RENAULT SCENIC 2014 J95 / 3.G Petrol Injection - Sagem3000 Workshop Manual

Manufacturer: RENAULT, Model Year: 2014, Model line: SCENIC, Model: RENAULT SCENIC 2014 J95 / 3.GPages: 181

Page 151 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 151V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET415

(CONTINUED 4)

STATUS 10Monitoring by injection computer

Status ET415 becomes STATUS 10 when driving with cruise control active (ET042

Cruise control/speed limiter: CRUISE CONTROL) if the injection computer detects a

fault anywhere in the engine management system, or an engine speed that is too high

or too low.

This signal is conveyed on the multiplex line and deactivates the cruise control.

Carry out a multiplex network test, then run fault finding on the injection computer.

Deal with present or stored faults (see Interpretation of faults).

Reinitialise status ET415 on the injection computer by running command RZ007

“Fault memory”.

If status 10 continues, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

1JSAA741.0

Page 152 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 152V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET703

CRUISE CONTROL/SPEED LIMITER BUTTONS

NOTESSpecial notes:

Only perform these tests if the statuses do not correspond with the system programming

functions.

INACTIVEStatus ET703 becomes "INACTIVE" when none of the cruise control/speed limiter

buttons is pressed. These buttons are located on the steering wheel.

If status ET703 does not display "INACTIVE",

●check the condition of the cruise control/speed limiter +/- button and the condition of

its connector,

check the condition of the cruise control/speed limiter R/0 button and the condition of its

connector.

INCREASEStatus ET703 becomes PLUS when the cruise control/speed limiter + button is pressed.

This button is on the steering wheel, on the left-hand side.

If status ET703 does not display PLUS, check the condition of the cruise control/speed

limiter +/- button, and the condition of its connector. Repair if necessary.

To carry out these checks and measurements in complete safety, observe the

recommendations for removing the driver's front airbag (see MR 364/370 Mechanical,

Electrical equipment 88C, Airbag and seat belt pretensioners, Driver's front

airbag, Removal - Refitting).

●Measure the resistance on the button between tracks P1 and P0 while pressing

the “+” button of component 331.

If the resistance is not approximately 300 , check the continuity of the connection when

the button is not pressed.

If there is continuity, replace the +/- control button.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Repair precautions), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

JSAA741.0

Page 153 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 153V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET703

CONTINUED 1

DECREASEStatus ET703 becomes MINUS when the cruise control/speed limiter - button is pressed.

This button is on the steering wheel, on the left-hand side.

If status ET703 does not change to MINUS, check the condition of the cruise control/

speed limiter “+/-” button, and the condition of its connector. Repair if necessary.

To carry out these checks and measurements in complete safety, observe the

recommendations for removing the driver's front airbag (see MR 364/370 Mechanical,

Electrical equipment 88C, Airbag and seat belt pretensioners, Driver's front

airbag, Removal - Refitting).

Repair if necessary.

Measure the resistance on the button between tracks P1 and P0 while pressing the

“-” button of component 331.

If the resistance is not approximately 100 , check the continuity of the connection when

the button is in rest position.

If there is continuity, replace the “+/-” control button.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Repair precautions), repair the wiring, otherwise replace it.

SUSPENDStatus ET703 becomes SUSPEND when the cruise control/speed limiter R button is

pressed. This button is located on the steering wheel, to the right.

If status ET703 does not change to SUSPEND, check the condition of the cruise control/

speed limiter R/0 button, and the condition of its connector.

To carry out these checks and measurements in complete safety, observe the

recommendations for removing the driver's front airbag (see MR 364/370 Mechanical,

Electrical equipment 88C, Airbag and seat belt pretensioners, Driver's front

airbag, Removal - Refitting).

Measure the resistance on the button between tracks P1 and P0 while pressing the

“0” button of component 331.

If the resistance is not approximately 0 , replace the R/0 control button.

If there is continuity, replace the “R/0” control button.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Repair precautions), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

JSAA741.0

Page 154 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 154V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET703

CONTINUED 2

RESUMEStatus ET703 becomes RESUME when the cruise control/speed limiter R button is

pressed. This button is located on the steering wheel, to the right.

If status ET703 does not change to RESUME, check the condition of the cruise control/

speed limiter R/0 button, and the condition of its connector.

Repair if necessary.

To carry out these checks and measurements in complete safety, observe the

recommendations for removing the driver's front airbag (see MR 364/370 Mechanical,

Electrical equipment 88C, Airbag and seat belt pretensioners, Driver's front

airbag, Removal - Refitting).

Measure the resistance on the button between tracks P1 and P0 while pressing the

“R” button of component 331.

If the resistance is not approximately 900 , check the continuity of the connection when

the button is not pressed.

If there is continuity, replace the “R/0” control button.

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

JSAA741.0

Page 155 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 155V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

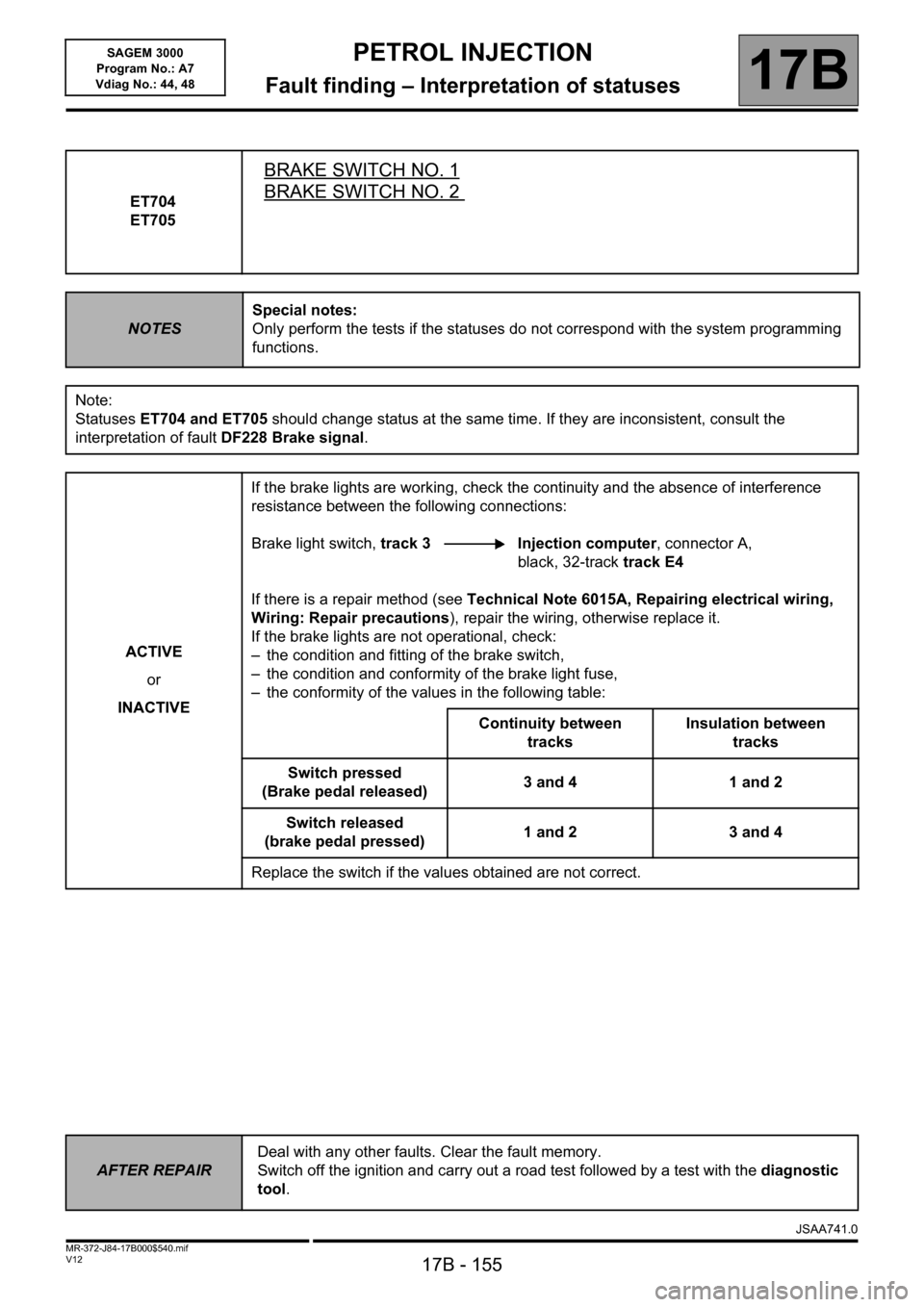

ET704

ET705

BRAKE SWITCH NO. 1

BRAKE SWITCH NO. 2

NOTESSpecial notes:

Only perform the tests if the statuses do not correspond with the system programming

functions.

Note:

Statuses ET704 and ET705 should change status at the same time. If they are inconsistent, consult the

interpretation of fault DF228 Brake signal.

ACTIVE

or

INACTIVEIf the brake lights are working, check the continuity and the absence of interference

resistance between the following connections:

Brake light switch, track 3 Injection computer, connector A,

black, 32-track track E4

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Repair precautions), repair the wiring, otherwise replace it.

If the brake lights are not operational, check:

– the condition and fitting of the brake switch,

– the condition and conformity of the brake light fuse,

– the conformity of the values in the following table:

Continuity between

tracksInsulation between

tracks

Switch pressed

(Brake pedal released)3 and 4 1 and 2

Switch released

(brake pedal pressed)1 and 2 3 and 4

Replace the switch if the values obtained are not correct.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

1JSAA741.0

Page 156 of 181

PETROL INJECTION

Fault finding – Parameter summary table17B

17B - 156V12 MR-372-J84-17B000$630.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Parameter summary table

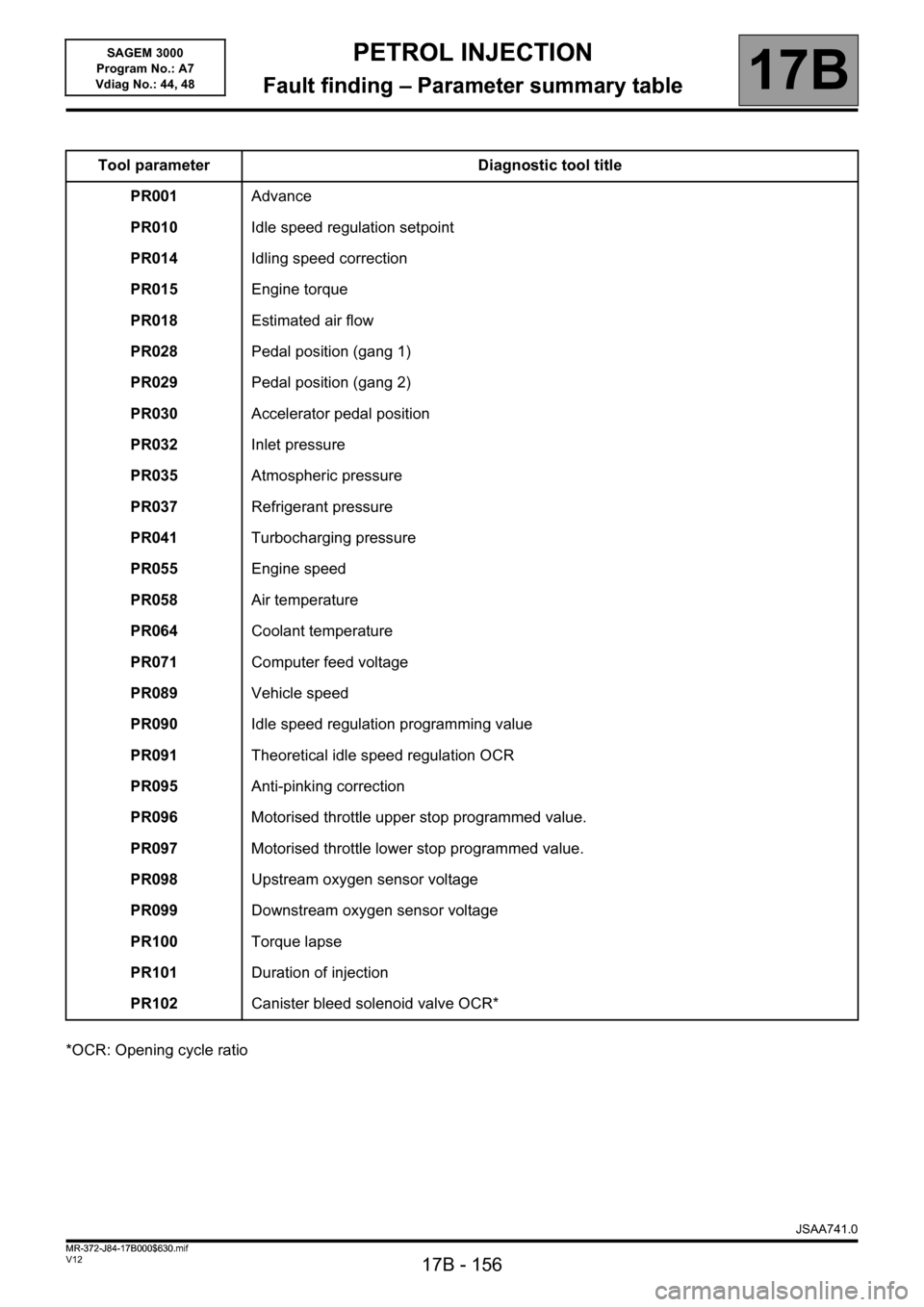

*OCR: Opening cycle ratioTool parameter Diagnostic tool title

PR001Advance

PR010Idle speed regulation setpoint

PR014Idling speed correction

PR015Engine torque

PR018Estimated air flow

PR028Pedal position (gang 1)

PR029Pedal position (gang 2)

PR030Accelerator pedal position

PR032Inlet pressure

PR035Atmospheric pressure

PR037Refrigerant pressure

PR041Turbocharging pressure

PR055Engine speed

PR058Air temperature

PR064Coolant temperature

PR071Computer feed voltage

PR089Vehicle speed

PR090Idle speed regulation programming value

PR091Theoretical idle speed regulation OCR

PR095Anti-pinking correction

PR096Motorised throttle upper stop programmed value.

PR097Motorised throttle lower stop programmed value.

PR098Upstream oxygen sensor voltage

PR099Downstream oxygen sensor voltage

PR100Torque lapse

PR101Duration of injection

PR102Canister bleed solenoid valve OCR*

JSAA741.0

MR-372-J84-17B000$630.mif

Page 157 of 181

PETROL INJECTION

Fault finding – Parameter summary table17B

17B - 157V12 MR-372-J84-17B000$630.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

*OCR: Opening cycle ratio

*AT: automatic transmission

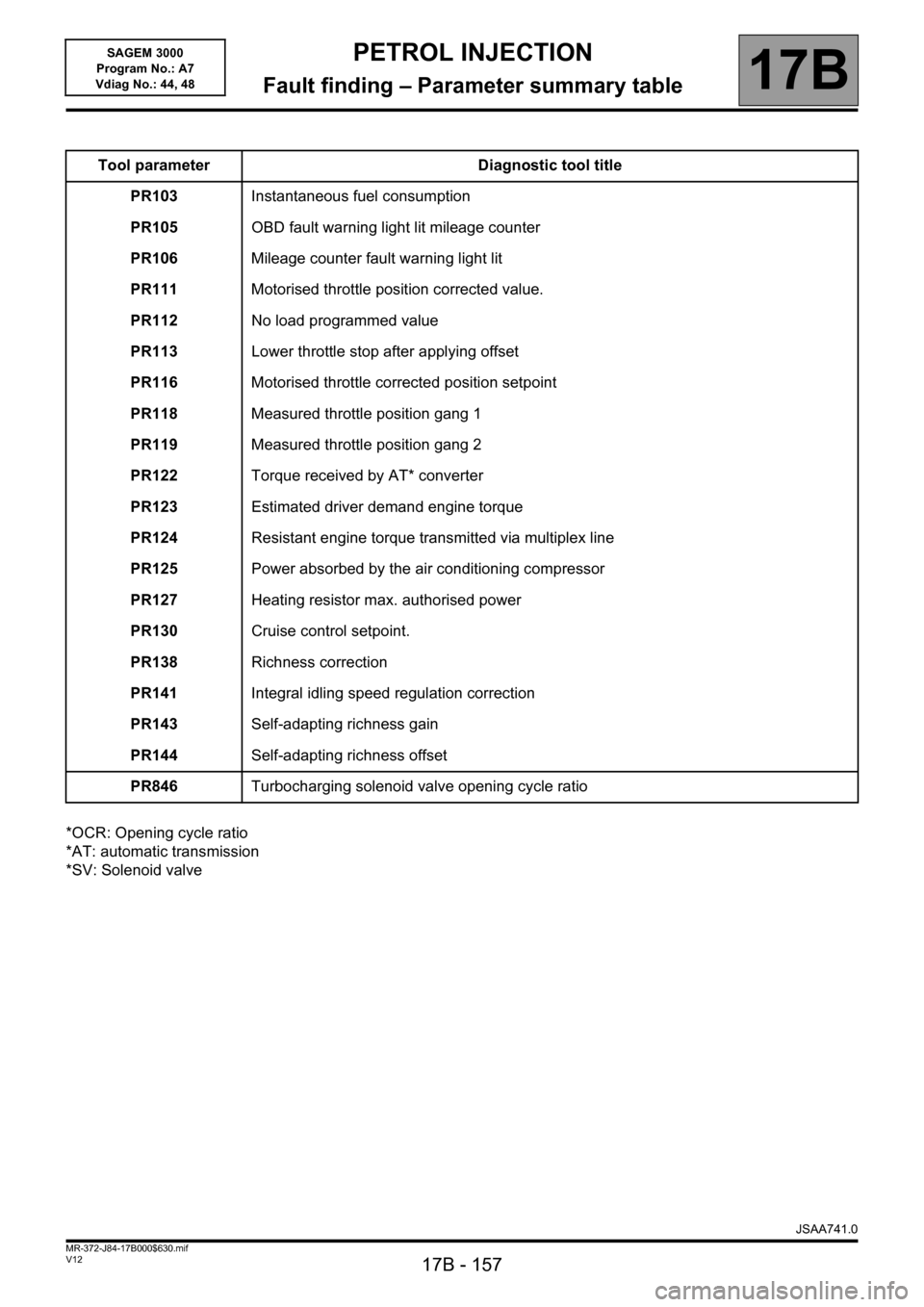

*SV: Solenoid valveTool parameter Diagnostic tool title

PR103Instantaneous fuel consumption

PR105OBD fault warning light lit mileage counter

PR106Mileage counter fault warning light lit

PR111Motorised throttle position corrected value.

PR112No load programmed value

PR113Lower throttle stop after applying offset

PR116Motorised throttle corrected position setpoint

PR118Measured throttle position gang 1

PR119Measured throttle position gang 2

PR122Torque received by AT* converter

PR123Estimated driver demand engine torque

PR124Resistant engine torque transmitted via multiplex line

PR125Power absorbed by the air conditioning compressor

PR127Heating resistor max. authorised power

PR130Cruise control setpoint.

PR138Richness correction

PR141Integral idling speed regulation correction

PR143Self-adapting richness gain

PR144Self-adapting richness offset

PR846Turbocharging solenoid valve opening cycle ratio

JSAA741.0

Page 158 of 181

PETROL INJECTION

Fault finding – Interpretation of parameters17B

17B - 158V12 MR-372-J84-17B000$675.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Interpretation of parameters

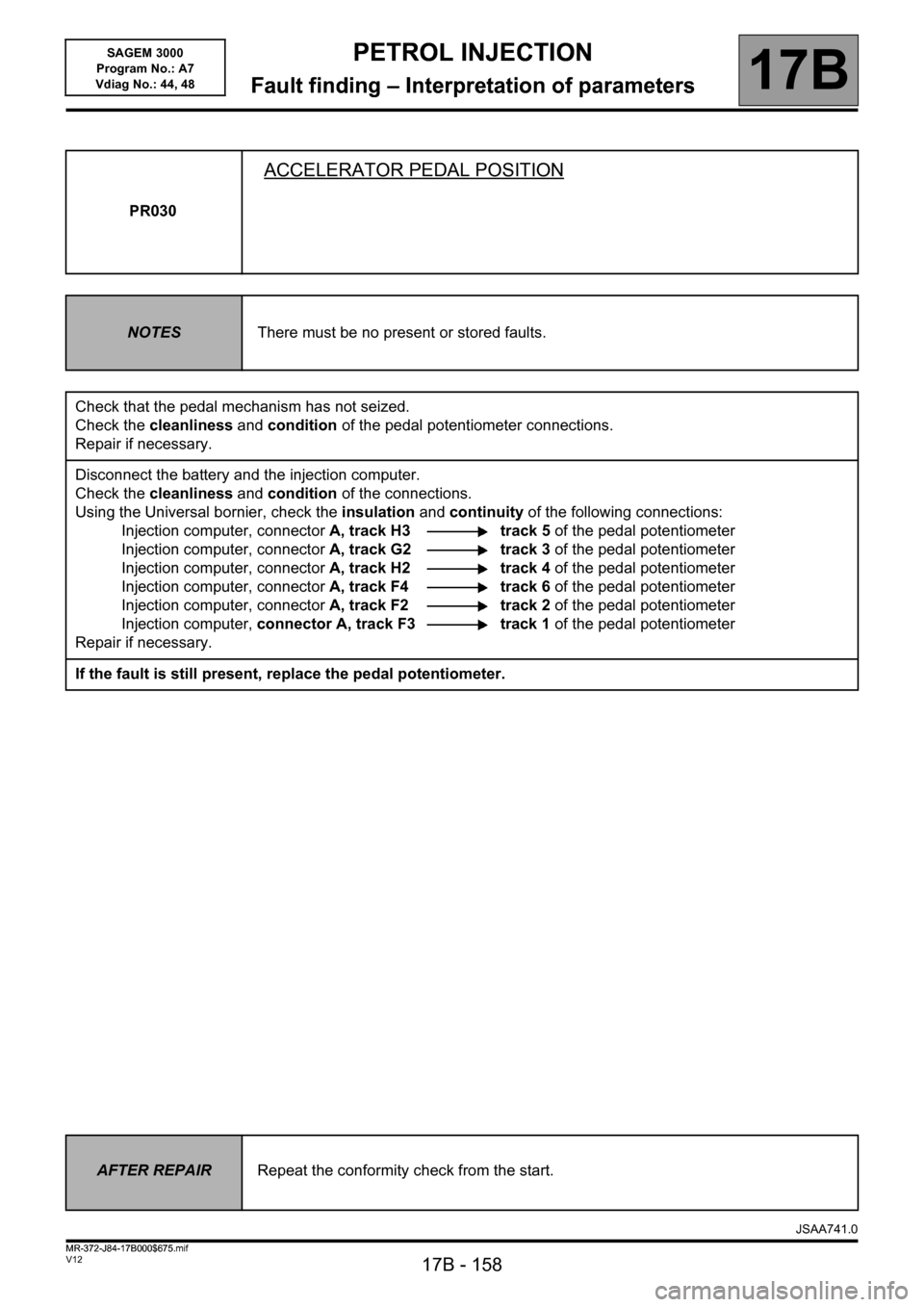

PR030

ACCELERATOR PEDAL POSITION

NOTESThere must be no present or stored faults.

Check that the pedal mechanism has not seized.

Check the cleanliness and condition of the pedal potentiometer connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer, connectorA, track H3 track 5 of the pedal potentiometer

Injection computer, connectorA, track G2 track 3 of the pedal potentiometer

Injection computer, connectorA, track H2 track 4 of the pedal potentiometer

Injection computer, connector A, track F4 track 6 of the pedal potentiometer

Injection computer, connectorA, track F2 track 2 of the pedal potentiometer

Injection computer, connector A, track F3 track 1 of the pedal potentiometer

Repair if necessary.

If the fault is still present, replace the pedal potentiometer.

AFTER REPAIRRepeat the conformity check from the start.

JSAA741.0

MR-372-J84-17B000$675.mif

Page 159 of 181

PETROL INJECTION

Fault finding – Interpretation of parameters17B

17B - 159V12 MR-372-J84-17B000$675.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

PR032

INLET PRESSURE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the manifold pressure sensor and its connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Computer, connectorB, track H2 track 1 of the manifold pressure sensor.

Computer, connectorB, track H3 track 3 of the manifold pressure sensor

Computer, connectorB, track H4 track 2 of the manifold pressure sensor

Repair if necessary.

If the fault is still present, replace the manifold pressure sensor.

If the fault is still present, carry out the following checks:

The inlet line must be perfectly sealed, from the throttle valve to the cylinder head.

Check:

– the condition of the air filter,

– that the air inlet circuit is not blocked,

– the sealing between the throttle valve and inlet manifold,

– the manifold pressure sensor sealing,

– the fuel vapour absorber bleed, which must not be jammed open,

– the fuel vapour absorber bleed system sealing,

– the brake servo system sealing,

– that there are no leaks in the turbocharger safety valve circuit,

– the cylinder head oil vapour recovery system sealing,

– the sealing between the inlet manifold and cylinder head,

– the exhaust pipe sealing between the cylinder head and catalytic converter.

Repair if necessary.

AFTER REPAIRRepeat the conformity check from the start.

JSAA741.0

Page 160 of 181

PETROL INJECTION

Fault finding – Interpretation of parameters17B

17B - 160V12 MR-372-J84-17B000$675.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

PR037

REFRIGERANT PRESSURE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the refrigerant pressure sensor and its connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the universal bornier, check the insulation and continuity on the following connections:

Injection computer, connectorB, track J2 track B, refrigerant pressure sensor

Injection computer, connectorB, track J3 track C of the refrigerant sensor

Injection computer, connectorB, track K2 track A of the refrigerant sensor

Repair if necessary.

If the fault is still present, replace the refrigerant sensor.

If the fault is still present, check the air conditioning circuit (see MR 364, Mechanics, 62A, Air conditioning).

AFTER REPAIRRepeat the conformity check from the start.

JSAA741.0