air RENAULT TWINGO 2009 2.G Chasiss User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 21 of 281

30A-17

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

V - CHECKING BENDING

aCheck the out-of-roundness of the outer diameter at

the centre of the curve radius (2) using a sliding cal-

liper (the out-of-roundness of the outer diameter is

correct if it is less than 10% flattening):

-nominal diameter of the pipe: 4.75 mm,

-minimum diameter after bending: 4.30 mm.VI - REFITTING THE PIPE

a

aTorque tighten the brake pipe bolts (8 N.m).

aTorque tighten the underbody unions (female/

male) (6 N.m).

128664

128670

Note:

When refitting the rigid brake pipe:

-respect the original routing as much as possi-

ble,

-adjust the pipe routing by hand when fitting

inside the clips.

WARNING

Contact points between the rigid brake pipe and

the surrounding components could cause dam-

age to the pipe. In order to avoid these contacts,

adjust the pipe routing by hand.

128644

128646

Page 22 of 281

30A-18

GENERAL INFORMATION

Brake fluid: Specifications

30A

BRAKE FLUID REPLACEMENT INTERVAL

Our braking technology, and in particular the disc

brakes (hollow pistons which conduct little heat, have a

low volume of fluid in the cylinder, sliding callipers

avoiding the need for a fluid reserve in the least cooled

area of the wheel), has allowed us to prevent the risk of

« vapour lock » as far as possible, even with heavy

braking (mountainous area). However, current brake

fluids are subject to minor deterioration during the first

months of use due to slight humidity intake. This is why

it is recommended that you change the brake fluid: see

maintenance booklet for the vehicle.

1 - Topping up the level

Wear of the brake pads will result in a gradual drop in

the fluid level in the reservoir.

Do not top up the fluid, as the level will rise again when

the pads are next changed. The brake fluid level must

not fall below the minimum mark.

2 - Approved brake fluid

Mixing two incompatible brake fluids in the brake circuit

may lead to:

-serious risk of leakage due mainly to deterioration of

the cups,

-deterioration in the operation of the ESP system.

To prevent such risks, it is essential to use only brake

fluids that comply with the RENAULT standard (see

Vehicle: Parts and consumables for the repair) .

Page 23 of 281

30A-19

GENERAL INFORMATION

Brake: Specifications

30A

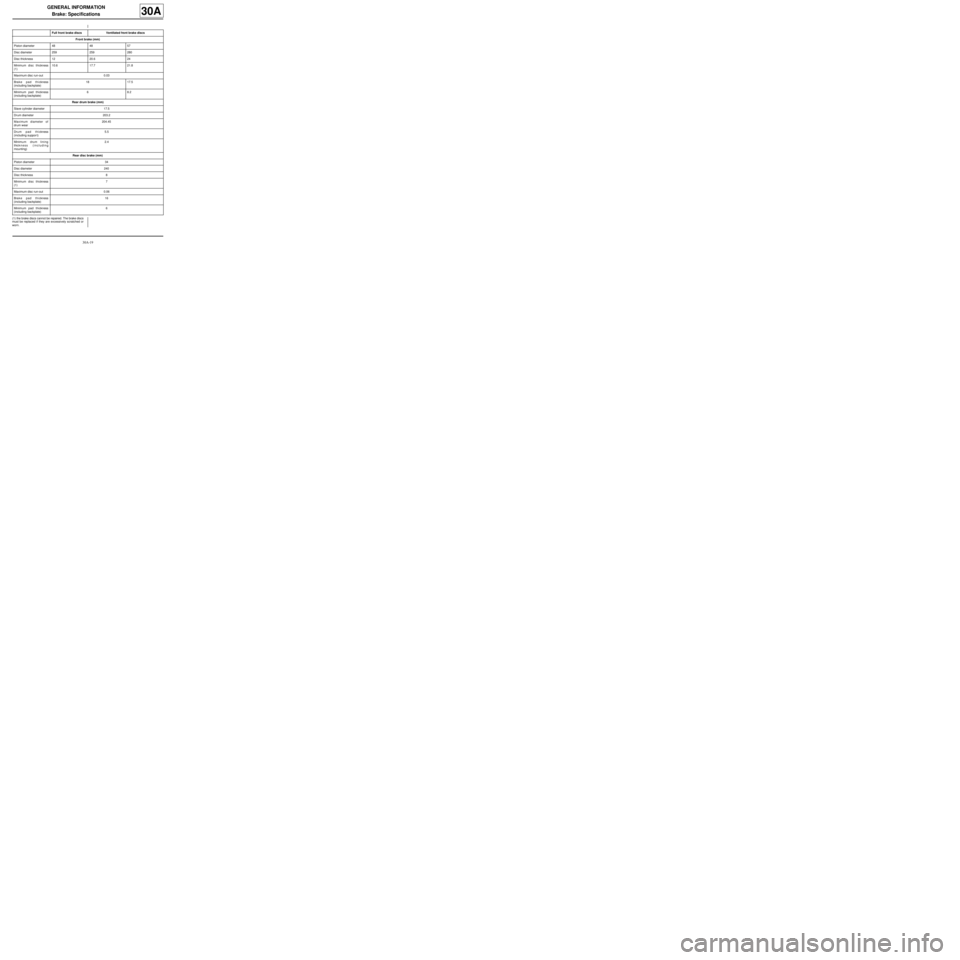

(1) the brake discs cannot be repaired. The brake discs

must be replaced if they are excessively scratched or

worn.Full front brake discs Ventilated front brake discs

Front brake (mm)

Piston diameter 48 48 57

Disc diameter 259 259 280

Disc thickness 12 20.6 24

Minimum disc thickness

(1)10.6 17.7 21.8

Maximum disc run-out 0.03

Brake pad thickness

(including backplate)18 17.5

Minimum pad thickness

(including backplate)68.2

Rear drum brake (mm)

Slave cylinder diameter 17.5

Drum diameter 203.2

Maximum diameter of

drum wear204.45

Drum pad thickness

(including suppor t)5.5

Minimu m d ru m lining

thickness (including

mounting)2.4

Rear disc brake (mm)

Piston diameter 34

Disc diameter 240

Disc thickness 8

Minimum disc thickness

(1)7

Maximum disc run-out 0.06

Brake pad thickness

(including backplate)16

Minimum pad thickness

(including backplate)6

Page 46 of 281

31A-3

FRONT AXLE COMPONENTS

Front brake pads: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aSet the wheels straight ahead.

aRemove the front wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - REMOVAL OPERATION

aRemove the retaining spring (1) using a wide, flat-

blade screwdriver.

aMark the position of the cap on the base of the shock

absorber using a indelible pencil.

aUnclip the cap from the base of the shock absorber. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

indelible pencil

Tightening torquesm

guide pin bolts28 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see Front axle components: Precautions for

the repair) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the surrounding

components.

145122

Page 47 of 281

31A-4

FRONT AXLE COMPONENTS

Front brake pads: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

aRemove:

-the guide pin bolt caps (2) ,

-the guide pin bolts.

aSuspend the brake calliper on the subframe.

aRemove the brake pads.

REFITTING

I - REFITTING PREPARATION OPERATION

aMeasure the thickness of the pads and then com-

pare them to the minimum values (see 30A, Gener-

al information, Brake: Specifications, page 30A-

19) .

aDo not allow friction materials to come into contact

with grease, oil or other lubricants and cleaning

products which are mineral oil based.

aparts always to be replaced: Front brake calliper

guide pin bolt.

aClean using a wire brush and BRAKE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products):

-the calliper supports,

-the callipers.aPush the piston fully into its housing using the tool

(Fre. 1190-01) part number 77 11 223 715.

145120103115

Page 49 of 281

31A-6

FRONT AXLE COMPONENTS

Front brake hose: Removal - Refitting

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) .

aSet the wheels straight ahead.

aPosition a pedal press on the brake pedal to limit

the outflow of brake fluid.

aRemove the front wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLoosen the hose union (1) on the rigid pipe union.

aRemove the retaining (2) fork from the hose.

aTo avoid the premature damage of the brake hose

by friction, observe the following procedure before

unclipping the hose:

aSet the wheels straight ahead.

aMark the position of the cap on the base of the shock

absorber using a permanent marker.

aUnclip the brake hose cap (3) from the shock ab-

sorber base.

aLoosen the hose union on the brake calliper.

aRemove the brake hose.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

a Equipment required

pedal press

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see Front axle components: Precautions

for the repair) .

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

135304

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

Page 53 of 281

31A-10

FRONT AXLE COMPONENTS

Front brake calliper: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

aFit a pedal press on the brake pedal to limit the out-

flow of brake fluid.II - REMOVAL OPERATION

aSlightly loosen the brake hose union (1) of the calli-

per.

aRemove:

-the brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) ,

-the brake hose union on the brake calliper.

aFit blanking plugs on the ends of the openings.

aRemove the brake calliper.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck:

-the condition of the calliper gaiter,

-the condition of the calliper piston; replace it if there

are deep scratches or cracks.

aReplace any faulty parts (see 31A, Front axle com-

ponents, Front brake calliper: Repair, page 31A-

12) .

aClean using a wire brush and BRAKE CLEANER

(see ) (04B, Consumables - Products):

-the calliper mounting,

-the calliper. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

pedal press

Tightening torquesm

brake hose union13 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see Front axle components: Precautions for

the repair) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

146248

Page 55 of 281

31A-12

FRONT AXLE COMPONENTS

Front brake calliper: Repair

31A

REPAIR

I - REPAIR PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aPosition the pedal press on the brake pedal to limit

the outflow of brake fluid.

aRemove:

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front brake calliper (see 31A, Front axle com-

ponents, Front brake calliper: Removal - Refit-

ting, page 31A-8) .II - REPAIR OPERATION FOR PART CONCERNED

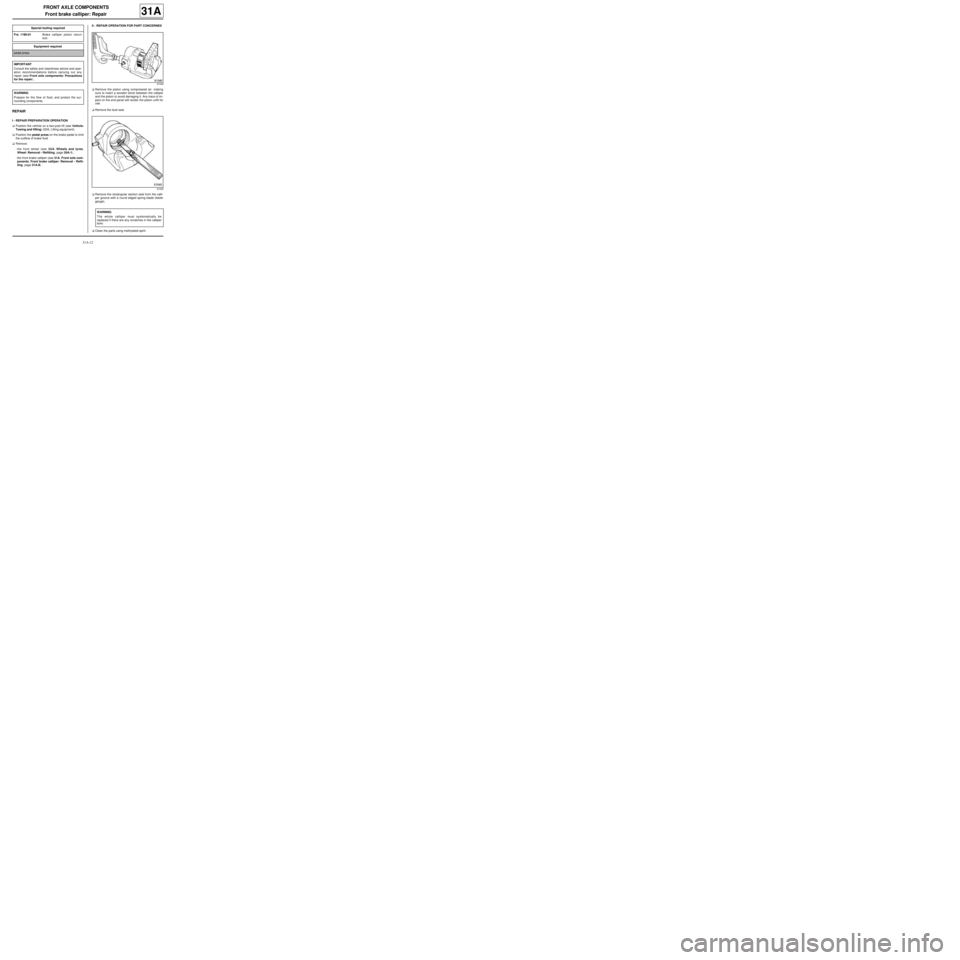

aRemove the piston using compressed air, making

sure to insert a wooden block between the calliper

and the piston to avoid damaging it. Any trace of im-

pact on the end panel will render the piston unfit for

use.

aRemove the dust seal.

aRemove the rectangular section seal from the calli-

per groove with a round edged spring blade (feeler

gauge).

aClean the parts using methylated spirit. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

pedal press

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see Front axle components: Precautions

for the repair) .

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

81546

81545

WARNING

The whole calliper must systematically be

replaced if there are any scratches in the calliper

bore.

Page 56 of 281

31A-13

FRONT AXLE COMPONENTS

Front brake calliper: Repair

31A

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the new rectangular section seal in the calliper

groove,

-the piston (after having smeared it with the grease

supplied in the repair kit) using the (Fre. 1190-01),

-the dust seal.

II - FINAL OPERATION.

aRefit:

-the brake calliper (see 31A, Front axle compo-

nents, Front brake calliper: Removal - Refitting,

page 31A-8) ,

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aRemove the pedal press.

aBleed the brake circuit (see 30A, General informa-

tion, Braking circuit: Bleed, page 30A-4) . IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.

Page 58 of 281

31A-15

FRONT AXLE COMPONENTS

Front brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

II - REMOVAL OPERATION

aRemove:

-the brake calliper mounting bolts (3) ,

-the brake calliper mounting.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the guide pin upper bolt.

aUsing the cleaning station, clean:

-the brake calliper mounting,

-the brake calliper.

aCoat the brake calliper mounting bolts with HIGH

STRENGTH THREAD LOCK (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) before refitting them.

II - REFITTING OPERATION

aRefit:

-the brake calliper mounting,

-the brake calliper mounting bolts.

aTorque tighten the brake calliper mounting bolts

(100 N.m).

III - FINAL OPERATION

aFit the front brake calliper.aRefit the upper bolt on the guide pin while holding

the nut.

aTorque tighten the guide pin upper bolt (29 N.m)

while holding the nut.

aRefit:

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) ,

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

119219