sensor RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 21 of 431

13B-21V9 MR-372-J84-13B450$050.mif

DIESEL INJECTION

Fault finding – Features13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Catalysed particle filter management (for F9Q816 engine only):

The particle filter prevents the escape of carbon particles emitted by the engine but not yet removed from the

exhaust gases.

The particle filter is a microporous structure containing channels arranged so as to force-filter the exhaust gases.

The exhaust pipe consists of several components:

– an oxidation catalytic converter mounted after the turbocharger. This catalytic converter ensures that HC/CO levels

meet current standards by generating the heat (rise in exhaust temperature caused by catalysis) required for

particle filter regeneration.

– a particle filter located under the body,

– a differential pressure sensor to inform the computer of the pressure difference upstream and downstream of the

particle filter

– a particle filter upstream temperature sensor,

– a particle filter downstream temperature sensor (only on certain F9Q816 engines in VDiag 48),

– a temperature sensor upstream of the turbine (TAVT).

During driving, the particle filter becomes loaded with particles of soot. When a given weight of soot determined by

computer mapping is reached, regeneration mode can be triggered if the maximum weight of soot in the particle filter

has not been reached and the engine operating conditions are met (coolant temperature, etc.)

Particle filter regeneration consists of burning the particles of soot that have accumulated in the filter.

The differential pressure sensor measures the particle filter inlet/outlet pressure differential; this measurement is

used to estimate the weight of soot present in the particle filter by mapping in the computer:

(soot weight = pressure differential as a function of exhaust volume flow rate).

Page 24 of 431

13B-24V9 MR-372-J84-13B450$050.mif

DIESEL INJECTION

Fault finding – Features13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

ORANGE particle filter specific warning light (F9Q816 engine only):

F9Q816 Vdiag 48 engines:

This warning light is used to warn the driver that the particle filter is loaded with particles (weight of soot greater than

36 g or more than 6 regeneration failures while driving due to driving conditions not being favourable for

regeneration). As soon as possible the driver must then drive at an average speed of 48 mph (80 km/h) subject to

the road conditions and authorised speed limits.

F9Q816 Vdiag 50 engines:

This warning light is used to warn the driver that the particle filter is loaded with particles.

European On Board Diagnostic management:

The OBD (On Board Diagnostic) system permits detection of any faults relating to the vehicle emission control

system (OBD EURO IV emission control standards being exceeded).

This system should be active for the entire life of the vehicle.

1. Conditions of an OBD fault appearing

An OBD fault will be detected after 3 trip cycles.

It allows the driver to know whether the vehicle has a fault directly linked to the emission control system.

2. System faults displayed by the OBD

List of the faults recorded by the OBD system:

– DF002 Air temperature sensor circuit.

– DF004 Turbocharging pressure sensor circuit.

– DF011 Sensor supply voltage no. 1.

– DF012 Sensor supply voltage no. 2.

– DF013 Sensor supply voltage no. 3.

– DF026 Cylinder 1 injector control circuit.

– DF027 Cylinder 2 injector control circuit.

– DF028 Cylinder 3 injector control circuit.

– DF029 Cylinder 4 injector control circuit.

– DF054 Turbocharging solenoid valve control circuit.

– DF055 Turbocharging pressure regulation circuit.

Page 25 of 431

13B-25V9 MR-372-J84-13B450$050.mif

DIESEL INJECTION

Fault finding – Features13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

– DF056 Air flowmeter circuit.

– DF107 Computer memory.

– DF200 Atmospheric pressure sensor.

– DF209 EGR valve position sensor circuit.

– DF272 EGR valve control circuit.

– DF310 Particle filter upstream temp.* sensor

– DF315 Particle filter diff.* pressure sensor

– DF316 Particle filter diff* pressure

– DF647 EGR valve position regulation.

Some repair operations require programming to ensure that certain engine components function correctly.

Follow the programming procedures (see Replacement of components), if replacing the exhaust gas

recirculation valve or an injector.

*temp: temperature

* diff: differential

3. Conditions for deleting an OBD fault

An OBD fault is deleted in several phases.

The fault present on the diagnostic tool will only become stored (after a repair operation) after the vehicle has

been driven 3 times.

The OBD warning light will only go out after these 3 trips.

The instrument panel warning light coming on does not automatically mean that the system has a fault.

In order for the OBD fault and display parameters to be cleared from the computer, the system requires

40 engine heating cycles.

An engine heating cycle is a driving cycle during which:

– the engine coolant temperature reaches at least 71.1°C,

– the engine coolant temperature varies by 22.2°C in relation to the engine starting temperature.

If one of these conditions is not fulfilled, the OBD fault will still be present or stored on the injection

computer.

Page 26 of 431

13B-26V9 MR-372-J84-13B450$060.mif

13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

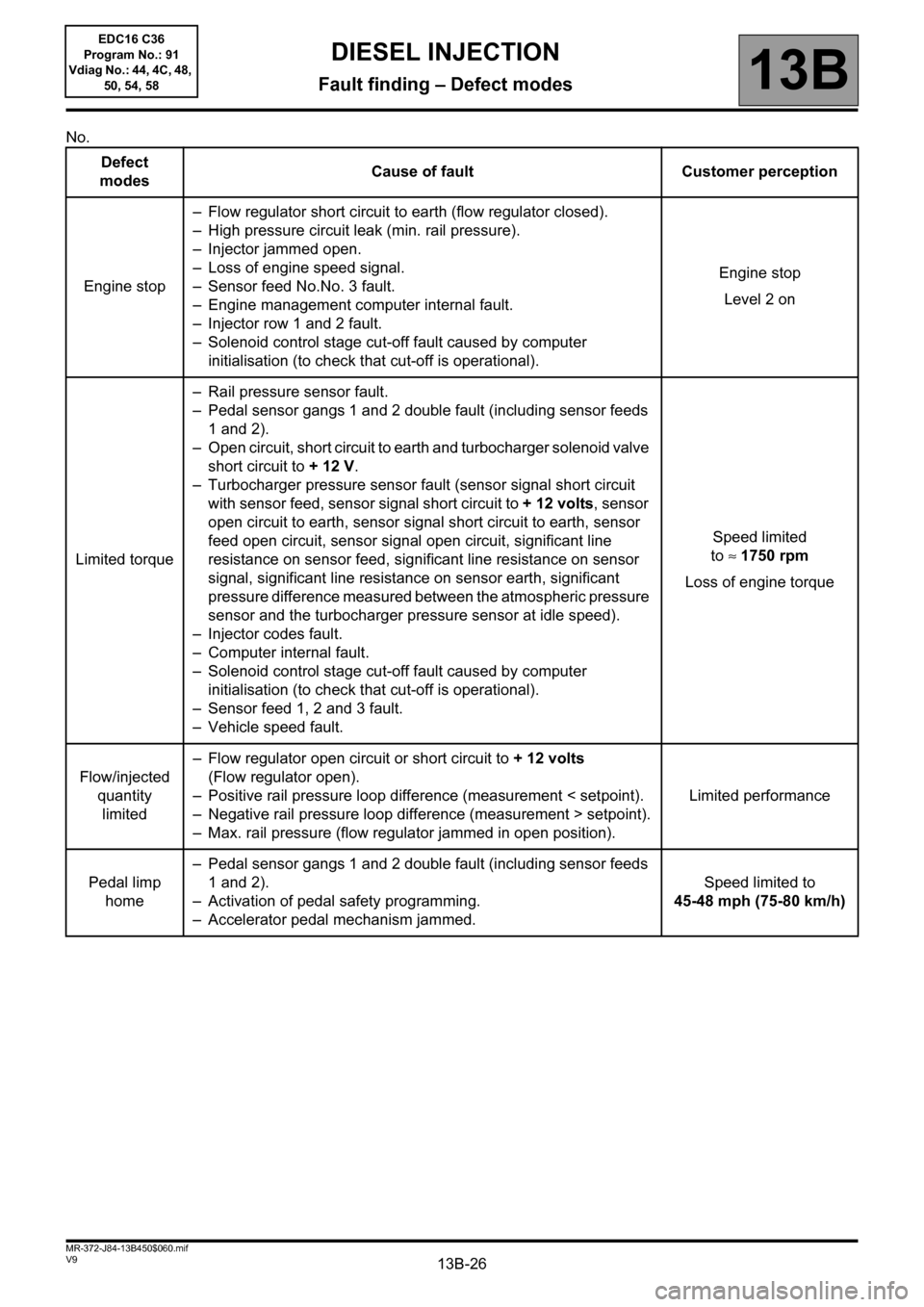

No.

Defect

modesCause of fault Customer perception

Engine stop– Flow regulator short circuit to earth (flow regulator closed).

– High pressure circuit leak (min. rail pressure).

– Injector jammed open.

– Loss of engine speed signal.

– Sensor feed No.No. 3 fault.

– Engine management computer internal fault.

– Injector row 1 and 2 fault.

– Solenoid control stage cut-off fault caused by computer

initialisation (to check that cut-off is operational).Engine stop

Level 2 on

Limited torque– Rail pressure sensor fault.

– Pedal sensor gangs 1 and 2 double fault (including sensor feeds

1 and 2).

– Open circuit, short circuit to earth and turbocharger solenoid valve

short circuit to + 12 V.

– Turbocharger pressure sensor fault (sensor signal short circuit

with sensor feed, sensor signal short circuit to +12volts, sensor

open circuit to earth, sensor signal short circuit to earth, sensor

feed open circuit, sensor signal open circuit, significant line

resistance on sensor feed, significant line resistance on sensor

signal, significant line resistance on sensor earth, significant

pressure difference measured between the atmospheric pressure

sensor and the turbocharger pressure sensor at idle speed).

– Injector codes fault.

– Computer internal fault.

– Solenoid control stage cut-off fault caused by computer

initialisation (to check that cut-off is operational).

– Sensor feed 1, 2 and 3 fault.

– Vehicle speed fault.Speed limited

to≈1750 rpm

Loss of engine torque

Flow/injected

quantity

limited– Flow regulator open circuit or short circuit to + 12 volts

(Flow regulator open).

– Positive rail pressure loop difference (measurement < setpoint).

– Negative rail pressure loop difference (measurement > setpoint).

– Max. rail pressure (flow regulator jammed in open position).Limited performance

Pedal limp

home– Pedal sensor gangs 1 and 2 double fault (including sensor feeds

1 and 2).

– Activation of pedal safety programming.

– Accelerator pedal mechanism jammed.Speed limited to

45-48 mph (75-80 km/h)

DIESEL INJECTION

Fault finding – Defect modes

Page 27 of 431

13B-27V9 MR-372-J84-13B450$060.mif

DIESEL INJECTION

Fault finding – Defect modes13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

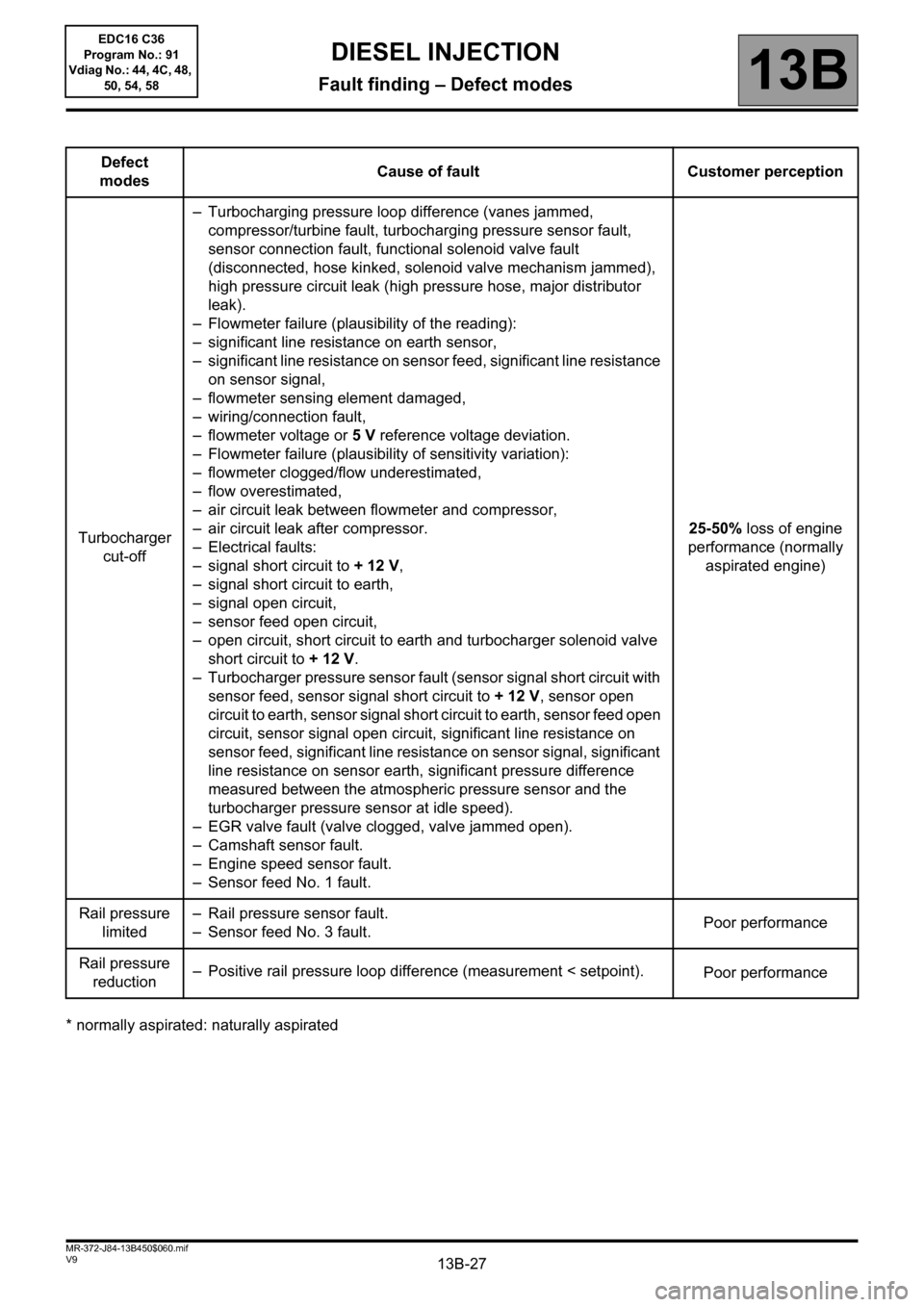

* normally aspirated: naturally aspiratedDefect

modesCause of fault Customer perception

Turbocharger

cut-off– Turbocharging pressure loop difference (vanes jammed,

compressor/turbine fault, turbocharging pressure sensor fault,

sensor connection fault, functional solenoid valve fault

(disconnected, hose kinked, solenoid valve mechanism jammed),

high pressure circuit leak (high pressure hose, major distributor

leak).

– Flowmeter failure (plausibility of the reading):

– significant line resistance on earth sensor,

– significant line resistance on sensor feed, significant line resistance

on sensor signal,

– flowmeter sensing element damaged,

– wiring/connection fault,

– flowmeter voltage or 5 V reference voltage deviation.

– Flowmeter failure (plausibility of sensitivity variation):

– flowmeter clogged/flow underestimated,

– flow overestimated,

– air circuit leak between flowmeter and compressor,

– air circuit leak after compressor.

– Electrical faults:

– signal short circuit to + 12 V,

– signal short circuit to earth,

– signal open circuit,

– sensor feed open circuit,

– open circuit, short circuit to earth and turbocharger solenoid valve

short circuit to + 12 V.

– Turbocharger pressure sensor fault (sensor signal short circuit with

sensor feed, sensor signal short circuit to + 12 V, sensor open

circuit to earth, sensor signal short circuit to earth, sensor feed open

circuit, sensor signal open circuit, significant line resistance on

sensor feed, significant line resistance on sensor signal, significant

line resistance on sensor earth, significant pressure difference

measured between the atmospheric pressure sensor and the

turbocharger pressure sensor at idle speed).

– EGR valve fault (valve clogged, valve jammed open).

– Camshaft sensor fault.

– Engine speed sensor fault.

– Sensor feed No. 1 fault.25-50% loss of engine

performance (normally

aspirated engine)

Rail pressure

limited– Rail pressure sensor fault.

– Sensor feed No. 3 fault.Poor performance

Rail pressure

reduction

– Positive rail pressure loop difference (measurement < setpoint).

Poor performance

Page 28 of 431

13B-28V9 MR-372-J84-13B450$070.mif

13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

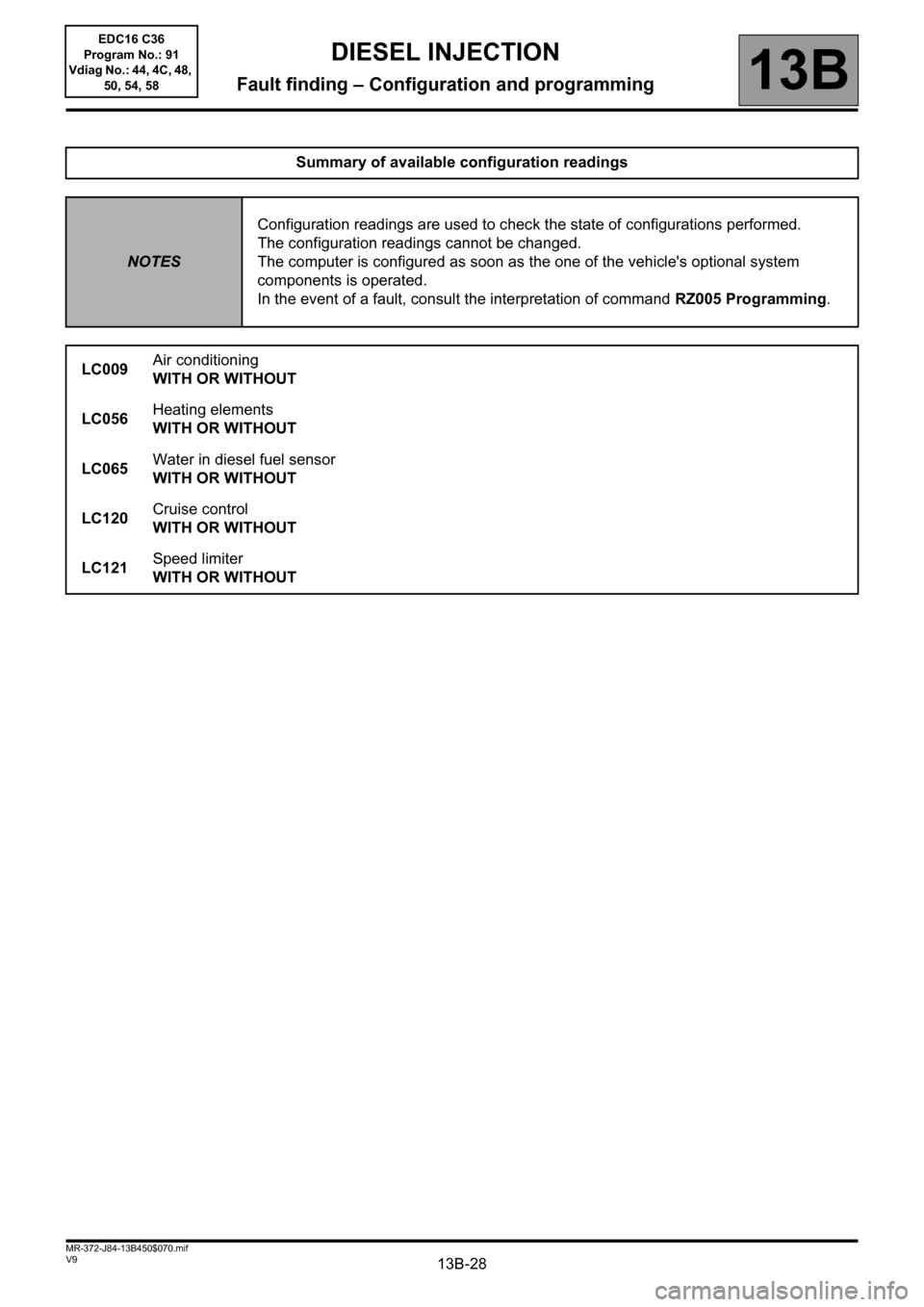

Summary of available configuration readings

NOTESConfiguration readings are used to check the state of configurations performed.

The configuration readings cannot be changed.

The computer is configured as soon as the one of the vehicle's optional system

components is operated.

In the event of a fault, consult the interpretation of command RZ005 Programming.

LC009Air conditioning

WITH OR WITHOUT

LC056Heating elements

WITH OR WITHOUT

LC065Water in diesel fuel sensor

WITH OR WITHOUT

LC120Cruise control

WITH OR WITHOUT

LC121Speed limiter

WITH OR WITHOUT

DIESEL INJECTION

Fault finding – Configuration and programming

Page 34 of 431

13B-34V9 MR-372-J84-13B450$090.mif

13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

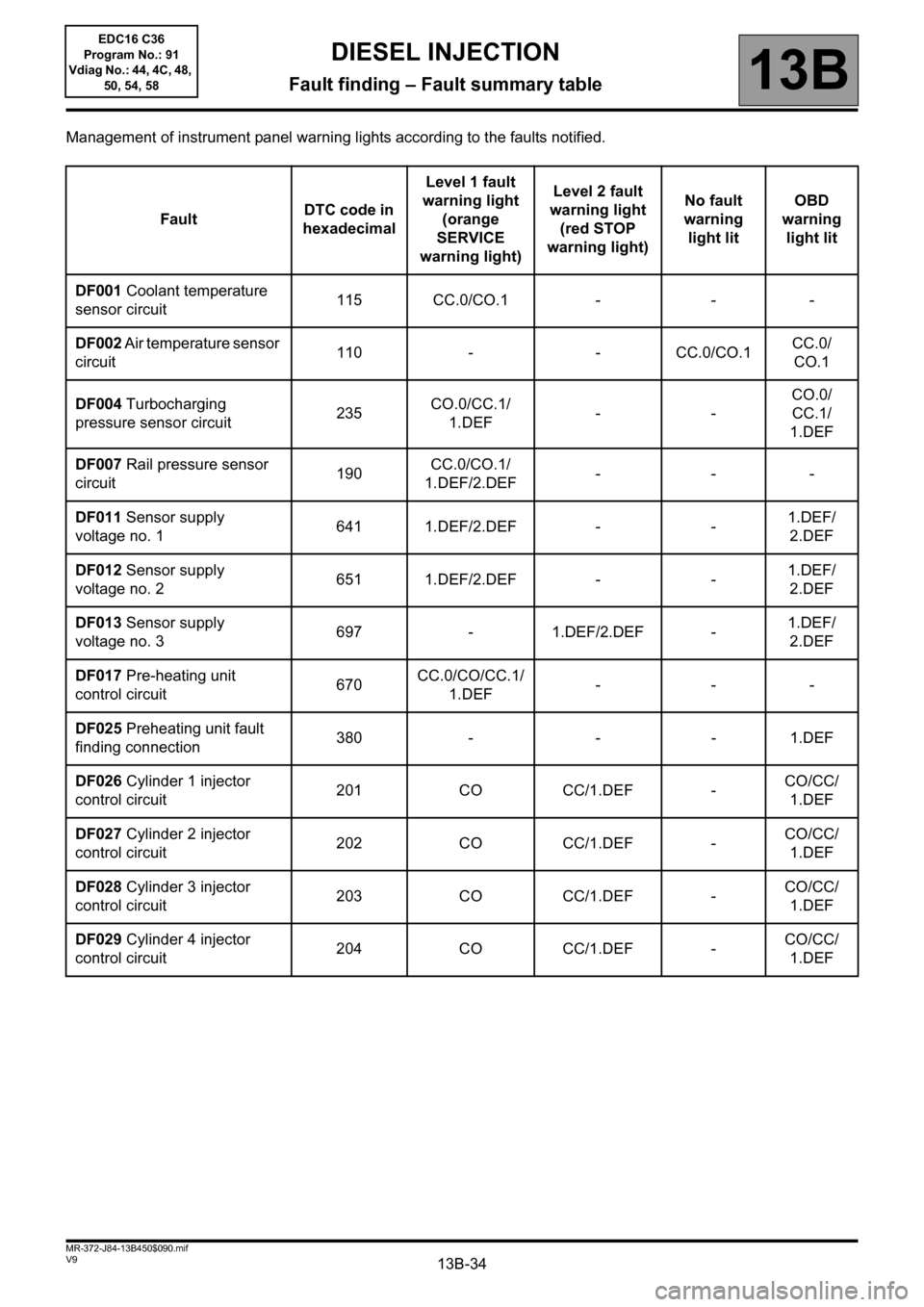

Management of instrument panel warning lights according to the faults notified.

FaultDTC code in

hexadecimalLevel 1 fault

warning light

(orange

SERVICE

warning light)Level 2 fault

warning light

(red STOP

warning light)No fault

warning

light litOBD

warning

light lit

DF001 Coolant temperature

sensor circuit115 CC.0/CO.1 - - -

DF002 Air temperature sensor

circuit110 - - CC.0/CO.1CC.0/

CO.1

DF004 Turbocharging

pressure sensor circuit235CO.0/CC.1/

1.DEF--CO.0/

CC.1/

1.DEF

DF007 Rail pressure sensor

circuit190CC.0/CO.1/

1.DEF/2.DEF---

DF011 Sensor supply

voltage no. 1641 1.DEF/2.DEF - -1.DEF/

2.DEF

DF012 Sensor supply

voltage no. 2651 1.DEF/2.DEF - -1.DEF/

2.DEF

DF013 Sensor supply

voltage no. 3697 - 1.DEF/2.DEF -1.DEF/

2.DEF

DF017 Pre-heating unit

control circuit670CC.0/CO/CC.1/

1.DEF---

DF025 Preheating unit fault

finding connection380 - - - 1.DEF

DF026 Cylinder 1 injector

control circuit201 CO CC/1.DEF -CO/CC/

1.DEF

DF027 Cylinder 2 injector

control circuit202 CO CC/1.DEF -CO/CC/

1.DEF

DF028 Cylinder 3 injector

control circuit203 CO CC/1.DEF -CO/CC/

1.DEF

DF029 Cylinder 4 injector

control circuit204 CO CC/1.DEF -CO/CC/

1.DEF

DIESEL INJECTION

Fault finding – Fault summary table

Page 35 of 431

13B-35V9 MR-372-J84-13B450$090.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

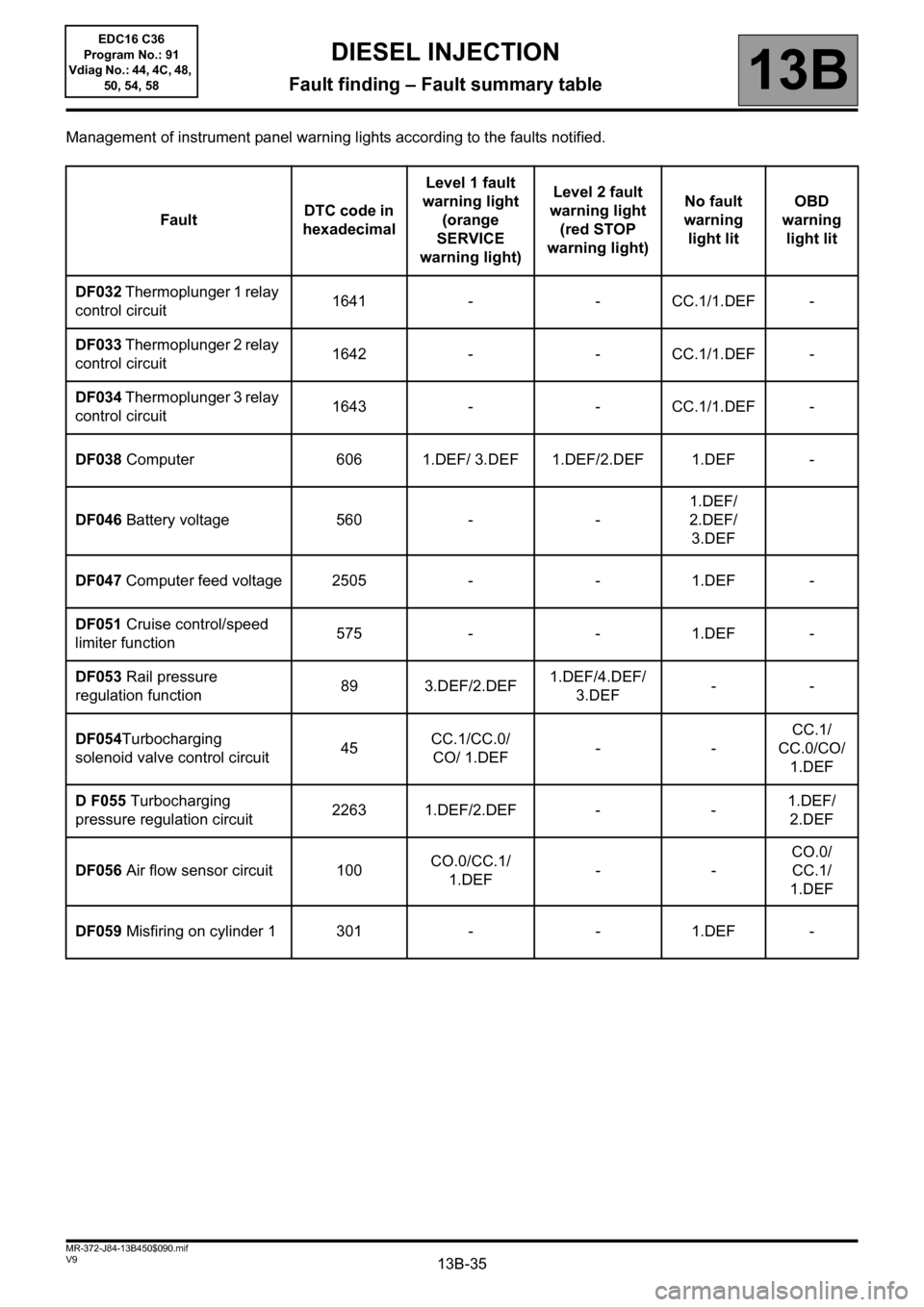

Management of instrument panel warning lights according to the faults notified.

FaultDTC code in

hexadecimalLevel 1 fault

warning light

(orange

SERVICE

warning light)Level 2 fault

warning light

(red STOP

warning light)No fault

warning

light litOBD

warning

light lit

DF032 Thermoplunger 1 relay

control circuit1641 - - CC.1/1.DEF -

DF033 Thermoplunger 2 relay

control circuit1642 - - CC.1/1.DEF -

DF034 Thermoplunger 3 relay

control circuit1643 - - CC.1/1.DEF -

DF038 Computer 606 1.DEF/ 3.DEF 1.DEF/2.DEF 1.DEF -

DF046 Battery voltage 560 - -1.DEF/

2.DEF/

3.DEF

DF047 Computer feed voltage 2505 - - 1.DEF -

DF051 Cruise control/speed

limiter function575 - - 1.DEF -

DF053 Rail pressure

regulation function89 3.DEF/2.DEF1.DEF/4.DEF/

3.DEF--

DF054Turbocharging

solenoid valve control circuit45CC.1/CC.0/

CO/ 1.DEF--CC.1/

CC.0/CO/

1.DEF

D F055 Turbocharging

pressure regulation circuit2263 1.DEF/2.DEF - -1.DEF/

2.DEF

DF056 Air flow sensor circuit 100CO.0/CC.1/

1.DEF--CO.0/

CC.1/

1.DEF

DF059 Misfiring on cylinder 1 301 - - 1.DEF -

Page 36 of 431

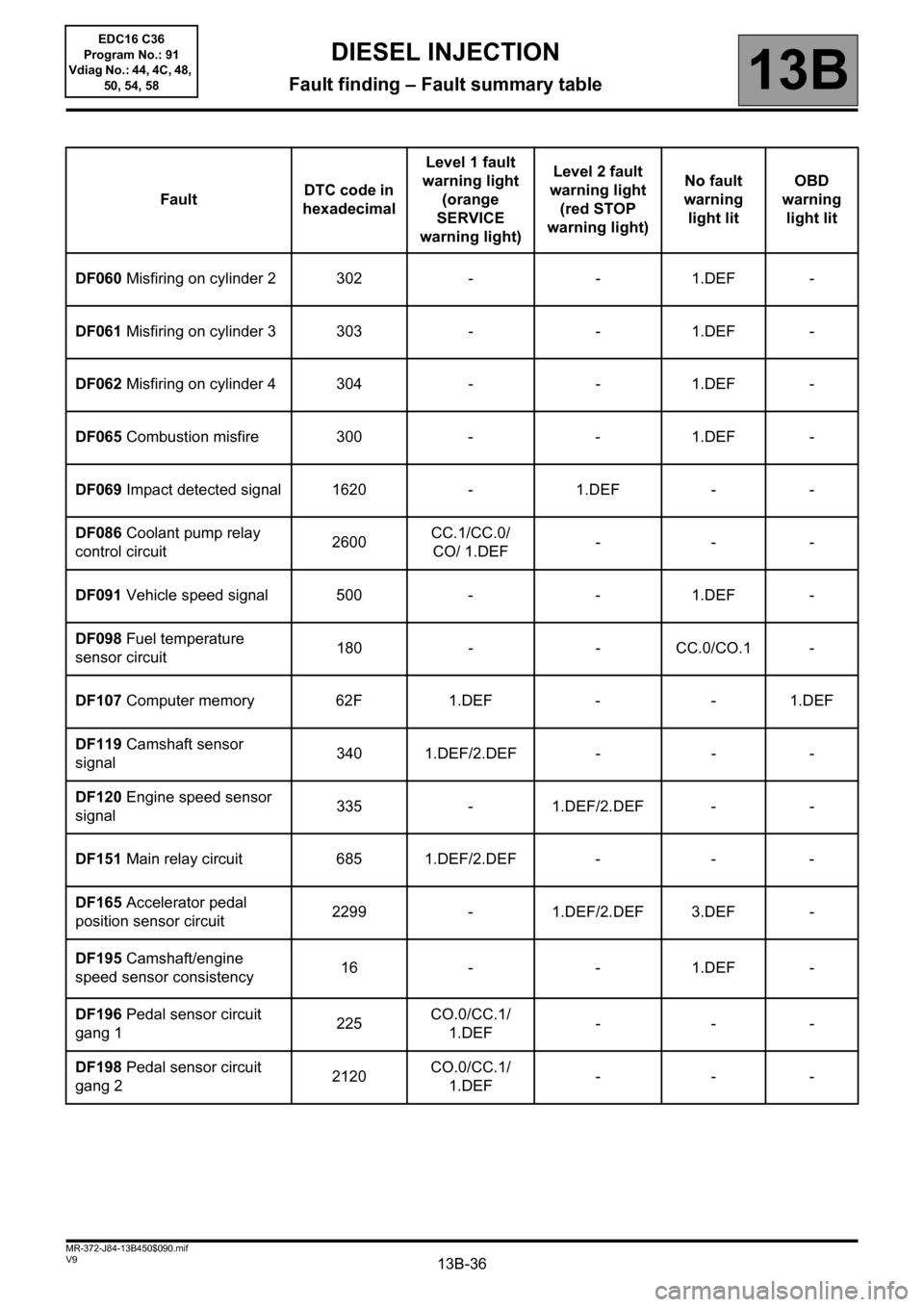

13B-36V9 MR-372-J84-13B450$090.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

FaultDTC code in

hexadecimalLevel 1 fault

warning light

(orange

SERVICE

warning light)Level 2 fault

warning light

(red STOP

warning light)No fault

warning

light litOBD

warning

light lit

DF060 Misfiring on cylinder 2 302 - - 1.DEF -

DF061 Misfiring on cylinder 3 303 - - 1.DEF -

DF062 Misfiring on cylinder 4 304 - - 1.DEF -

DF065 Combustion misfire 300 - - 1.DEF -

DF069 Impact detected signal 1620 - 1.DEF - -

DF086 Coolant pump relay

control circuit2600CC.1/CC.0/

CO/ 1.DEF---

DF091 Vehicle speed signal 500 - - 1.DEF -

DF098 Fuel temperature

sensor circuit180 - - CC.0/CO.1 -

DF107 Computer memory 62F 1.DEF - - 1.DEF

DF119 Camshaft sensor

signal340 1.DEF/2.DEF - - -

DF120 Engine speed sensor

signal335 - 1.DEF/2.DEF - -

DF151 Main relay circuit 685 1.DEF/2.DEF - - -

DF165 Accelerator pedal

position sensor circuit2299 - 1.DEF/2.DEF 3.DEF -

DF195 Camshaft/engine

speed sensor consistency16 - - 1.DEF -

DF196 Pedal sensor circuit

gang 1225CO.0/CC.1/

1.DEF---

DF198 Pedal sensor circuit

gang 22120CO.0/CC.1/

1.DEF---

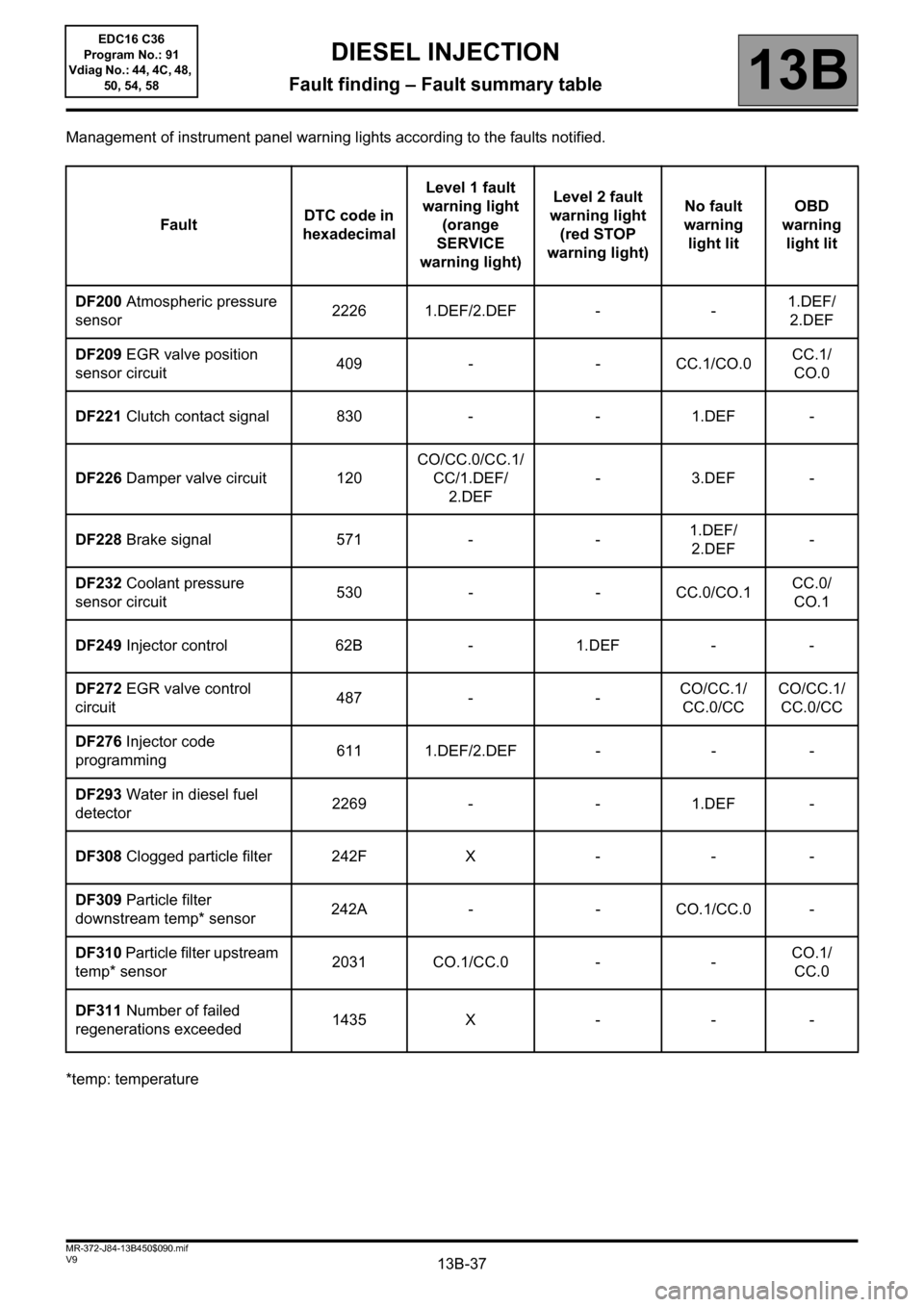

Page 37 of 431

13B-37V9 MR-372-J84-13B450$090.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Management of instrument panel warning lights according to the faults notified.

*temp: temperatureFaultDTC code in

hexadecimalLevel 1 fault

warning light

(orange

SERVICE

warning light)Level 2 fault

warning light

(red STOP

warning light)No fault

warning

light litOBD

warning

light lit

DF200 Atmospheric pressure

sensor2226 1.DEF/2.DEF - -1.DEF/

2.DEF

DF209 EGR valve position

sensor circuit409 - - CC.1/CO.0CC.1/

CO.0

DF221 Clutch contact signal 830 - - 1.DEF -

DF226 Damper valve circuit 120CO/CC.0/CC.1/

CC/1.DEF/

2.DEF-3.DEF-

DF228 Brake signal 571 - -1.DEF/

2.DEF-

DF232 Coolant pressure

sensor circuit530 - - CC.0/CO.1CC.0/

CO.1

DF249 Injector control 62B - 1.DEF - -

DF272 EGR valve control

circuit487 - -CO/CC.1/

CC.0/CCCO/CC.1/

CC.0/CC

DF276 Injector code

programming611 1.DEF/2.DEF - - -

DF293 Water in diesel fuel

detector2269 - - 1.DEF -

DF308 Clogged particle filter 242F X - - -

DF309 Particle filter

downstream temp* sensor242A - - CO.1/CC.0 -

DF310 Particle filter upstream

temp* sensor2031 CO.1/CC.0 - -CO.1/

CC.0

DF311 Number of failed

regenerations exceeded1435 X - - -