warning RENAULT TWINGO 2009 2.G Engine And Peripherals Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 67 of 652

10A-61

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil pressure: Check

K4M

10A

Oil pressure tables:

End pieces to be used:

I - REMOVAL PREPARATION OPERATION

a

II - CHECK

aRemove the oil pressure sensor (see 10A, Engine

and cylinder block assembly, Oil pressure sen-

sor: Removal - Refitting, page 10A-45) .aIn place of the oil pressure sensor, fit the (Mot. 836-

05) with suitable adapters using the (Mot. 1495-01)

or a 22 mm long socket.

aStart the vehicle.

aMonitor the engine oil pressure as the oil tempera-

ture rises (approximately 80˚C or the first time the

engine cooling fan is activated); it should not be less

than the pressure at idle speed.

aIf the oil pressure is lower than the pressure at idle

speed, check that:

-the oil filter is not clogged,

-dirt or swarf is not present in the engine oil,

-the oil pump is in good condition and being correct-

ly driven. Special tooling required

Mot. 836-05Oil pressure gauge kit.

Mot. 1495-0122 mm socket for removal -

refitting of oxygen sensors.

Engine Engine suffixMinimum oil pressure (bar) Maximu m o i l

pressure (max)

Idling speed 4000 rpm 4000 rpm

K4M 8540.5 3.1 4.4

Engine End pieces

K4M E+C+F

WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

delivering the vehicle to the customer.

Note:

When topping up the engine oil, always leave at

least 10 minutes before checking the level with a

dipstick.

87363

Page 84 of 652

10A-78

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

D4F or D7F

10A

aDrain the coolant circuit (see Refrigerant circuit:

Draining - Filling) .

aRemove:

-the air conditioning pipe bolts on the compressor,

-the air conditioning pipe bolt on the dehydrator res-

ervoir.

aDisconnect the air conditioning pressostat connec-

tor.

a

aDisconnect the fuel supply pipe union.

aInsert the blanking plugs.

aUnclip the fuel pipe on the upper timing cover.aSet the wheels straight ahead.

aPosition the flywheel immobiliser.

aRemove the cover from the universal joint (do not

keep).

aRemove the universal joint bolt (do not keep).

aRemove the universal joint from the steering box.

aDetach the electrical wiring on the cross member.

aLoosen the tie rod lower bolts.

aRemove:

-the tie rod upper bolts.

-the track rod end nuts,

-the track rod ends using the (Tav. 476),

-the lower guide pin bolts,

-the brake pads,

-the calliper mounting bolts,

-the brake callipers, and attach them to the suspen-

sion springs,

-the ABS sensor bolts (if fitted to the vehicle),

-the ABS sensors,

-the shock absorber base lower bolts, AIR CONDITIONING

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which

are open to the air.

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

119544

Page 95 of 652

10A-89

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K9K

10A

aUnclip the fuel supply pipes at (12) .

aDisconnect the inlet pipe (13) from the high pressure

pump.

aDisconnect the return pipe (14) from the high pres-

sure pump.

aInsert the blanking plugs.

aUnclip the blower unit wiring.

aDisconnect the connectors from the fan assembly

wiring.

aCut the clip on the battery mounting.aRemove:

-the engine compartment connection unit cover

bolts (15) ,

-the cover of the engine compartment connection

unit.

aDisconnect the connector (16) from the pre-posthe-

ating unit.

121423

WARNING

To prevent impurities from entering the circuit,

plugs must be fitted to the openings of all the fuel

circuit components exposed to the open air.

120324

121429

K9K, and 718

141240

Page 98 of 652

10A-92

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K9K

10A

aRemove:

-the connecting pipe union bolts (24) on the com-

pressor,

-the bolt (25) from the connecting pipe mounting on

the compressor,

-the connecting pipes on the compressor.

aDisconnect the pressostat connector (26) .

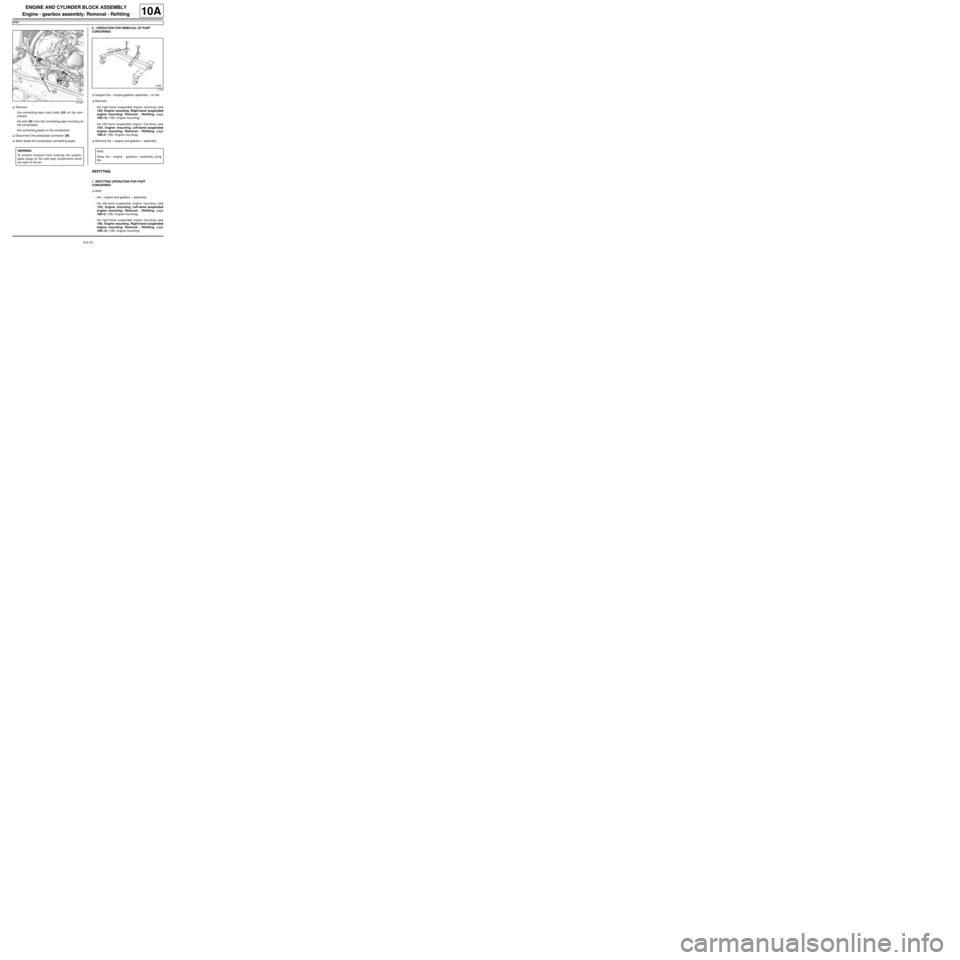

aMove aside the compressor connecting pipes.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aSupport the « engine-gearbox assembly » on the.

aRemove:

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) (19D, Engine mounting),

-the left-hand suspended engine mounting (see

19D, Engine mounting, Left-hand suspended

engine mounting: Removal - Refitting, page

19D-4) (19D, Engine mounting).

aRemove the « engine and gearbox » assembly.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the « engine and gearbox » assembly,

-the left-hand suspended engine mounting (see

19D, Engine mounting, Left-hand suspended

engine mounting: Removal - Refitting, page

19D-4) (19D, Engine mounting),

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) (19D, Engine mounting).

121431

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which

are open to the air.

17765

Note:

Strap the « engine - gearbox » assembly using

the.

Page 99 of 652

10A-93

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K9K

10A

II - FINAL OPERATION

aRemove the.

aLubricate the seals using recommended air condi-

tioning oil to make fitting easier.

aRefit:

-the connecting pipes to the compressor,

-the connecting pipe union bolts on the compressor,

-the bolt for the connecting pipe mounting on the

compressor.

aConnect:

-the pressostat connector,

-the hose to the coolant pump inlet pipe using the

tool (Mot. 1448).

aFit:

-the hose clip on the coolant pump inlet pipe using

the tool (Mot. 1448),

-the earth on the front left-hand wing.

aRefit the earth nut on the front left-hand wing.

aClip:

-the engine compartment connection unit relay

plates,

-the fuse holders.

aRefit the fuses.

aConnect the preheating unit connector.

aRefit the earth nut on the front left-hand side mem-

ber.

aFit the engine compartment connection unit.

aRefit the engine compartment connection unit

mountings on the body.

aConnect the black connector.

aClip on the black connector.

aRefit:

-the engine compartment connection unit cover,

-a new clip on the battery mounting to hold the elec-

trical wiring.

aConnect the wiring connectors to the fan assembly.aClip the fan assembly wiring.

aRemove the blanking plugs.

aConnect the high pressure pump inlet pipe.

aClip on the fuel supply pipe.

aConnect the high pressure pump return pipe.

aClip on the fuel return pipe.

aRemove the blanking plugs on the clutch hydraulic

control and on the control pipe.

aConnect the clutch hydraulic control to the gearbox.

aClip:

-the clutch control hydraulic pipe on the gearbox,

-the gearbox controls on the cable sleeve stops,

-the gearbox controls on the gear selectors.

aConnect:

-the hoses to the heater radiator,

-the top hose to the water chamber.

aFit:

-the hose clips on the heater radiator using the tool

(Mot. 1448),

-the clip for the top hose on the water chamber us-

ing the tool (Mot. 1448).

aRefit:

-the front section of the intermediate pipe (see 19B,

Exhaust, Intermediate pipe: Removal - Refit-

ting, page 19B-28) ,

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the front left-hand wheel driveshaft (see Front left-

hand driveshaft: Removal - Refitting) (29A,

Driveshafts),

-the radiator mounting cross member (see Radiator

mounting cross member: Removal - Refitting)

(41A, Front lower structure),

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) . WARNING

To prevent any leaks, check that the seal and the

surface of the pipe are in good condition. The

seal and the surface must be clean and scratch

free.

Page 104 of 652

10A-98

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K4M

10A

aDisconnect:

-the fuel vapour absorber bleed solenoid valve pipe

(12) ,

-the fuel vapour absorber bleed solenoid valve con-

nector (13) .aUnclip the fuel supply pipe at (14) .

aDisconnect the fuel supply pipe (15) .

131766131767

WARNING

To prevent impur ities from entering the circuit,

place protective plugs on all fuel circuit compo-

nents exposed to the open air.

Page 107 of 652

10A-101

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K4M

10A

aRemove:

-the bolt (27) from the « compressor - intermediate

pipe » connecting pipe,

-the bolt (28) on the « compressor - condenser »

connecting pipe,

-the bolt (29) from the « compressor - intermediate

pipe » connecting pipe mounting.

aDisconnect:

-the pressure sensor connector (30) ,

-the « compressor - intermediate pipe » connecting

pipe,-the « compressor - condenser » connecting pipe.

aInsert the blanking plugs.

aDisconnect the brake servo vacuum pipe union (31)

.

131782

132335

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which

are open to the air.

121348

Page 120 of 652

11A-3

TOP AND FRONT OF ENGINE

Accessories belt: Removal - Refitting

D4F, and 772, and STANDARD HEATING – D7F, and STANDARD HEATING

11A

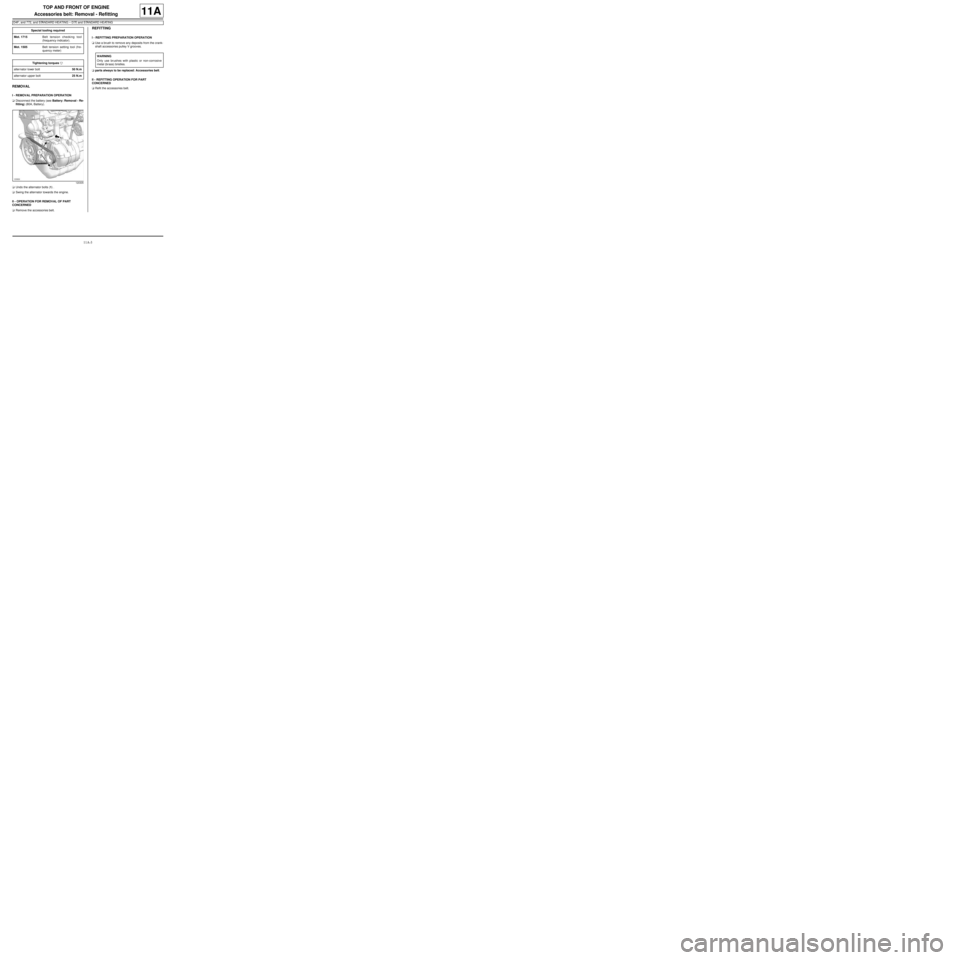

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aUndo the alternator bolts (1) .

aSwing the alternator towards the engine.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the accessories belt.

REFITTING

I - REFITTING PREPARATION OPERATION

aUse a brush to remove any deposits from the crank-

shaft accessories pulley V grooves.

aparts always to be replaced: Accessories belt.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the accessories belt. Special tooling required

Mot. 1715Belt tension checking tool

(frequency indicator).

Mot. 1505Belt tension setting tool (fre-

quency meter)

Tightening torquesm

alter nator lower bolt50 N.m

alter nator upper bolt25 N.m

120305

WARNING

Only use brushes with plastic or non-corrosive

metal (br ass) bristles.

Page 125 of 652

11A-8

TOP AND FRONT OF ENGINE

Accessories belt: Removal - Refitting

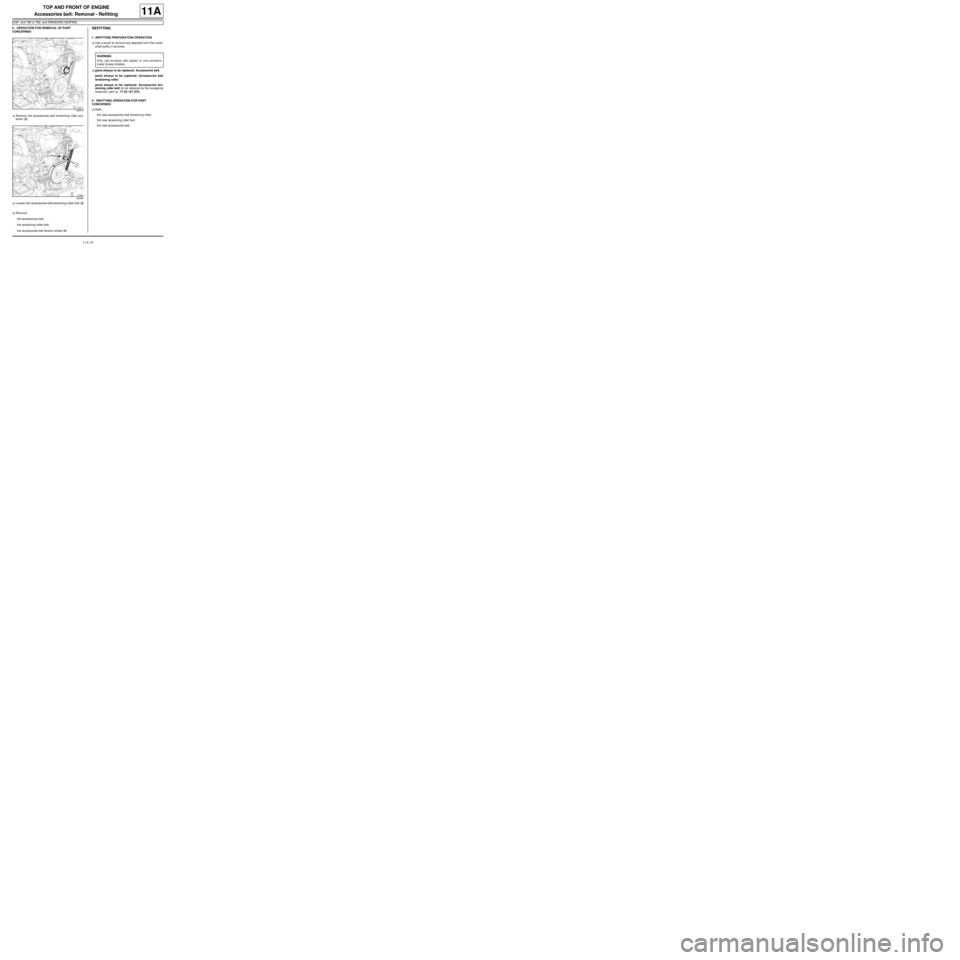

D4F, and 772 or 780 or 782, and AIR CONDITIONING – D7F, and AIR CONDITIONING

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner clips,

-the front right-hand wheel arch liner bolts,

aRemove the lower section of the front right-hand

wheel arch liner.II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

aRemove the accessories belt tensioning roller pro-

tector.

aUndo the accessories belt tensioning roller bolt.

aRemove:

-the accessories belt,

-the accessories belt tensioning roller bolt,

-the accessories belt tension wheel.

REFITTING

I - REFITTING PREPARATION OPERATION

aUse a brush to remove any deposits from the crank-

shaft pulley V-grooves.

aparts always to be replaced: Accessories belt.

aparts always to be replaced: Accessories belt

tensioning roller. Special tooling required

Mot. 1715Belt tension checking tool

(frequency indicator).

Mot. 1505Belt tension setting tool (fre-

quency meter)

Equipment required

open-ended spanner

Tightening torquesm

tensioning roller bolt44 N.m

120775

109766

IMPORTANT

Wear cut-resistant gloves during the operation.

WARNING

Only use brushes with plastic or non-corrosive

metal (br ass) bristles.

Page 131 of 652

11A-14

TOP AND FRONT OF ENGINE

Accessories belt: Removal - Refitting

D4F, and 780 or 782, and STANDARD HEATING

11A

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the accessories belt tensioning roller pro-

tector (2) .

aLoosen the accessories belt tensioning roller bolt (3)

.

aRemove:

-the accessories belt,

-the tensioning roller bolt,

-the accessories belt tension wheel (4) .REFITTING

I - REFITTING PREPARATION OPERATION

aUse a brush to remove any deposits from the crank-

shaft pulley V-grooves.

aparts always to be replaced: Accessories belt,

parts always to be replaced: Accessories belt

tensioning roller,

parts always to be replaced: Accessories ten-

sioning roller bolt (to be replaced by the hexagonal

head bolt, part no. 77 03 101 075).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the new accessories belt tensioning roller,

-the new tensioning roller bolt,

-the new accessories belt.

122672

122669

WARNING

Only use brushes with plastic or non-corrosive

metal (br ass) bristles.