RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

TWINGO 2009 2.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1710/w960_1710-0.png

RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

Trending: key, wiring, wipers, wiper size, transmission oil, belt, ECU

Page 581 of 652

19A-71

COOLING

Coolant temperature sensor: Removal - Refitting

K4M

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .II - REMOVAL OPERATION

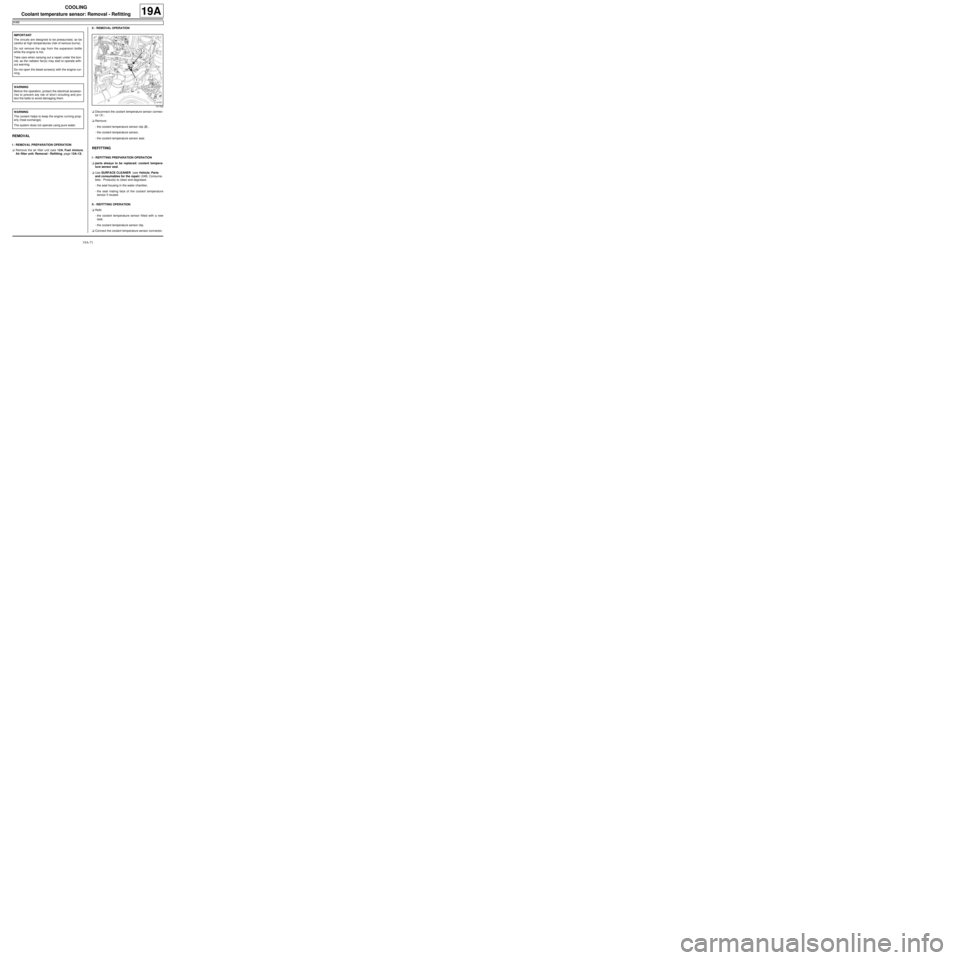

aDisconnect the coolant temperature sensor connec-

tor (1) .

aRemove:

-the coolant temperature sensor clip (2) ,

-the coolant temperature sensor,

-the coolant temperature sensor seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: coolant tempera-

ture sensor seal.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the seal housing in the water chamber,

-the seal mating face of the coolant temperature

sensor if reused.

II - REFITTING OPERATION

aRefit:

-the coolant temperature sensor fitted with a new

seal,

-the coolant temperature sensor clip.

aConnect the coolant temperature sensor connector. IMPORTANT

The circuits are designed to be pressurised, so be

careful at high temperatures (risk of serious burns).

Do not remove the cap from the expansion bottle

while the engine is hot.

Take care when carrying out a repair under the bon-

net, as the radiator fan(s) may start to operate with-

out warning.

Do not open the bleed screw(s) with the engine run-

ning.

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

WARNING

The coolant helps to keep the engine running prop-

erly (heat exchange).

The system does not operate using pure water.

131762

Page 582 of 652

19A-72

COOLING

Coolant temperature sensor: Removal - Refitting

K4M

19A

III - FINAL OPERATION

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aPerform the following operations:

-top up the coolant level,

-bleed the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

Page 583 of 652

19B-1

EXHAUST

Exhaust: List and location of components

19B

Page 584 of 652

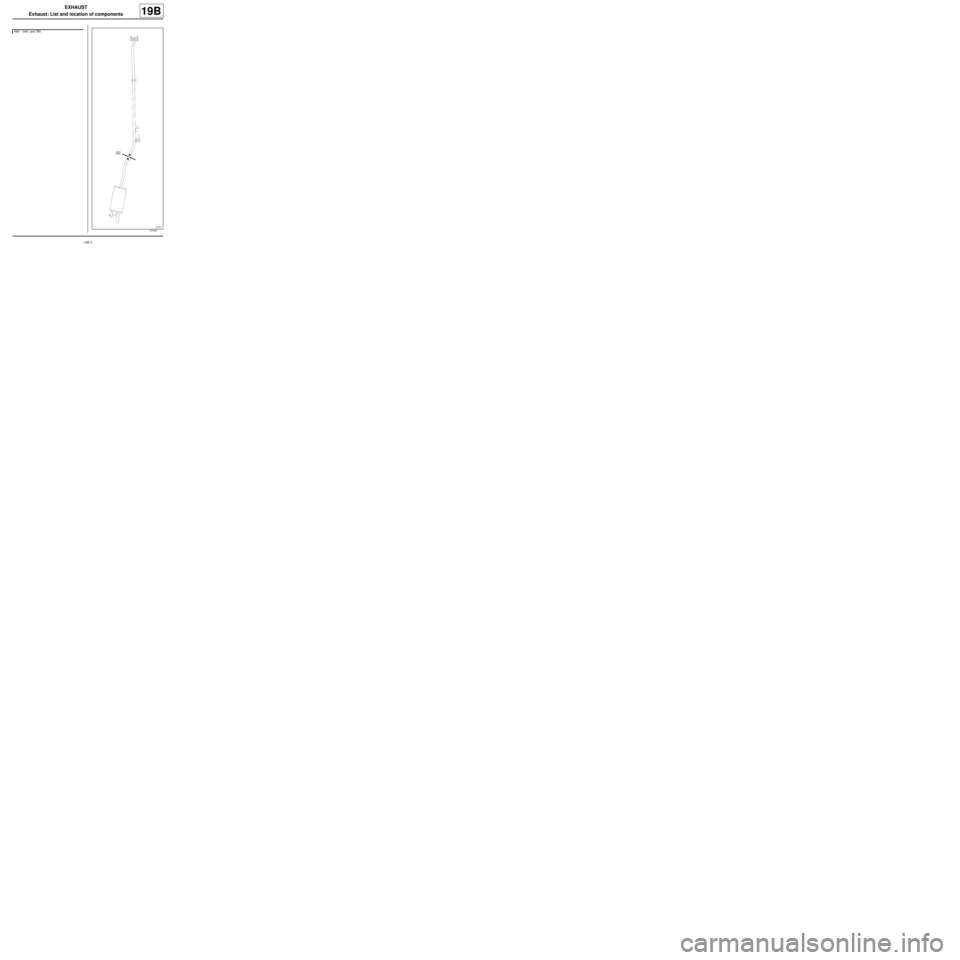

19B-2

EXHAUST

Exhaust: List and location of components

19B

K9K – D4F, and 780

121642

Page 585 of 652

19B-3

EXHAUST

Exhaust: List and location of components

19B

(ZC) : Area to be cut

Page 586 of 652

19B-4

EXHAUST

Exhaust: List and location of components

19B

D4F, and 772 – D7F

121641

Page 587 of 652

19B-5

EXHAUST

Exhaust: List and location of components

19B

(ZC) : Area to be cut

Page 588 of 652

19B-6

EXHAUST

Exhaust: List and location of components

19B

K4M

132480

Page 589 of 652

19B-7

EXHAUST

Exhaust: List and location of components

19B

(ZC) : Area to be cut

Page 590 of 652

19B-8

EXHAUST

Exhaust: Precautions for the repair

19B

I - PARTS AND CONSUMABLES FOR THE REPAIR

1 - Parts always to be replaced:

- the exhaust trunking (if fitted)

- the seal or sealing ring on the connection between the

catalytic converter or catalytic pre-converter and the

rest of the exhaust system

- the exhaust clip(s) (if fitted)

2 - Consumables (see part no. in Technical Note

5068, 04B, Consumables - Products):

- exhaust mastic

- surface cleaner

- abrasive pads

II - ADVICE TO OBSERVE

1 - During removal and refitting, the catalytic converter

or catalytic pre-converter must not receive any knocks

or impacts as this could damage it.

2 - The whole exhaust pipe is made of stainless steel.

3 - After working on the bracket between the catalytic

converter or catalytic pre-converter and the rest of the

exhaust system, ensure that the connection is perfectly

sealed.

To do this:

-clean the pressure faces of the connection using the

ABRASIVE PADS,-degrease the pressure faces of the connection using

SURFACE CLEANER and clean cloths,

-always replace the seal or sealing ring on the connec-

tion.

III - SPECIAL NOTES ON THE SINGLE UNIT

EXHAUST PIPE

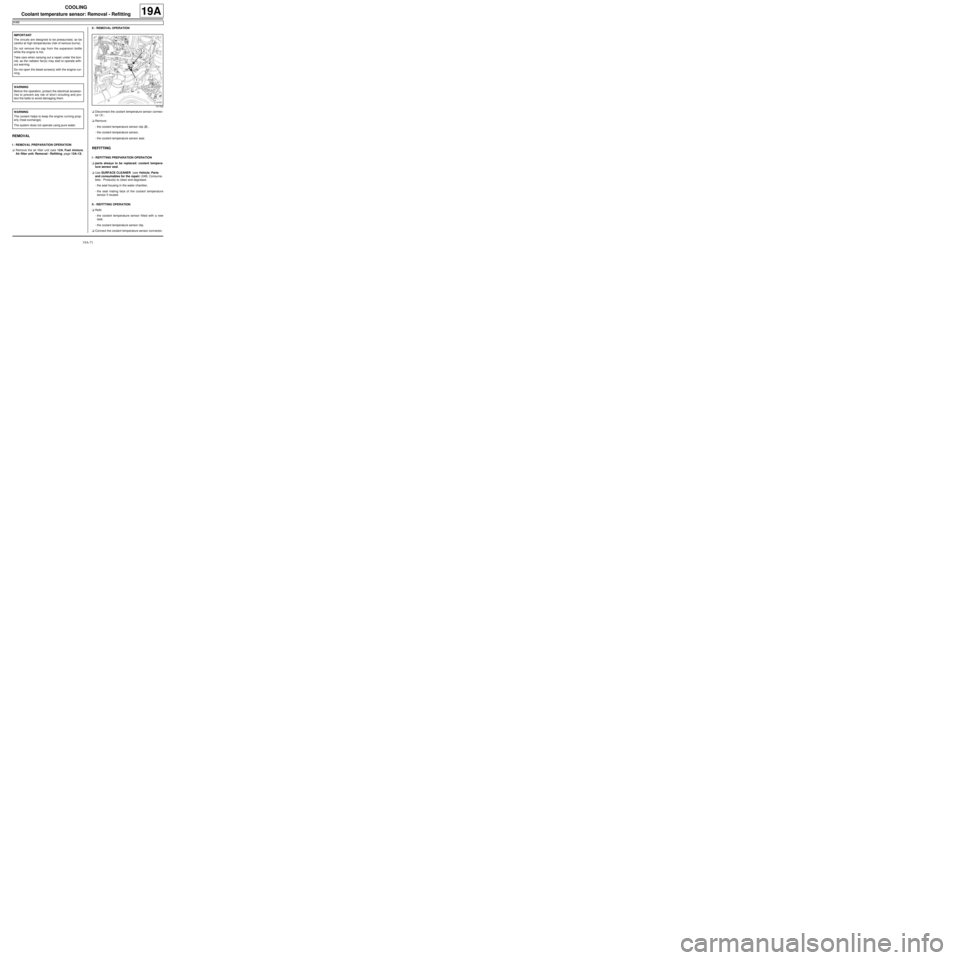

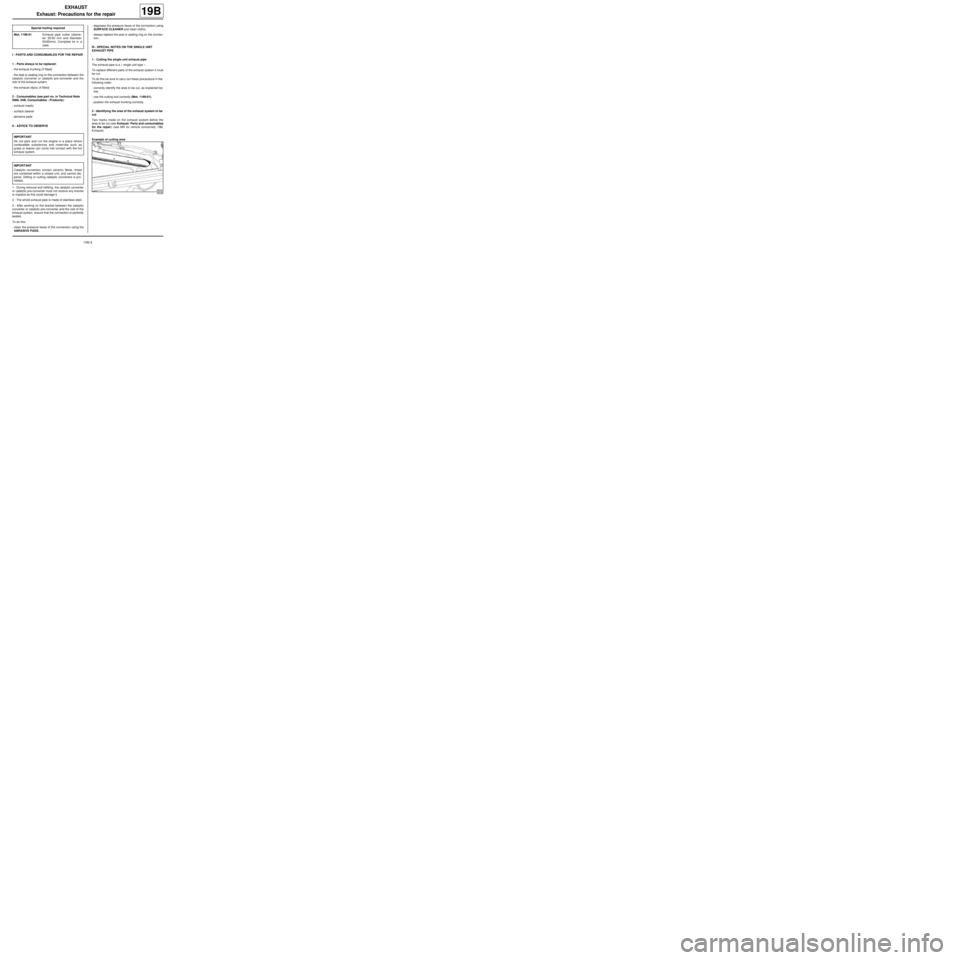

1 - Cutting the single unit exhaust pipe

The exhaust pipe is a « single unit type » .

To replace different parts of the exhaust system it must

be cut.

To do this be sure to carry out these precautions in the

following order:

-correctly identify the area to be cut, as explained be-

low,

-use the cutting tool correctly (Mot. 1199-01),

-position the exhaust trunking correctly.

2 - Identifying the area of the exhaust system to be

cut

Two marks made on the exhaust system define the

area to be cut (see Exhaust: Parts and consumables

for the repair) (see MR for vehicle concerned, 19B,

Exhaust).

Example of cutting area Special tooling required

Mot. 1199-01Exhaust pipe cutter (diame-

ter 35/50 mm and diameter

50/65mm). Complete kit in a

case.

IMPORTANT

Do not park and run the engine in a place where

combustible substances and materials such as

grass or leaves can come into contact with the hot

exhaust system.

IMPORTANT

Catalytic converters contain ceramic fibres , these

are contained within a closed unit, and cannot dis-

perse. Drilling or cutting catalytic converters is pro-

hibited.

99226

Trending: warning lights, glove box, fuses, parking brake, towing, fuel, recommended oil