oil RENAULT TWINGO 2009 2.G Engine And Peripherals Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 65 of 652

10A-59

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil pressure: Check

D4F or D7F or K9K

10A

I - RECOMMENDATIONS FOR REPAIR

a

II - PARTS AND CONSUMABLES FOR THE REPAIR

WORK

aParts which must be replaced:

-the sump plug sealing washer (in the event of an oil

change),

-oil filter (if removed).

aConsumable:

-Engine oil (see Engine oil: Specifications) (Tech-

nical Note 6013, 04A, Lubricants).

III - CHECK

aRemove the oil pressure sensor (see 10A, Engine

and cylinder block assembly, Oil pressure sen-

sor: Removal - Refitting, page 10A-45) .aCheck the correct operation of the oil pressure sen-

sor valve using the roll pin punch with a diameter of

2 mm and the multimeter. Special tooling required

Mot. 836-05Oil pressure gauge kit.

Mot. 1495-0122 mm socket for removal -

refitting of oxygen sensors.

Equipment required

roll pin punch

multimeter

1/2" long socket (12.7 mm square dr ive)

WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

delivering the vehicle to the customer.

Note:

When topping up the engine oil, always leave at

least 10 minutes before checking the level with a

dipstick.

It is essential to monitor the engine oil pressure

as the engine oil temperature rises (approxi-

mately 80˚C or the first time the engine cool-

ing fan is activated).

Page 66 of 652

10A-60

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil pressure: Check

D4F or D7F or K9K

10A

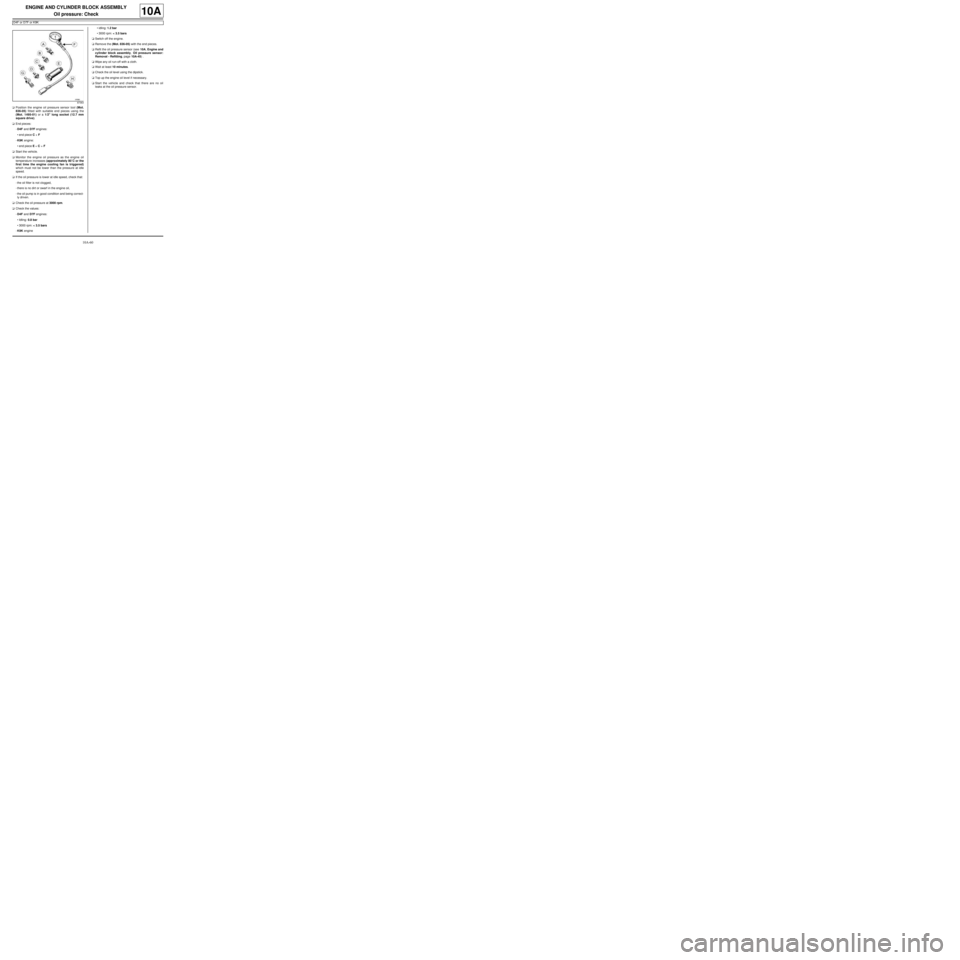

aPosition the engine oil pressure sensor tool (Mot.

836-05) fitted with suitable end pieces using the

(Mot. 1495-01) or a 1/2" long socket (12.7 mm

square drive).

aEnd pieces:

-D4F and D7F engines:

•end piece C + F

-K9K engine:

•end piece E + C + F

aStart the vehicle.

aMonitor the engine oil pressure as the engine oil

temperature increases (approximately 80˚C or the

first time the engine cooling fan is triggered)

which must not be lower than the pressure at idle

speed.

aIf the oil pressure is lower at idle speed, check that:

-the oil filter is not clogged,

-there is no dirt or swarf in the engine oil,

-the oil pump is in good condition and being correct-

ly driven.

aCheck the oil pressure at 3000 rpm.

aCheck the values:

-D4F and D7F engines:

•Idling: 0.8 bar

•3000 rpm: < 3.5 bars

-K9K engine•idling: 1.2 bar

•3000 rpm: < 3.5 bars

aSwitch off the engine.

aRemove the (Mot. 836-05) with the end pieces.

aRefit the oil pressure sensor (see 10A, Engine and

cylinder block assembly, Oil pressure sensor:

Removal - Refitting, page 10A-45) .

aWipe any oil run-off with a cloth.

aWait at least 10 minutes.

aCheck the oil level using the dipstick.

aTop up the engine oil level if necessary.

aStart the vehicle and check that there are no oil

leaks at the oil pressure sensor.

87363

Page 67 of 652

10A-61

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil pressure: Check

K4M

10A

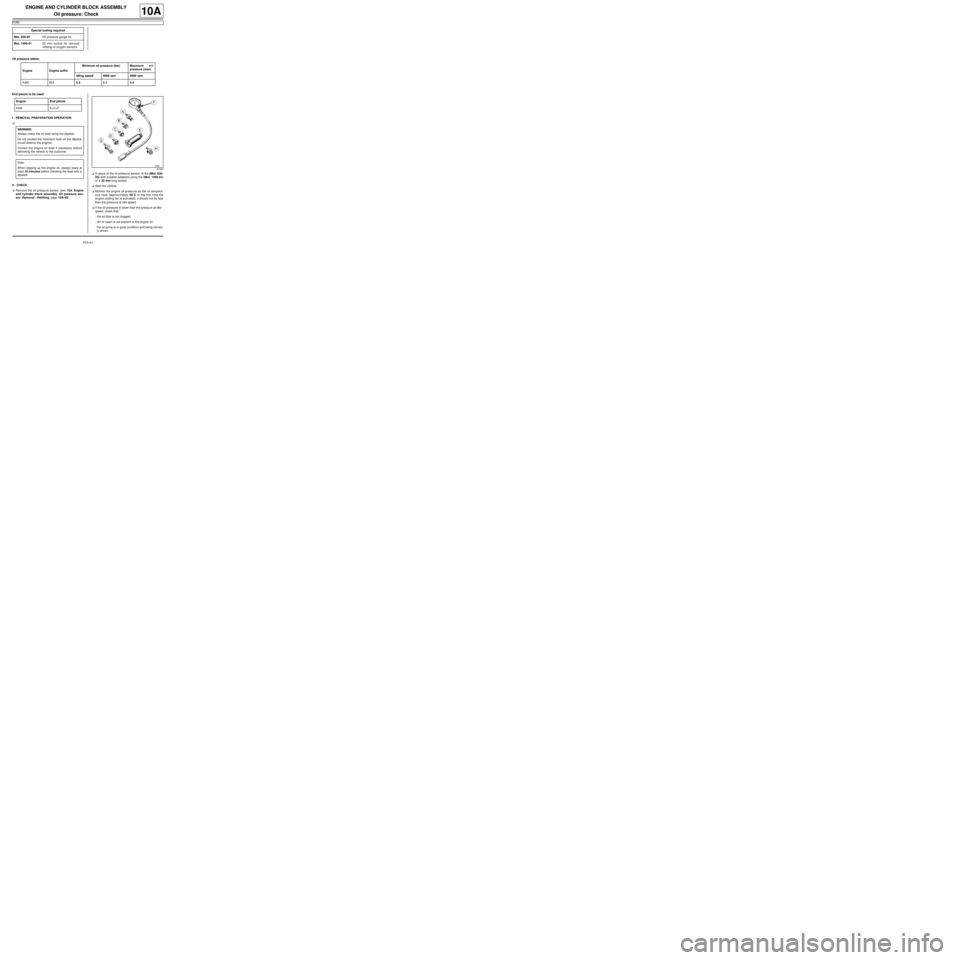

Oil pressure tables:

End pieces to be used:

I - REMOVAL PREPARATION OPERATION

a

II - CHECK

aRemove the oil pressure sensor (see 10A, Engine

and cylinder block assembly, Oil pressure sen-

sor: Removal - Refitting, page 10A-45) .aIn place of the oil pressure sensor, fit the (Mot. 836-

05) with suitable adapters using the (Mot. 1495-01)

or a 22 mm long socket.

aStart the vehicle.

aMonitor the engine oil pressure as the oil tempera-

ture rises (approximately 80˚C or the first time the

engine cooling fan is activated); it should not be less

than the pressure at idle speed.

aIf the oil pressure is lower than the pressure at idle

speed, check that:

-the oil filter is not clogged,

-dirt or swarf is not present in the engine oil,

-the oil pump is in good condition and being correct-

ly driven. Special tooling required

Mot. 836-05Oil pressure gauge kit.

Mot. 1495-0122 mm socket for removal -

refitting of oxygen sensors.

Engine Engine suffixMinimum oil pressure (bar) Maximu m o i l

pressure (max)

Idling speed 4000 rpm 4000 rpm

K4M 8540.5 3.1 4.4

Engine End pieces

K4M E+C+F

WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

delivering the vehicle to the customer.

Note:

When topping up the engine oil, always leave at

least 10 minutes before checking the level with a

dipstick.

87363

Page 68 of 652

10A-62

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil pressure: Check

K4M

10A

aCheck the oil pressure in comparison with the values

given in the table above.

aSwitch off the engine.

aRemove the (Mot. 836-05) with the end pieces.

aRefit the oil pressure sensor (see 10A, Engine and

cylinder block assembly, Oil pressure sensor:

Removal - Refitting, page 10A-45) .

aWipe any oil run-off with a cloth.

aWait at least 10 minutes.

aCheck the oil level using the dipstick.

aTop up the oil level if necessary (see Engine oil:

Specifications) (Technical Note 6013A, 04A, Lubri-

cants).

aStart the vehicle and check that there are no oil

leaks at the oil pressure sensor.

Page 75 of 652

10A-69

ENGINE AND CYLINDER BLOCK ASSEMBLY

Multifunction support: Removal - Refitting

D4F, and 780 or 782

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the alternator (see 16A, Starting - Charging, Al-

ternator: Removal - Refitting, page 16A-1) .

aRemove the air conditioning compressor (see Com-

pressor: Removal - Refitting) (62A, Air condition-

ing).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the bolt of the coolant-oil heat exchanger cooling

pipes support from the multifunction support,

-the bolts (4) from the coolant pump inlet pipe,

-the multifunction support bolts (3) ,

-the multifunction support.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the multifunction support,

-the multifunction support bolts,

-the coolant pump inlet pipe bolts,

-the bolt of the coolant-oil heat exchanger cooling

pipes support on the multifunction support.

aTorque tighten:

-the multifunction support bolts (50 N.m),

-the coolant pump inlet pipe bolts (10 N.m). Tightening torquesm

multifunction support

bolts50 N.m

coolant pump inlet pipe

bolts10 N.m

AIR CONDITIONING

120956

Page 83 of 652

10A-77

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

D4F or D7F

10A

a

aUndo the clip from the intercooler outlet pipe.

aDisconnect the intercooler outlet air pipe.

aRemove the turbocharger air outlet rigid pipe bolt (9)from the throttle valve.

aDetach the turbocharger air outlet pipe from the tur-

bocharger in the direction of the arrow (10) .

aDisconnect the turbocharger air outlet pipe from the

turbocharger.

aUnclip the intercooler air inlet pipe.

aDisconnect the intercooler air inlet pipe from the in-

tercooler.

aRemove the turbocharger air outlet pipe.

aDisconnect the air filter box air inlet pipe from the air

filter box cover (12) .

aRemove:

-the air filter unit air inlet pipe bolt from the cross

member (13) ,

-the air filter unit air inlet pipe.

aDrain:

-the cooling system (see 19A, Cooling, Cooling

system: Draining - Refilling, page 19A-9) ,

-the gearbox (see Manual gearbox oils: Draining -

Filling) (21A, Manual gearbox),

-the engine if necessary (see 10A, Engine and cyl-

inder block assembly, Engine oil: Draining - Re-

filling, page 10A-22) .

aAttach the cooling unit to the engine.

aDisconnect:

-the heater matrix hoses,

-the brake servo pipe on the brake servo,

-the petrol vapour rebreathing solenoid valve con-

nector,

-the petrol vapour rebreather pipe. D4F, and 780 or 782

122833

122673

Note:

If the turbocharger outlet air pipe tightening clip

(7) is removed, the rubber flexible pipe (8) and

the tightening clip (7) must be replaced.

Note:

If the clip (11) is removed from the heat resistant

protector, the latter must be replaced.

Page 88 of 652

10A-82

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

D4F or D7F

10A

aSupport the engine and gearbox assembly on (Mot.

1390).

aRemove the bolts from the subframe.

aRemove the engine and transmission assembly by

lifting the body.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: refrigerant pipe

seal.

aConsumables (see Vehicle: Parts and consuma-

bles for the repair) (04B, Consumables - Products):

-gearbox oil,-engine oil (if necessary) (see Engine oil: Specifi-

cations) (Technical Note 6013A, 04A, Lubricants),

-coolant,

-refrigerant.

a

aFor standard engine replacements (see Standard

replacement) (Technical Note 6004A, 10A, Engine

and peripherals).

II - REFITTING OPERATION FOR PART

CONCERNED

a

aPosition the engine and transmission assembly in

the vehicle.

aRefit:

-the front subframe bolts,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the left-hand suspended engine mounting nut.

aRemove:

-the (Mot. 1390),

-the (Mot. 1379),

-the shims.

III - FINAL OPERATION

aRefit:

-the subframe rear tie rod bolts,

-the engine tie-bar,

-the engine tie-bar bolts on the gearbox,

-the engine tie-bar bolt on the subframe.

17765

121643

Note:

For an operation which requires the engine-gear-

box assembly to be separated from the sub-

frame, ensure that the position of the engine on

the subframe is noted, by mar king the position of

the (Mot. 1379) and the position of the gearbox

in relation to the subframe .

Note:

Lining up the subframe with the body can be

made easier by positioning two threaded rods of

the (Tav. 1233-01), in the two subframe/body

front mountings.

Page 90 of 652

10A-84

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

D4F or D7F

10A

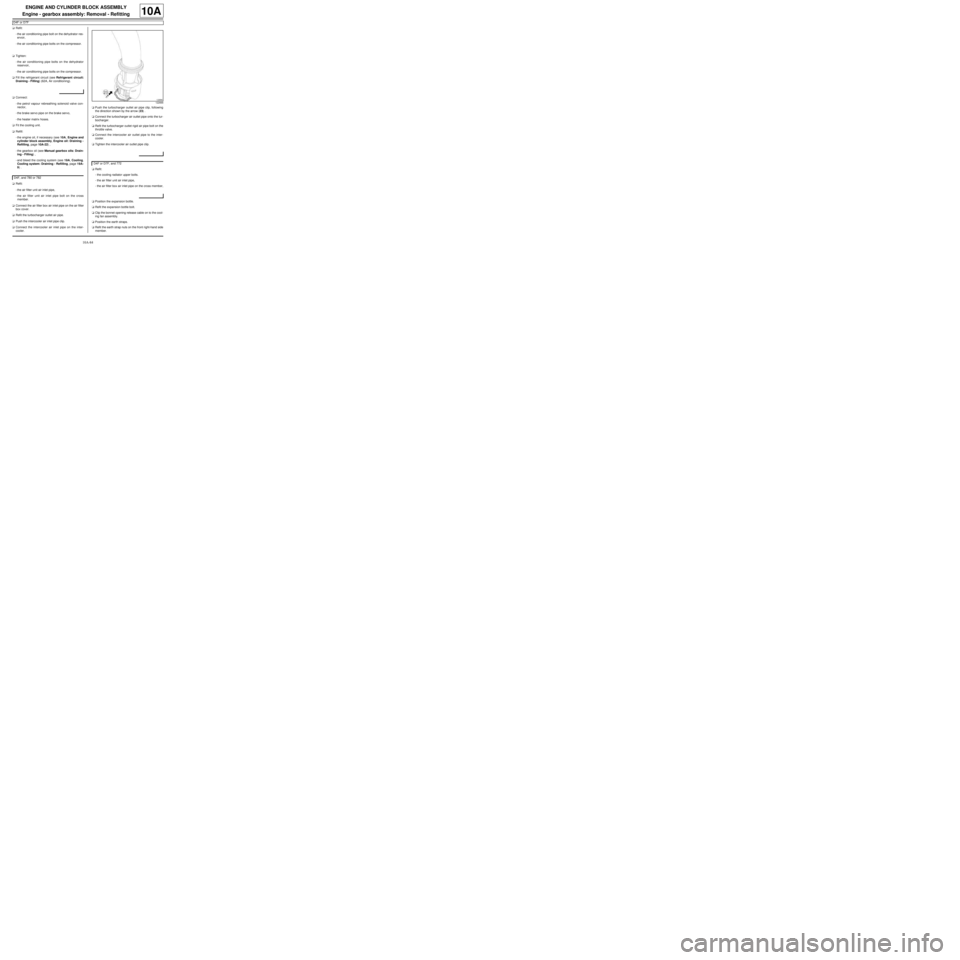

aRefit:

-the air conditioning pipe bolt on the dehydrator res-

ervoir,

-the air conditioning pipe bolts on the compressor.

aTighten:

-the air conditioning pipe bolts on the dehydrator

reservoir,

-the air conditioning pipe bolts on the compressor.

aFill the refrigerant circuit (see Refrigerant circuit:

Draining - Filling) (62A, Air conditioning).

aConnect:

-the petrol vapour rebreathing solenoid valve con-

nector,

-the brake servo pipe on the brake servo,

-the heater matrix hoses.

aFit the cooling unit.

aRefill:

-the engine oil, if necessary (see 10A, Engine and

cylinder block assembly, Engine oil: Draining -

Refilling, page 10A-22) ,

-the gearbox oil (see Manual gearbox oils: Drain-

ing - Filling) ,

-and bleed the cooling system (see 19A, Cooling,

Cooling system: Draining - Refilling, page 19A-

9) .

aRefit:

-the air filter unit air inlet pipe,

-the air filter unit air inlet pipe bolt on the cross

member.

aConnect the air filter box air inlet pipe on the air filter

box cover.

aRefit the turbocharger outlet air pipe.

aPush the intercooler air inlet pipe clip.

aConnect the intercooler air inlet pipe on the inter-

cooler.aPush the turbocharger outlet air pipe clip, following

the direction shown by the arrow (23) .

aConnect the turbocharger air outlet pipe onto the tur-

bocharger.

aRefit the turbocharger outlet rigid air pipe bolt on the

throttle valve.

aConnect the intercooler air outlet pipe to the inter-

cooler.

aTighten the intercooler air outlet pipe clip.

aRefit:

-the cooling radiator upper bolts.

-the air filter unit air inlet pipe,

-the air filter box air inlet pipe on the cross member,

aPosition the expansion bottle.

aRefit the expansion bottle bolt.

aClip the bonnet opening release cable on to the cool-

ing fan assembly.

aPosition the earth straps.

aRefit the earth strap nuts on the front right-hand side

member. D4F, and 780 or 782

122666

D4F or D7F, and 772

Page 93 of 652

10A-87

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K9K

10A

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

aDrain:

-the gearbox (see Sequential gearbox oil: Drain-

ing - Filling) (21A, Manual gearbox),

-the engine cooling system (see 19A, Cooling,

Cooling system: Draining - Refilling, page 19A-

9) ,

-the engine, if necessary (see 10A, Engine and

cylinder block assembly, Engine oil: Draining -

Refilling, page 10A-22) ,

-the refrigerant circuit using a refrigerant charging

station (see Refrigerant circuit: Draining - Fill-

ing) (62A, Air conditioning) (if fitted).

aLoosen the clip (5) on the intercooler air outlet pipe.

aPull the clip (6) of the intercooler air inlet pipe.

aDisconnect:

-the intercooler air outlet pipe,

-the intercooler air inlet pipe.

aAttach the « engine cooling radiator - condenser -

intercooler » assembly to the front upper cross

member using a safety strap(s).aAttach the « engine cooling radiator - condenser »

assembly to the front upper cross member.

aRemove:

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the radiator mounting cross member (see Radiator

mounting cross member: Removal - Refitting)

(41A, Front lower structure),

-the front left-hand wheel driveshaft (see Front left-

hand driveshaft: Removal - Refitting) (29A,

Driveshafts),

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the front section of the intermediate pipe (see 19B,

Exhaust, Intermediate pipe: Removal - Refit-

ting, page 19B-28) . K9K, and 718

122830

K9K, and 740

Page 99 of 652

10A-93

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K9K

10A

II - FINAL OPERATION

aRemove the.

aLubricate the seals using recommended air condi-

tioning oil to make fitting easier.

aRefit:

-the connecting pipes to the compressor,

-the connecting pipe union bolts on the compressor,

-the bolt for the connecting pipe mounting on the

compressor.

aConnect:

-the pressostat connector,

-the hose to the coolant pump inlet pipe using the

tool (Mot. 1448).

aFit:

-the hose clip on the coolant pump inlet pipe using

the tool (Mot. 1448),

-the earth on the front left-hand wing.

aRefit the earth nut on the front left-hand wing.

aClip:

-the engine compartment connection unit relay

plates,

-the fuse holders.

aRefit the fuses.

aConnect the preheating unit connector.

aRefit the earth nut on the front left-hand side mem-

ber.

aFit the engine compartment connection unit.

aRefit the engine compartment connection unit

mountings on the body.

aConnect the black connector.

aClip on the black connector.

aRefit:

-the engine compartment connection unit cover,

-a new clip on the battery mounting to hold the elec-

trical wiring.

aConnect the wiring connectors to the fan assembly.aClip the fan assembly wiring.

aRemove the blanking plugs.

aConnect the high pressure pump inlet pipe.

aClip on the fuel supply pipe.

aConnect the high pressure pump return pipe.

aClip on the fuel return pipe.

aRemove the blanking plugs on the clutch hydraulic

control and on the control pipe.

aConnect the clutch hydraulic control to the gearbox.

aClip:

-the clutch control hydraulic pipe on the gearbox,

-the gearbox controls on the cable sleeve stops,

-the gearbox controls on the gear selectors.

aConnect:

-the hoses to the heater radiator,

-the top hose to the water chamber.

aFit:

-the hose clips on the heater radiator using the tool

(Mot. 1448),

-the clip for the top hose on the water chamber us-

ing the tool (Mot. 1448).

aRefit:

-the front section of the intermediate pipe (see 19B,

Exhaust, Intermediate pipe: Removal - Refit-

ting, page 19B-28) ,

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the front left-hand wheel driveshaft (see Front left-

hand driveshaft: Removal - Refitting) (29A,

Driveshafts),

-the radiator mounting cross member (see Radiator

mounting cross member: Removal - Refitting)

(41A, Front lower structure),

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) . WARNING

To prevent any leaks, check that the seal and the

surface of the pipe are in good condition. The

seal and the surface must be clean and scratch

free.