RENAULT SCENIC 2014 J95 / 3.G Petrol Injection - Sagem3000 Workshop Manual

Manufacturer: RENAULT, Model Year: 2014, Model line: SCENIC, Model: RENAULT SCENIC 2014 J95 / 3.GPages: 181

Page 141 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 141V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET054

CONTINUED

IDLING SPEED

TOO HIGH

Check:

– the engine oil level (too high oil combustion),

– that the restrictions are present in the oil vapour rebreathing circuit,

– the sealing between the throttle valve and inlet manifold,

– the manifold pressure sensor sealing,

– the fuel vapour absorber bleed, which must not be jammed open,

– the fuel vapour absorber bleed system sealing,

– the brake servo system sealing,

– the sealing between the inlet manifold and cylinder head,

– the oil vapour recovery circuit sealing between the inlet manifold and cylinder head,

– the fuel pressure and flow (see MR 364 Mechanics, 17B, Petrol injection),

– the condition and cleanliness of the injectors,

– the cylinder compression's,

– the timing adjustment,

– the hydraulic tappets if there is camshaft noise (see MR 364 Mechanics, 11A, Top and front of engine).

Repair the defective component if necessary.

AFTER REPAIRRepeat the conformity check from the start.

JSAA741.0

Page 142 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 142V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET055

UPSTREAM SENSOR RICHNESS LOOP

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the upstream oxygen sensor connections.

Repair if necessary.

With the ignition on, check for + 12 V on track A of the upstream oxygen sensor connector.

If +12V is not present:

– disconnect the battery,

– disconnect the connector marked PPM1 in the Protection and Switching Unit,

– check the cleanliness and condition of the connections,

– using the Universal bornier, check for continuity on the following connection:

Protection and Switching Unit track 2 connector PPM1 track A of the upstream oxygen sensor

Reconnect the Protection and Switching Unit connector and reconnect the battery.

With the ignition on, if there is still no +12V at the upstream oxygen sensor connector, there is a fault in the

Protection and Switching Unit.

Contact the Techline.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the universal bornier, check the insulation and continuity on the following connections:

Injection computer connectorC, track C1 track D of the upstream oxygen sensor

Injection computer, connectorC, track B1 track C of the upstream oxygen sensor

Injection computer, connectorC, track L2 track B of the upstream oxygen sensor

Repair if necessary.

Measure the heating resistance between tracks A and B of the upstream oxygen sensor.

Replace the upstream oxygen sensor if the resistance is not approximately 9 at 20 °C.

Check the condition and secure fitting of the upstream oxygen sensor.

If the vehicle is driven frequently in town, carry out a decoking procedure.

JSAA741.0

Page 143 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 143V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET055

CONTINUED

Check:

– the condition of the air filter,

– that the air inlet circuit is not blocked,

– the condition and conformity of the spark plugs,

– the sealing between the throttle valve and inlet manifold,

– the manifold pressure sensor sealing,

– the fuel vapour absorber bleed, which must not be jammed open,

– the fuel vapour absorber bleed system sealing,

– the brake servo system sealing,

– the turbocharger safety valve circuit sealing,

– the cylinder head oil vapour recovery system sealing,

– the sealing between the inlet manifold and cylinder head,

– the exhaust pipe sealing between the cylinder head and catalytic converter.

– the fuel flow rate and pressure.

If the idling speed is not stable, check:

– the timing adjustment,

– the hydraulic tappets if there is camshaft noise (seeMR 364 Mechanical, 11A, Top and front of engine),

– the cylinder compression's.

Drive the vehicle to check the repair.

Repair the defective components.

AFTER REPAIRRepeat the conformity check from the start.

JSAA741.0

Page 144 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 144V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET062

FLYWHEEL SIGNAL

NOTESThere must be no present or stored faults.

Information:

If the flywheel has been replaced or removed, reinitialise the flywheel target

programming.

Check the mounting and positioning of the TDC sensor (see MR 364 Mechanics, 10A, Engine and

peripherals).

Repair if necessary.

Check the cleanliness and condition of the TDC sensor and its connections.

Check the condition of the wire.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the universal bornier, check the insulation and continuity on the following connections:

Injection computer, connectorB, track E4 Track 2 of the TDC sensor

Injection computer, connectorB, track F3 track 1 of the TDC sensor

Repair if necessary.

Measure the resistance of the TDC sensor between tracks 1 and 2.

Replace the sensor if the resistance is not 200 to 270 at 23 °C.

If the sensor has been replaced, reset the flywheel signal programming.

Flywheel signal programming reinitialisation procedure:

Accelerate up to 4000 rpm in third gear ratio, then decelerate to power take-up speed*.

Then repeat immediately.

(* This is the moment when, during deceleration with no load, the engine drops to idle speed and recovers torque.)

If the fault is still present, check the cleanliness and condition of the flywheel.

AFTER REPAIRIf the TDC sensor has been replaced, reinitialise the programming (RZ005).

Repeat the conformity check from the start.

JSAA741.0

Page 145 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 145V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

JSAA741.0

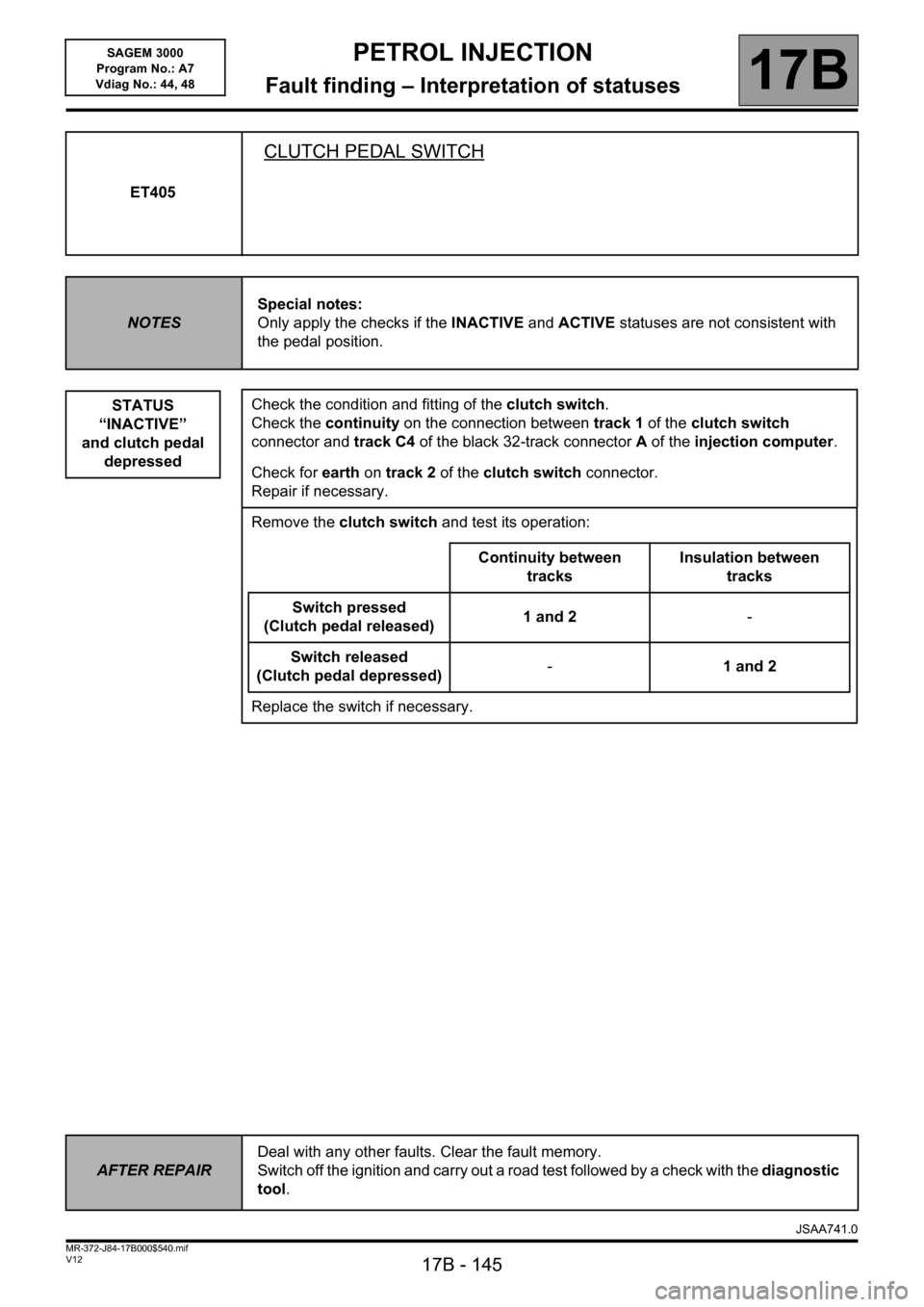

ET405

CLUTCH PEDAL SWITCH

NOTESSpecial notes:

Only apply the checks if the INACTIVE and ACTIVE statuses are not consistent with

the pedal position.

STATUS

“INACTIVE”

and clutch pedal

depressed

Check the condition and fitting of the clutch switch.

Check the continuity on the connection between track 1 of the clutch switch

connector and track C4 of the black 32-track connector A of the injection computer.

Check for earth on track 2 of the clutch switch connector.

Repair if necessary.

Remove the clutch switch and test its operation:

Continuity between

tracksInsulation between

tracks

Switch pressed

(Clutch pedal released)1 and 2-

Switch released

(Clutch pedal depressed)-1 and 2

Replace the switch if necessary.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a check with the diagnostic

tool.

Page 146 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 146V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

1

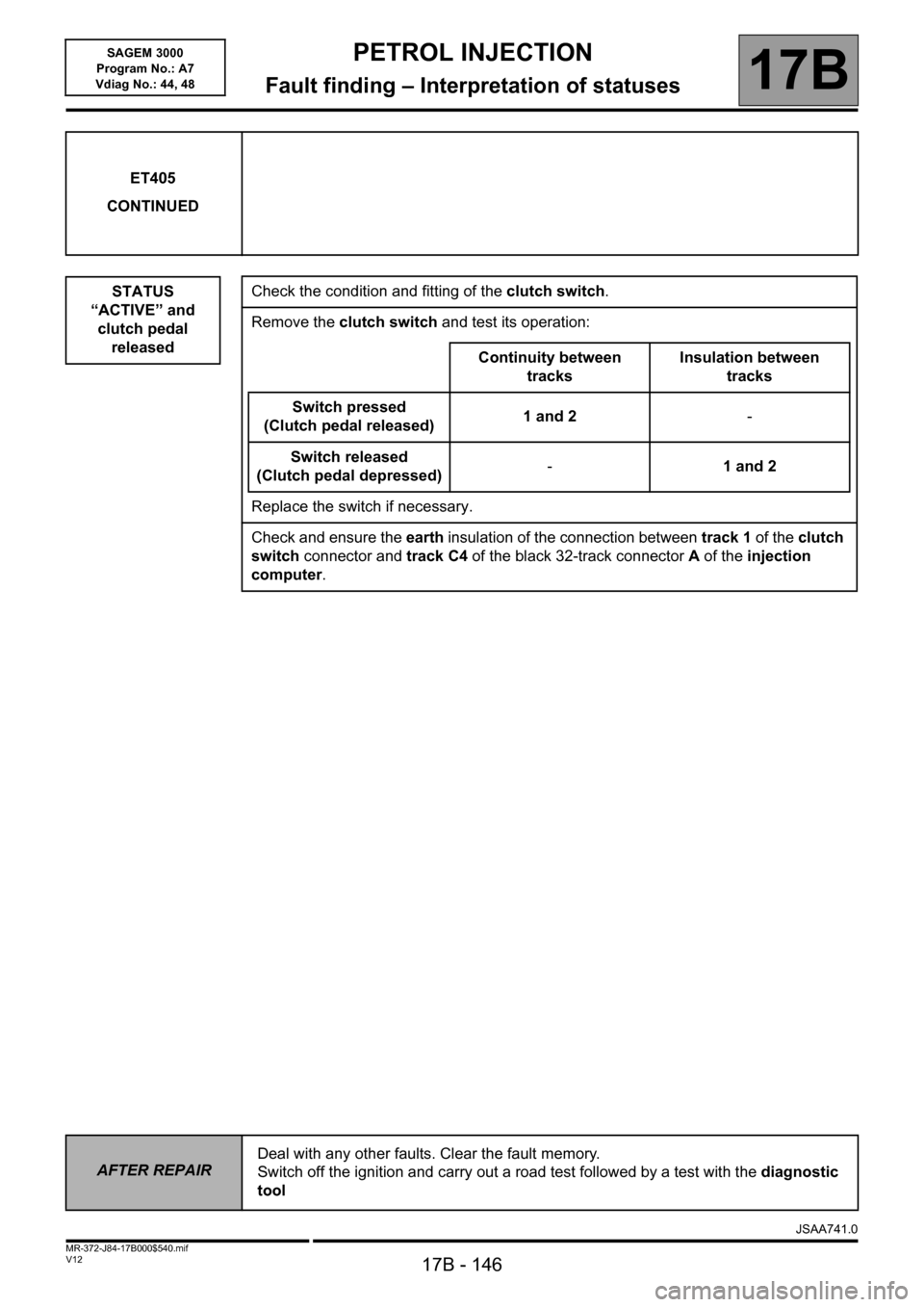

ET405

CONTINUED

STATUS

“ACTIVE” and

clutch pedal

released

Check the condition and fitting of the clutch switch.

Remove the clutch switch and test its operation:

Continuity between

tracksInsulation between

tracks

Switch pressed

(Clutch pedal released)1 and 2-

Switch released

(Clutch pedal depressed)-1 and 2

Replace the switch if necessary.

Check and ensure the earth insulation of the connection between track 1 of the clutch

switch connector and track C4 of the black 32-track connectorA of the injection

computer.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool

JSAA741.0

Page 147 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 147V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

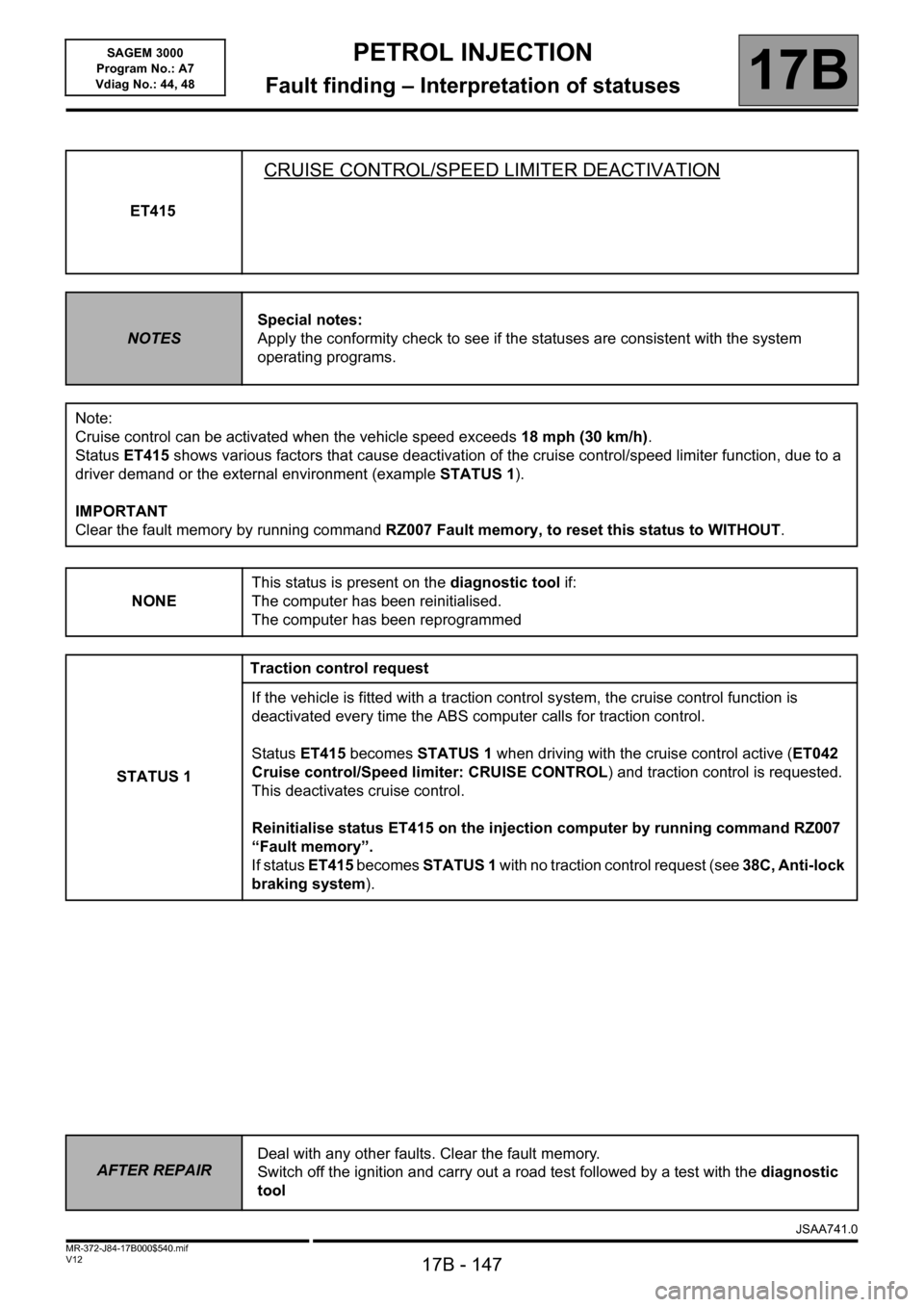

ET415

CRUISE CONTROL/SPEED LIMITER DEACTIVATION

NOTESSpecial notes:

Apply the conformity check to see if the statuses are consistent with the system

operating programs.

Note:

Cruise control can be activated when the vehicle speed exceeds 18 mph (30 km/h).

Status ET415 shows various factors that cause deactivation of the cruise control/speed limiter function, due to a

driver demand or the external environment (example STATUS 1).

IMPORTANT

Clear the fault memory by running command RZ007 Fault memory, to reset this status to WITHOUT.

NONEThis status is present on the diagnostic tool if:

The computer has been reinitialised.

The computer has been reprogrammed

STATUS 1Traction control request

If the vehicle is fitted with a traction control system, the cruise control function is

deactivated every time the ABS computer calls for traction control.

Status ET415 becomes STATUS 1 when driving with the cruise control active (ET042

Cruise control/Speed limiter: CRUISE CONTROL) and traction control is requested.

This deactivates cruise control.

Reinitialise status ET415 on the injection computer by running command RZ007

“Fault memory”.

If status ET415 becomes STATUS 1 with no traction control request (see 38C, Anti-lock

braking system).

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool

1JSAA741.0

Page 148 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 148V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

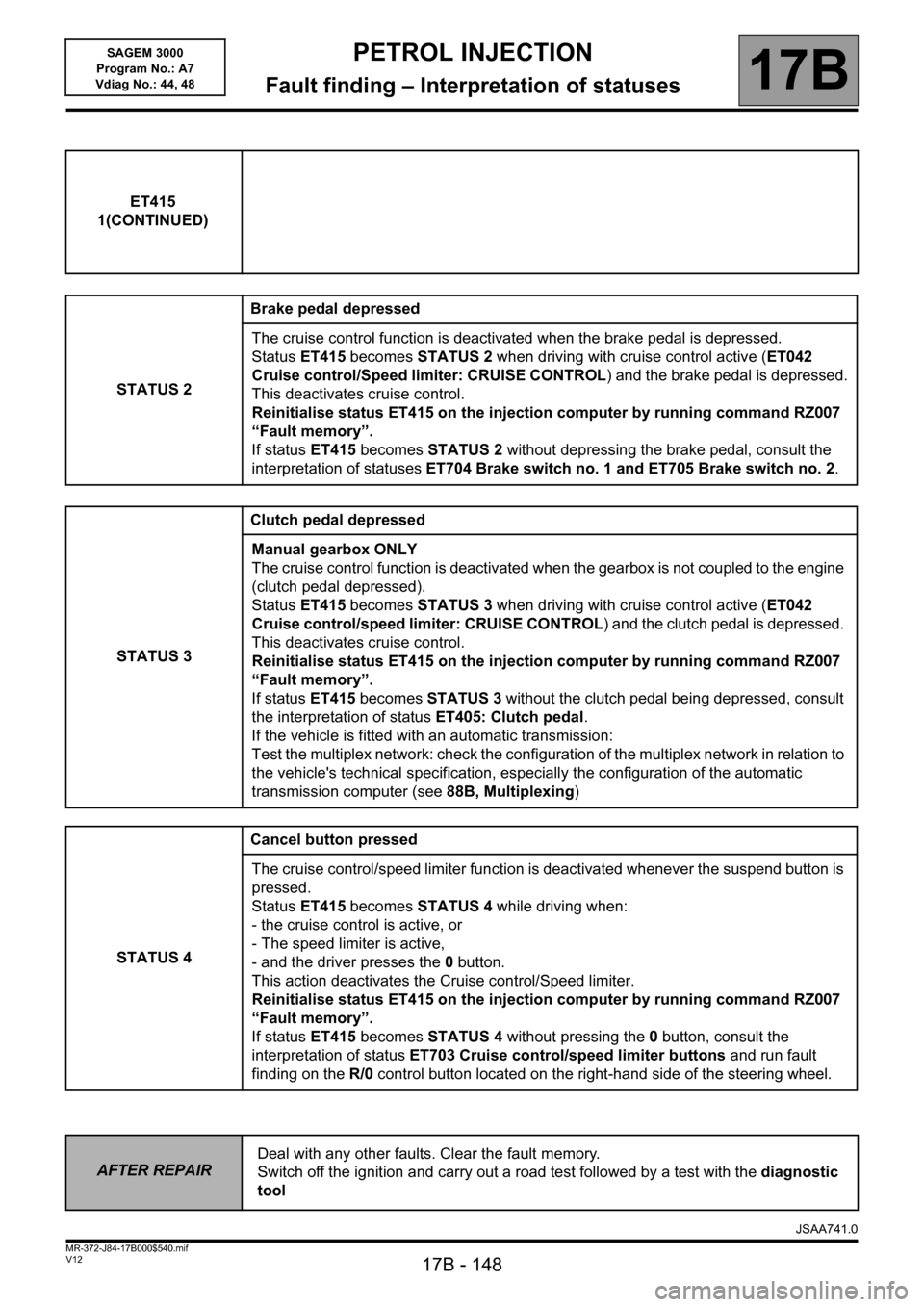

ET415

1(CONTINUED)

STATUS 2Brake pedal depressed

The cruise control function is deactivated when the brake pedal is depressed.

Status ET415 becomes STATUS 2 when driving with cruise control active (ET042

Cruise control/Speed limiter: CRUISE CONTROL) and the brake pedal is depressed.

This deactivates cruise control.

Reinitialise status ET415 on the injection computer by running command RZ007

“Fault memory”.

If status ET415 becomes STATUS 2 without depressing the brake pedal, consult the

interpretation of statuses ET704 Brake switch no. 1 and ET705 Brake switch no. 2.

STATUS 3Clutch pedal depressed

Manual gearbox ONLY

The cruise control function is deactivated when the gearbox is not coupled to the engine

(clutch pedal depressed).

Status ET415 becomes STATUS 3 when driving with cruise control active (ET042

Cruise control/speed limiter: CRUISE CONTROL) and the clutch pedal is depressed.

This deactivates cruise control.

Reinitialise status ET415 on the injection computer by running command RZ007

“Fault memory”.

If status ET415 becomes STATUS 3 without the clutch pedal being depressed, consult

the interpretation of status ET405: Clutch pedal.

If the vehicle is fitted with an automatic transmission:

Test the multiplex network: check the configuration of the multiplex network in relation to

the vehicle's technical specification, especially the configuration of the automatic

transmission computer (see 88B, Multiplexing)

STATUS 4Cancel button pressed

The cruise control/speed limiter function is deactivated whenever the suspend button is

pressed.

Status ET415 becomes STATUS 4 while driving when:

- the cruise control is active, or

- The speed limiter is active,

- and the driver presses the 0 button.

This action deactivates the Cruise control/Speed limiter.

Reinitialise status ET415 on the injection computer by running command RZ007

“Fault memory”.

If status ET415 becomes STATUS 4 without pressing the 0 button, consult the

interpretation of status ET703 Cruise control/speed limiter buttons and run fault

finding on the R/0 control button located on the right-hand side of the steering wheel.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool

JSAA741.0

Page 149 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 149V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET415

(CONTINUED 2)

STATUS 5Cruise control or speed limiter monitoring

This status appears when the vehicle brakes or decelerates sharply without the injection

computer receiving a signal indicating that the brake pedal switch has been pressed.

If status ET415 is STATUS 5, refer to the interpretation of:

- status ET042 Cruise control/Speed limiter,

- status ET703 Cruise control/speed limiter buttons,

- status ET704 Brake switch no. 1,

- and status ET705 Brake switch No 2,

to test the cruise control/speed limiter system components and find the defective

component.

In addition, check the operation of the accelerator pedal, and use the diagnostic tool to

check for a fault on it. Deal with them if necessary.

Reinitialise status ET415 on the injection computer by running command RZ007

“Fault memory”.

If status ET415 changes to STATUS 5, deal with present faults or those stored in the

injection computer.

If the fault is still present, contact Techline.

STATUS 6Gear lever in neutral (manual gearbox) or the neutral position (automatic gearbox)

Status ET415 becomes STATUS 6, when driving with cruise control active (ET042:

Cruise control/speed limiter: CRUISE CONTROL) and:

- If the driver puts the gear lever in neutral position on a manual gearbox without

declutching or,

- if the gear lever is in neutral on an automatic gearbox.

This deactivates cruise control.

Reinitialise status ET415 on the injection computer by running command RZ007

“Fault memory”.

If status ET415 becomes STATUS 6 without shifting the gear lever into neutral on a

manual gearbox without declutching, or into neutral on an automatic transmission, run

fault finding on the ABS computer and check the configuration of the tyre size stored in

the computer. If the configuration is correct, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

1JSAA741.0

Page 150 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 150V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET415

(CONTINUED 3)

STATUS 7Inconsistency between the request and the vehicle speed

Status ET415 becomes STATUS 7 if the computer detects too great a difference

between the speed requested by the driver and the vehicle speed.

This could occur when driving with cruise control active (ET042 Cruise control/ speed

limiter: CRUISE CONTROL) and when there is a significant difference.

This inconsistency deactivates cruise control.

Reinitialise status ET415 on the injection computer by running command RZ007

“Fault memory”.

If status ET415 changes to STATUS 7 where there is no significant difference in the

levels, contact the Techline.

STATUS 8Automatic transmission in defect mode.

Status ET415 becomes STATUS 8, when driving with cruise control active (ET042:

Cruise control/speed limiter: CRUISE CONTROL) and if the automatic transmission

is in defect mode.

This signal is conveyed on the multiplex line and deactivates the cruise control.

Carry out a multiplex network test, then run fault finding on the automatic transmission

computer.

Deal with any present or stored faults (see 23A, Automatic transmission,

interpretation of faults).

Clear the automatic transmission computer fault memory by running command RZ007

“Fault memory”.

Reinitialise status ET415 on the injection computer by running command RZ007

“Fault memory”.

If status 8 continues, contact the Techline.

STATUS 9Vehicle speed monitoring

Status ET415 changes to STATUS 9 if the vehicle speed received by the computer is

invalid or absent.

This signal is conveyed on the multiplex line and deactivates the cruise control.

Carry out a multiplex network test, then run fault finding on the ABS computer.

Deal with any present or stored faults (see 38C, Interpretation of faults).

Reinitialise status ET415 on the injection computer by running command RZ007

“Fault memory”.

If STATUS 9 is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

JSAA741.0