RENAULT SCENIC 2014 J95 / 3.G Petrol Injection - Sagem3000 Workshop Manual

Manufacturer: RENAULT, Model Year: 2014, Model line: SCENIC, Model: RENAULT SCENIC 2014 J95 / 3.GPages: 181

Page 131 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B - 131V12 MR-372-J84-17B000$495.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

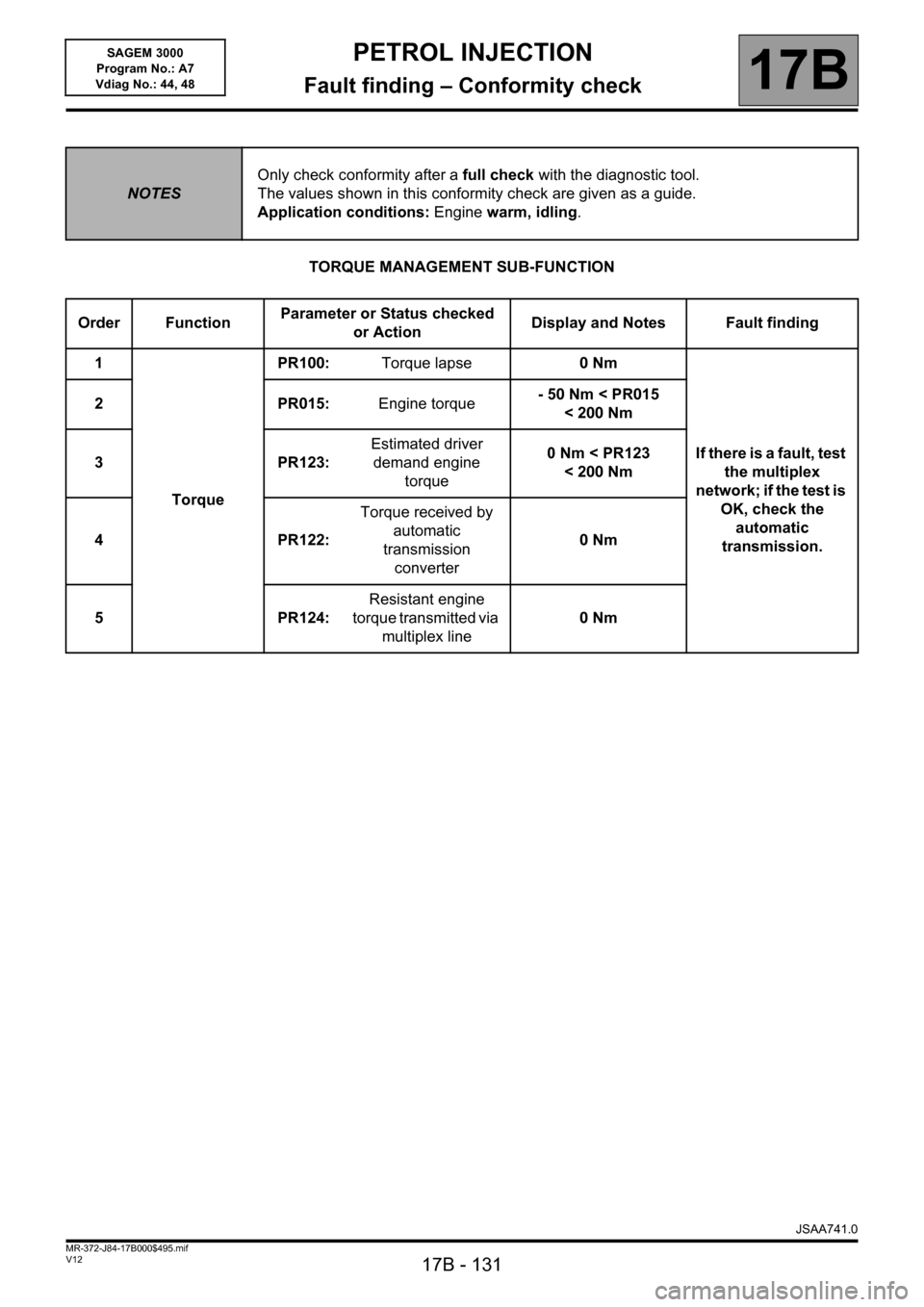

TORQUE MANAGEMENT SUB-FUNCTION

NOTESOnly check conformity after a full check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status checked

or ActionDisplay and Notes Fault finding

1

TorquePR100: Torque lapse0Nm

If there is a fault, test

the multiplex

network; if the test is

OK, check the

automatic

transmission. 2 PR015: Engine torque- 50 Nm < PR015

< 200 Nm

3 PR123: Estimated driver

demand engine

torque0 Nm < PR123

< 200 Nm

4 PR122: Torque received by

automatic

transmission

converter0Nm

5 PR124: Resistant engine

torque transmitted via

multiplex line0Nm

JSAA741.0

Page 132 of 181

PETROL INJECTION

Fault finding – Status summary table17B

17B - 132V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Status summary table

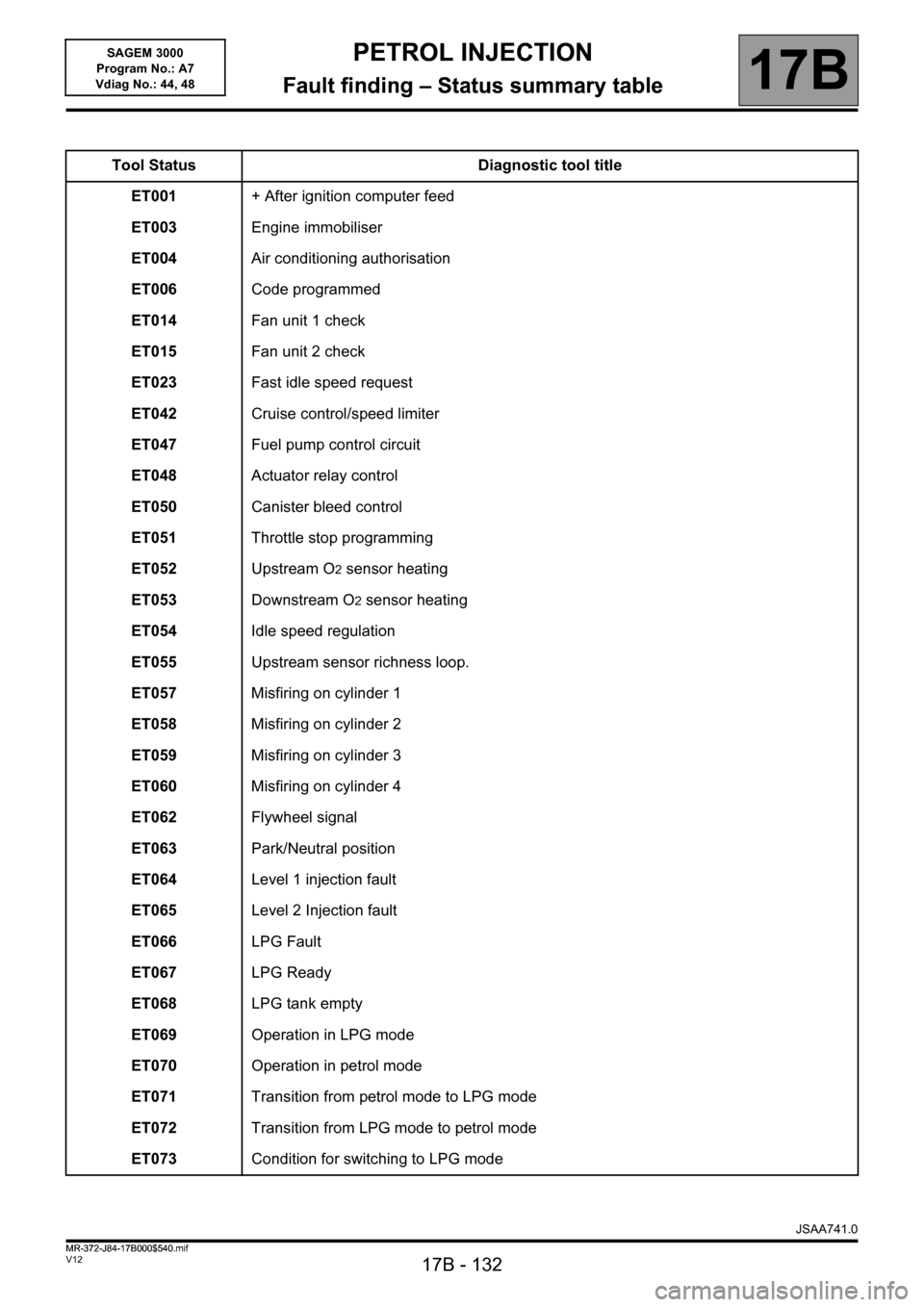

Tool Status Diagnostic tool title

ET001+ After ignition computer feed

ET003Engine immobiliser

ET004Air conditioning authorisation

ET006Code programmed

ET014Fan unit 1 check

ET015Fan unit 2 check

ET023Fast idle speed request

ET042Cruise control/speed limiter

ET047Fuel pump control circuit

ET048Actuator relay control

ET050Canister bleed control

ET051Throttle stop programming

ET052Upstream O

2 sensor heating

ET053Downstream O

2 sensor heating

ET054Idle speed regulation

ET055Upstream sensor richness loop.

ET057Misfiring on cylinder 1

ET058Misfiring on cylinder 2

ET059Misfiring on cylinder 3

ET060Misfiring on cylinder 4

ET062Flywheel signal

ET063Park/Neutral position

ET064Level 1 injection fault

ET065Level 2 Injection fault

ET066LPG Fault

ET067LPG Ready

ET068LPG tank empty

ET069Operation in LPG mode

ET070Operation in petrol mode

ET071Transition from petrol mode to LPG mode

ET072Transition from LPG mode to petrol mode

ET073Condition for switching to LPG mode

JSAA741.0

MR-372-J84-17B000$540.mif

Page 133 of 181

PETROL INJECTION

Fault finding – Status summary table17B

17B - 133V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

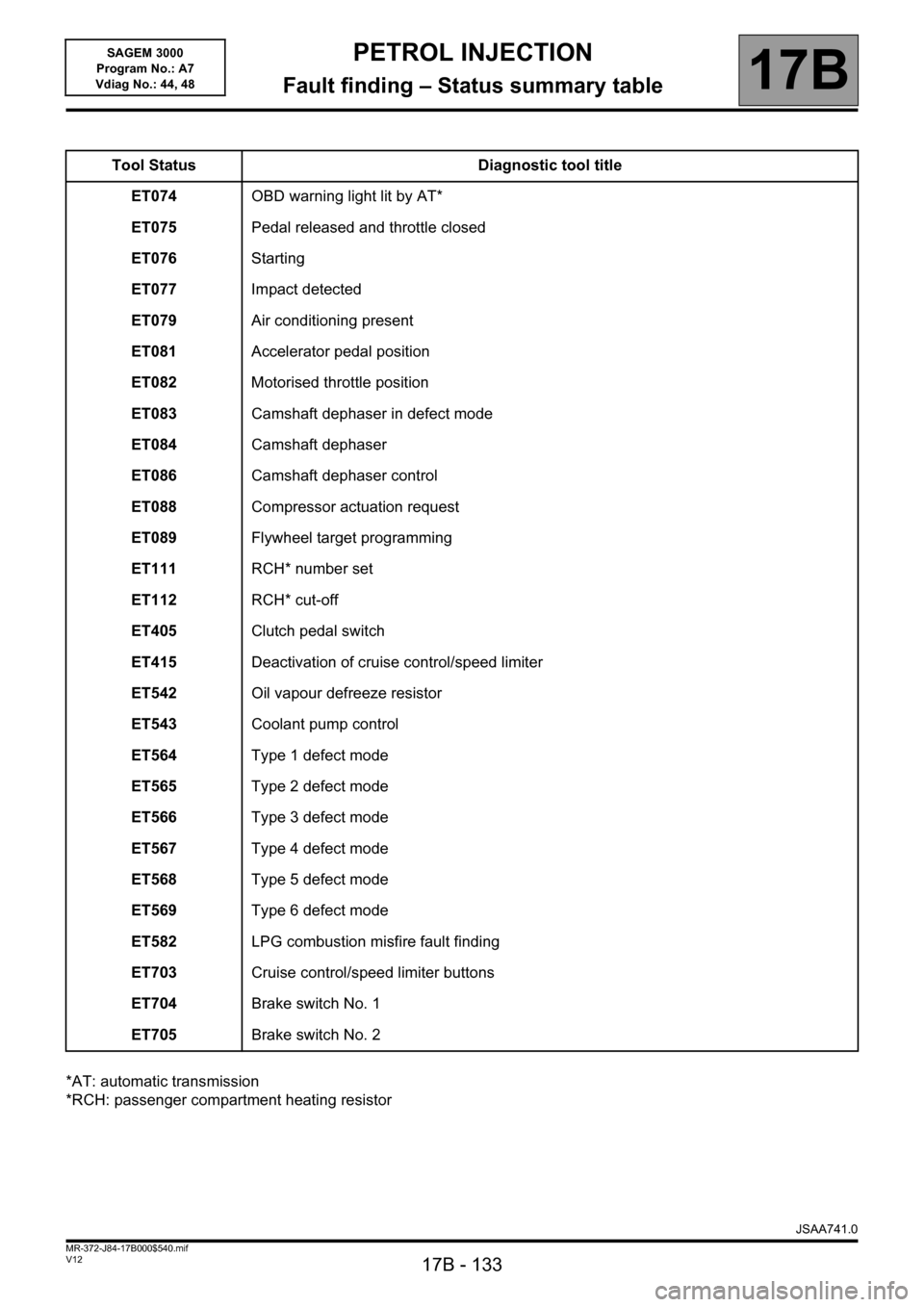

*AT: automatic transmission

*RCH: passenger compartment heating resistorTool Status Diagnostic tool title

ET074OBD warning light lit by AT*

ET075Pedal released and throttle closed

ET076Starting

ET077Impact detected

ET079Air conditioning present

ET081Accelerator pedal position

ET082Motorised throttle position

ET083Camshaft dephaser in defect mode

ET084Camshaft dephaser

ET086Camshaft dephaser control

ET088Compressor actuation request

ET089Flywheel target programming

ET111RCH* number set

ET112RCH* cut-off

ET405Clutch pedal switch

ET415Deactivation of cruise control/speed limiter

ET542Oil vapour defreeze resistor

ET543Coolant pump control

ET564Type 1 defect mode

ET565Type 2 defect mode

ET566Type 3 defect mode

ET567Type 4 defect mode

ET568Type 5 defect mode

ET569Type 6 defect mode

ET582LPG combustion misfire fault finding

ET703Cruise control/speed limiter buttons

ET704Brake switch No. 1

ET705Brake switch No. 2

JSAA741.0

Page 134 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 134V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Interpretation of statuses

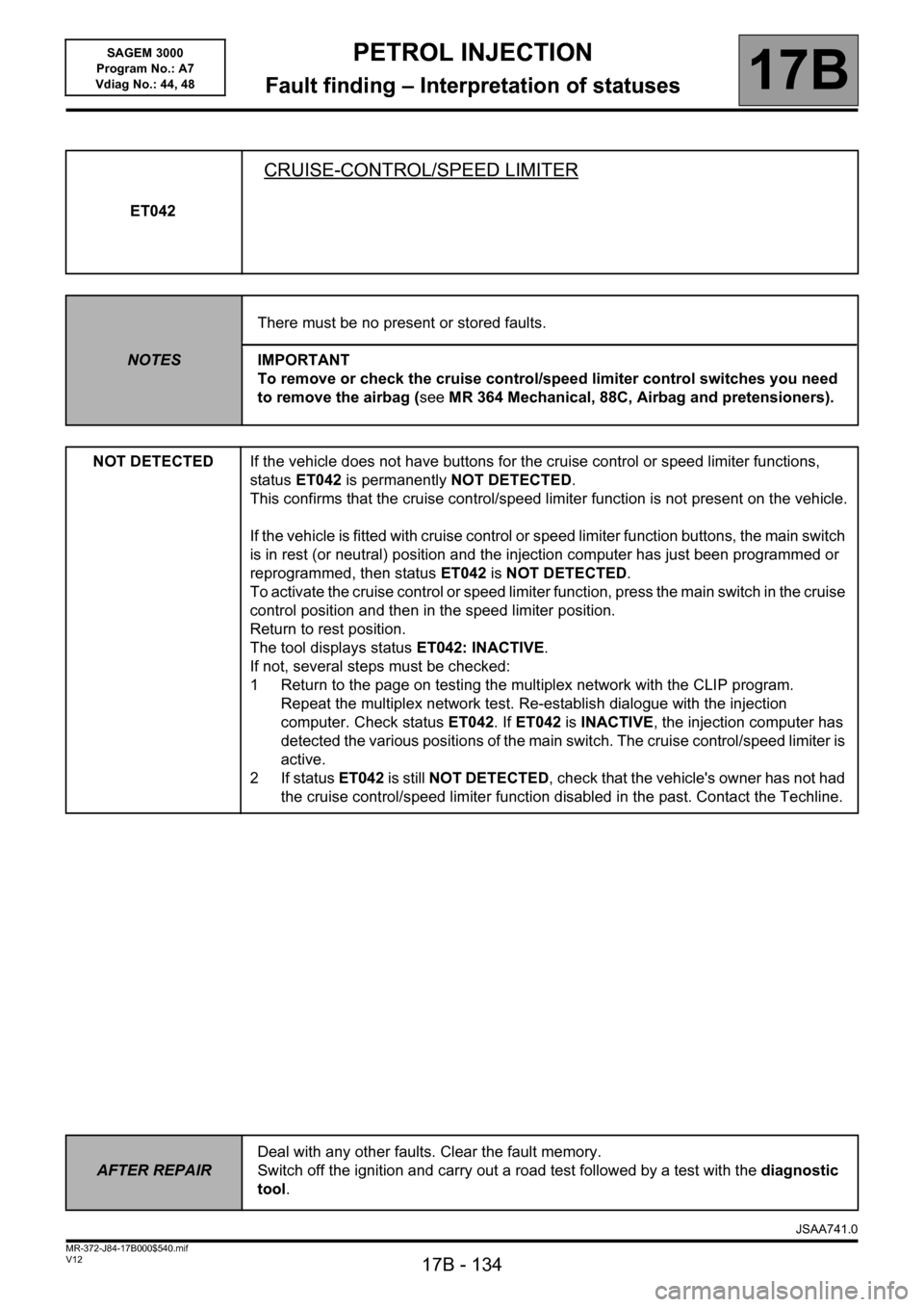

ET042

CRUISE-CONTROL/SPEED LIMITER

NOTESThere must be no present or stored faults.

IMPORTANT

To remove or check the cruise control/speed limiter control switches you need

to remove the airbag (see MR 364 Mechanical, 88C, Airbag and pretensioners).

NOT DETECTEDIf the vehicle does not have buttons for the cruise control or speed limiter functions,

status ET042 is permanently NOT DETECTED.

This confirms that the cruise control/speed limiter function is not present on the vehicle.

If the vehicle is fitted with cruise control or speed limiter function buttons, the main switch

is in rest (or neutral) position and the injection computer has just been programmed or

reprogrammed, then status ET042 is NOT DETECTED.

To activate the cruise control or speed limiter function, press the main switch in the cruise

control position and then in the speed limiter position.

Return to rest position.

The tool displays status ET042: INACTIVE.

If not, several steps must be checked:

1 Return to the page on testing the multiplex network with the CLIP program.

Repeat the multiplex network test. Re-establish dialogue with the injection

computer. Check status ET042. If ET042 is INACTIVE, the injection computer has

detected the various positions of the main switch. The cruise control/speed limiter is

active.

2 If status ET042 is still NOT DETECTED, check that the vehicle's owner has not had

the cruise control/speed limiter function disabled in the past. Contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

JSAA741.0

Page 135 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 135V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Interpretation of statuses

ET042

CONTINUED 1

INACTIVEWhen the main switch is in rest position (or neutral), status ET042 is INACTIVE.

If CRUISE CONTROL or SPEED LIMITER appears despite the main button being in the

rest (or neutral) position, carry out the following operations:

Check the connections on the steering column top control module.

Check for +12 V APC on track 9 of the steering column top control module

connector.

Disconnect the top steering column control module connector and with the switch in

the rest position, check the insulation between tracks 9 and 6 and between tracks 9

and 12.

Check the continuity of the top steering column control module connector between

tracks 9 and 6, with the switch in the speed limiter position.

Check the continuity of the steering column top control module connector on

tracks 9 and 12, with the control in the cruise control position.

If the these checks do not produce the correct results, replace the steering column top

control module.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

JSAA741.0

Page 136 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 136V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Interpretation of statuses

ET042

CONTINUED 2

SPEED LIMITERWhen the driver presses the main switch in the speed limiter position, status ET042

becomes SPEED LIMITER.

If CRUISE CONTROL or INACTIVE appears although the switch was pressed in the

speed limiter position, carry out the following operations:

Check the connections on the steering column top control module.

Check for + 12 V APC on track 9 of the steering column top control module connector.

Disconnect the top steering column control module connector and with the switch in

the rest position, check the insulation between tracks 9 and 6 and between tracks 9

and 12.

Check the continuity of the top steering column control module connector between

tracks 9 and 6, with the switch in the speed limiter position.

Check the continuity of the steering column top control module connector on

tracks 9 and 12, with the control in the cruise control position.

If the these checks do not produce the correct results, replace the steering column top

control module.

Check the insulation, continuity and absence of interference resistance on the

following connections:

Steering column top

control module,

white connector track 12

Steering column top

control module,

white connector track 6Injection computer, black connector

track A2

Injection computer, black connector

track C3

Check the engine management computer connections.

Repair if necessary.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a check with the diagnostic

tool.

JSAA741.0

Page 137 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 137V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

ET042

CONTINUED 3

CRUISE CONTROLWhen the driver presses the main switch in the speed limiter position, status ET042

becomes SPEED LIMITER.

If CRUISE CONTROL or INACTIVE appears although the switch was pressed in the

speed limiter position, carry out the following operations:

Check the connections on the steering column top control module.

Check for + 12 V APC on track 9 of the steering column top control module connector.

Disconnect the top steering column control module connector and with the switch in

the rest position, check the insulation between tracks 9 and 6 and between tracks 9

and 12.

Check the continuity of the top steering column control module connector between

tracks 9 and 6, with the switch in the speed limiter position.

Check the continuity of the steering column top control module connector on

tracks 9 and 12, with the control in the cruise control position.

If the these checks do not produce the correct results, replace the steering column top

control module.

Check the insulation, continuity and absence of interference resistance on the

following connections:

Steering column top

control module,

white connector track 12

Steering column top

control module,

white connector track 6Injection computer, black connector

track A2

Injection computer, black connector

track C3

Also check the engine management computer connectors.

Repair if necessary.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

Page 138 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 138V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET052

UPSTREAM O2 SENSOR

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the upstream oxygen sensor and its connections.

Repair if necessary.

With the ignition on, check for + 12 V on track A of the upstream oxygen sensor connector.

If +12V is not present:

– disconnect the battery,

– disconnect the connector marked PPM1 from the Protection and Switching Unit,

– check the cleanliness and condition of the connections,

– using the Universal bornier, check the continuity on the following connection:

Protection and Switching Unit track 2 connector PPM1 track A of the upstream oxygen sensor

Reconnect the Protection and Switching Unit connector and reconnect the battery.

With the ignition on, if there is still no +12V at the upstream oxygen sensor connector, there is a fault in the

Protection and Switching Unit.

Contact the Techline.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the universal bornier, check for insulation and continuity on the following connection:

Injection computer, connectorC, track L2 track B of the upstream oxygen sensor

Repair if necessary.

Measure the heating resistance between tracks A and B of the upstream oxygen sensor.

Replace the upstream oxygen sensor if the resistance is not approximately 9 at 20 °C.

If the fault is still present, replace the upstream oxygen sensor.

AFTER REPAIRRepeat the conformity check from the start.

JSAA741.0

Page 139 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 139V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET053

DOWNSTREAM O2 SENSOR HEATING

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the downstream oxygen sensor and its connections.

Repair if necessary.

Check for the + 12 V feed on track A, downstream oxygen sensor connector with the ignition on.

If +12V is not present:

– disconnect the battery,

– disconnect the connector marked PPM1 in the Protection and Switching Unit,

–check the cleanliness and condition of the connections,

– using the Universal bornier, check for continuity on the following connection:

Protection and Switching Unit track 2 connector PPM1 track A of the downstream oxygen sensor

Reconnect the Protection and Switching Unit connector and reconnect the battery.

With the ignition on, if the +12V is still not present on the downstream oxygen sensor connector, there is a fault

in the Protection and Switching Unit.

Contact the Techline.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the universal bornier, check for insulation and continuity on the following connection:

Injection computer, connectorC, track L3 track B of the downstream oxygen sensor

Repair if necessary.

Measure the heating resistance between tracks A and B of the downstream oxygen sensor.

Replace the downstream oxygen sensor if the resistance is not approximately 9 at 20 °C.

If the fault is still present, replace the downstream oxygen sensor.

AFTER REPAIRRepeat the conformity check from the start.

JSAA741.0

Page 140 of 181

PETROL INJECTION

Fault finding – Interpretation of statuses17B

17B - 140V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

ET054

IDLING SPEED REGULATION

NOTESThere must be no present or stored faults.

Check the parameters PR032, PR058, PR064, PR118, PR119 and PR030.

Check that all these parameters are completely correct.

IDLING SPEED

TOO LOW

Check:

– the engine oil level (too high splashing),

– that the exhaust pipe is not blocked (catalytic converter damaged),

– the cleanliness and conformity of the air filter,

– that the air inlet circuit is not blocked,

– that the throttle valve is not clogged,

– the condition and conformity of the spark plugs,

– the fuel circuit sealing,

– the fuel pressure and flow (see MR 364 Mechanics, 17B, Petrol injection),

– the condition and cleanliness of the injectors,

– the cylinder compression's,

– the timing adjustment,

– the hydraulic tappets if there is camshaft noise (see MR 364 Mechanics, 11A, Top and front of engine).

Repair the defective component if necessary.

JSAA741.0