RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Owner's Guide

Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 31 of 431

13B-31V9 MR-372-J84-13B450$080.mif

DIESEL INJECTION

Fault finding – Replacement of components13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

REPLACING THE INJECTORS

After one or more injectors have been replaced, enter the IMA codes again and then run command SC036

Reinitialise programming.

The system must be configured via the diagnostic socket using the RENAULT CLIP diagnostic tool.

PROCEDURE to be followed after replacing one or more injectors:

– Note the "IMA" code(s) engraved on the injector bodies,

– enter these codes in the computer using command SC002 Enter injector codes, then follow the instructions given

by the diagnostic tool,

– once the command has finished,

–switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes) Communication

lost with computer: EDC16 C36, check the tool connection and computer power supply before switching the

ignition back on.

– Return to fault finding mode.

– select the Identify computer function from the main screen.

– check that the injector codes entered into the computer match those found on the bodies of the injectors:

– If the codes do not match, restart the command SC002 Enter injector codes procedure.

– If the codes correspond, run command SC036 Reinitialise programming,

–select Injectors as the type of operation, then follow the instructions given by the diagnostic tool.

– Then check the system faults, and clear any stored faults.

– if there are faults, deal with the present faults,

– clear the faults from the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

End of the procedure.Note:

The IMA coding (individual injector correction) is a calibration made in production on each injector to adjust

the flow accurately.

These correction values are etched onto the Bakelite body of each injector (7 alphanumeric characters) and then

entered into the computer which then controls each injector taking into account its individual manufacturing

variation.

IMPORTANT

Cylinder no. 1 is located on the engine flywheel end.

IMPORTANT

Engines can only operate correctly if the correct IMA codes have been entered.

If no code has been entered, or if an implausible code has been entered, fault DF276 "Injector Code

Programming" will be present, and the engine will be in defect mode (engine speed is reduced

significantly).

If another injector's code has been entered, the system will accept it but will make the wrong correction.

This could lead to engine damage, loss of performance and excessive pollution.

Always use the correct injector codes for the engine cylinder/computer.

Page 32 of 431

13B-32V9 MR-372-J84-13B450$080.mif

DIESEL INJECTION

Fault finding – Replacement of components13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

REPLACING THE EXHAUST GAS RECIRCULATION VALVE (EGR valve)

After the exhaust gas recirculation valve has been replaced, the computer must store the new valve's offset and the

offset measured the last time the ignition was switched off, which is when the valve closed.

Using this data, the computer can detect whether the valve is clogged or seized.

When the valve is replaced, clear the stored offsets so that the program uses the new valve’s offset value.

The data linked to this strategy is compiled in the Emission control/OBD sub-function.

– PR128: First EGR valve offset.

–PR129: Last EGR valve offset > or = PR128 if the valve is new.

The PR128 and PR129 programming must be cleared every time the exhaust gas recirculation valve is replaced.

PROCEDURE to be followed after replacing the exhaust gas recirculation valve:

– Run command SC036 Reinitialise programming,

–select EGR valve as the type of operation, then follow the instructions given by the diagnostic tool,

– When the command is finished,

– switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes) Communication lost

with computer: EDC16 C36, check the tool connection and computer power supply before switching the ignition

back on.

When the ignition is next switched on again the new EGR valve offset is automatically reprogrammed.

– Start the vehicle to enable the latest EGR valve offset to be programmed,

– Switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes) Communication lost

with computer: EDC16 C36, check the tool connection and computer power supply before switching the

ignition back on.

The last EGR valve offset reprogrammed is stored on the computer.

– Then check the system faults, and clear any stored faults.

– if there are faults, deal with the present faults,

– clear the faults from the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

End of the procedure.Note:

When the reinitialisation is complete, the Emission control/OBD sub-function displays:

PR128 = PR129 > 100 %

Note:

When the new EGR valve offset is reprogrammed, the Emission control/OBD sub-function displays:

10 % < PR128 < 40 %

PR129 > 100 %

Note:

When the reprogramming of the last EGR valve offset is complete, the Emission control/OBD sub-function

displays:

10 % < PR128 < 40 %

10% < PR129 < 40% and -1%

≤ PR129 – PR128 ≤ 5%

Page 33 of 431

13B-33V9 MR-372-J84-13B450$080.mif

DIESEL INJECTION

Fault finding – Replacement of components13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

REPLACING THE DAMPER VALVE

After replacing the damper valve, reconfigure the computer.

The system must be configured via the diagnostic socket using the RENAULT CLIP tool.

PROCEDURE to be followed after replacing the damper valve:

– Switch on the ignition.

– establish dialogue with the injection computer,

– run command SC036 Reinitialise programming,

–select Damper valve as the type of operation, then follow the instructions given by the diagnostic tool,

– switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes) Communication lost

with computer: EDC16 C36, check the tool connection and computer power supply before switching the

ignition back on.

– Check that PR420 Damper valve error counter = 0,

– then check the system faults, and clear any stored faults,

– if there are faults, deal with the present faults,

– clear the faults from the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

REPLACEMENT OF THE PARTICLE FILTER (F9Q816 engine only).

After replacing the particle filter, reconfigure the computer.

The system must be configured using the RENAULT CLIP tool.

PROCEDURE to be followed after replacing the particle filter:

– Switch on the ignition.

– establish dialogue with the injection computer,

– run command SC036 Reinitialise programming,

–select After particle filter replacement as the operation type, then follow the instructions given by the diagnostic

tool,

–switch off the ignition,

– wait for the diagnostic tool message (maximum time 8 minutes) Communication lost with computer:

EDC16C36, check the tool connection and computer power supply before switching the ignition back on,

– clear the faults from the computer memory (this operation must be carried out within 3 minutes of the ignition being

switched on).

– Check the weight of the soot: PR383 Weight of soot in the particle filter.

– If PR383

≥ 1 g. Apply the procedure of test 12 Manual clearing of the soot weight.

Carry out a road test followed by another check with the diagnostic tool.

Page 34 of 431

13B-34V9 MR-372-J84-13B450$090.mif

13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

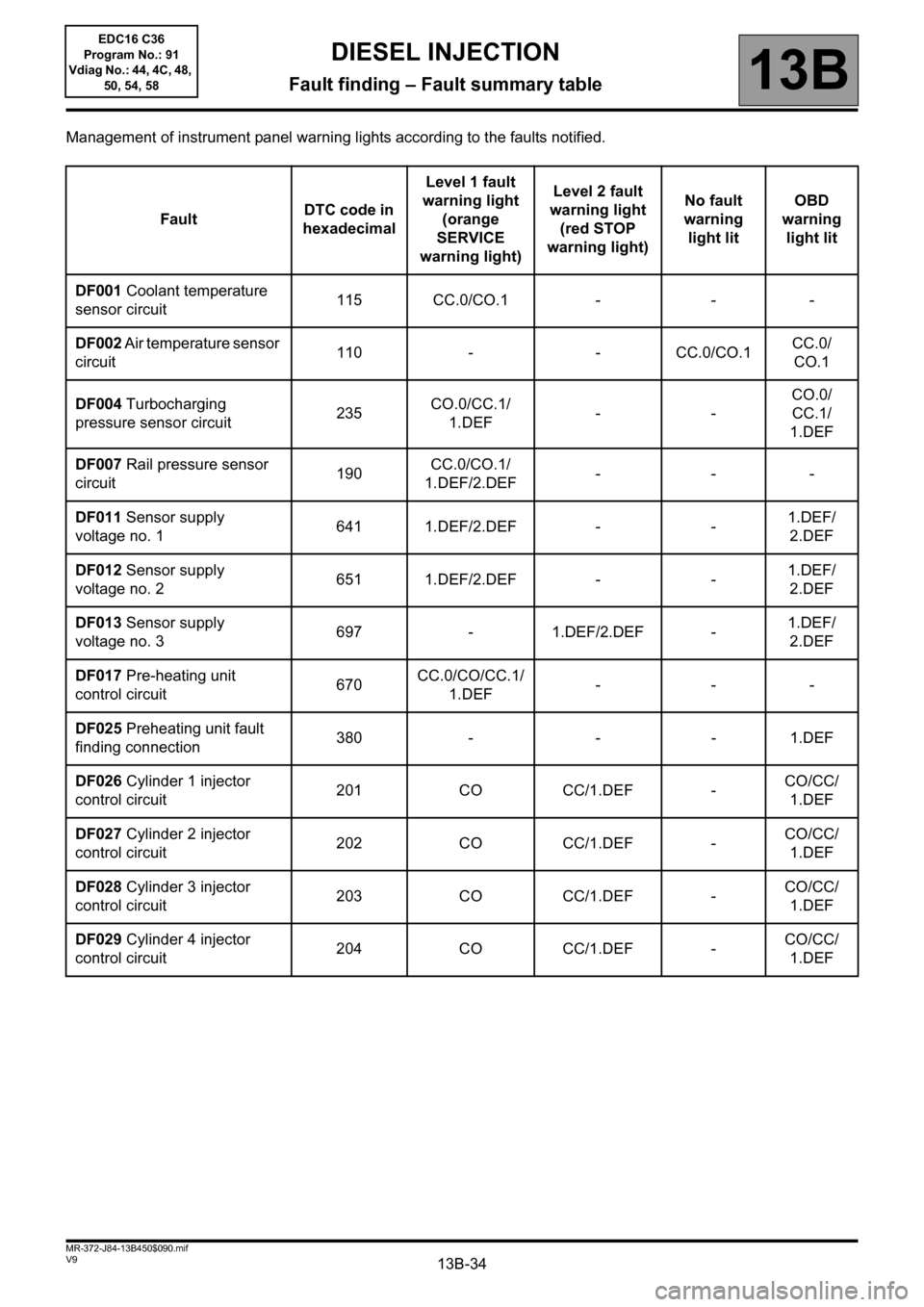

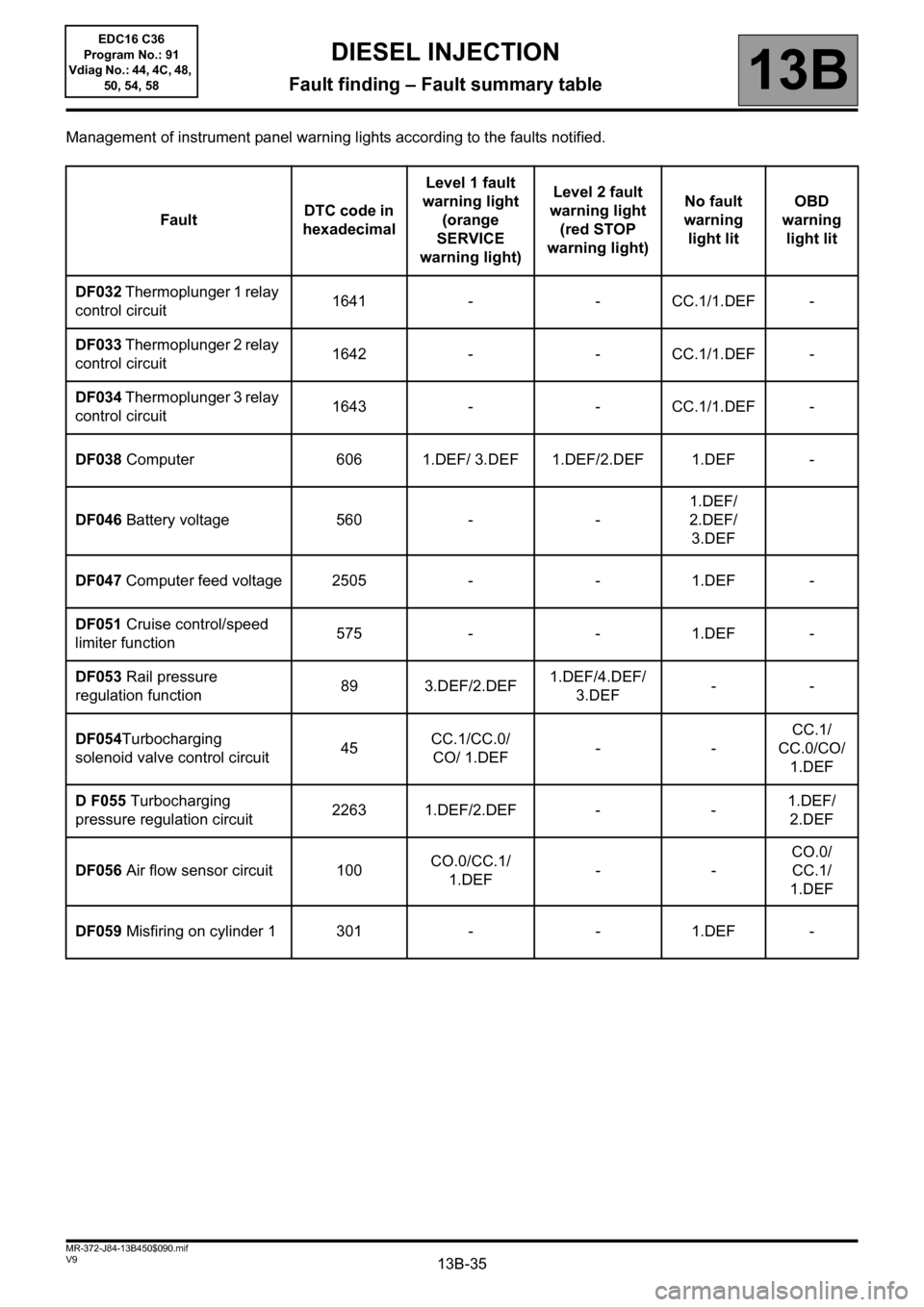

Management of instrument panel warning lights according to the faults notified.

FaultDTC code in

hexadecimalLevel 1 fault

warning light

(orange

SERVICE

warning light)Level 2 fault

warning light

(red STOP

warning light)No fault

warning

light litOBD

warning

light lit

DF001 Coolant temperature

sensor circuit115 CC.0/CO.1 - - -

DF002 Air temperature sensor

circuit110 - - CC.0/CO.1CC.0/

CO.1

DF004 Turbocharging

pressure sensor circuit235CO.0/CC.1/

1.DEF--CO.0/

CC.1/

1.DEF

DF007 Rail pressure sensor

circuit190CC.0/CO.1/

1.DEF/2.DEF---

DF011 Sensor supply

voltage no. 1641 1.DEF/2.DEF - -1.DEF/

2.DEF

DF012 Sensor supply

voltage no. 2651 1.DEF/2.DEF - -1.DEF/

2.DEF

DF013 Sensor supply

voltage no. 3697 - 1.DEF/2.DEF -1.DEF/

2.DEF

DF017 Pre-heating unit

control circuit670CC.0/CO/CC.1/

1.DEF---

DF025 Preheating unit fault

finding connection380 - - - 1.DEF

DF026 Cylinder 1 injector

control circuit201 CO CC/1.DEF -CO/CC/

1.DEF

DF027 Cylinder 2 injector

control circuit202 CO CC/1.DEF -CO/CC/

1.DEF

DF028 Cylinder 3 injector

control circuit203 CO CC/1.DEF -CO/CC/

1.DEF

DF029 Cylinder 4 injector

control circuit204 CO CC/1.DEF -CO/CC/

1.DEF

DIESEL INJECTION

Fault finding – Fault summary table

Page 35 of 431

13B-35V9 MR-372-J84-13B450$090.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Management of instrument panel warning lights according to the faults notified.

FaultDTC code in

hexadecimalLevel 1 fault

warning light

(orange

SERVICE

warning light)Level 2 fault

warning light

(red STOP

warning light)No fault

warning

light litOBD

warning

light lit

DF032 Thermoplunger 1 relay

control circuit1641 - - CC.1/1.DEF -

DF033 Thermoplunger 2 relay

control circuit1642 - - CC.1/1.DEF -

DF034 Thermoplunger 3 relay

control circuit1643 - - CC.1/1.DEF -

DF038 Computer 606 1.DEF/ 3.DEF 1.DEF/2.DEF 1.DEF -

DF046 Battery voltage 560 - -1.DEF/

2.DEF/

3.DEF

DF047 Computer feed voltage 2505 - - 1.DEF -

DF051 Cruise control/speed

limiter function575 - - 1.DEF -

DF053 Rail pressure

regulation function89 3.DEF/2.DEF1.DEF/4.DEF/

3.DEF--

DF054Turbocharging

solenoid valve control circuit45CC.1/CC.0/

CO/ 1.DEF--CC.1/

CC.0/CO/

1.DEF

D F055 Turbocharging

pressure regulation circuit2263 1.DEF/2.DEF - -1.DEF/

2.DEF

DF056 Air flow sensor circuit 100CO.0/CC.1/

1.DEF--CO.0/

CC.1/

1.DEF

DF059 Misfiring on cylinder 1 301 - - 1.DEF -

Page 36 of 431

13B-36V9 MR-372-J84-13B450$090.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

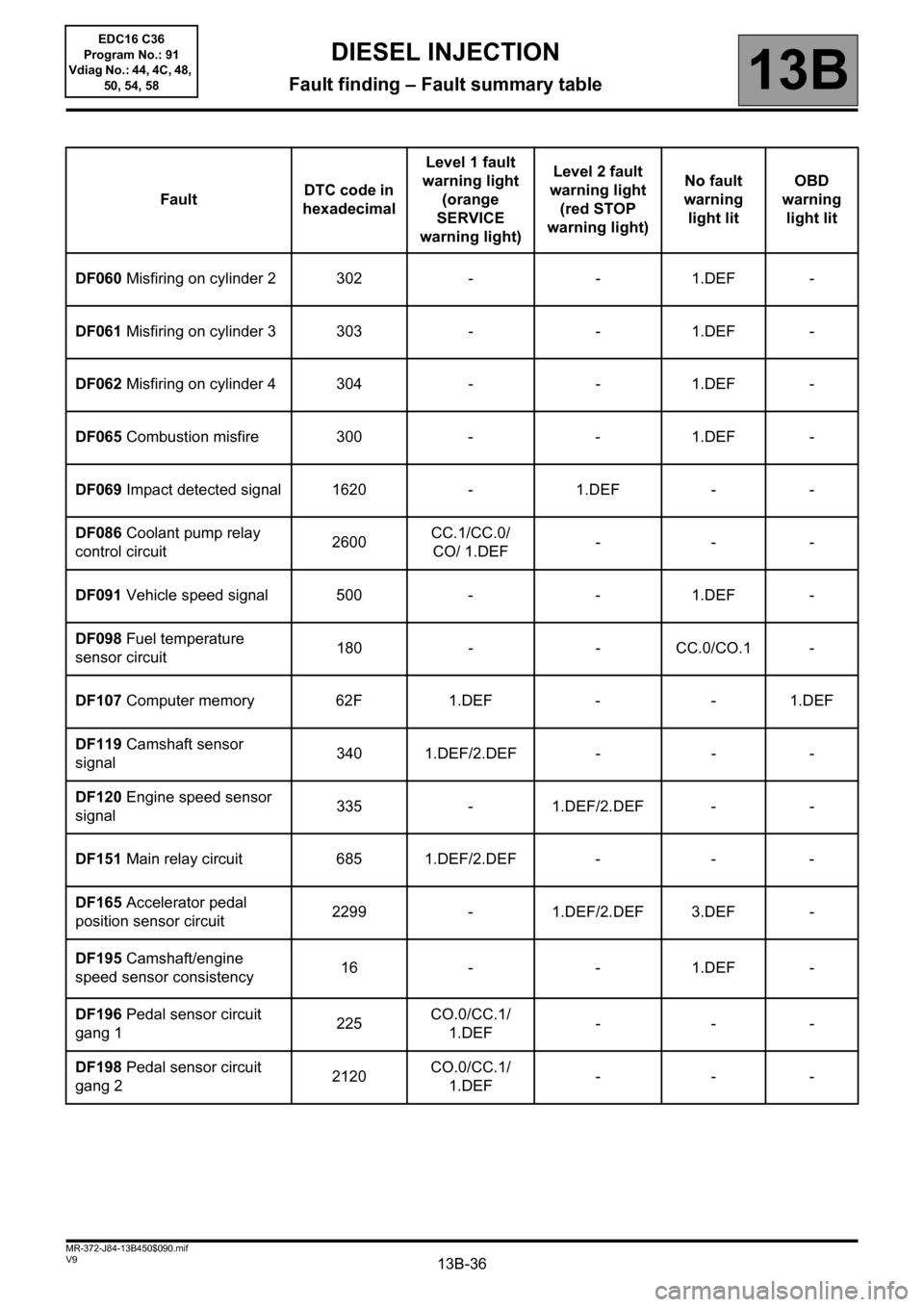

FaultDTC code in

hexadecimalLevel 1 fault

warning light

(orange

SERVICE

warning light)Level 2 fault

warning light

(red STOP

warning light)No fault

warning

light litOBD

warning

light lit

DF060 Misfiring on cylinder 2 302 - - 1.DEF -

DF061 Misfiring on cylinder 3 303 - - 1.DEF -

DF062 Misfiring on cylinder 4 304 - - 1.DEF -

DF065 Combustion misfire 300 - - 1.DEF -

DF069 Impact detected signal 1620 - 1.DEF - -

DF086 Coolant pump relay

control circuit2600CC.1/CC.0/

CO/ 1.DEF---

DF091 Vehicle speed signal 500 - - 1.DEF -

DF098 Fuel temperature

sensor circuit180 - - CC.0/CO.1 -

DF107 Computer memory 62F 1.DEF - - 1.DEF

DF119 Camshaft sensor

signal340 1.DEF/2.DEF - - -

DF120 Engine speed sensor

signal335 - 1.DEF/2.DEF - -

DF151 Main relay circuit 685 1.DEF/2.DEF - - -

DF165 Accelerator pedal

position sensor circuit2299 - 1.DEF/2.DEF 3.DEF -

DF195 Camshaft/engine

speed sensor consistency16 - - 1.DEF -

DF196 Pedal sensor circuit

gang 1225CO.0/CC.1/

1.DEF---

DF198 Pedal sensor circuit

gang 22120CO.0/CC.1/

1.DEF---

Page 37 of 431

13B-37V9 MR-372-J84-13B450$090.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

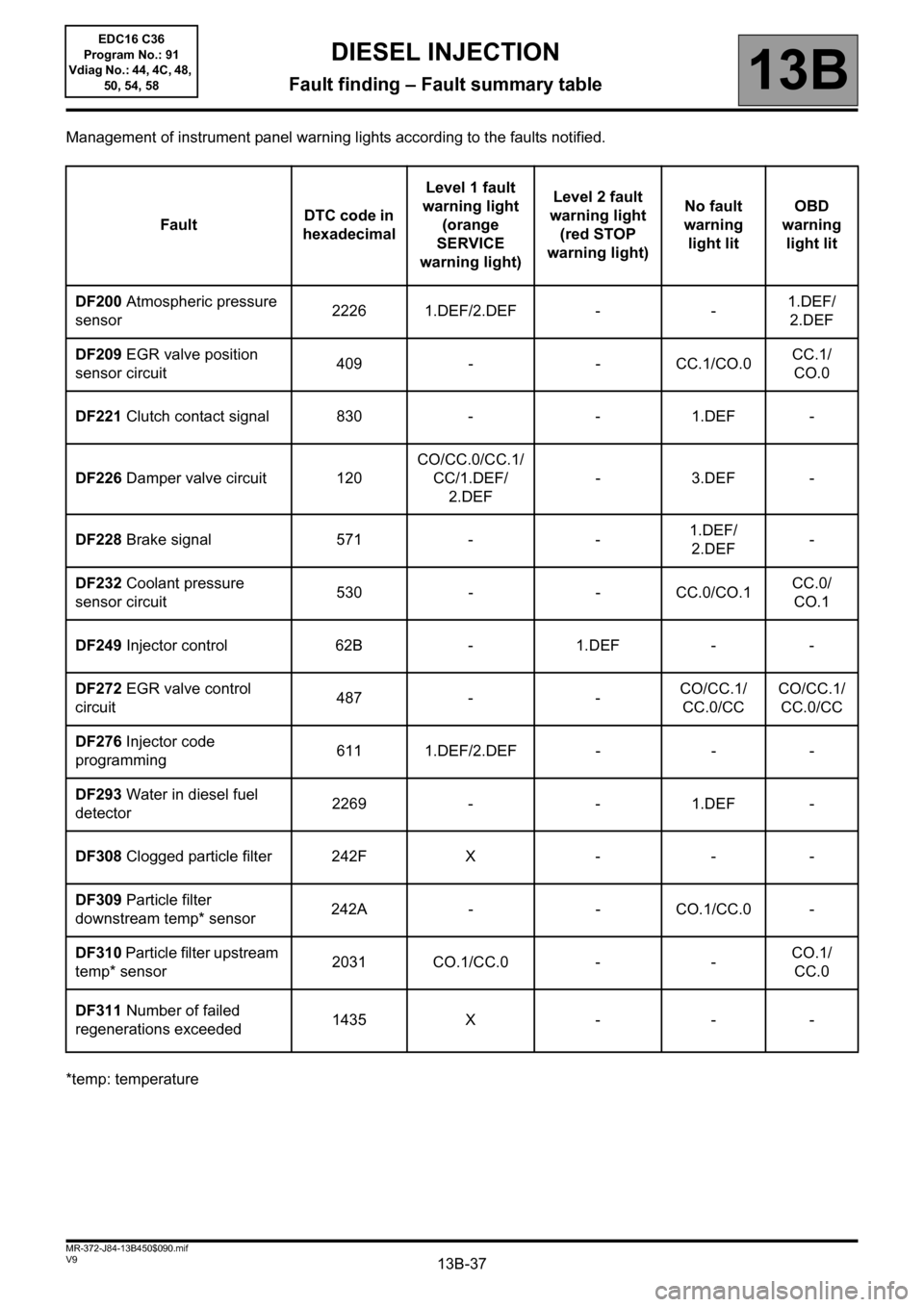

Management of instrument panel warning lights according to the faults notified.

*temp: temperatureFaultDTC code in

hexadecimalLevel 1 fault

warning light

(orange

SERVICE

warning light)Level 2 fault

warning light

(red STOP

warning light)No fault

warning

light litOBD

warning

light lit

DF200 Atmospheric pressure

sensor2226 1.DEF/2.DEF - -1.DEF/

2.DEF

DF209 EGR valve position

sensor circuit409 - - CC.1/CO.0CC.1/

CO.0

DF221 Clutch contact signal 830 - - 1.DEF -

DF226 Damper valve circuit 120CO/CC.0/CC.1/

CC/1.DEF/

2.DEF-3.DEF-

DF228 Brake signal 571 - -1.DEF/

2.DEF-

DF232 Coolant pressure

sensor circuit530 - - CC.0/CO.1CC.0/

CO.1

DF249 Injector control 62B - 1.DEF - -

DF272 EGR valve control

circuit487 - -CO/CC.1/

CC.0/CCCO/CC.1/

CC.0/CC

DF276 Injector code

programming611 1.DEF/2.DEF - - -

DF293 Water in diesel fuel

detector2269 - - 1.DEF -

DF308 Clogged particle filter 242F X - - -

DF309 Particle filter

downstream temp* sensor242A - - CO.1/CC.0 -

DF310 Particle filter upstream

temp* sensor2031 CO.1/CC.0 - -CO.1/

CC.0

DF311 Number of failed

regenerations exceeded1435 X - - -

Page 38 of 431

13B-38V9 MR-372-J84-13B450$090.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

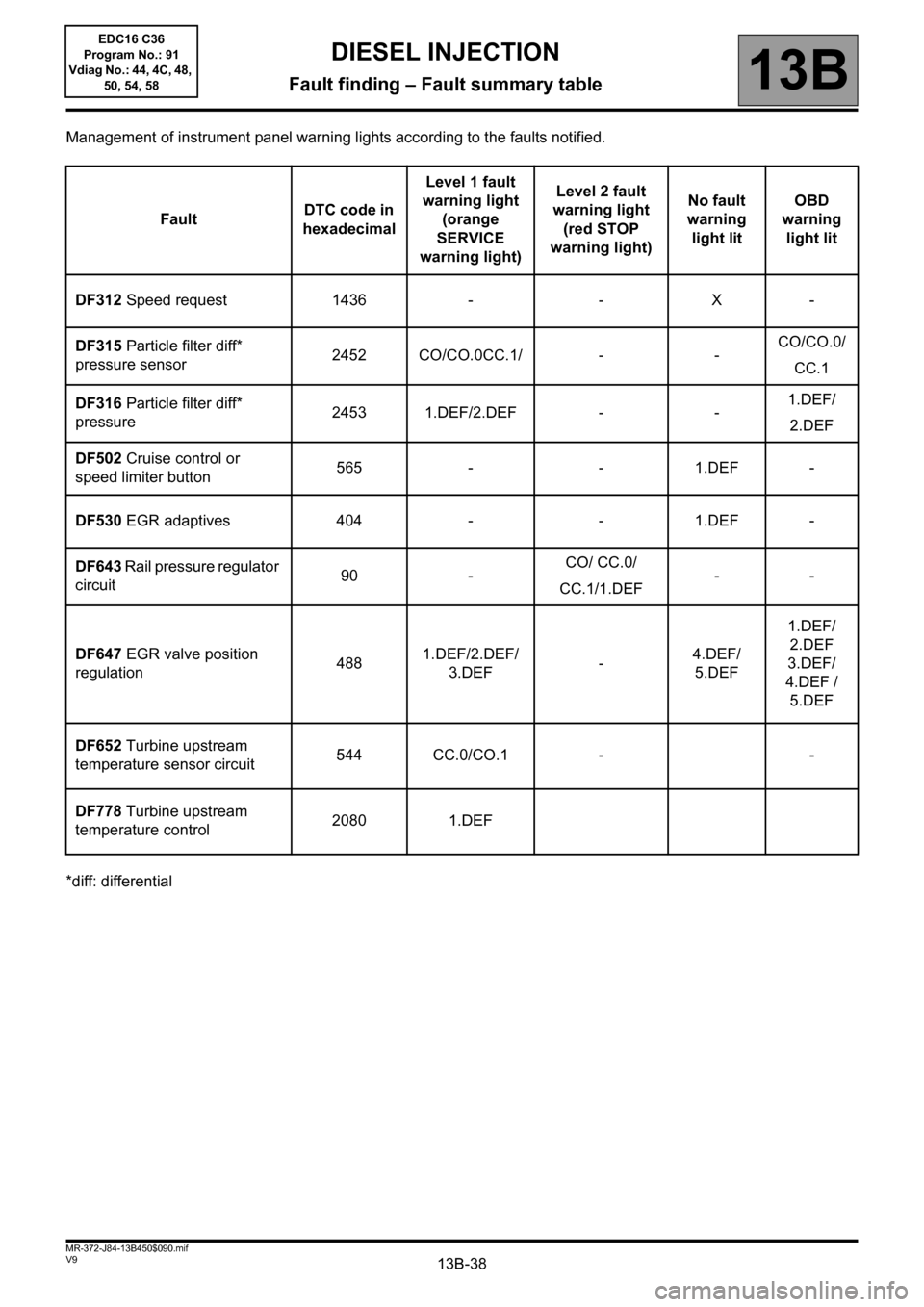

Management of instrument panel warning lights according to the faults notified.

*diff: differentialFaultDTC code in

hexadecimalLevel 1 fault

warning light

(orange

SERVICE

warning light)Level 2 fault

warning light

(red STOP

warning light)No fault

warning

light litOBD

warning

light lit

DF312 Speed request 1436 - - X -

DF315 Particle filter diff*

pressure sensor2452 CO/CO.0CC.1/ - -CO/CO.0/

CC.1

DF316 Particle filter diff*

pressure2453 1.DEF/2.DEF - -1.DEF/

2.DEF

DF502 Cruise control or

speed limiter button565 - - 1.DEF -

DF530 EGR adaptives 404 - - 1.DEF -

DF643 Rail pressure regulator

circuit90 -CO/ CC.0/

CC.1/1.DEF--

DF647 EGR valve position

regulation4881.DEF/2.DEF/

3.DEF-4.DEF/

5.DEF1.DEF/

2.DEF

3.DEF/

4.DEF /

5.DEF

DF652 Turbine upstream

temperature sensor circuit544 CC.0/CO.1 - -

DF778 Turbine upstream

temperature control 2080 1.DEF

Page 39 of 431

13B-39V9 MR-372-J84-13B450$090.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

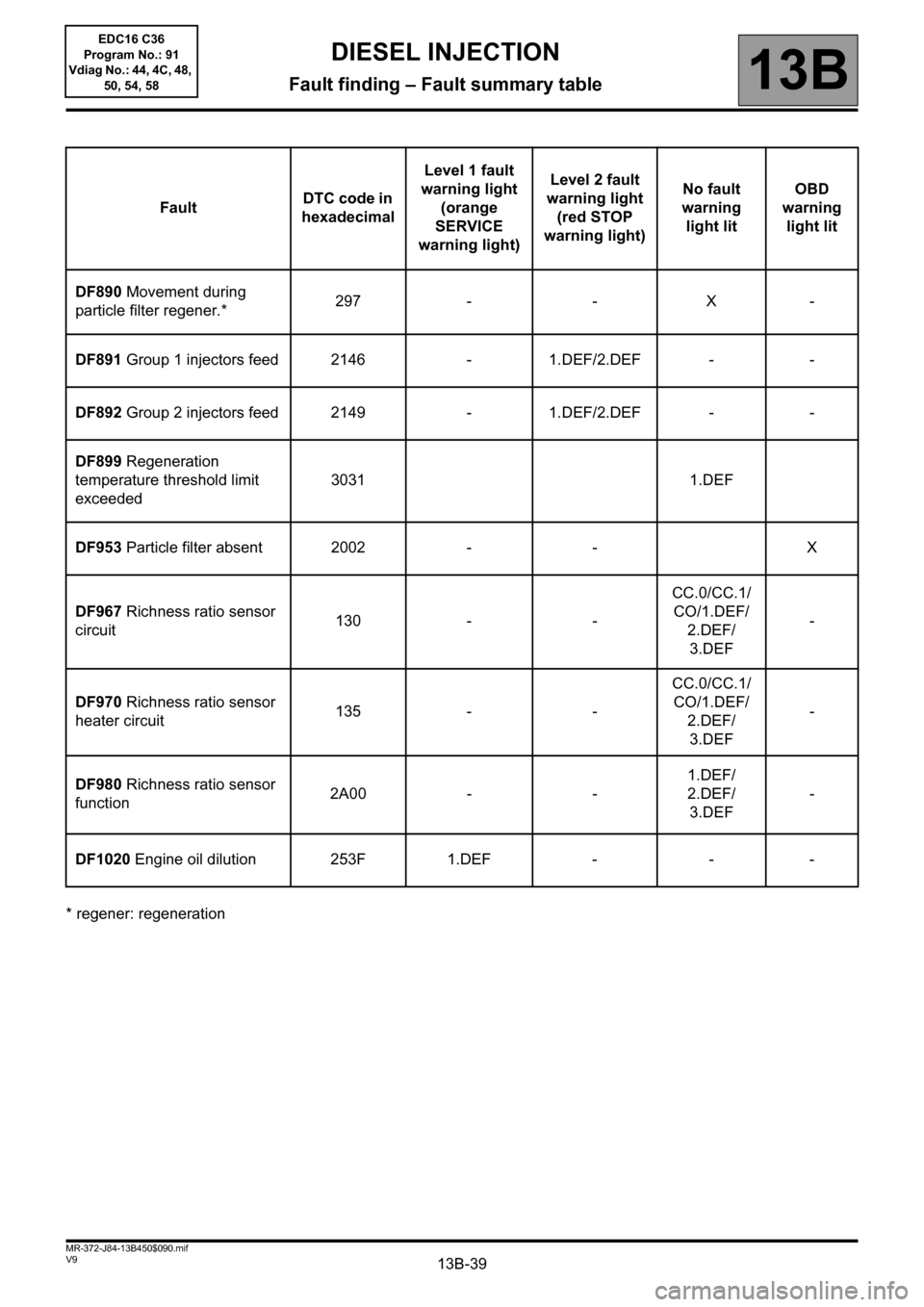

* regener: regenerationFaultDTC code in

hexadecimalLevel 1 fault

warning light

(orange

SERVICE

warning light)Level 2 fault

warning light

(red STOP

warning light)No fault

warning

light litOBD

warning

light lit

DF890 Movement during

particle filter regener.* 297 - - X -

DF891 Group 1 injectors feed 2146 - 1.DEF/2.DEF - -

DF892 Group 2 injectors feed 2149 - 1.DEF/2.DEF - -

DF899 Regeneration

temperature threshold limit

exceeded 3031 1.DEF

DF953 Particle filter absent 2002 - - X

DF967 Richness ratio sensor

circuit130 - -CC.0/CC.1/

CO/1.DEF/

2.DEF/

3.DEF-

DF970 Richness ratio sensor

heater circuit135 - -CC.0/CC.1/

CO/1.DEF/

2.DEF/

3.DEF-

DF980 Richness ratio sensor

function2A00 - -1.DEF/

2.DEF/

3.DEF-

DF1020 Engine oil dilution 253F 1.DEF - - -

Page 40 of 431

13B-40V9 MR-372-J84-13B450$101.mif

13B

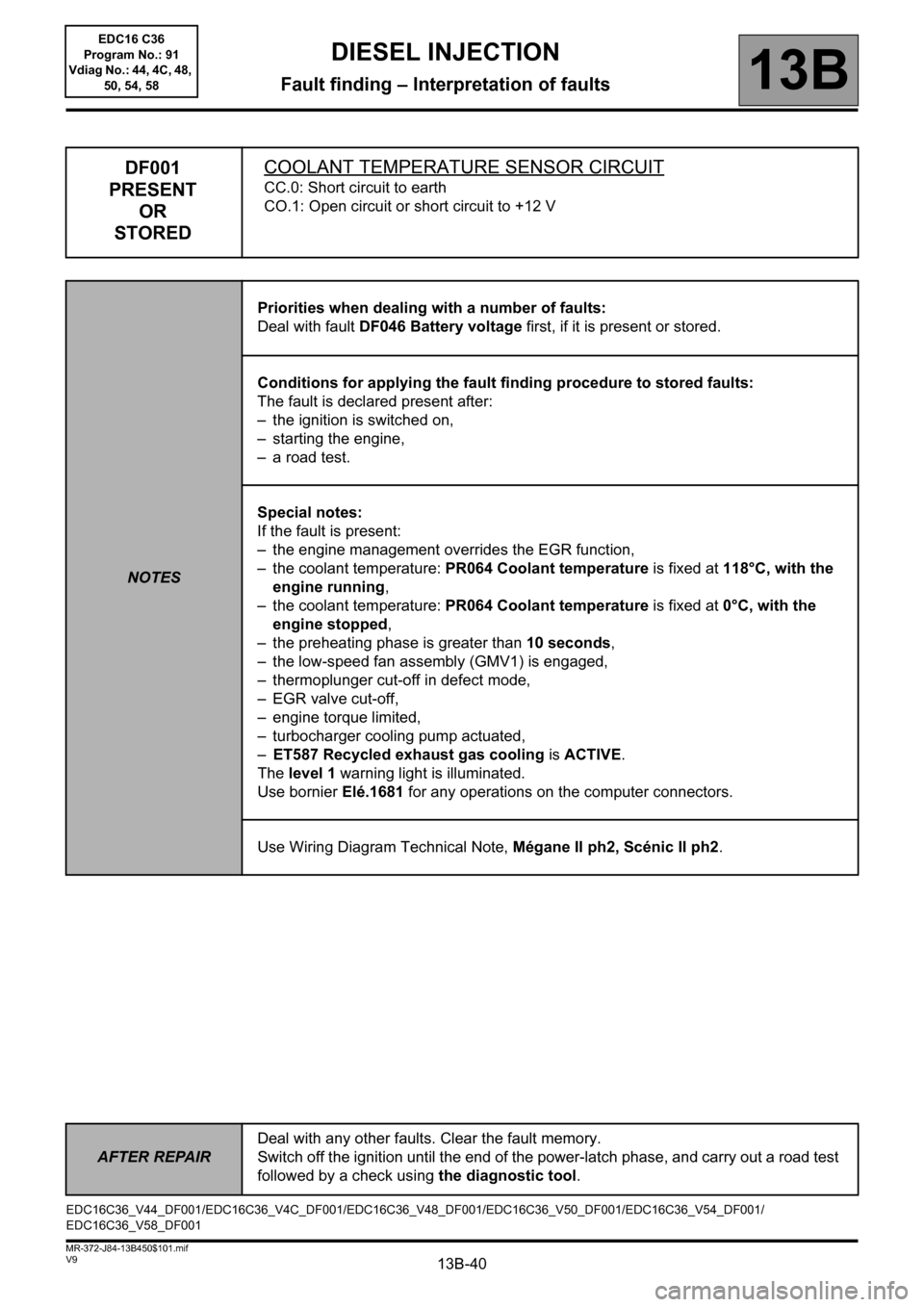

DF001

PRESENT

OR

STOREDCOOLANT TEMPERATURE SENSOR CIRCUIT

CC.0: Short circuit to earth

CO.1: Open circuit or short circuit to +12 V

NOTESPriorities when dealing with a number of faults:

Deal with fault DF046 Battery voltage first, if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after:

– the ignition is switched on,

– starting the engine,

– a road test.

Special notes:

If the fault is present:

– the engine management overrides the EGR function,

– the coolant temperature: PR064 Coolant temperature is fixed at 118°C, with the

engine running,

– the coolant temperature: PR064 Coolant temperature is fixed at 0°C, with the

engine stopped,

– the preheating phase is greater than 10 seconds,

– the low-speed fan assembly (GMV1) is engaged,

– thermoplunger cut-off in defect mode,

– EGR valve cut-off,

– engine torque limited,

– turbocharger cooling pump actuated,

–ET587 Recycled exhaust gas cooling is ACTIVE.

The level 1 warning light is illuminated.

Use bornier Elé.1681 for any operations on the computer connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V44_DF001/EDC16C36_V4C_DF001/EDC16C36_V48_DF001/EDC16C36_V50_DF001/EDC16C36_V54_DF001/

EDC16C36_V58_DF001

DIESEL INJECTION

Fault finding – Interpretation of faults

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58