heater RENAULT TWINGO 2009 2.G Engine And Peripherals User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 234 of 652

11A-117

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K9K

11A

aIf necessary, carry out a complete check of the cylin-

der head (see Cylinder head: Check) .

II - REFITTING OPERATION FOR PART

CONCERNED

aBring the pistons to mid-stroke position to prevent

them from coming into contact with the valves during

the tightening of the cylinder head.

aRefit:

-a new cylinder head gasket,

-the cylinder head.

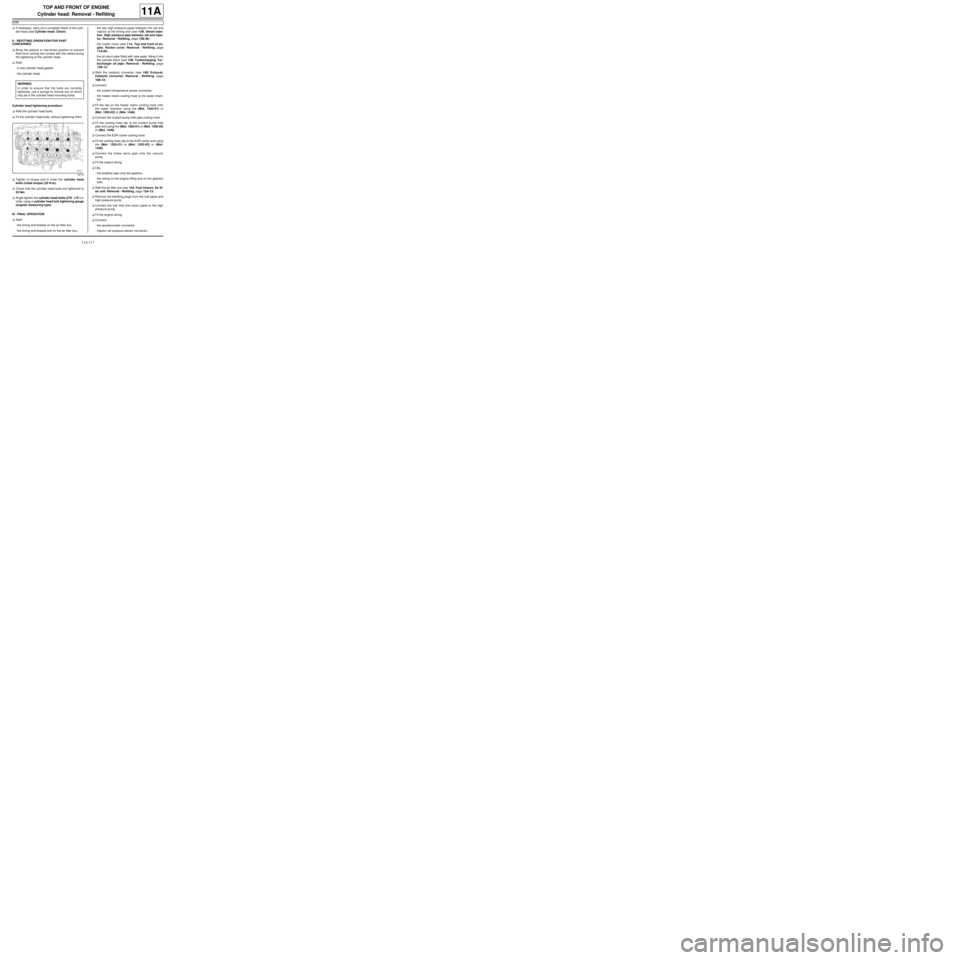

Cylinder head tightening procedure

aRefit the cylinder head bolts.

aFit the cylinder head bolts, without tightening them.

aTighten to torque and in order the cylinder head

bolts (initial torque) (25 N.m).

aCheck that the cylinder head bolts are tightened to

25 Nm.

aAngle tighten the cylinder head bolts (270˚ ±± ± ±

10˚) in

order using a cylinder head bolt tightening gauge

(angular measuring type).

III - FINAL OPERATION

aRefit:

-the timing end bracket on the air filter box.

-the timing end bracket bolt on the air filter box,-the two high pressure pipes between the rail and

injector at the timing end (see 13B, Diesel injec-

tion, High pressure pipe between rail and injec-

tor: Removal - Refitting, page 13B-39) ,

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

-the oil return pipe fitted with new seals, fitting it into

the cylinder block (see 12B, Turbocharging, Tur-

bocharger oil pipe: Removal - Refitting, page

12B-12) .

aRefit the catalytic converter (see 19B, Exhaust,

Catalytic converter: Removal - Refitting, page

19B-12) .

aConnect:

-the coolant temperature sensor connector,

-the heater matrix cooling hose to the water cham-

ber.

aFit the clip on the heater matrix cooling hose onto

the water chamber using the (Mot. 1202-01) or

(Mot. 1202-02) or (Mot. 1448).

aConnect the coolant pump inlet pipe cooling hose.

aFit the cooling hose clip at the coolant pump inlet

pipe end using the (Mot. 1202-01) or (Mot. 1202-02)

or (Mot. 1448).

aConnect the EGR cooler cooling hose.

aFit the cooling hose clip at the EGR cooler end using

the (Mot. 1202-01) or (Mot. 1202-02) or (Mot.

1448).

aConnect the brake servo pipe onto the vacuum

pump.

aFit the engine wiring.

aClip:

-the breather pipe onto the gearbox,

-the wiring on the engine lifting eye on the gearbox

side.

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aRemove the blanking plugs from the fuel pipes and

high pressure pump.

aConnect the fuel inlet and return pipes to the high

pressure pump.

aFit the engine wiring.

aConnect:

-the accelerometer connector,

-injector rail pressure sensor connector, WARNING

In order to ensure that the bolts are correctly

tightened, use a syringe to remove any oil which

may be in the cylinder head mounting holes.

19712

Page 235 of 652

11A-118

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K9K

11A

-the connectors to the high pressure pump,

-the heater plug connectors ,

-the injector connectors.

aRefit:

-the engine wiring channel nut,

-the dipstick guide,

-the dipstick guide nut.

aRefit:

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) .

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

aConnect the battery (see ) (80A, Battery).

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aRefit the engine cover.

Page 237 of 652

11A-120

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K4M

11A

-the camshafts (see 11A, Top and front of engine,

Camshaft: Removal - Refitting, page 11A-82) .

aDrain the gearbox (see Manual gearbox oils:

Draining - Filling) (21A, Manual gearbox).

aRemove:

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the exhaust manifold (see 12A, Fuel mixture, Ex-

haust manifold: Removal - Refitting, page 12A-

48) .

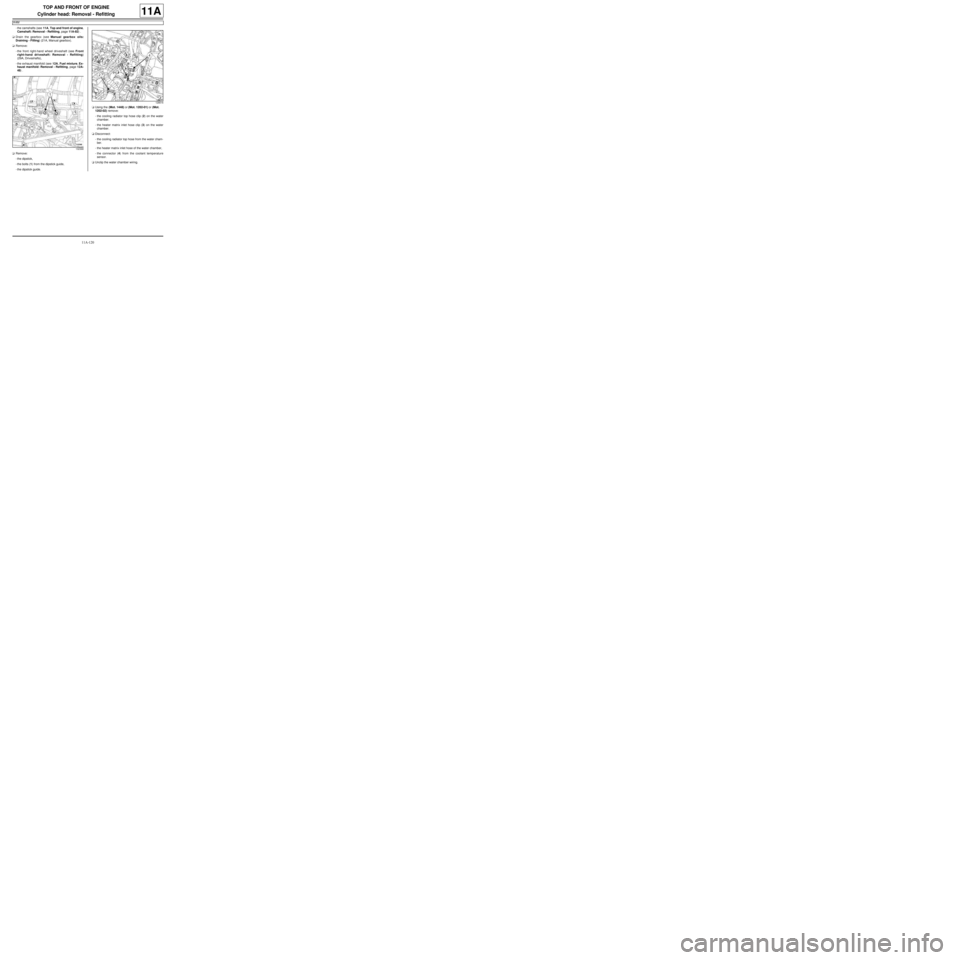

aRemove:

-the dipstick,

-the bolts (1) from the dipstick guide,

-the dipstick guide.aUsing the (Mot. 1448) or (Mot. 1202-01) or (Mot.

1202-02) remove:

-the cooling radiator top hose clip (2) on the water

chamber.

-the heater matrix inlet hose clip (3) on the water

chamber.

aDisconnect:

-the cooling radiator top hose from the water cham-

ber.

-the heater matrix inlet hose of the water chamber,

-the connector (4) from the coolant temperature

sensor.

aUnclip the water chamber wiring.

132368

128616

Page 240 of 652

11A-123

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K4M

11A

II - REFITTING OPERATION

aRefit:

-the cylinder head,

-the new cylinder head bolts.

aWithout tightening, fit the cylinder head bolts in or-

der.

aPretighten to torque and in order the cylinder head

bolts (initial torque) (20 N.m).

aCheck that all of the new cylinder head bolts are

tightened to the correct torque (20 N.m).

aAngle tighten in order the cylinder head bolts (240˚

±± ± ±

6˚).III - FINAL OPERATION

aPosition the injector wiring.

aConnect the injector connectors.

aFit the wiring bracket on the water chamber.

aRefit:

-the wiring bracket bolt on the water chamber,

-the bolts of the engine wiring channel.

aClip on the water chamber wiring.

aConnect:

-the coolant temperature sensor connector,

-the heater matrix inlet hose to the water chamber,

-the cooling radiator top hose to the water chamber.

aUsing the (Mot. 1448) or (Mot. 1202-01) or (Mot.

1202-02) fit:

-the cooling radiator top hose clip on the water

chamber,

-the heater matrix inlet hose clip on the water cham-

ber.

aRefit:

-dipstick guide ,

-the dipstick,

-the exhaust manifold (see 12A, Fuel mixture, Ex-

haust manifold: Removal - Refitting, page 12A-

48) .

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the camshafts (see 11A, Top and front of engine,

Camshaft: Removal - Refitting, page 11A-82) ,

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

-the camshaft seals on the timing end (see 11A,

Top and front of engine, Camshaft seal, timing

end: Removal - Refitting, page 11A-138) ,

-the camshaft dephaser (see 11A, Top and front of

engine, Camshaft dephaser: Removal - Refit-

ting, page 11A-135) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

103259

WARNING

In order to ensure that the bolts are correctly

tightened, use a syringe to remove any oil which

may be in the cylinder head mounting holes.

WARNING

Do not oil the new bolts. Be sure to oil bolts

being reused.

WARNING

Do not retighten the cylinder head bolts after

applying this procedure.

Page 344 of 652

13A-1

FUEL SUPPLY

Diesel supply circuit: Operating diagram

K9K

13A

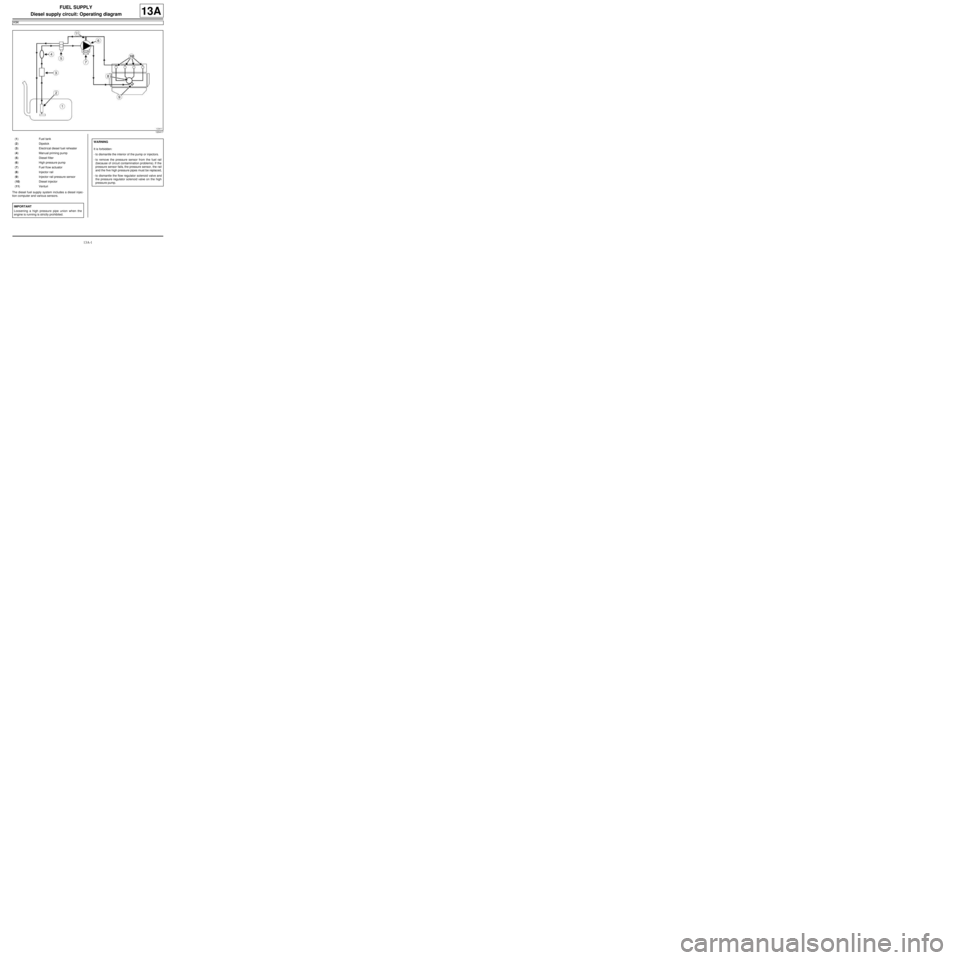

The diesel fuel supply system includes a diesel injec-

tion computer and various sensors.

120417

(1) Fuel tank

(2) Dipstick

(3) Electrical diesel fuel reheater

(4) Man ual priming pump

(5) Diesel filter

(6) High pressure pump

(7) Fuel fl ow actuator

(8) Injector rail

(9) Injector rail pressure sensor

(10) Diesel injector

(11) Venturi

IMPORTANT

Loosening a high pressure pipe union when the

engine is running is strictly prohibited.

WARNING

It is forbidden:

-to dismantle the interior of the pump or injectors.

-to remove the pressure sensor from the fuel rail

(because of circuit contamination problems). If the

pressure sensor fails, the pressure sensor, the rail

and the five high pressure pipes must be replaced,

-to dismantle the flow regulator solenoid valve and

the pressure regulator solenoid valve on the high

pressure pump.

Page 345 of 652

13A-2

FUEL SUPPLY

Manual priming pump: Removal - Refitting

K9K

13A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aCONSUMABLES:

-cleaning cloths.

a

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove the front engine cover.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDetach the fuel pipe from the body.

aDisconnect the electric diesel fuel heater fuel pipe

union (1) .

aUnclip the fuel pipe. IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear latex gloves during the operation.

IMPORTANT

Consult the safety and cleanliness advice and

operation recommendations before carrying out

any repair (see 13B, Diesel injection, Diesel

injection: Precautions for the repair, page

13B-1) .

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

120049

WARNING

To prevent impur ities from entering the circuit,

plugs must be fitted to the openings of all the fuel

circuit components exposed to the open air.

WARNING

Keep the pipe unions away from contaminated

areas.

Page 346 of 652

13A-3

FUEL SUPPLY

Manual priming pump: Removal - Refitting

K9K

13A

aDisconnect the fuel pipe union (2) .

aRemove the manual priming pump.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

a

aRefit the manual priming pump.

aConnect the fuel pipe union.

aClip on the fuel pipe.

aConnect the fuel pipe union to the electric diesel fuel

heater.

aClip the fuel pipe on to the body.

II - FINAL OPERATION.

aOpen the bleed screw on top of the fuel filter.

aPrime the fuel circuit using a manual priming pump

until the disconnected pipes are filled with fuel.

aClose the bleed screw on top of the fuel filter.aCheck that there are no fuel leaks.

aStart the engine.

aCheck that there are no fuel leaks.

aSwitch off the engine.

aRefit the engine cover.

120045

WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

Page 350 of 652

13A-7

FUEL SUPPLY

Electric diesel fuel heater: Removal - Refitting

C44, and K9K

13A

REMOVAL

I - OPERATION FOR REMOVAL OF PART

CONCERNED

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the electric diesel fuel heater electrical

connector (1) .

aRemove the nut (2) from the electric diesel fuel heat-

er mounting on the body.

aDisconnect the inlet and outlet fuel supply pipes (3)

from the electric diesel fuel heater.

aRemove the electric diesel fuel heater and its mount-

ing from the vehicle.

aSeparate the electric diesel fuel heater from its

mounting, letting it flow.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aFit then lock the electric diesel fuel heater to its

mounting.

aFit the electric diesel fuel heater and its mounting to

the vehicle.

aConnect the electric diesel fuel heater inlet and out-

let fuel supply pipes.

aRefit the electric diesel fuel heater mounting nut on

the body.

aTighten the diesel heater mounting nut on the body.

aConnect the electric diesel fuel heater electrical con-

nector.

aPrime the diesel circuit using the manual priming

pump (4) .

aStart the engine then let it run for a few minutes to

check that it starts properly and to check that there

are no leaks.

II - FINAL OPERATION.

aDeal with possible fuel leaks.

120049

Note:

Make preparations for fuel outfl ow.

120045

Page 369 of 652

13B-8

DIESEL INJECTION

Diesel injection: List and location of components

K9K, and 740

13B

121418

(1) High pressure pump

(2) Venturi

(3) Injectors

(4) Heater plugs

102315

(5) Fuel fl ow actuator

(6) Diesel fuel temperature sensor

(7) Accelerometer

121420

(8) Injector rail

(9) Injector rail pressure sensor

121422

(10) Diesel injection computer

Page 371 of 652

13B-10

DIESEL INJECTION

Diesel injection: List and location of components

K9K, and 718

13B

121418

(1) High pressure pump

(2) Venturi

(3) Injectors

(4) Heater plugs

102315

(5) Fuel fl ow actuator

(6) Diesel temperature sensor

(7) Accelerometer

121420

(8) Injector rail

(9) Injector rail pressure sensor

121422

(10) Diesel injection computer