ESP RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 119 of 431

13B-119V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF119

CONTINUED 2

2.DEFNOTESPriorities when dealing with a number of faults:

Deal with fault DF120 Engine speed sensor signal, 1.DEF

first if it is present or stored.

Check the condition of the camshaft sensor connector (see Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2, component code 746).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the sensor mounting and the conformity of the camshaft target.

Check that the camshaft sensor/camshaft sprocket air gap is 3 mm maximum.

Check the continuity of the following connections:

– Connection code 3PL between components 746 and 120.

– Connection code 3CQ between components 746 and 120.

Check for + 12 V after relay on connection 3FB of component 746.

If the connector(s) is/are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

– Check the tension of the timing belt.

– Check the conformity of the camshaft sprocket/camshaft assembly.

– Check the timing adjustment.

Carry out the necessary repairs.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 125 of 431

13B-125

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF165

PRESENT

OR

STOREDACCELERATOR PEDAL POSITION SENSOR CIRCUIT

1.DEF: No signal

2.DEF: Accelerator pedal sensor locked

3.DEF: Detection of accelerator pedal depressed at same time as brake pedal.

1.DEF

2.DEF

NOTESPriorities when dealing with a number of faults:

Deal with fault DF012 Sensor supply no. 2 voltage first, if

it is present or stored.

Conditions for applying the fault finding procedure to a

stored fault:

The fault occurs if the brake pedal and the accelerator pedal

are depressed simultaneously for more than 1 second.

Special notes:

If the fault is present,

–the level 2 warning light illuminates if 1.DEF or 2.DEF is

present,

– turbocharging and cruise control are not authorised,

– the engine speed is fixed at 1400 rpm,

– cruise control/speed limiter function unusable,

– limitation of the quantity of fuel injected.

Use bornier Elé.1681 for any operations on the computer

connectors.

Use Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2.

EDC16C36_V44_DF165/EDC16C36_V4C_DF165/EDC16C36_V48_DF165/EDC16C36_V50_DF165/EDC16C36_V54_DF165/

EDC16C36_V58_DF165EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 127 of 431

13B-127

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF165

CONTINUED 2

3.DEFNOTESPriorities when dealing with a number of faults:

Deal with fault DF012 Sensor feed voltage no. 2 first, if it is

present or stored.

Conditions for applying the fault finding procedure to a

stored fault:

The fault occurs if the brake pedal and the accelerator pedal

are depressed simultaneously for more than 30 seconds

without any movement.

Special notes:

Do not interpret the conditions under which the fault occurs.

Make sure that the accelerator pedal is not mechanically jammed (broken spring, floor carpet, etc.).

Check that the brake switch is correctly positioned in its housing.

If the fault is still present, deal with fault DF165 2.DEF.

If the fault is still present, contact the Techline.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 128 of 431

13B-128

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF195

PRESENT

OR

STOREDENGINE SPEED/CAMSHAFT SENSOR CONSISTENCY

1.DEF: Signal incoherent

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

–10 seconds with the starter active,

– a delay of 1 minute with the engine running.

Special notes:

Use bornier Elé. 1681 for any operations on the computer connector.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

1.DEF

NOTESPriorities when dealing with a number of faults:

Apply the interpretation of faults DF119 Camshaft sensor

signal and DF120 Engine speed sensor signal first, if they

are present or stored.

Check the sensor mounting and the conformity of the camshaft target.

Check that the camshaft sensor/camshaft sprocket air gap is 3 mm maximum.

Check the engine speed sensor mounting.

Check the condition of the engine speed sensor and camshaft sensor connectors (see Wiring Diagram Technical

Note, Mégane II ph2, Scénic II ph2, component codes 149 and 746).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

– Check the tension of the timing belt.

– Check the conformity of the camshaft sprocket/camshaft assembly.

– Check the timing adjustment.

Carry out the necessary repairs.

If the fault is still present, contact the Techline.

EDC16C36_V44_DF195/EDC16C36_V4C_DF195/EDC16C36_V48_DF195/EDC16C36_V50_DF195/EDC16C36_V54_DF195/

EDC16C36_V58_DF195EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 129 of 431

13B-129

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF196

PRESENT

OR

STOREDPEDAL SENSOR CIRCUIT GANG 1

CO.0: Open circuit or short circuit to earth

CC.1: Short circuit to +12 V

1.DEF: Consistency between gang 1 and gang 2

NOTESPriorities when dealing with a number of faults:

Deal with fault DF011 Sensor supply voltage no. 1 first if it is present or stored

Conditions for applying the fault finding procedure to a stored fault:

The fault is declared present after a series of full load / no load actions on the

accelerator pedal.

Special notes:

If the fault is present:

– engine torque limited,

– cruise control not authorised,

–the level 1 warning light is lit,

–the level 2 warning light is lit if 1.DEF and only if 2 gangs lost,

– the idle speed is 1400 rpm if 2 gangs lost.

Use bornier Elé.1681 for any operations on the computer connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V44_DF196/EDC16C36_V4C_DF196/EDC16C36_V48_DF196/EDC16C36_V50_DF196/EDC16C36_V54_DF196/

EDC16C36_V58_DF196EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 133 of 431

13B-133

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF198

PRESENT

OR

STOREDPEDAL SENSOR CIRCUIT GANG 2

CO.0: Open circuit or short circuit to earth

CC.1: Short circuit to +12 V

1.DEF: Consistency between gang 1 and gang 2

NOTESPriorities when dealing with a number of faults:

Deal with fault DF012 Sensor feed voltage no. 2 first, if it is present or stored.

Conditions for applying the fault finding procedure to a stored fault:

The fault is declared present after a series of full load / no load actions on the

accelerator pedal.

Special notes:

If the fault is present:

– engine torque is limited

– cruise control not authorised.

–the level 1 warning light is lit,

–the level 2 warning light is lit if 1.DEF and only if 2 gangs lost,

– the idle speed is 1400 rpm if 2 gangs lost.

Use bornier Elé.1681 for any operations on the computer connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V44_DF198/EDC16C36_V4C_DF198/EDC16C36_V48_DF198/EDC16C36_V50_DF198/EDC16C36_V54_DF198/

EDC16C36_V58_DF198EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 139 of 431

13B-139

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF209

PRESENT

OR

STOREDEGR VALVE POSITION SENSOR CIRCUIT

CC.1: Short circuit to +12 V

CO.0: Open circuit or short circuit to earth

NOTESPriorities when dealing with a number of faults:

– DF046 Battery voltage,

– DF012 Sensor supply voltage no. 2,

if present or stored.

Conditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on.

– the engine is started,

– a road test.

Special notes:

If the fault is present:

–the European On Board Diagnostic warning light is lit,

– increase in polluting emissions,

– EGR programming cut-off: valve in the closed position.

Use bornier Ele. 1681 for all operations on the engine management computer

connector.

For EGR valves with a flat connector, it is not possible to check the sensor resistance.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V44_DF209/EDC16C36_V4C_DF209/EDC16C36_V48_DF209/EDC16C36_V50_DF209/EDC16C36_V54_DF209/

EDC16C36_V58_DF209EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 148 of 431

13B-148

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF228

CONTINUED 1

From the List of Statuses menu, check ET012 and ET013 and check:

– brake pedal in rest position ET012 = "RELEASED" and ET013 = "RELEASED"

– brake pedal depressed ET012 = "DEPRESSED" and ET013 = "DEPRESSED"

Has ET013 been correctly recognised?

Has ET012 been correctly recognised?Clear the fault

End of fault finding

procedure

Check the connections of the brake pedal switch, the ABS computer, the electronic stability program

computer and the engine management computer.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Check for + 12 V after ignition feed on the connections of the brake pedal switch connector and the

condition of the fuse.

– Connection code AP10 of component 160.

– Connection code SP13 of component 160.

Disconnect the ABS - ESP and check the continuity and insulation against + 12 V and against earth

of the following connection:

– Connection code 65A between components 160 and 1094.

Check that the brake pedal switch is working correctly:

in rest position: infinite resistance continuity between the following connections:

– Connection code 65A of component 160.

– Connection code AP10 of component 160.

depressed: continuity between the following connections:

– Connection code 65A of component 160.

– Connection code AP10 of component 160.

Replace the switch if necessary.

If the fault is still present, carry out fault finding on the anti-lock braking system - electronic stability

program; if no irregularity is detected, then carry out fault finding on the multiplex network.

YES

YES

NONO

A

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 150 of 431

13B-150

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF232

PRESENT

OR

STOREDREFRIGERANT PRESSURE SENSOR CIRCUIT

CC.0: Short circuit to earth

CO.1: Open circuit or short circuit to +12 V

NOTESPriority when dealing with a number of faults:

If DF012 Sensor feed voltage no. 2 is present or stored:

– deal with it first,

– fan assembly GMV1 activated (low-speed),

– heating and air conditioning system inhibited.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Check the condition of the refrigerant pressure sensor connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 1202) and ensure that it is operating correctly.

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation, continuity and the absence of interference resistance on the following connections:

– connection codes 38U, 38X, 38Y between components 1202 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

•3XU between components 120 and 1288,

•3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

EDC16C36_V44_DF232/EDC16C36_V4C_DF232/EDC16C36_V48_DF232/EDC16C36_V50_DF232/EDC16C36_V54_DF232/

EDC16C36_V58_DF232EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 172 of 431

13B-172

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

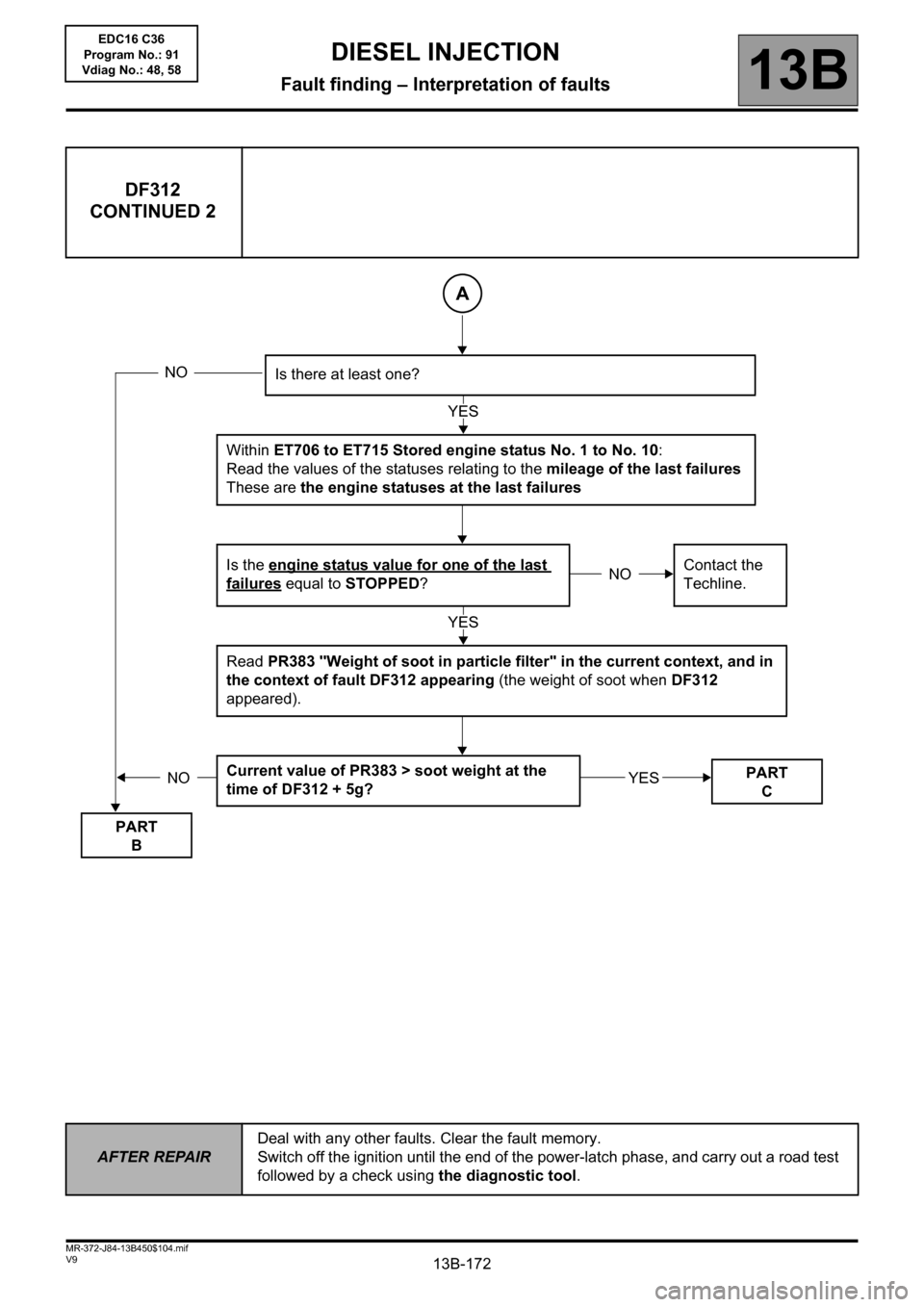

DF312

CONTINUED 2

Is there at least one?

Within ET706 to ET715 Stored engine status No. 1 to No. 10:

Read the values of the statuses relating to the mileage of the last failures

These are the engine statuses at the last failures

Is the engine status value for one of the last

failures equal to STOPPED?Contact the

Techline.

Read PR383 "Weight of soot in particle filter" in the current context, and in

the context of fault DF312 appearing (the weight of soot when DF312

appeared).

Current value of PR383 > soot weight at the

time of DF312 + 5g?

A

YES

NO

NO

YES

PART

B

NOYESPART

C

EDC16 C36

Program No.: 91

Vdiag No.: 48, 58