warning RENAULT TWINGO 2009 2.G Engine And Peripherals Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 134 of 652

11A-17

TOP AND FRONT OF ENGINE

Accessories belt: Removal - Refitting

K4M

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure).aUnclip:

-the wiring at (1) ,

-the windscreen washer bottle filler neck at (2) ,

-the air conditioning pipe from the right-hand head-

light carrier panel.

aRemove:

-the nut (3) from the right-hand headlight carrier

panel,

-the bolts (4) from the right-hand headlight carrier

panel,

-the right-hand headlight carrier panel. Tightening torquesm

tensioning roller40 N.m

WARNING

Do not r un the engine without the accessories belt

to avoid damaging the crankshaft accessories pul-

ley.

IMPORTANT

Wear cut-resistant gloves during the operation.132339

Page 138 of 652

11A-21

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

D4F or D7F, and AIR CONDITIONING or STANDARD HEATING

11A

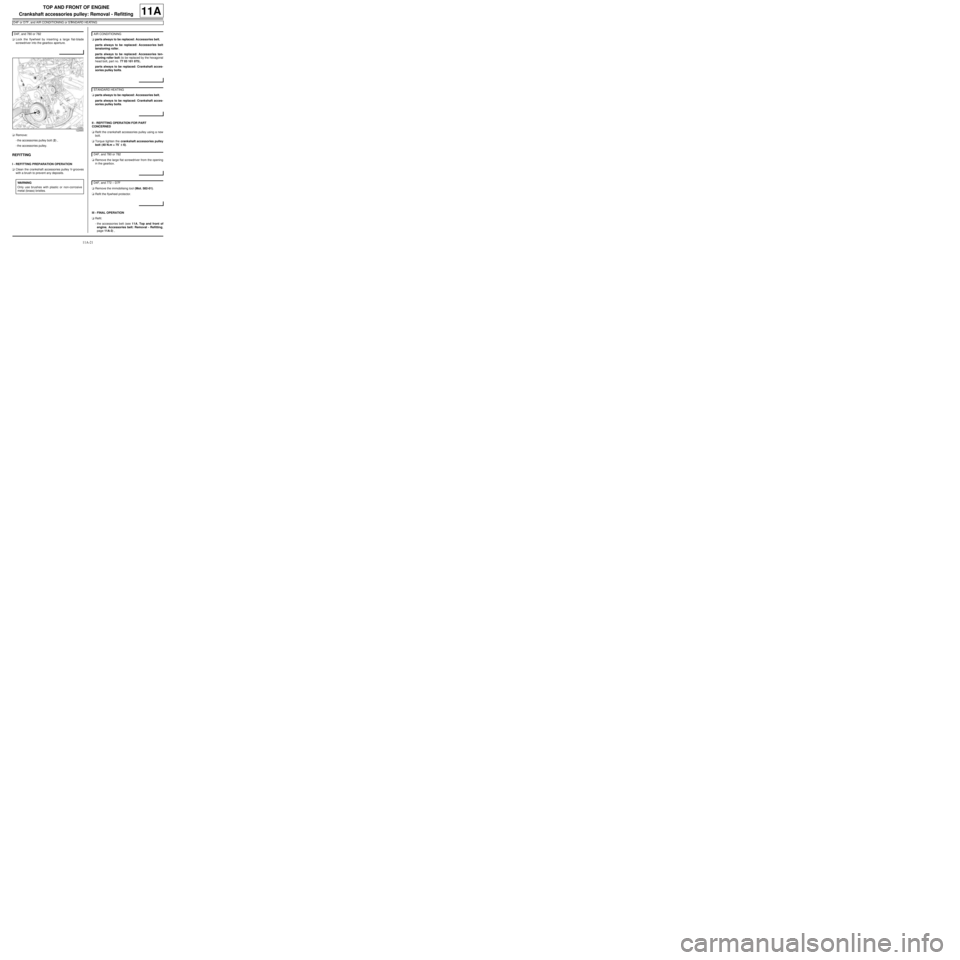

aLock the flywheel by inserting a large flat-blade

screwdriver into the gearbox aperture.

aRemove:

-the accessories pulley bolt (2) ,

-the accessories pulley.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the crankshaft accessories pulley V-grooves

with a brush to prevent any deposits.aparts always to be replaced: Accessories belt,

parts always to be replaced: Accessories belt

tensioning roller,

parts always to be replaced: Accessories ten-

sioning roller bolt (to be replaced by the hexagonal

head bolt, part no. 77 03 101 075),

parts always to be replaced: Crankshaft acces-

sories pulley bolts.

aparts always to be replaced: Accessories belt,

parts always to be replaced: Crankshaft acces-

sories pulley bolts.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the crankshaft accessories pulley using a new

bolt.

aTorque tighten the crankshaft accessories pulley

bolt (40 N.m + 75˚ ±± ± ±

6).

aRemove the large flat screwdriver from the opening

in the gearbox.

aRemove the immobilising tool (Mot. 582-01).

aRefit the flywheel protector.

III - FINAL OPERATION

aRefit:

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) , D4F, and 780 or 782

122665

WARNING

Only use brushes with plastic or non-corrosive

metal (brass) bristles.

AIR CONDITIONING

STANDARD HEATING

D4F, and 780 or 782

D4F, and 772 – D7F

Page 142 of 652

11A-25

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

K4M

11A

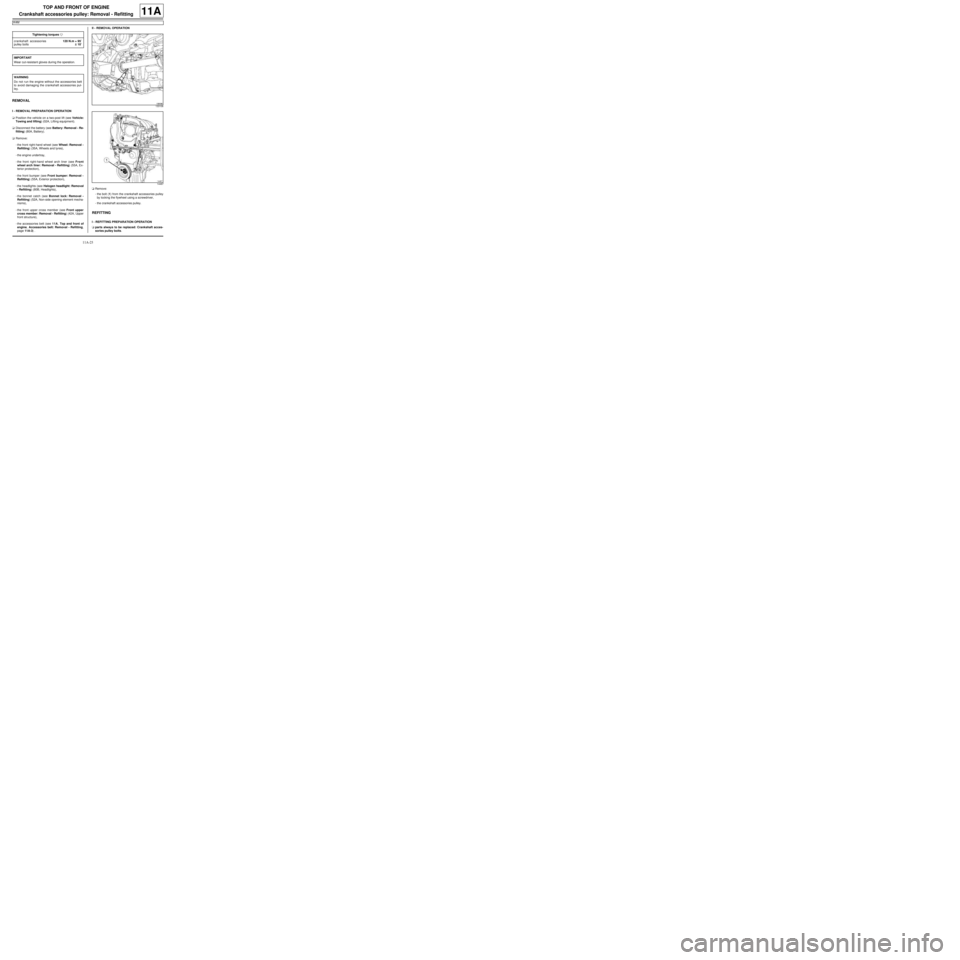

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .II - REMOVAL OPERATION

aRemove:

-the bolt (1) from the crankshaft accessories pulley

by locking the flywheel using a screwdriver,

-the crankshaft accessories pulley.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Crankshaft acces-

sories pulley bolts. Tightening torquesm

crankshaft accessories

pulley bolts120 N.m + 95˚

±± ± ±

10˚

IMPORTANT

Wear cut-resistant gloves during the operation.

WARNING

Do not r un the engine without the accessories belt

to avoid damaging the crankshaft accessories pul-

ley.

133106

14487

Page 155 of 652

11A-38

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K9K

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (80B, Headlights),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) . Special tooling required

Mot. 1672Low er engine support.

Mot. 1489TDC locating pin.

Mot. 1430Set of 5 crankshaft and cam-

shaft pulley timing pins.

Tightening torquesm

tensioning roller bolt27 N.m

camshaft pulley wheel

bolts14 N.m

TDC setting pin plug25 N.m

cylinder head sus-

pended mounting bolts25 Nm

IMPORTANT

Wear protective gloves during the operation.

WARNING

The belt must be replaced with a new one if it has

been removed.

WARNING

When replacing the belt, always replace the tension

wheels and idler pulleys.

WARNING

Do not r un the engine without the accessories belt

to avoid damaging the crankshaft accessories pul-

ley.

Page 175 of 652

11A-58

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K4M

11A

II - REFITTING OPERATION

1 - Adjusting the timing

a

aSet the camshaft grooves horizontally and below the

centre line by turning the camshafts with the (Mot.

1496) if necessary.

aFit the (Mot. 1496) with the (Mot. 1750).aFit:

-the (Mot. 1496) fitted with the (Mot. 1750) on the

end of the camshaft,

-a lifting eye bolt to secure the (Mot. 1496).

aIf fitting a new camshaft dephaser, check the

dephaser locking mechanism (see 11A, Top and

front of engine, Camshaft dephaser: Removal -

Refitting, page 11A-135) .

aRefit the camshaft dephaser (see 11A, Top and

front of engine, Camshaft dephaser: Removal -

Refitting, page 11A-135) . Note:

If the stud loosens with the nut (see 11A, Top

and front of engine, Camshaft: Removal -

Refitting, page 11A-82) (Technical Note 3887A,

11A, Top and front of engine).

WARNING

Always degrease:

-the end of the crankshaft (timing end),

-the timing sprocket bore and bear ing faces,

-the crankshaft accessories pulley bearing

faces,

-the camshaft ends (timing end),

-the camshaft sprocket bores and bear ing faces.

This is to avoid timing slippage.

This slippage leads to engine damage.

111337

111336

Page 186 of 652

11A-69

TOP AND FRONT OF ENGINE

Rocker cover: Removal - Refitting

D4F, and 772

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-the ignition coil (see 17A, Ignition, Coils: Remov-

al - Refitting, page 17A-1) .

aUnclip the rocker cover electric wiring harnesses.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the rocker cover bolts,

-the rocker cover,

-the rocker cover gasket.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the joint faces with SUPER CLEANER FOR

JOINT FACES (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts) to dissolve any part of the seal still adhering.

aparts always to be replaced: rocker cover seal.

110422

WARNING

Do not allow this product to dr ip onto the paint-

work.

Clean the cylinder head carefully to prevent for-

eign bodies from entering the oil supply and

return galleries.

Failure to follow this advice could lead to the

blocking of the various oil inlet galleries, which

would quickly result in engine damage.

Page 190 of 652

11A-73

TOP AND FRONT OF ENGINE

Rocker cover: Removal - Refitting

D4F, and 780 or 782 or 784

11A

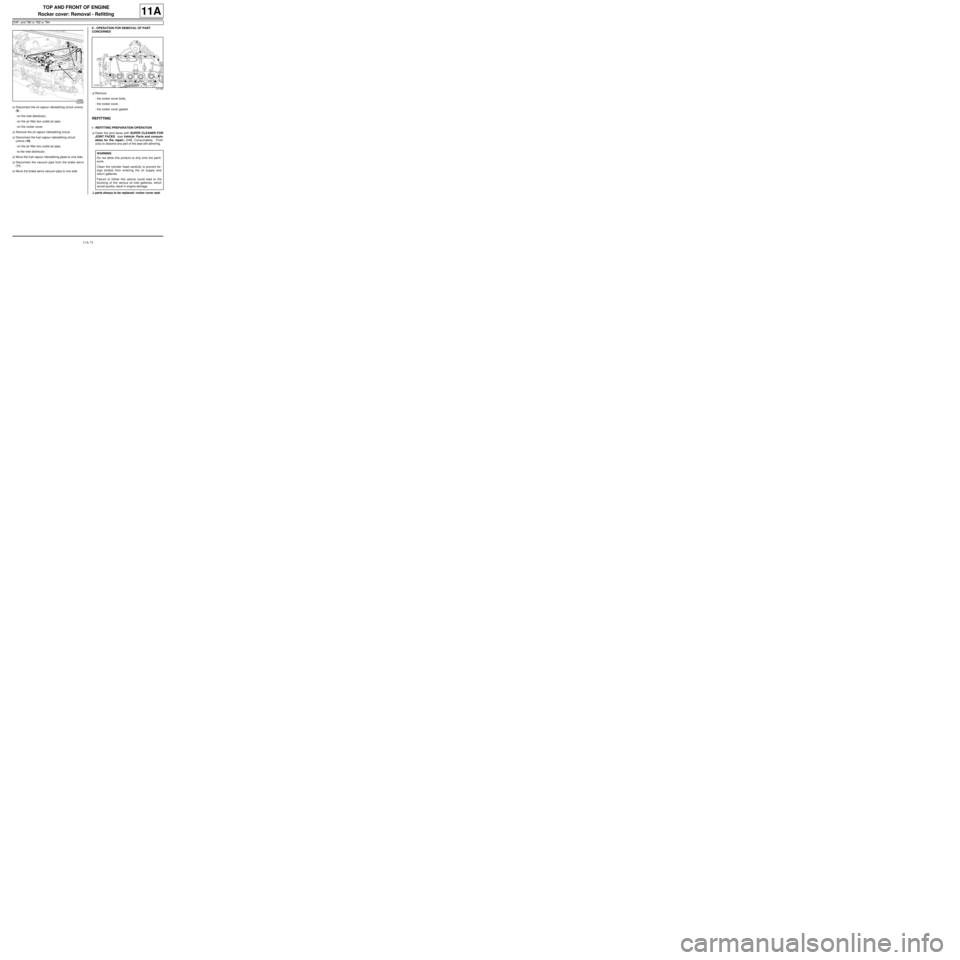

aDisconnect the oil vapour rebreathing circuit unions

(9) .

-on the inlet distributor,

-on the air filter box outlet air pipe,

-on the rocker cover.

aRemove the oil vapour rebreathing circuit.

aDisconnect the fuel vapour rebreathing circuit

unions (10) .

-on the air filter box outlet air pipe,

-to the inlet distributor.

aMove the fuel vapour rebreathing pipes to one side.

aDisconnect the vacuum pipe from the brake servo

(11) .

aMove the brake servo vacuum pipe to one side.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the rocker cover bolts,

-the rocker cover,

-the rocker cover gasket.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the joint faces with SUPER CLEANER FOR

JOINT FACES (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts) to dissolve any part of the seal still adhering.

aparts always to be replaced: rocker cover seal.

122828

121026

WARNING

Do not allow this product to dr ip onto the paint-

work.

Clean the cylinder head carefully to prevent for-

eign bodies from entering the oil supply and

return galleries.

Failure to follow this advice could lead to the

blocking of the various oil inlet galleries, which

would quickly result in engine damage.

Page 191 of 652

11A-74

TOP AND FRONT OF ENGINE

Rocker cover: Removal - Refitting

D4F, and 780 or 782 or 784

11A

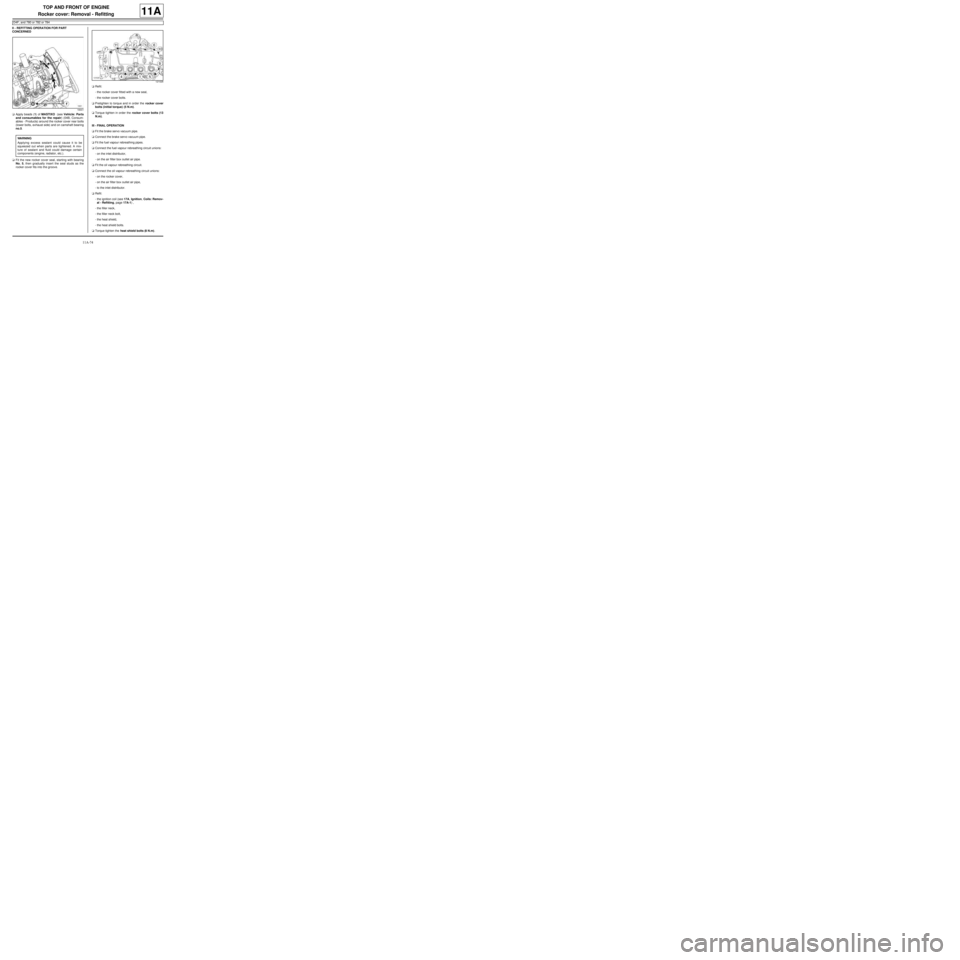

II - REFITTING OPERATION FOR PART

CONCERNED

aApply beads (1) of MASTIXO (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) around the rocker cover rear bolts

(lower bolts, exhaust side) and on camshaft bearing

no.5.

aFit the new rocker cover seal, starting with bearing

No. 5, then gradually insert the seal studs as the

rocker cover fits into the groove.aRefit:

-the rocker cover fitted with a new seal,

-the rocker cover bolts.

aPretighten to torque and in order the rocker cover

bolts (initial torque) (5 N.m).

aTorque tighten in order the rocker cover bolts (13

N.m).

III - FINAL OPERATION

aFit the brake servo vacuum pipe.

aConnect the brake servo vacuum pipe.

aFit the fuel vapour rebreathing pipes.

aConnect the fuel vapour rebreathing circuit unions:

-on the inlet distributor,

-on the air filter box outlet air pipe.

aFit the oil vapour rebreathing circuit.

aConnect the oil vapour rebreathing circuit unions:

-on the rocker cover,

-on the air filter box outlet air pipe,

-to the inlet distributor.

aRefit:

-the ignition coil (see 17A, Ignition, Coils: Remov-

al - Refitting, page 17A-1) ,

-the filler neck,

-the filler neck bolt,

-the heat shield,

-the heat shield bolts.

aTorque tighten the heat shield bolts (8 N.m).

18441

WARNING

Applying excess sealant could cause it to be

squeezed out when parts are tightened. A mix-

ture of sealant and fluid could damage certain

components (engine, radiator, etc.).

121026

Page 195 of 652

11A-78

TOP AND FRONT OF ENGINE

Rocker cover: Removal - Refitting

K4M

11A

II - REMOVAL OPERATION

aRemove the rocker cover bolts.

aDetach the rocker cover using a screwdriver.

aRemove the rocker cover.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace:

-the camshaft position sensor seal,

-the camshaft dephaser solenoid valve seal.

aUse SUPER CLEANER FOR JOINT FACES (see

Vehicle: Parts and consumables for the repair)

(04B, Consumables - Products) to clean:

-the rocker cover joint face if it is to be re-used,

-the cylinder head joint face.aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to degrease:

-the rocker cover joint face if it is to be re-used,

-the cylinder head joint face.

14497-5

Note:

The rocker cover bolts are not the same length;

mark their positions.

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

Page 196 of 652

11A-79

TOP AND FRONT OF ENGINE

Rocker cover: Removal - Refitting

K4M

11A

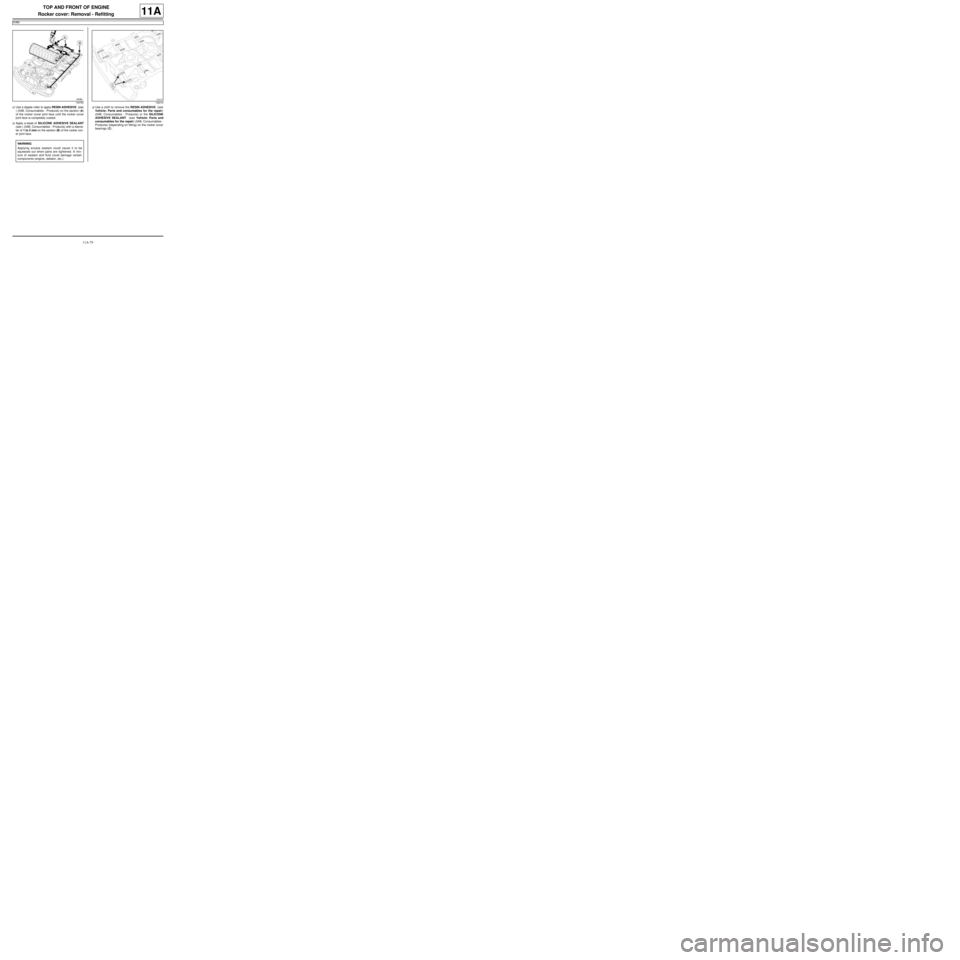

aUse a stipple roller to apply RESIN ADHESIVE (see

) (04B, Consumables - Products) on the section (A)

of the rocker cover joint face until the rocker cover

joint face is completely coated.

aApply a bead of SILICONE ADHESIVE SEALANT

(see ) (04B, Consumables - Products) with a diame-

ter of 1 to 2 mm on the section (B) of the rocker cov-

er joint face.aUse a cloth to remove the RESIN ADHESIVE (see

Vehicle: Parts and consumables for the repair)

(04B, Consumables - Products) or the SILICONE

ADHESIVE SEALANT (see Vehicle: Parts and

consumables for the repair) (04B, Consumables -

Products) (depending on fitting) on the rocker cover

bearings (C) .

145782

WARNING

Applying excess sealant could cause it to be

squeezed out when parts are tightened. A mix-

ture of sealant and fluid could damage certain

components (engine, radiator, etc.).

126216