032.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

With the ignition on and the engine stopped for over 1 minute:

View parameter PR038 Rail pressure.

– If the pressure is below 90 bar, the sensor is in order.

– If the pressure is above 90 bar, contact the Techline.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 108 of 431

13B-108V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF065

CONTINUED

DF065 appears on the diagnostic tool when the engine management computer has detected a fault during the

combustion phase several times in succession.

Several components may be responsible:

– the piston rings,

– the piston,

– the valves,

– the injector,

– the heater plug sealing.

Check that the stored injector codes are consistent with those engraved on each injector. If not, run command

SC002 Enter injector codes, and follow the procedure.

When dealing with a number of misfiring faults, check the fuel conformity by running test 11 Diesel fuel

conformity check.

Check the engine compressions.

Carry out the necessary repairs.

If the fault is still present, apply test 10: Incorrect injector operation.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 113 of 431

13B-113V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF098

PRESENT

OR

STOREDFUEL TEMPERATURE SENSOR CIRCUIT

CC.0: Short circuit to earth

CO.1: Open circuit or short circuit to +12 V

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on.

– Engine running

Special notes:

If the fault is present:

– the fuel temperature safe value PR063 Fuel temperature = 100°C.

Use bornier Elé. 1681 for all operations on the engine management computer

connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

CC.0

NOTESNone.

Check the condition of the fuel temperature sensor connector (see Wiring Diagram Technical Note, Mégane II

ph2, Scénic II ph2, component code 1066).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Measure the resistance of the fuel temperature sensor between the following connections:

– Connection code 3FAB of component 1066.

– Connection code 3LD of component 1066.

Replace the sensor if resistance is less than 85Ω or greater than 50 kΩ.

EDC16C36_V44_DF098/EDC16C36_V4C_DF098/EDC16C36_V48_DF098/EDC16C36_V50_DF098/EDC16C36_V54_DF098/

EDC16C36_V58_DF098

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 114 of 431

13B-114V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF098

CONTINUED

Check the insulation to earth of the following connection:

– Connection code 3FAB between components 1066 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

•3XU between components 120 and 1288,

•3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

CO.1

NOTESNone.

Check the condition of the fuel temperature sensor connector (see Wiring Diagram Technical Note, Mégane II

ph2, Scénic II ph2, component code 1066).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair) repair the wiring, otherwise replace it.

Measure the resistance of the fuel temperature sensor between the following connections:

– Connection code 3FAB of component 1066.

– Connection code 3LD of component 1066.

Replace the sensor if resistance is less than 85Ω or greater than 50 kΩ.

Check the continuity and insulation to + 12 V on the following connections:

– Connection code 3FAB between components 1066 and 120.

– Connection code 3LD between components 1066 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 125 of 431

13B-125

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

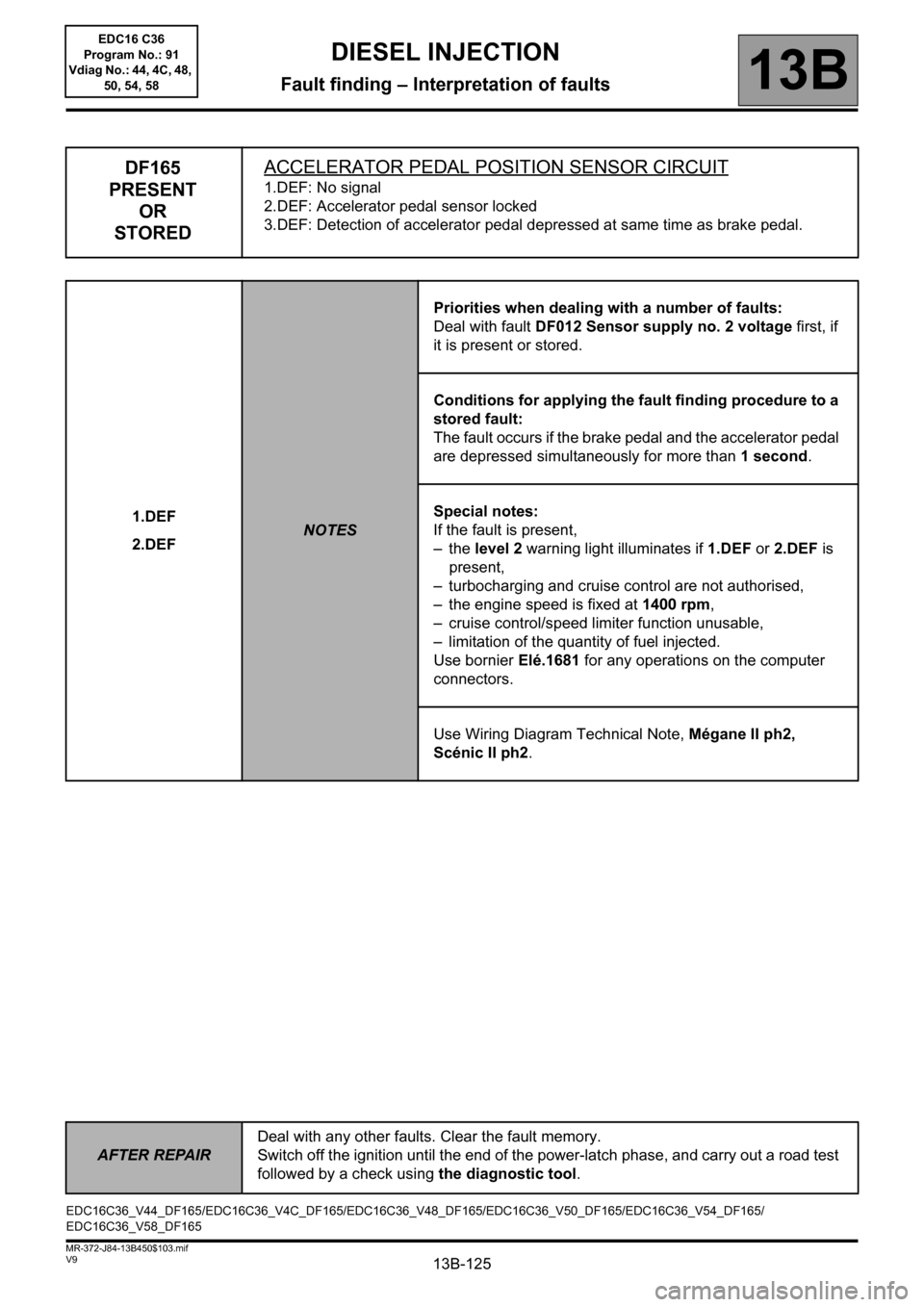

DF165

PRESENT

OR

STOREDACCELERATOR PEDAL POSITION SENSOR CIRCUIT

1.DEF: No signal

2.DEF: Accelerator pedal sensor locked

3.DEF: Detection of accelerator pedal depressed at same time as brake pedal.

1.DEF

2.DEF

NOTESPriorities when dealing with a number of faults:

Deal with fault DF012 Sensor supply no. 2 voltage first, if

it is present or stored.

Conditions for applying the fault finding procedure to a

stored fault:

The fault occurs if the brake pedal and the accelerator pedal

are depressed simultaneously for more than 1 second.

Special notes:

If the fault is present,

–the level 2 warning light illuminates if 1.DEF or 2.DEF is

present,

– turbocharging and cruise control are not authorised,

– the engine speed is fixed at 1400 rpm,

– cruise control/speed limiter function unusable,

– limitation of the quantity of fuel injected.

Use bornier Elé.1681 for any operations on the computer

connectors.

Use Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2.

EDC16C36_V44_DF165/EDC16C36_V4C_DF165/EDC16C36_V48_DF165/EDC16C36_V50_DF165/EDC16C36_V54_DF165/

EDC16C36_V58_DF165EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 159 of 431

13B-159

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

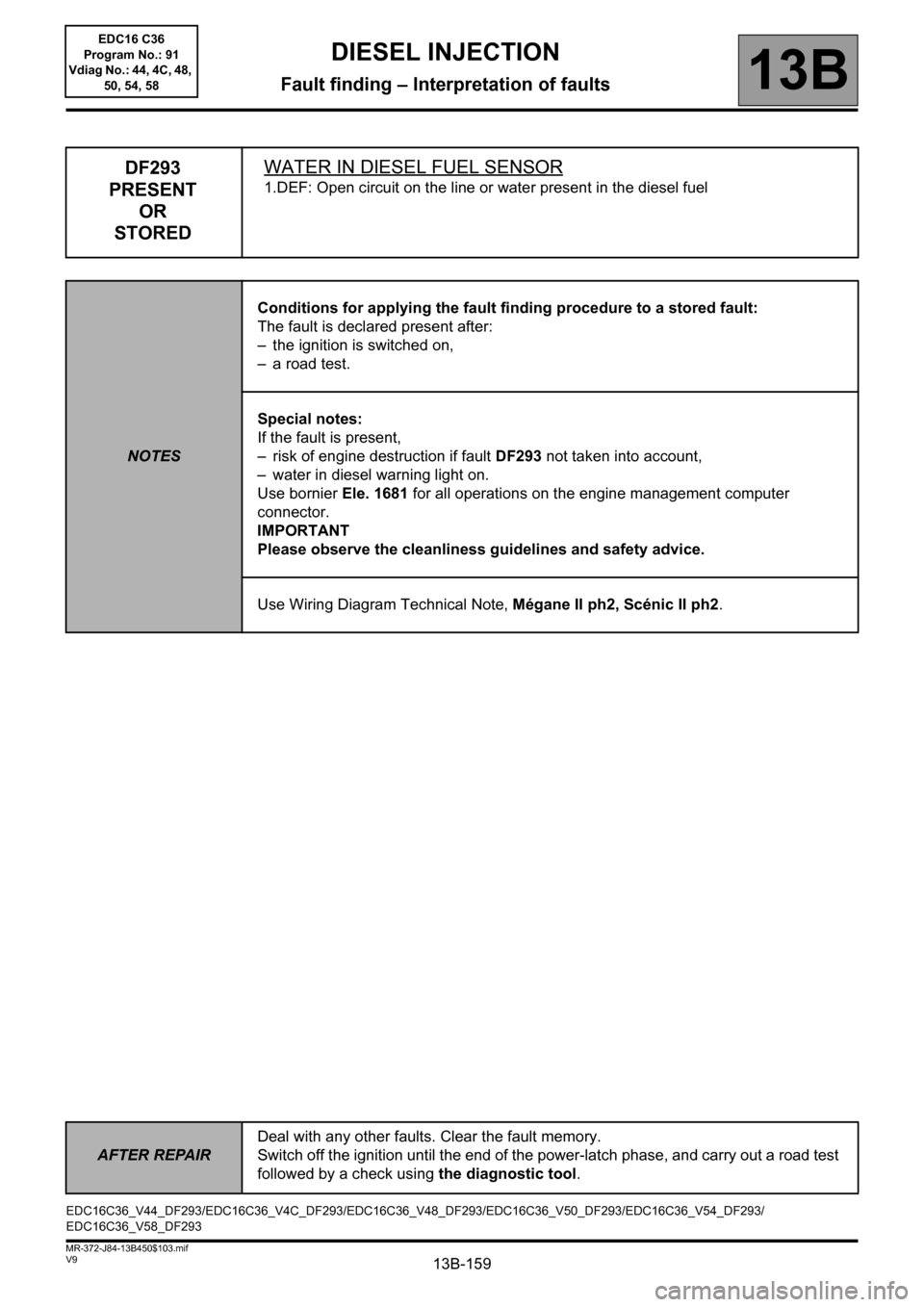

DF293

PRESENT

OR

STOREDWATER IN DIESEL FUEL SENSOR

1.DEF: Open circuit on the line or water present in the diesel fuel

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on,

– a road test.

Special notes:

If the fault is present,

– risk of engine destruction if fault DF293 not taken into account,

– water in diesel warning light on.

Use bornier Ele. 1681 for all operations on the engine management computer

connector.

IMPORTANT

Please observe the cleanliness guidelines and safety advice.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V44_DF293/EDC16C36_V4C_DF293/EDC16C36_V48_DF293/EDC16C36_V50_DF293/EDC16C36_V54_DF293/

EDC16C36_V58_DF293EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 160 of 431

13B-160

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

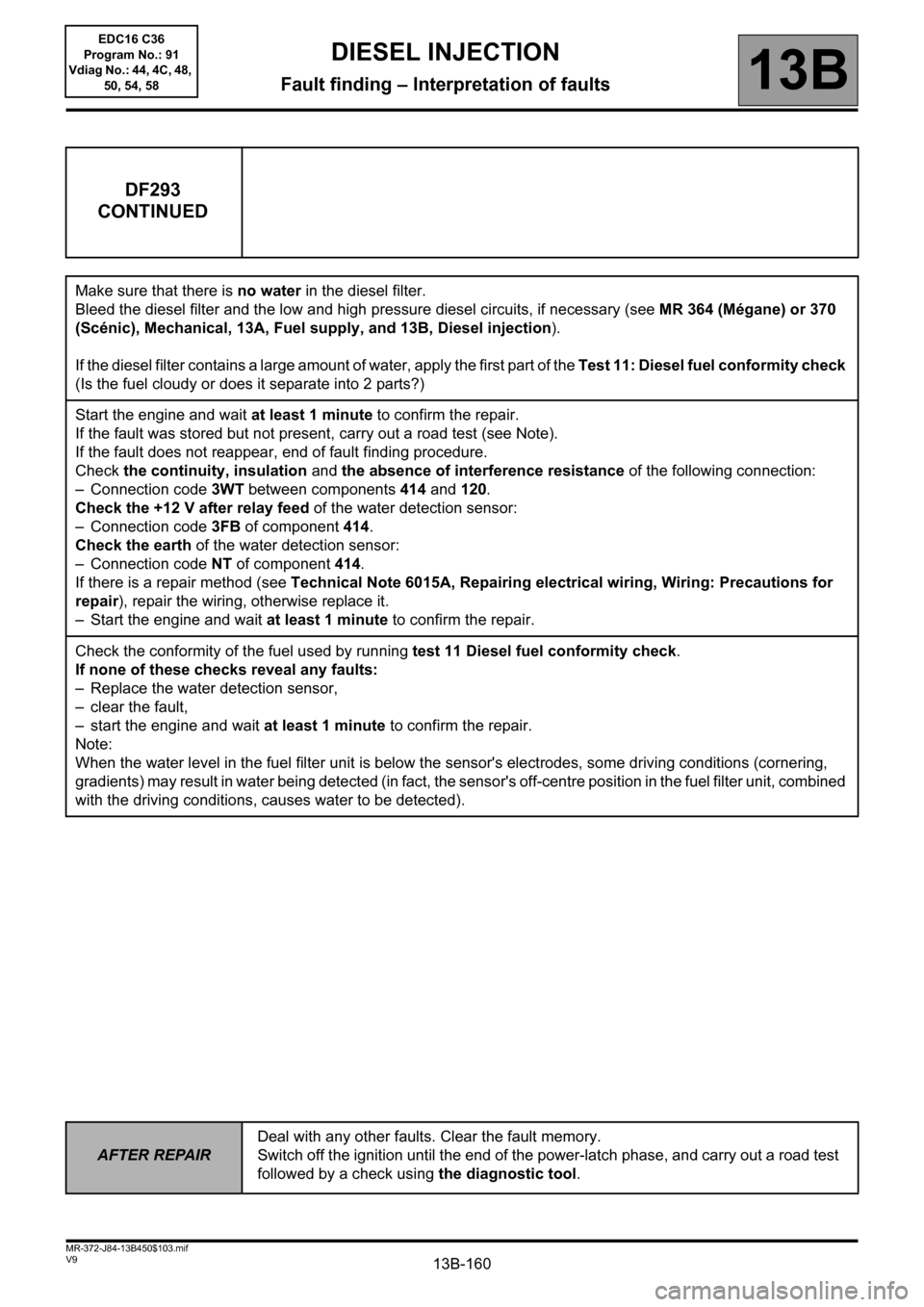

DF293

CONTINUED

Make sure that there is no water in the diesel filter.

Bleed the diesel filter and the low and high pressure diesel circuits, if necessary (see MR 364 (Mégane) or 370

(Scénic), Mechanical, 13A, Fuel supply, and 13B, Diesel injection).

If the diesel filter contains a large amount of water, apply the first part of the Test 11: Diesel fuel conformity check

(Is the fuel cloudy or does it separate into 2 parts?)

Start the engine and wait at least 1 minute to confirm the repair.

If the fault was stored but not present, carry out a road test (see Note).

If the fault does not reappear, end of fault finding procedure.

Check the continuity, insulation and the absence of interference resistance of the following connection:

– Connection code 3WT between components 414 and 120.

Check the +12 V after relay feed of the water detection sensor:

– Connection code3FB of component414.

Check the earth of the water detection sensor:

– Connection code NT of component 414.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

– Start the engine and wait at least 1 minute to confirm the repair.

Check the conformity of the fuel used by running test 11 Diesel fuel conformity check.

If none of these checks reveal any faults:

– Replace the water detection sensor,

– clear the fault,

– start the engine and wait at least 1 minute to confirm the repair.

Note:

When the water level in the fuel filter unit is below the sensor's electrodes, some driving conditions (cornering,

gradients) may result in water being detected (in fact, the sensor's off-centre position in the fuel filter unit, combined

with the driving conditions, causes water to be detected).

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 259 of 431

13B-259V9 MR-372-J84-13B450$140.mif

13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

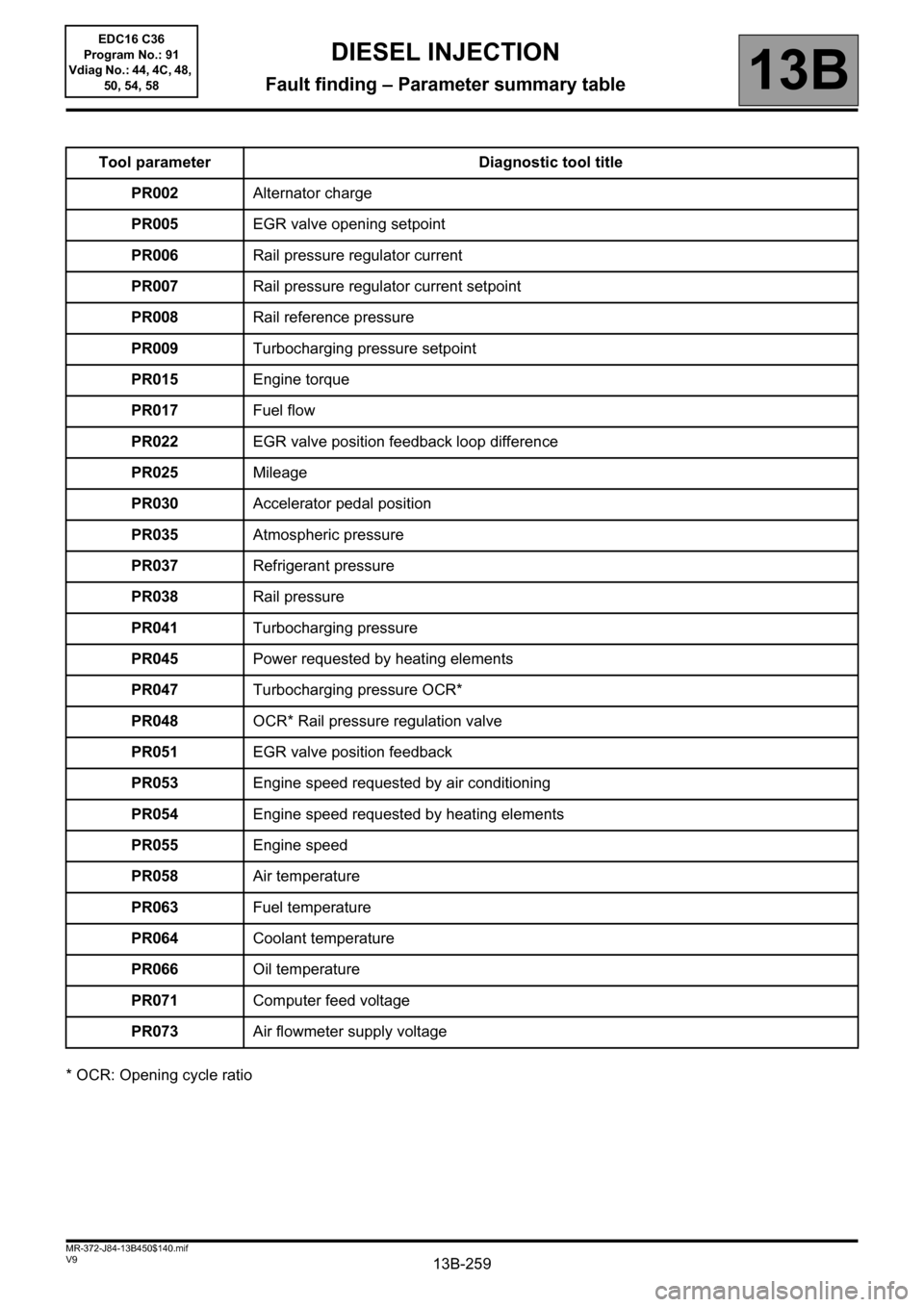

* OCR: Opening cycle ratioTool parameter Diagnostic tool title

PR002Alternator charge

PR005EGR valve opening setpoint

PR006Rail pressure regulator current

PR007Rail pressure regulator current setpoint

PR008Rail reference pressure

PR009Turbocharging pressure setpoint

PR015Engine torque

PR017Fuel flow

PR022EGR valve position feedback loop difference

PR025Mileage

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR041Turbocharging pressure

PR045Power requested by heating elements

PR047Turbocharging pressure OCR*

PR048OCR* Rail pressure regulation valve

PR051EGR valve position feedback

PR053Engine speed requested by air conditioning

PR054Engine speed requested by heating elements

PR055Engine speed

PR058Air temperature

PR063Fuel temperature

PR064Coolant temperature

PR066Oil temperature

PR071Computer feed voltage

PR073Air flowmeter supply voltage

DIESEL INJECTION

Fault finding – Parameter summary table

Page 260 of 431

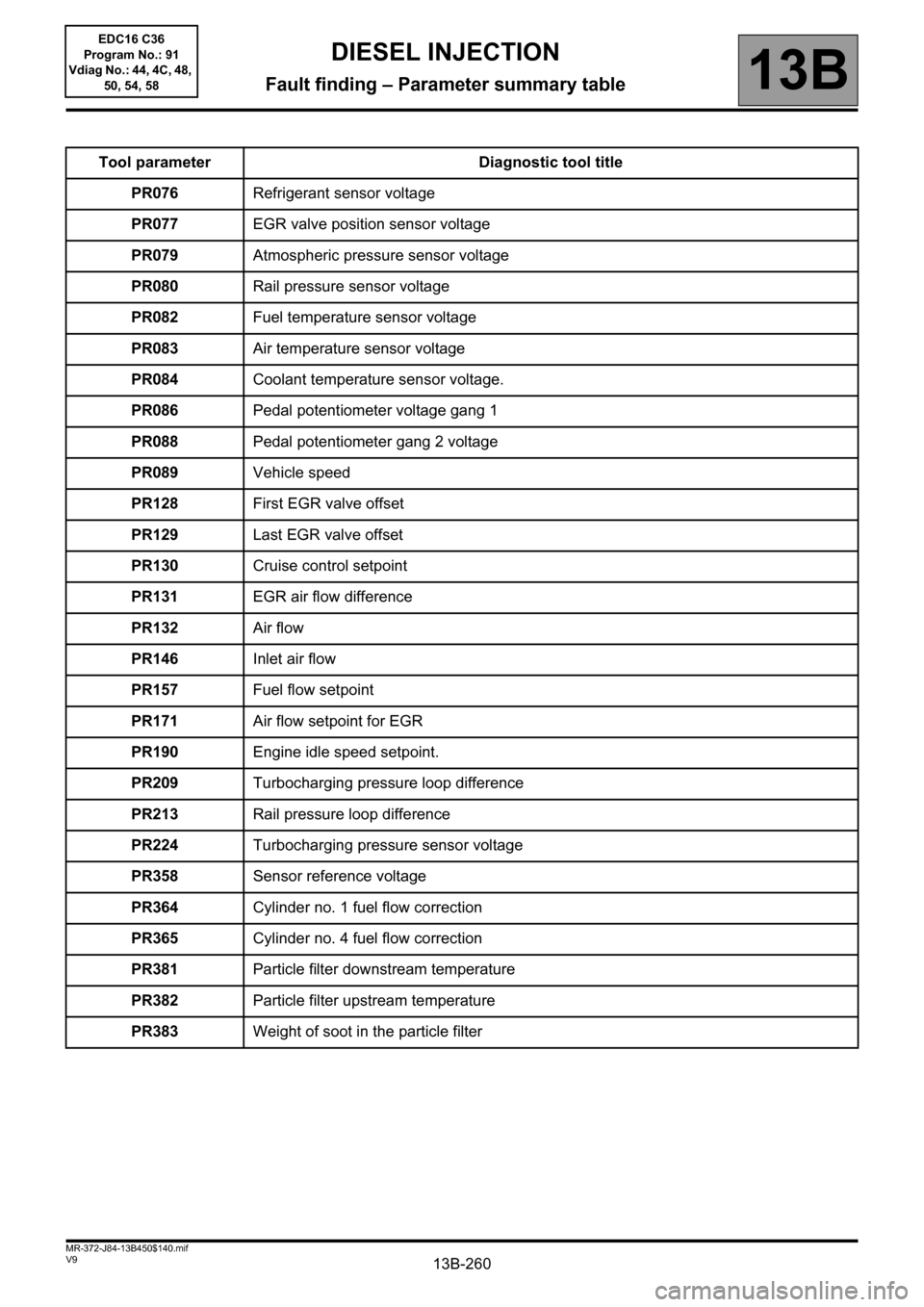

13B-260V9 MR-372-J84-13B450$140.mif

DIESEL INJECTION

Fault finding – Parameter summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Tool parameter Diagnostic tool title

PR076Refrigerant sensor voltage

PR077EGR valve position sensor voltage

PR079Atmospheric pressure sensor voltage

PR080Rail pressure sensor voltage

PR082Fuel temperature sensor voltage

PR083Air temperature sensor voltage

PR084Coolant temperature sensor voltage.

PR086Pedal potentiometer voltage gang 1

PR088Pedal potentiometer gang 2 voltage

PR089Vehicle speed

PR128First EGR valve offset

PR129Last EGR valve offset

PR130Cruise control setpoint

PR131EGR air flow difference

PR132Air flow

PR146Inlet air flow

PR157Fuel flow setpoint

PR171Air flow setpoint for EGR

PR190Engine idle speed setpoint.

PR209Turbocharging pressure loop difference

PR213Rail pressure loop difference

PR224Turbocharging pressure sensor voltage

PR358Sensor reference voltage

PR364Cylinder no. 1 fuel flow correction

PR365Cylinder no. 4 fuel flow correction

PR381Particle filter downstream temperature

PR382Particle filter upstream temperature

PR383Weight of soot in the particle filter

Page 261 of 431

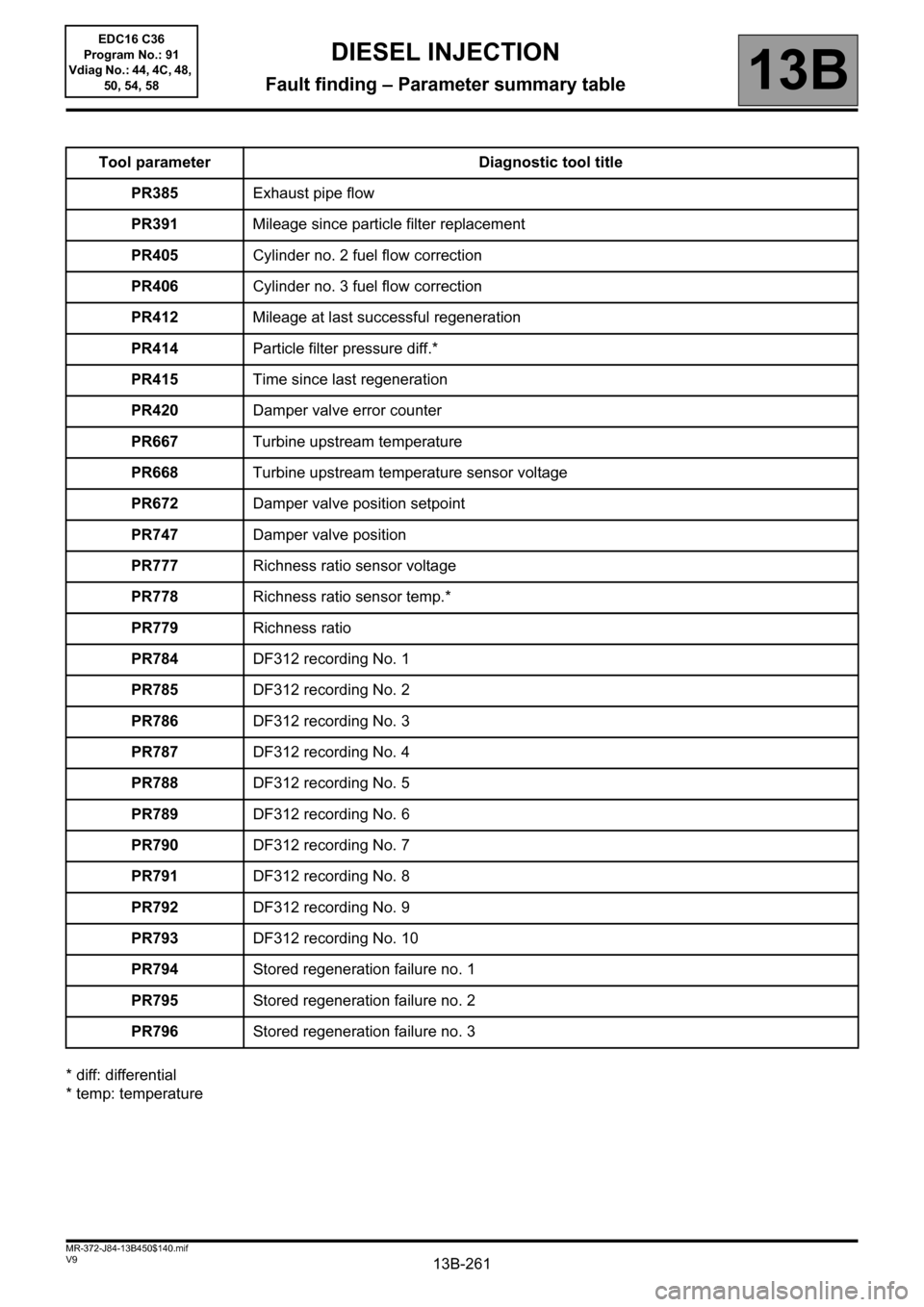

13B-261V9 MR-372-J84-13B450$140.mif

DIESEL INJECTION

Fault finding – Parameter summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

* diff: differential

* temp: temperatureTool parameter Diagnostic tool title

PR385Exhaust pipe flow

PR391Mileage since particle filter replacement

PR405Cylinder no. 2 fuel flow correction

PR406Cylinder no. 3 fuel flow correction

PR412Mileage at last successful regeneration

PR414Particle filter pressure diff.*

PR415Time since last regeneration

PR420Damper valve error counter

PR667Turbine upstream temperature

PR668Turbine upstream temperature sensor voltage

PR672Damper valve position setpoint

PR747Damper valve position

PR777Richness ratio sensor voltage

PR778Richness ratio sensor temp.*

PR779Richness ratio

PR784DF312 recording No. 1

PR785DF312 recording No. 2

PR786DF312 recording No. 3

PR787DF312 recording No. 4

PR788DF312 recording No. 5

PR789DF312 recording No. 6

PR790DF312 recording No. 7

PR791DF312 recording No. 8

PR792DF312 recording No. 9

PR793DF312 recording No. 10

PR794Stored regeneration failure no. 1

PR795Stored regeneration failure no. 2

PR796Stored regeneration failure no. 3