check engine RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 386 of 431

13B-386

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

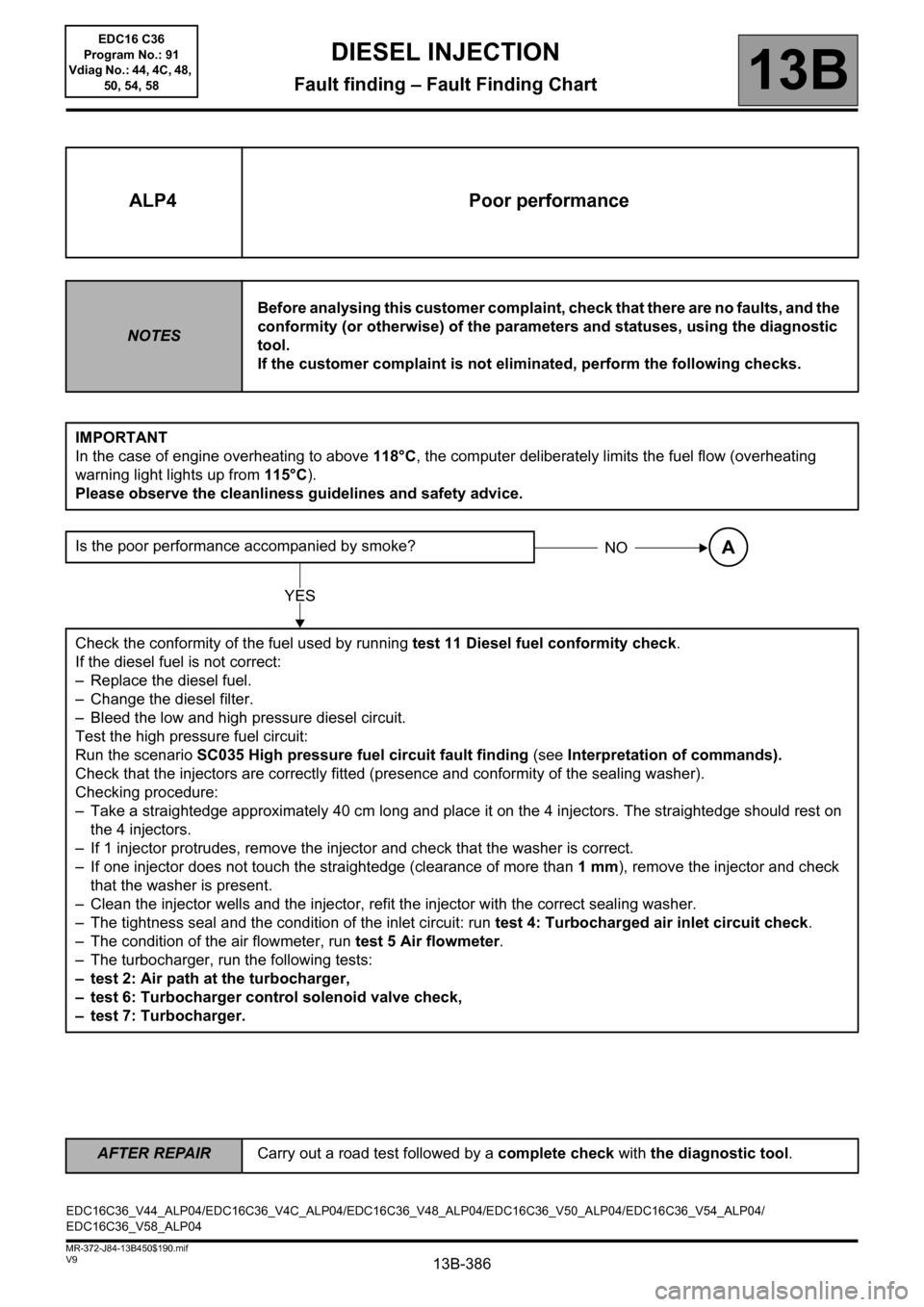

ALP4 Poor performance

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

IMPORTANT

In the case of engine overheating to above 118°C, the computer deliberately limits the fuel flow (overheating

warning light lights up from 115°C).

Please observe the cleanliness guidelines and safety advice.

Is the poor performance accompanied by smoke?

Check the conformity of the fuel used by running test 11 Diesel fuel conformity check.

If the diesel fuel is not correct:

– Replace the diesel fuel.

– Change the diesel filter.

– Bleed the low and high pressure diesel circuit.

Test the high pressure fuel circuit:

Run the scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

Check that the injectors are correctly fitted (presence and conformity of the sealing washer).

Checking procedure:

– Take a straightedge approximately 40 cm long and place it on the 4 injectors. The straightedge should rest on

the 4 injectors.

– If 1 injector protrudes, remove the injector and check that the washer is correct.

– If one injector does not touch the straightedge (clearance of more than 1 mm), remove the injector and check

that the washer is present.

– Clean the injector wells and the injector, refit the injector with the correct sealing washer.

– The tightness seal and the condition of the inlet circuit: run test 4: Turbocharged air inlet circuit check.

– The condition of the air flowmeter, run test 5 Air flowmeter.

– The turbocharger, run the following tests:

– test 2: Air path at the turbocharger,

– test 6: Turbocharger control solenoid valve check,

– test 7: Turbocharger.

NOA

YES

EDC16C36_V44_ALP04/EDC16C36_V4C_ALP04/EDC16C36_V48_ALP04/EDC16C36_V50_ALP04/EDC16C36_V54_ALP04/

EDC16C36_V58_ALP04EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 387 of 431

13B-387

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

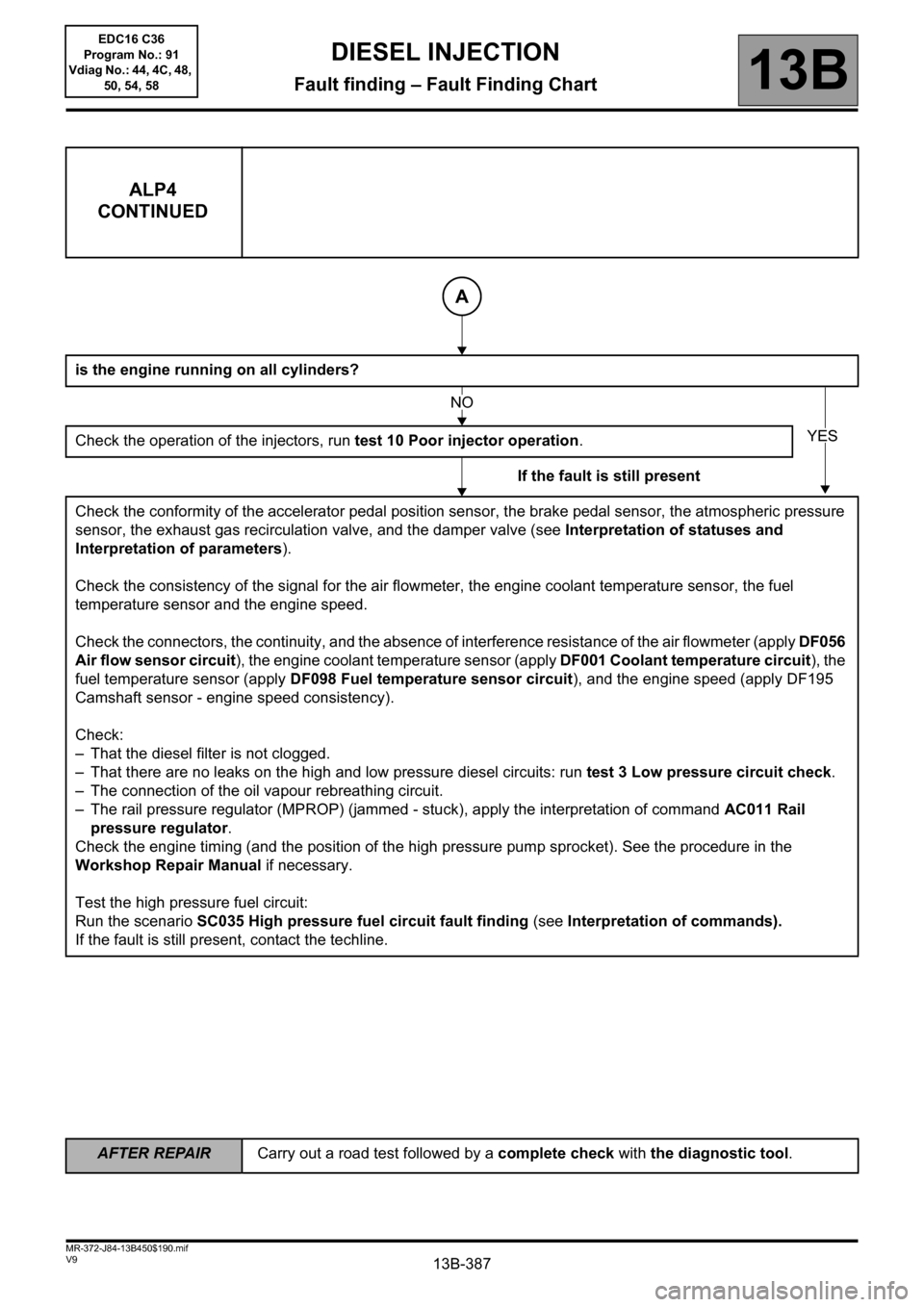

ALP4

CONTINUED

is the engine running on all cylinders?

Check the operation of the injectors, run test 10 Poor injector operation.

If the fault is still present

Check the conformity of the accelerator pedal position sensor, the brake pedal sensor, the atmospheric pressure

sensor, the exhaust gas recirculation valve, and the damper valve (see Interpretation of statuses and

Interpretation of parameters).

Check the consistency of the signal for the air flowmeter, the engine coolant temperature sensor, the fuel

temperature sensor and the engine speed.

Check the connectors, the continuity, and the absence of interference resistance of the air flowmeter (apply DF056

Air flow sensor circuit), the engine coolant temperature sensor (apply DF001 Coolant temperature circuit), the

fuel temperature sensor (apply DF098 Fuel temperature sensor circuit), and the engine speed (apply DF195

Camshaft sensor - engine speed consistency).

Check:

– That the diesel filter is not clogged.

– That there are no leaks on the high and low pressure diesel circuits: run test 3 Low pressure circuit check.

– The connection of the oil vapour rebreathing circuit.

– The rail pressure regulator (MPROP) (jammed - stuck), apply the interpretation of command AC011 Rail

pressure regulator.

Check the engine timing (and the position of the high pressure pump sprocket). See the procedure in the

Workshop Repair Manual if necessary.

Test the high pressure fuel circuit:

Run the scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

If the fault is still present, contact the techline.

A

NO

YES

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 388 of 431

13B-388

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

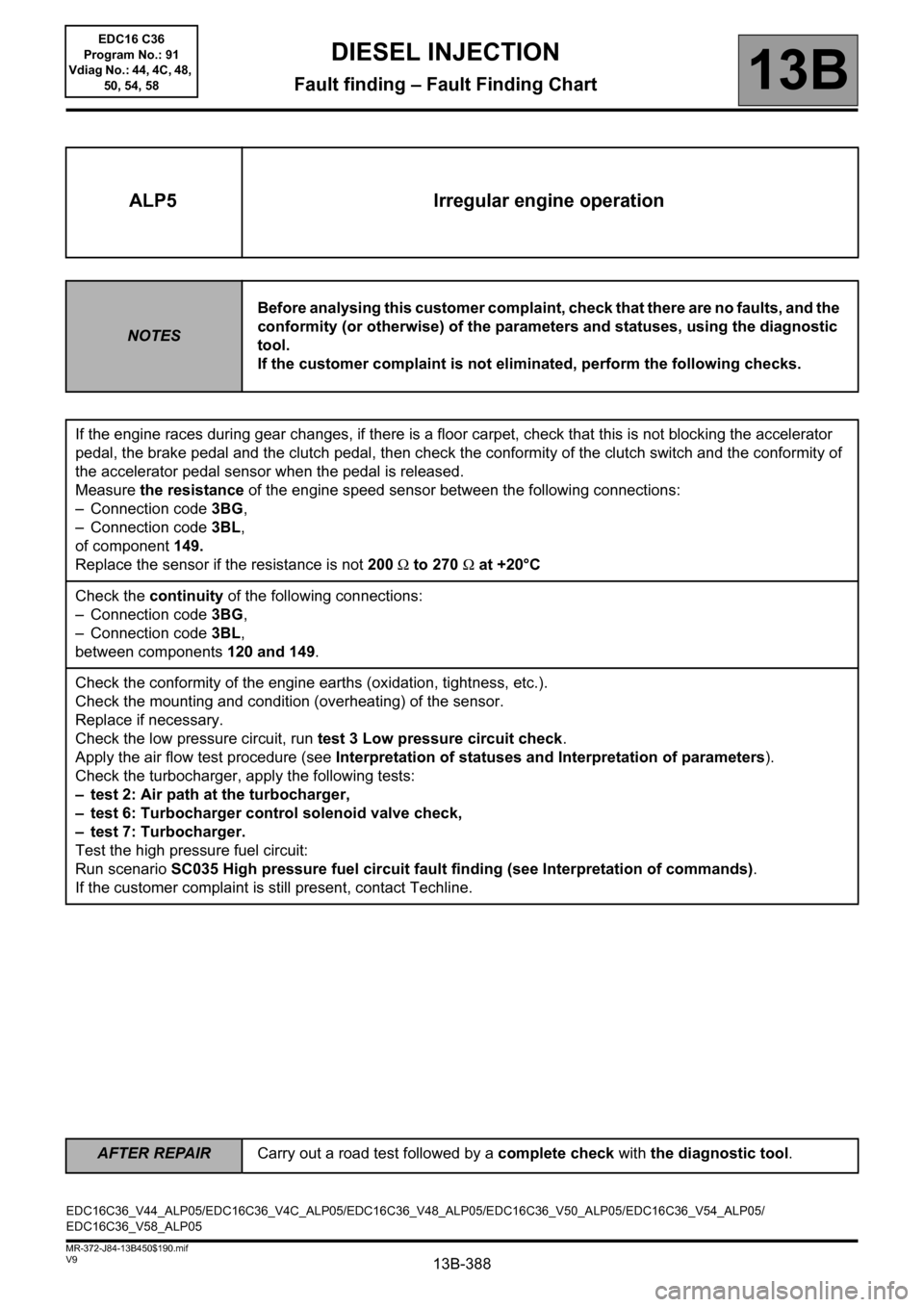

ALP5 Irregular engine operation

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

If the engine races during gear changes, if there is a floor carpet, check that this is not blocking the accelerator

pedal, the brake pedal and the clutch pedal, then check the conformity of the clutch switch and the conformity of

the accelerator pedal sensor when the pedal is released.

Measure the resistance of the engine speed sensor between the following connections:

– Connection code 3BG,

– Connection code 3BL,

of component 149.

Replace the sensor if the resistance is not 200 Ω to 270 Ω at +20°C

Check the continuity of the following connections:

– Connection code 3BG,

– Connection code 3BL,

between components120 and 149.

Check the conformity of the engine earths (oxidation, tightness, etc.).

Check the mounting and condition (overheating) of the sensor.

Replace if necessary.

Check the low pressure circuit, run test 3 Low pressure circuit check.

Apply the air flow test procedure (see Interpretation of statuses and Interpretation of parameters).

Check the turbocharger, apply the following tests:

– test 2: Air path at the turbocharger,

– test 6: Turbocharger control solenoid valve check,

– test 7: Turbocharger.

Test the high pressure fuel circuit:

Run scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

If the customer complaint is still present, contact Techline.

EDC16C36_V44_ALP05/EDC16C36_V4C_ALP05/EDC16C36_V48_ALP05/EDC16C36_V50_ALP05/EDC16C36_V54_ALP05/

EDC16C36_V58_ALP05EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 389 of 431

13B-389

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

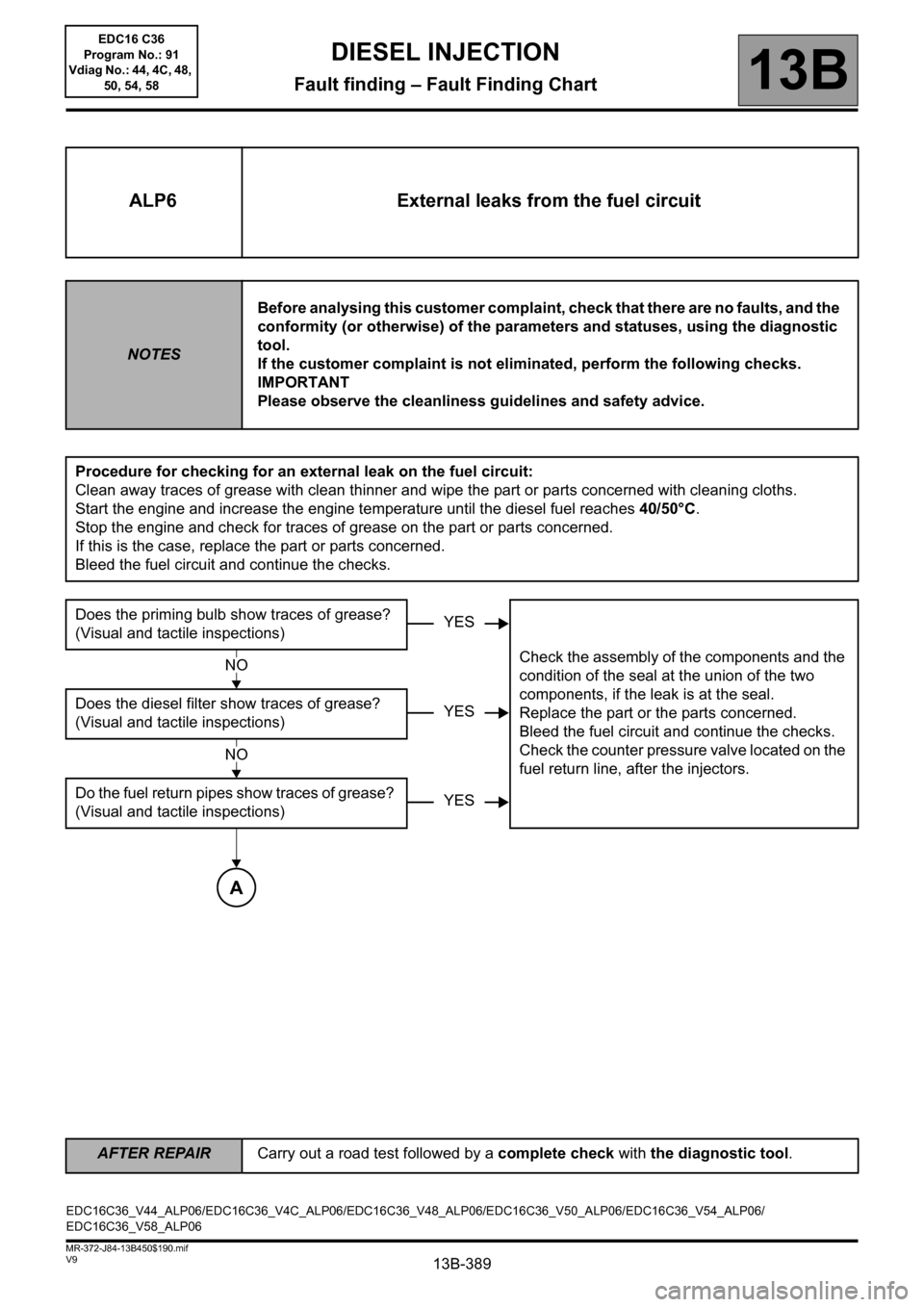

ALP6 External leaks from the fuel circuit

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

IMPORTANT

Please observe the cleanliness guidelines and safety advice.

Procedure for checking for an external leak on the fuel circuit:

Clean away traces of grease with clean thinner and wipe the part or parts concerned with cleaning cloths.

Start the engine and increase the engine temperature until the diesel fuel reaches 40/50°C.

Stop the engine and check for traces of grease on the part or parts concerned.

If this is the case, replace the part or parts concerned.

Bleed the fuel circuit and continue the checks.

Does the priming bulb show traces of grease?

(Visual and tactile inspections)

Check the assembly of the components and the

condition of the seal at the union of the two

components, if the leak is at the seal.

Replace the part or the parts concerned.

Bleed the fuel circuit and continue the checks.

Check the counter pressure valve located on the

fuel return line, after the injectors. Does the diesel filter show traces of grease?

(Visual and tactile inspections)

Do the fuel return pipes show traces of grease?

(Visual and tactile inspections)

YES

NO

YES

NO

YES

A

EDC16C36_V44_ALP06/EDC16C36_V4C_ALP06/EDC16C36_V48_ALP06/EDC16C36_V50_ALP06/EDC16C36_V54_ALP06/

EDC16C36_V58_ALP06EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 391 of 431

13B-391

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

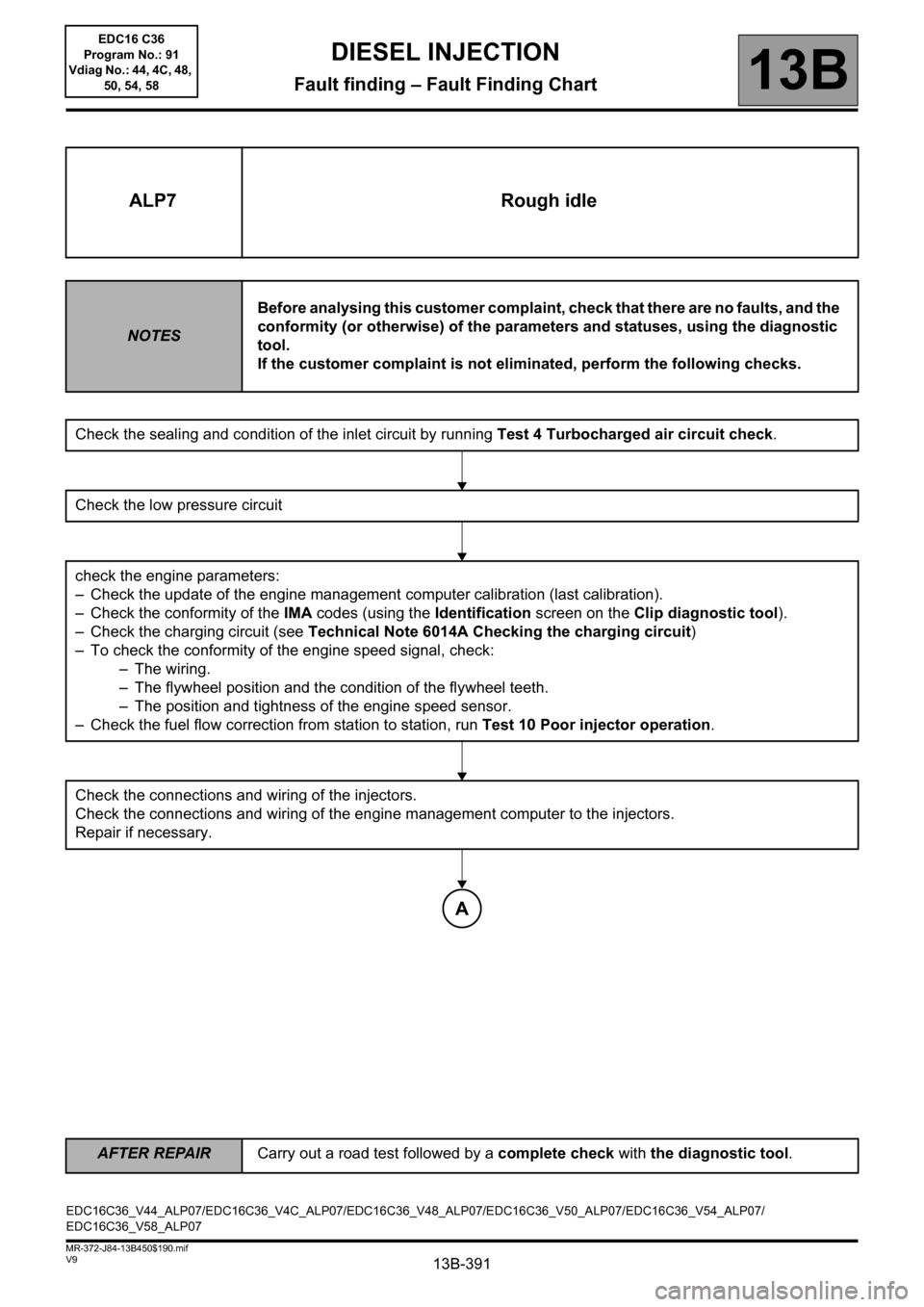

ALP7 Rough idle

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

Check the sealing and condition of the inlet circuit by running Test 4 Turbocharged air circuit check.

Check the low pressure circuit

check the engine parameters:

– Check the update of the engine management computer calibration (last calibration).

– Check the conformity of the IMA codes (using the Identification screen on the Clip diagnostic tool).

– Check the charging circuit (see Technical Note 6014A Checking the charging circuit)

– To check the conformity of the engine speed signal, check:

– The wiring.

– The flywheel position and the condition of the flywheel teeth.

– The position and tightness of the engine speed sensor.

– Check the fuel flow correction from station to station, run Test 10 Poor injector operation.

Check the connections and wiring of the injectors.

Check the connections and wiring of the engine management computer to the injectors.

Repair if necessary.

A

EDC16C36_V44_ALP07/EDC16C36_V4C_ALP07/EDC16C36_V48_ALP07/EDC16C36_V50_ALP07/EDC16C36_V54_ALP07/

EDC16C36_V58_ALP07EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 392 of 431

13B-392

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

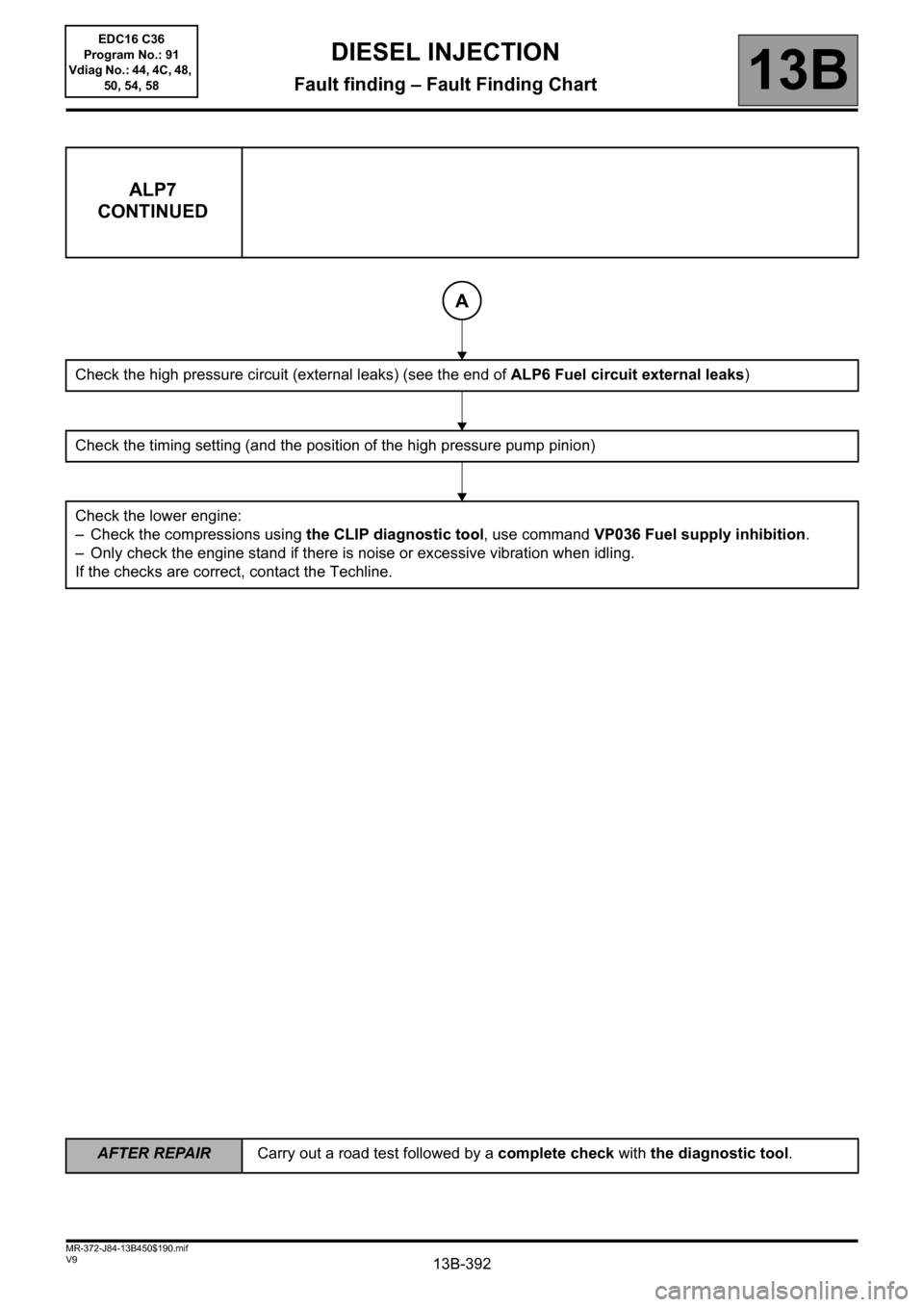

ALP7

CONTINUED

Check the high pressure circuit (external leaks) (see the end of ALP6 Fuel circuit external leaks)

Check the timing setting (and the position of the high pressure pump pinion)

Check the lower engine:

– Check the compressions using the CLIP diagnostic tool, use command VP036 Fuel supply inhibition.

– Only check the engine stand if there is noise or excessive vibration when idling.

If the checks are correct, contact the Techline.

A

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 393 of 431

13B-393

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

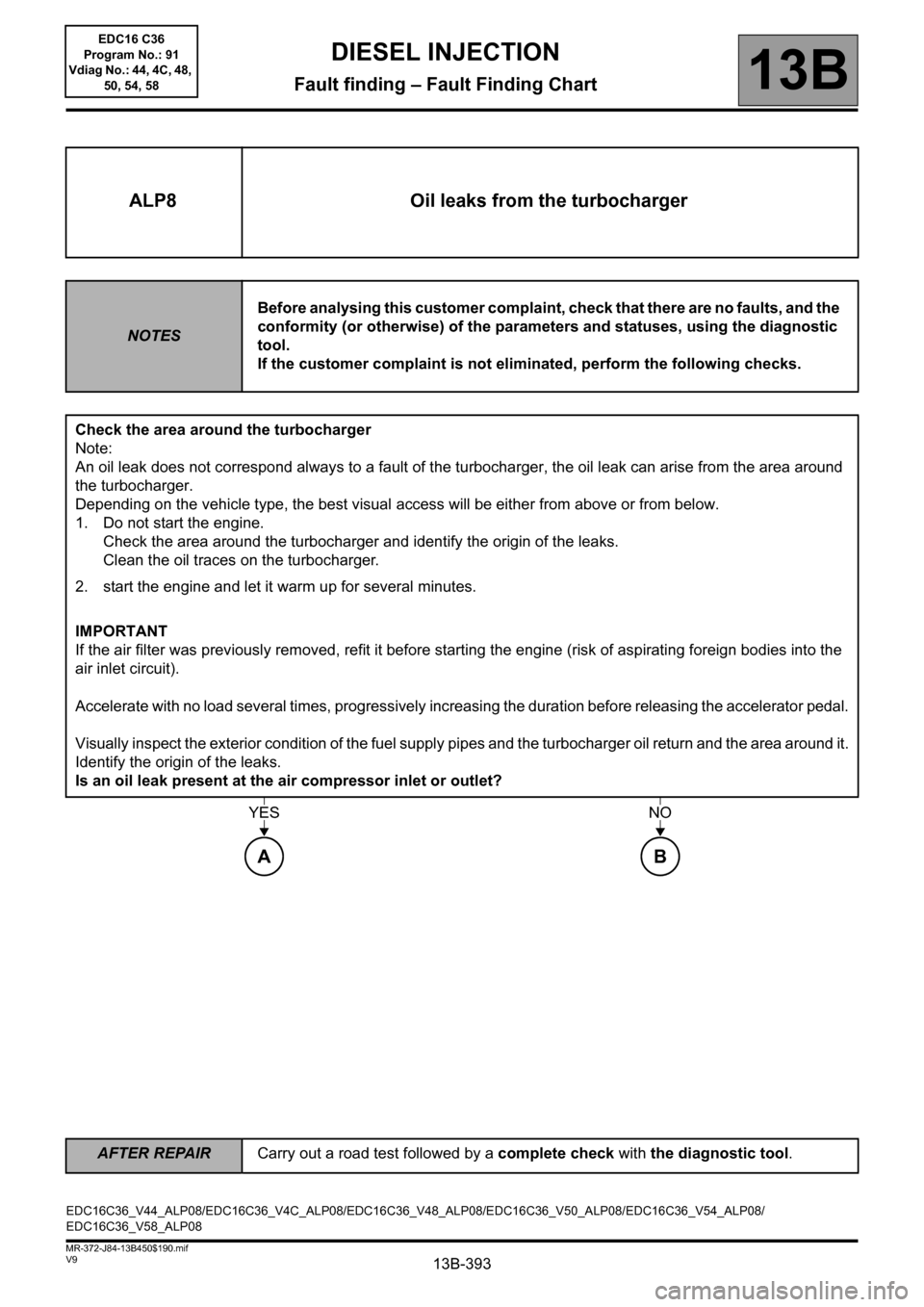

ALP8 Oil leaks from the turbocharger

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

Check the area around the turbocharger

Note:

An oil leak does not correspond always to a fault of the turbocharger, the oil leak can arise from the area around

the turbocharger.

Depending on the vehicle type, the best visual access will be either from above or from below.

1. Do not start the engine.

Check the area around the turbocharger and identify the origin of the leaks.

Clean the oil traces on the turbocharger.

2. start the engine and let it warm up for several minutes.

IMPORTANT

If the air filter was previously removed, refit it before starting the engine (risk of aspirating foreign bodies into the

air inlet circuit).

Accelerate with no load several times, progressively increasing the duration before releasing the accelerator pedal.

Visually inspect the exterior condition of the fuel supply pipes and the turbocharger oil return and the area around it.

Identify the origin of the leaks.

Is an oil leak present at the air compressor inlet or outlet?

YESNO

AB

EDC16C36_V44_ALP08/EDC16C36_V4C_ALP08/EDC16C36_V48_ALP08/EDC16C36_V50_ALP08/EDC16C36_V54_ALP08/

EDC16C36_V58_ALP08EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 394 of 431

13B-394

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

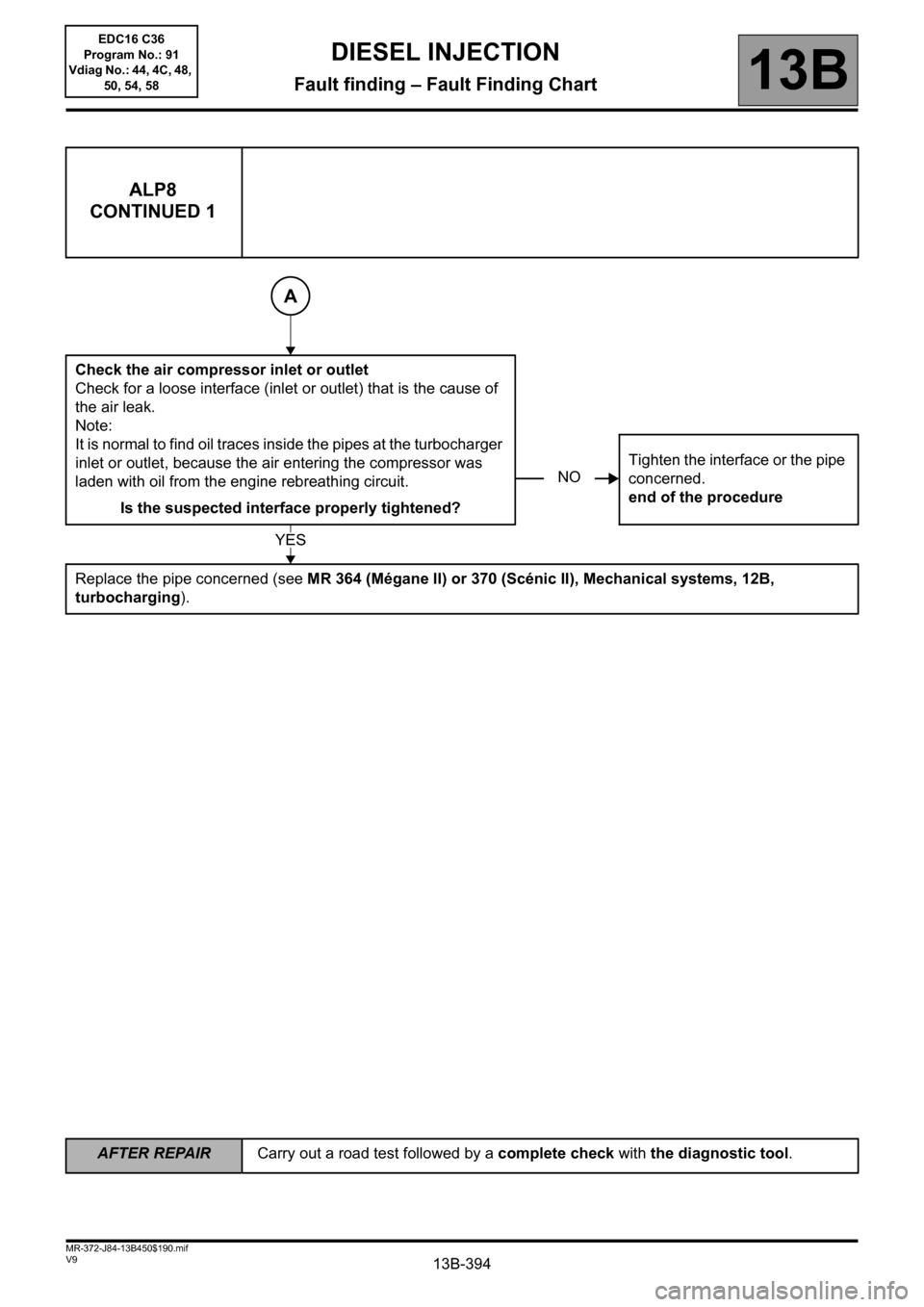

ALP8

CONTINUED 1

Check the air compressor inlet or outlet

Check for a loose interface (inlet or outlet) that is the cause of

the air leak.

Note:

It is normal to find oil traces inside the pipes at the turbocharger

inlet or outlet, because the air entering the compressor was

laden with oil from the engine rebreathing circuit.

Is the suspected interface properly tightened?Tighten the interface or the pipe

concerned.

end of the procedure

Replace the pipe concerned (see MR 364 (Mégane II) or 370 (Scénic II), Mechanical systems, 12B,

turbocharging).

A

NO

YES

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 395 of 431

13B-395

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

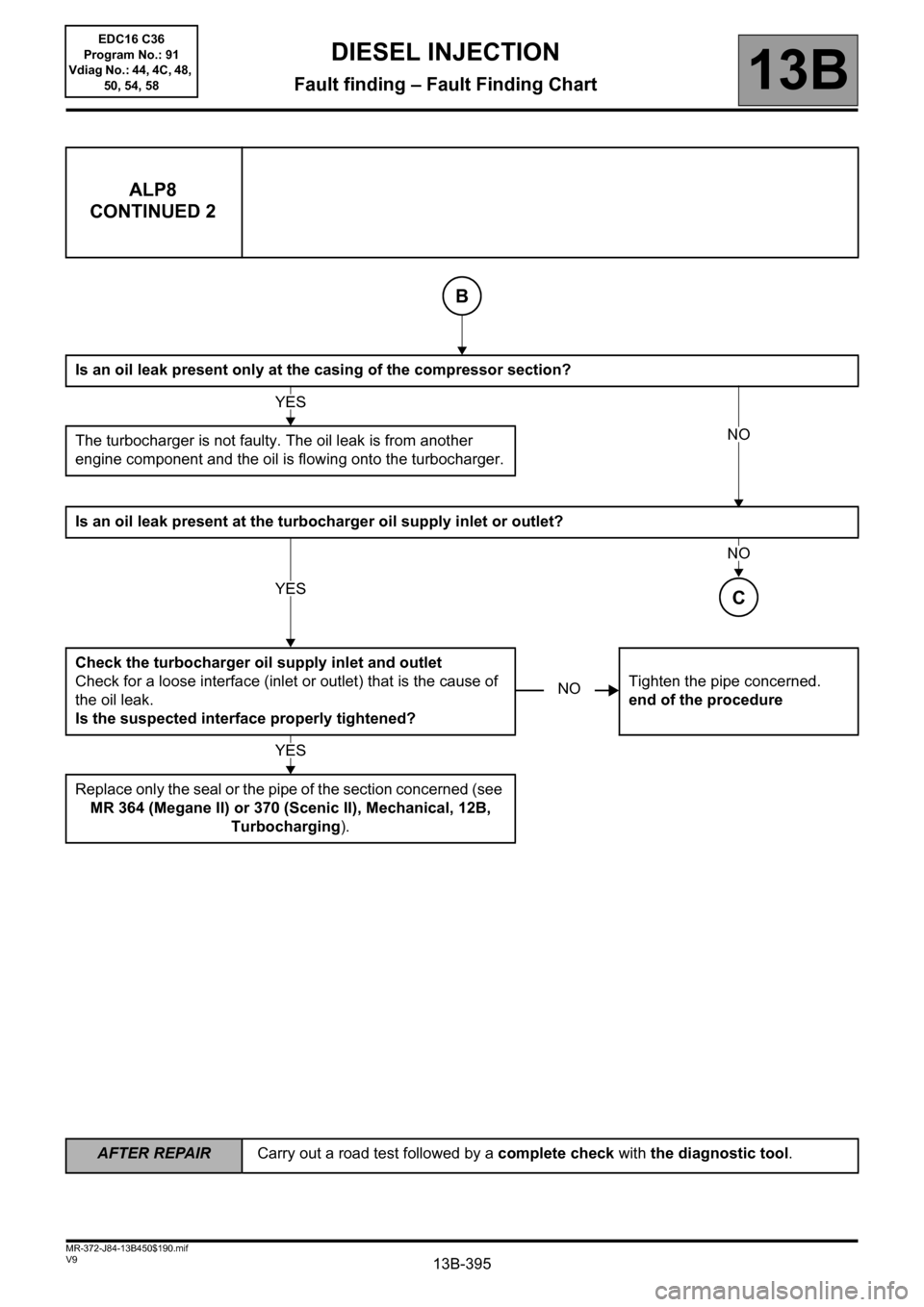

ALP8

CONTINUED 2

Is an oil leak present only at the casing of the compressor section?

The turbocharger is not faulty. The oil leak is from another

engine component and the oil is flowing onto the turbocharger.

Is an oil leak present at the turbocharger oil supply inlet or outlet?

Check the turbocharger oil supply inlet and outlet

Check for a loose interface (inlet or outlet) that is the cause of

the oil leak.

Is the suspected interface properly tightened?Tighten the pipe concerned.

end of the procedure

Replace only the seal or the pipe of the section concerned (see

MR 364 (Megane II) or 370 (Scenic II), Mechanical, 12B,

Turbocharging).

B

YES

NO

YES

NO

C

NO

YES

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 396 of 431

13B-396

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

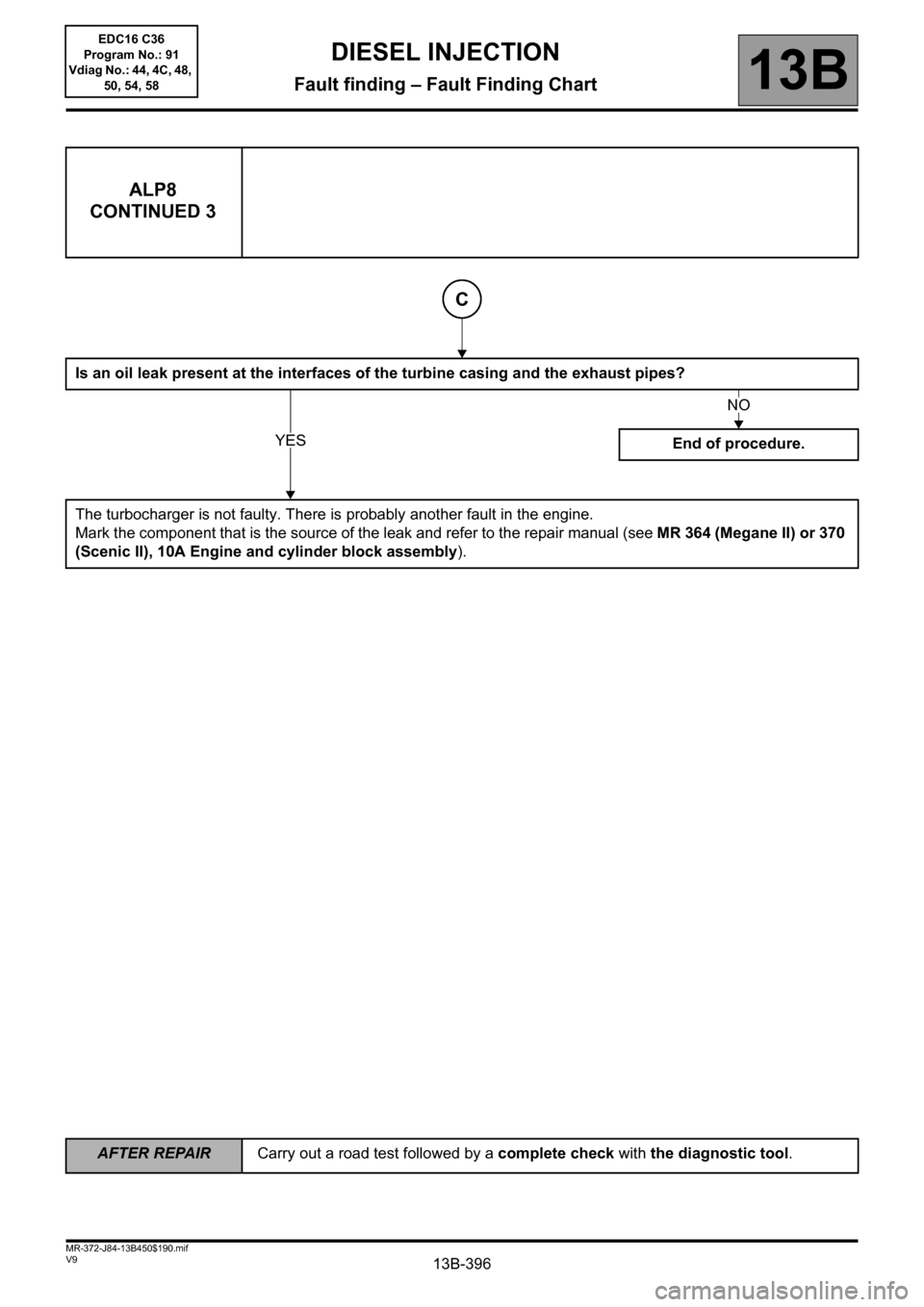

ALP8

CONTINUED 3

Is an oil leak present at the interfaces of the turbine casing and the exhaust pipes?

End of procedure.

The turbocharger is not faulty. There is probably another fault in the engine.

Mark the component that is the source of the leak and refer to the repair manual (see MR 364 (Megane II) or 370

(Scenic II), 10A Engine and cylinder block assembly).

C

YES

NO

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58