RENAULT TWINGO 2009 2.G Panelwork Workshop Manual

TWINGO 2009 2.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1724/w960_1724-0.png

RENAULT TWINGO 2009 2.G Panelwork Workshop Manual

Trending: ESP, belt, gas type, towing, jacking, steering, torque

Page 171 of 209

44A-16

REAR UPPER STRUCTURE

Quarter panel lining: General description

44A

DESIGN OF THE STRUCTURAL COMPONENT

The special feature of this part it that it concurrently

serves two functions:

-quarter panel lining,

-outer rear wheel arch.

If there are other issues regarding access to mating fa-

ces, the various replacement options are described in

the basic instructions for structural bodywork repair

(see MR 400, 40A, General Information). WARNING

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion, see MR 400, 40A, General Information.

121050

Page 172 of 209

44A-17

REAR UPPER STRUCTURE

Quarter panel lining: Description

44A

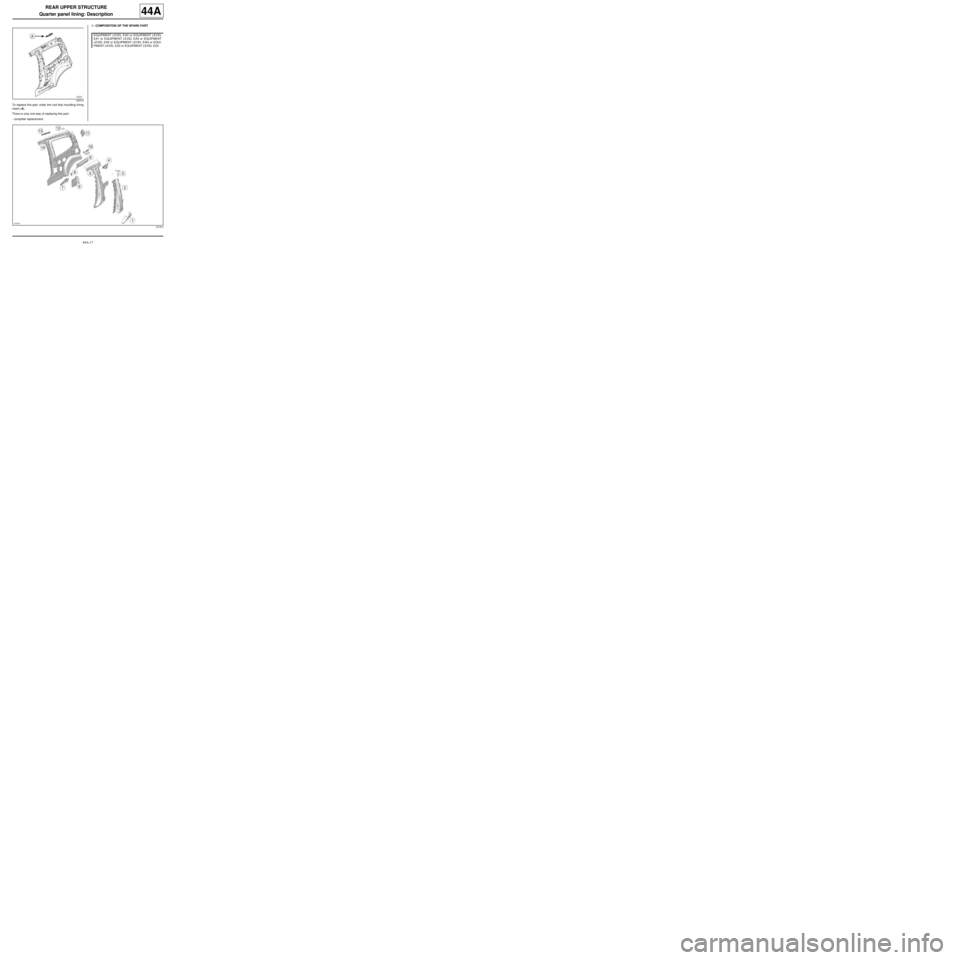

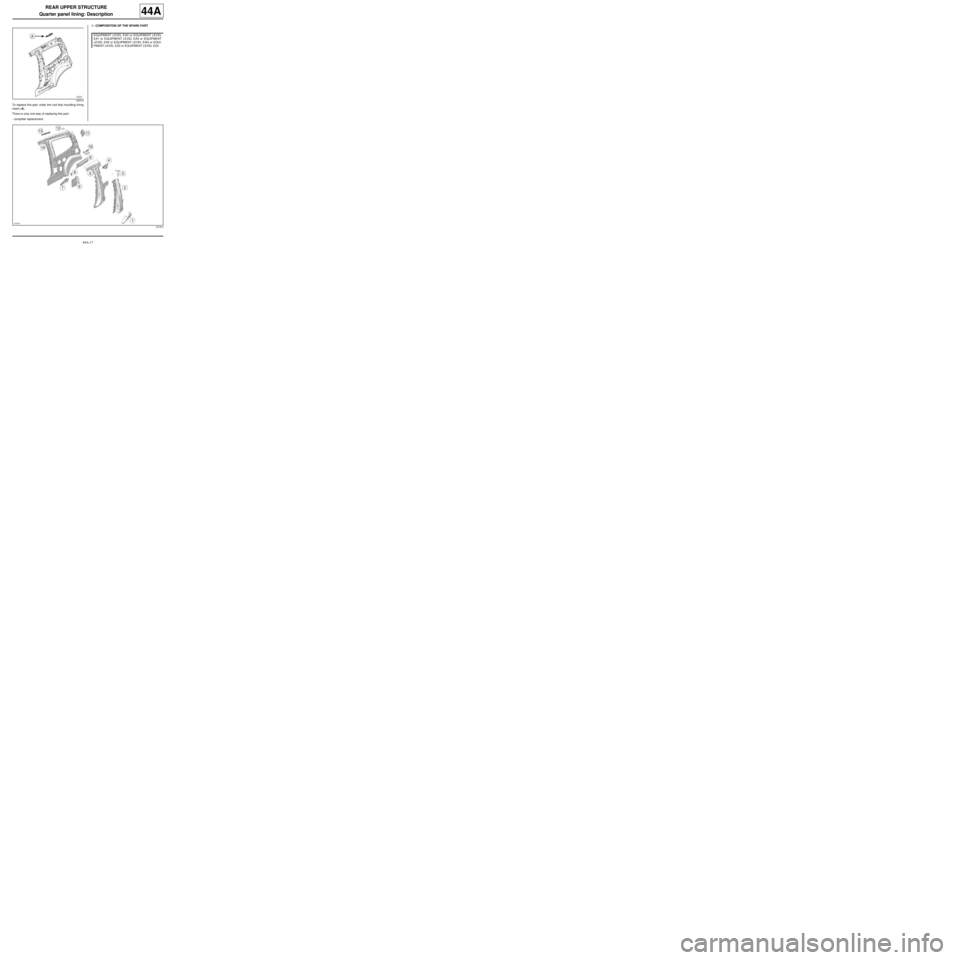

To replace this part, order the roof drip moulding lining

insert (A) .

There is only one way of replacing this part:

-complete replacement.I - COMPOSITION OF THE SPARE PART

125416

EQUIPMENT LEVEL EA0 or EQUIPMENT LEVEL

EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT

LEVEL EA5 or EQUIPMENT LEVEL EAG or EQUI-

PMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

121913

Page 173 of 209

44A-18

REAR UPPER STRUCTURE

Quarter panel lining: Description

44A

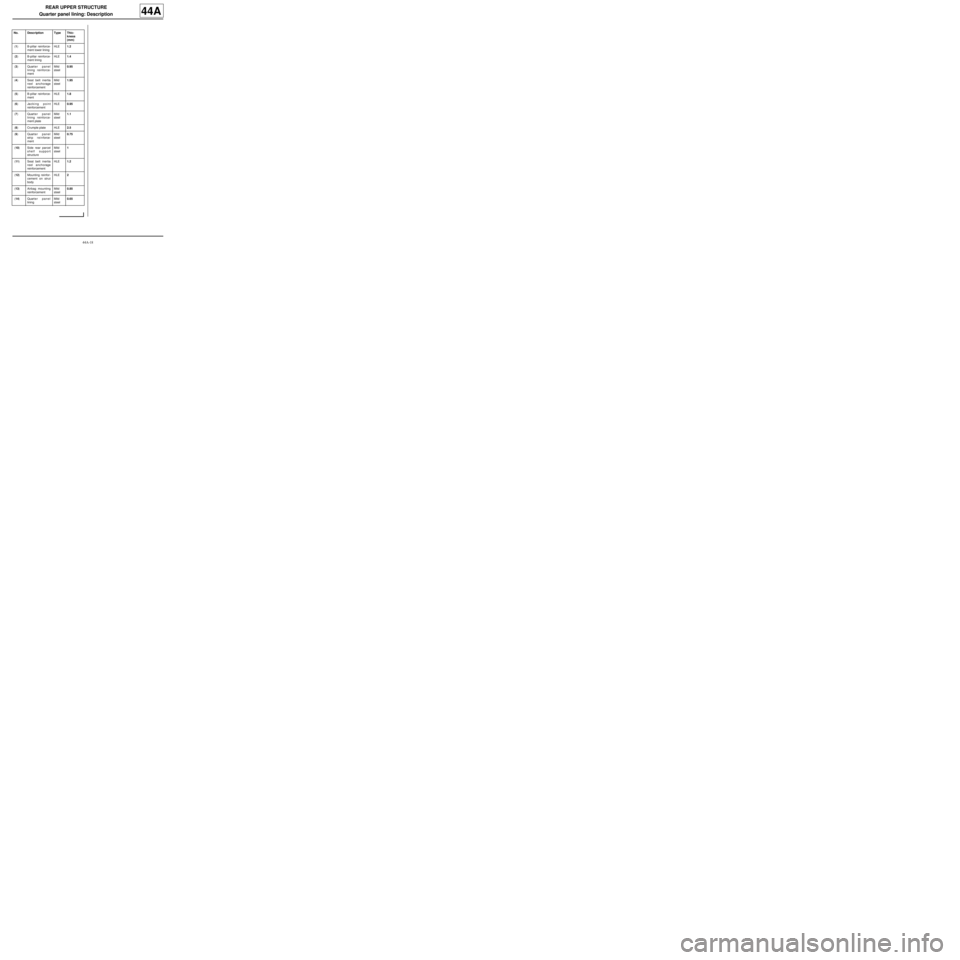

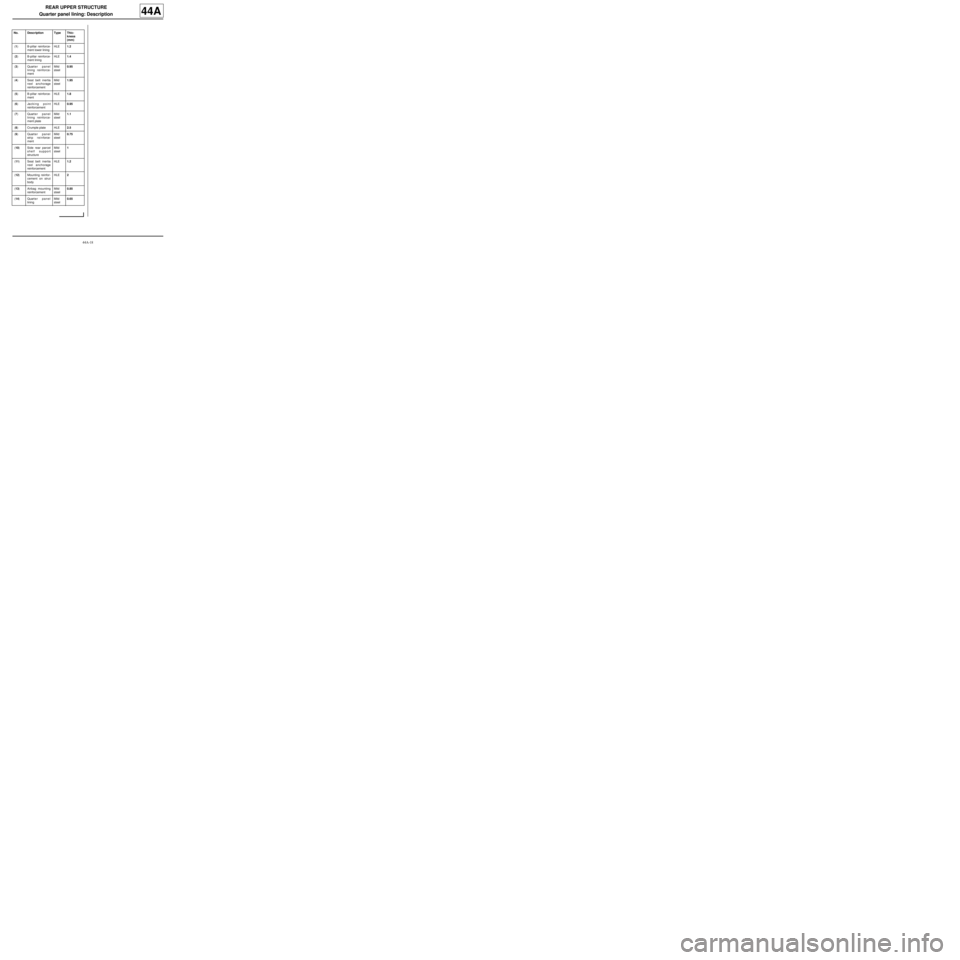

No. Description Type Thic-

kness

(mm)

(1) B-pillar reinforce-

ment lower liningHLE1.2

(2) B-pillar reinforce-

ment liningHLE1.4

(3) Quart e r panel

lining reinforce-

mentMild

steel0.95

(4) Seat belt inertia

reel anchorage

reinforcementMild

steel1.95

(5) B-pillar reinforce-

mentHLE1.8

(6) Jacking point

reinforcementHLE0.95

(7) Quart e r panel

lining reinforce-

ment plateMild

steel1.1

(8) Crumple plate HLE2.5

(9) Quart e r panel

strip reinforce-

mentMild

steel0.75

(10) Side rear parcel

shelf support

structureMild

steel1

(11) Seat belt inertia

reel anchorage

reinforcementHLE1.2

(12) Mounting reinfor-

cement on strut

bodyHLE2

(13) Airbag mounting

reinforcementMild

steel0.85

(14) Quart e r panel

liningMild

steel0.65

Page 174 of 209

44A-19

REAR UPPER STRUCTURE

Quarter panel lining: Description

44A

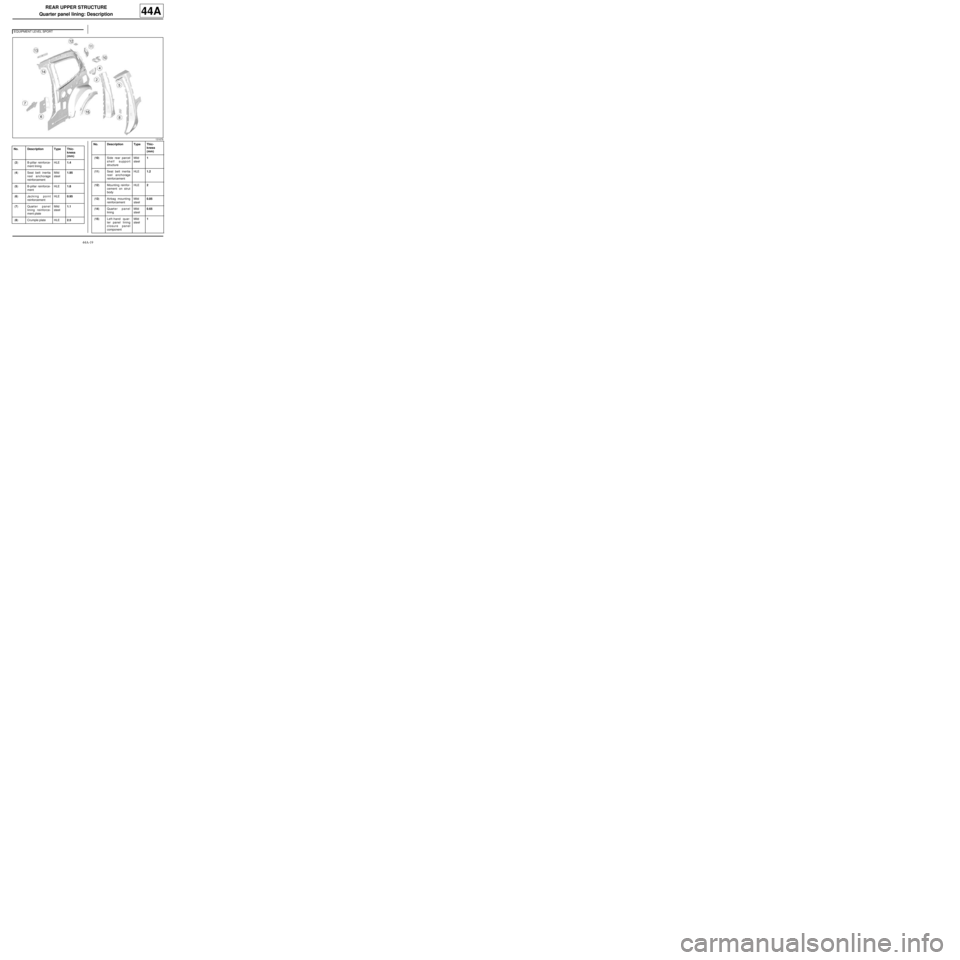

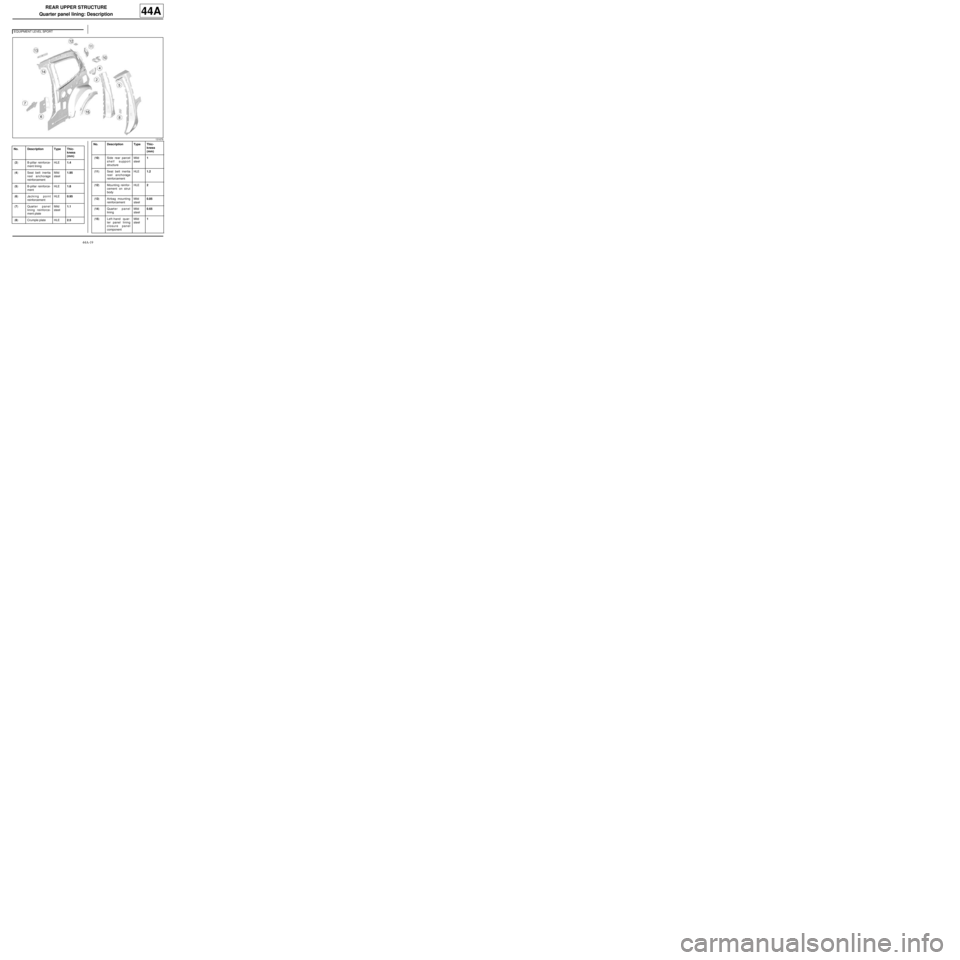

EQ UIPMENT LEVEL SPORT

131676

No. Description Type Thic-

kness

(mm)

(2) B-pillar reinforce-

ment liningHLE1.4

(4) Seat belt inertia

reel anchorage

reinforcementMild

steel1.95

(5) B-pillar reinforce-

mentHLE1.8

(6) Jacking point

reinforcementHLE0.95

(7) Quarter panel

lining reinforce-

ment plateMild

steel1.1

(8) Crumple plate HLE2.5

(10) Side rear parcel

shelf support

structureMild

steel1

(11) Seat belt inertia

reel anchorage

reinforcementHLE1.2

(12) Mounting reinfor-

cement on strut

bodyHLE2

(13) Airbag mounting

reinforcementMild

steel0.85

(14) Quart e r p a n e l

liningMild

steel0.65

(15) Left-hand quar-

ter panel lining

closure panel

componentMild

steel1 No. Description Type Thic-

kness

(mm)

Page 175 of 209

44A-20

REAR UPPER STRUCTURE

Quarter panel lining: Description

44A

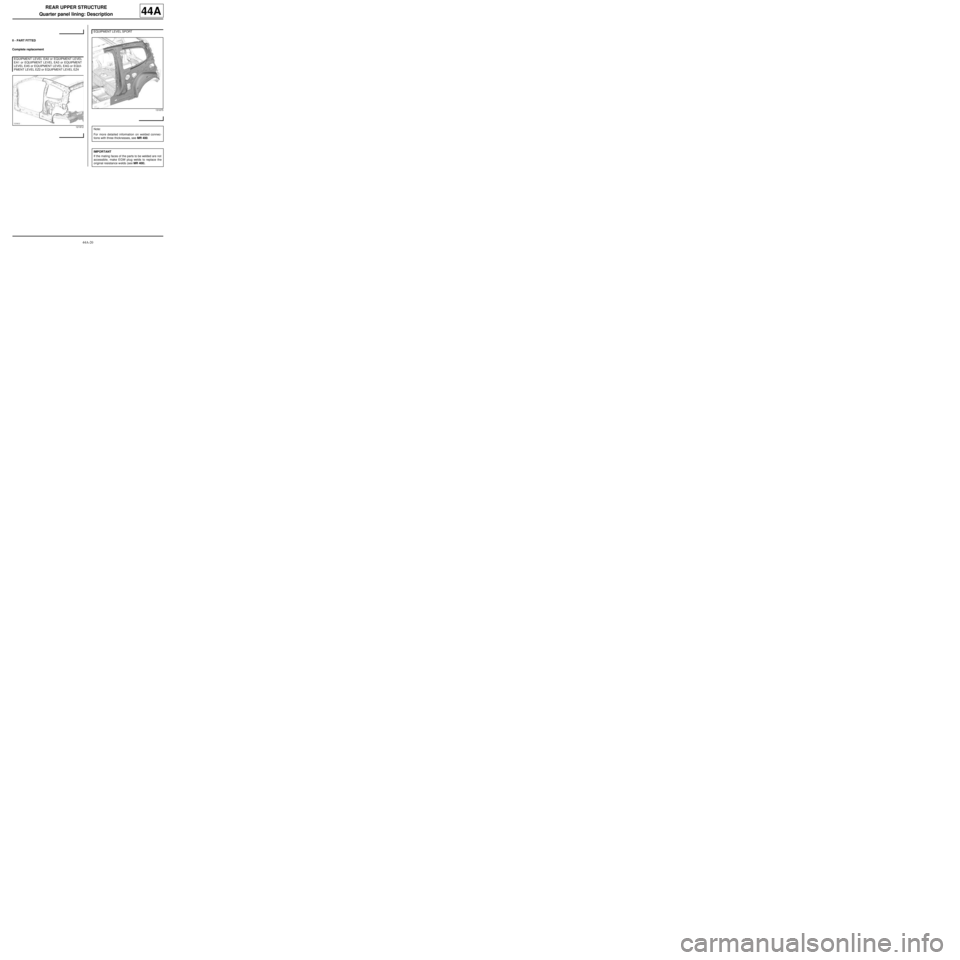

II - PART FITTED

Complete replacement

EQUIPMENT LEVEL EA0 or EQUIPMENT LEVEL

EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT

LEVEL EA5 or EQUIPMENT LEVEL EAG or EQUI-

PMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

121912

EQUIPMENT LEVEL SPORT

131675

Note:

For more detailed information on welded connec-

tions with three thicknesses, see MR 400.

IMPORTANT

If the mating faces of the parts to be welded are not

accessible, make EGW plug welds to replace the

original resistance welds (see MR 400).

Page 176 of 209

44A-21

REAR UPPER STRUCTURE

Quarter panel lining: Description

44A

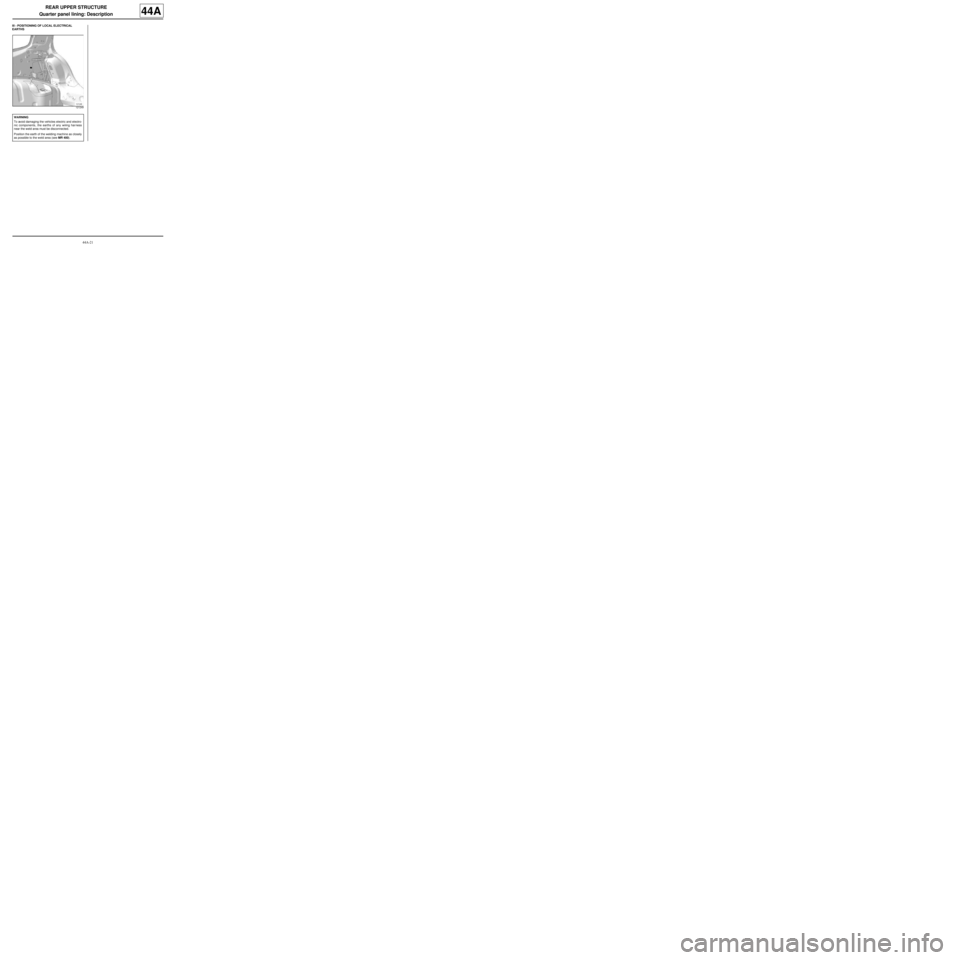

III - POSITIONING OF LOCAL ELECTRICAL

EARTHS

121249

WARNING

To avoid damaging the vehicles electric and electro-

nic components, the earths of any wiring harness

near the weld area must be disconnected.

Position the earth of the welding machine as closely

as possible to the weld area (see MR 400).

Page 177 of 209

44A-22

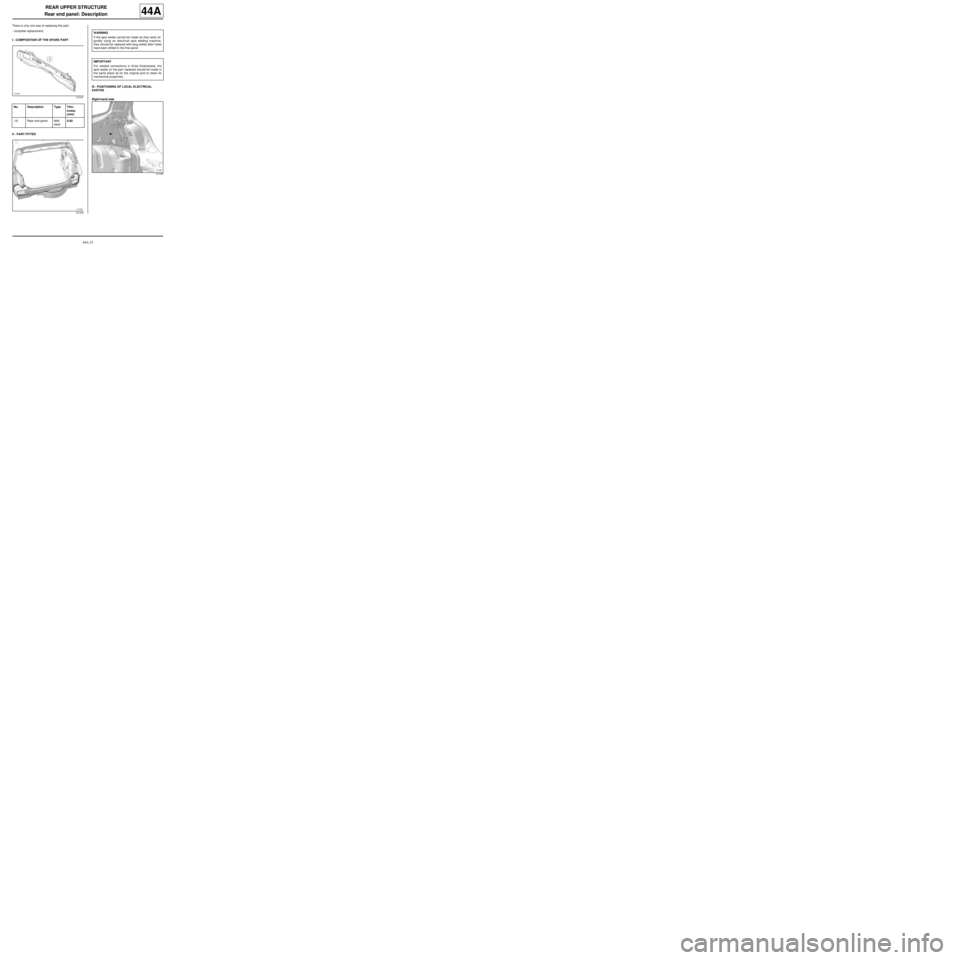

REAR UPPER STRUCTURE

Rear end panel assembly: Description

44A

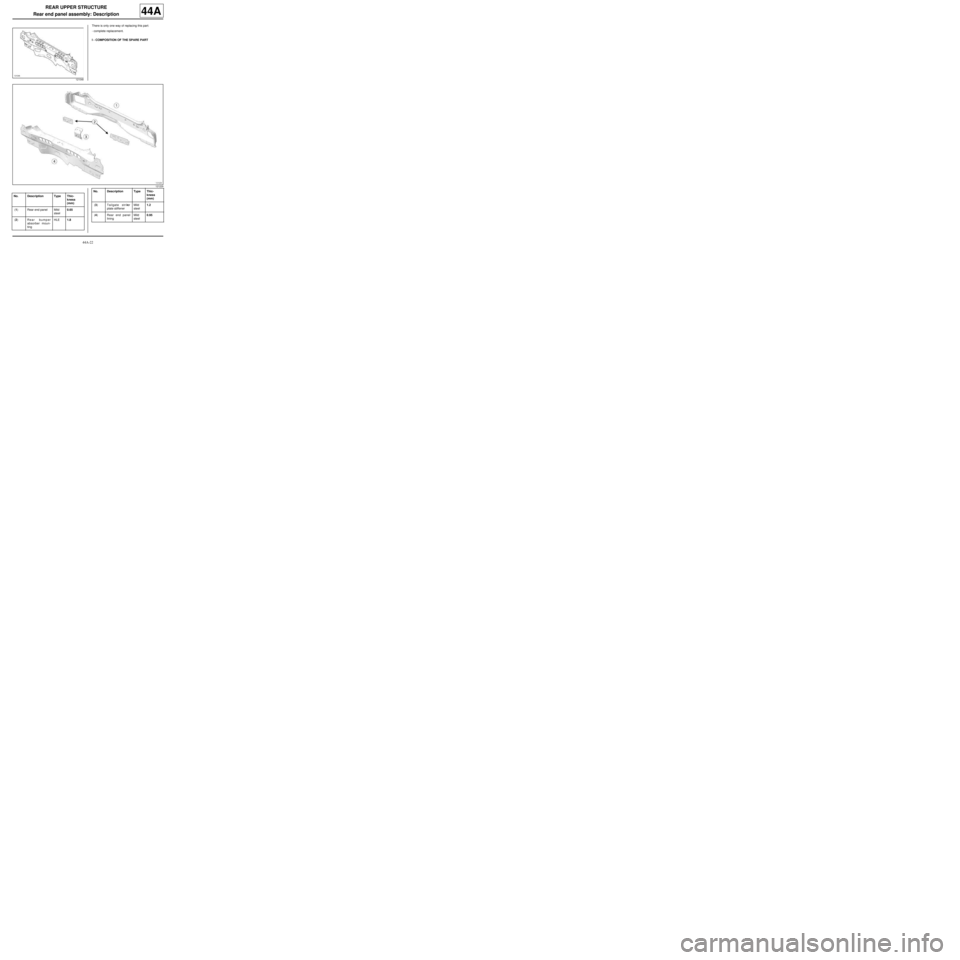

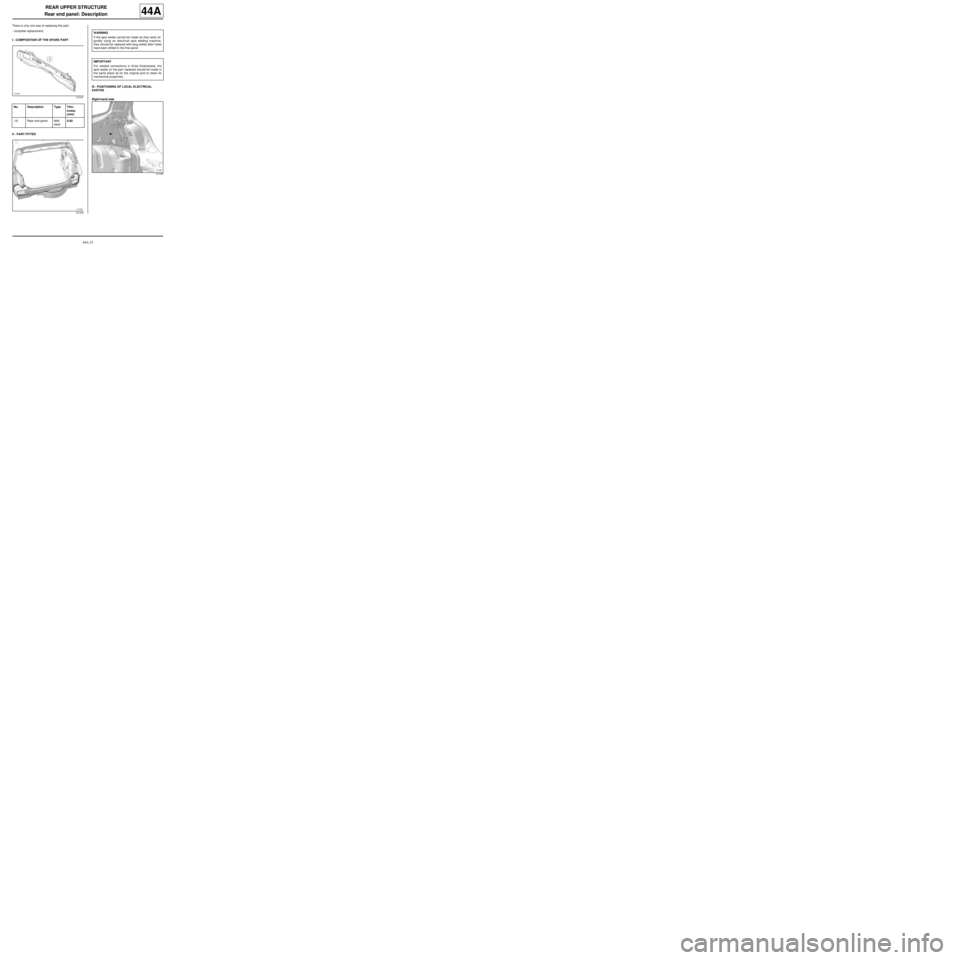

There is only one way of replacing this part:

-complete replacement.

I - COMPOSITION OF THE SPARE PART

121048

121229

No. Description Type Thic-

kness

(mm)

(1) Rear end panel Mild

steel0.65

(2) Rear bumper

absorber moun-

tingHLE1.8

(3) Tailgate striker

plate stiffenerMild

steel1.2

(4) Rear end panel

liningMild

steel0.95 No. Description Type Thic-

kness

(mm)

Page 178 of 209

44A-23

REAR UPPER STRUCTURE

Rear end panel assembly: Description

44A

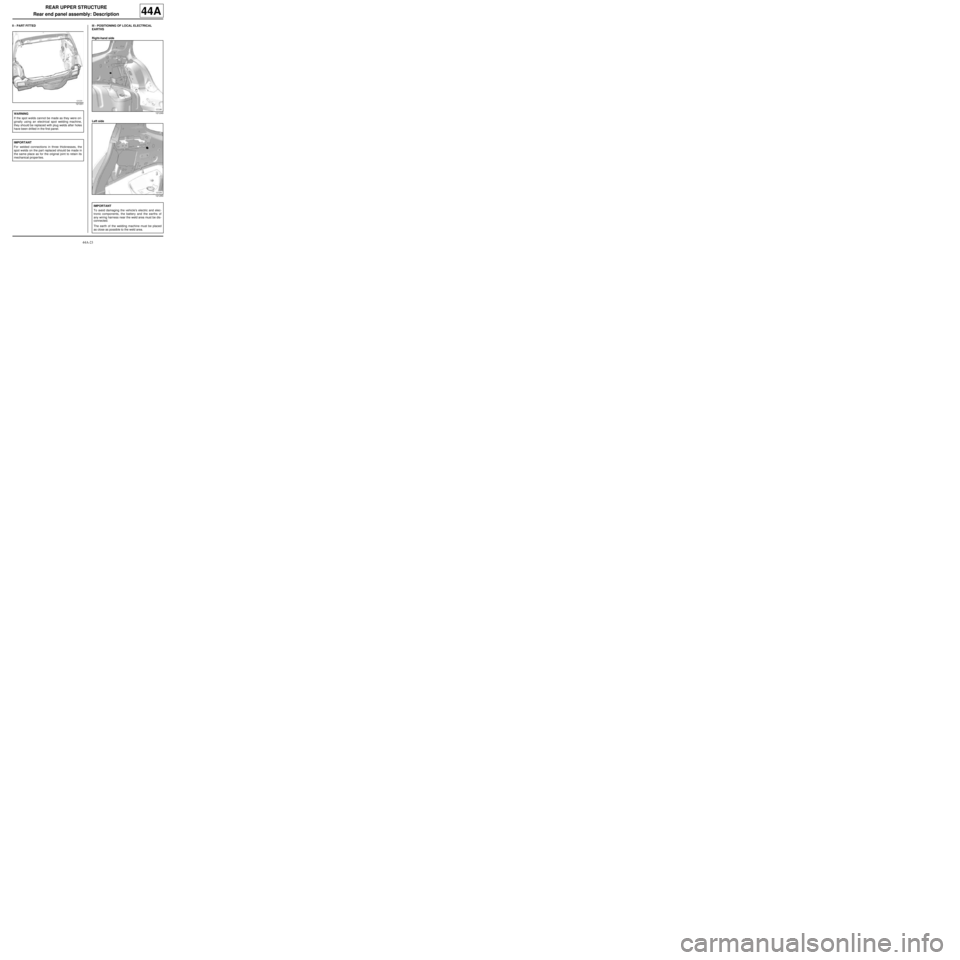

II - PART FITTED III - POSITIONING OF LOCAL ELECTRICAL

EARTHS

Right-hand side

Left side

121231

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

IMPORTANT

For welded connections in three thicknesses, the

spot welds on the part replaced should be made in

the same place as for the original joint to retain its

mechanical proper ties.121249

121250

IMPORTANT

To avoid damaging the vehicle's electric and elec-

tronic components, the battery and the earths of

any wiring harness near the weld area must be dis-

connected.

The earth of the welding machine must be placed

as close as possible to the weld area.

Page 179 of 209

44A-24

REAR UPPER STRUCTURE

Rear end panel: General description

44A

DESIGN OF THE STRUCTURAL COMPONENT

The special feature of this part it that it concurrently

serves two functions:

-rear end panel,

-rear end panel lining.

If there are other issues regarding access to mating fa-

ces, the various replacement options are described in

the basic instructions for structural bodywork repair

(see MR 400). Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion, see MR 400.

121047

Page 180 of 209

44A-25

REAR UPPER STRUCTURE

Rear end panel: Description

44A

There is only one way of replacing this part:

-complete replacement.

I - COMPOSITION OF THE SPARE PART

II - PART FITTEDIII - POSITIONING OF LOCAL ELECTRICAL

EARTHS

Right-hand side

121047

No. Description Type Thic-

kness

(mm)

(1) Rear end panel Mild

steel0.65

121230

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

IMPORTANT

For welded connections in three thicknesses, the

spot welds on the par t replaced should be made in

the same place as for the original joint to retain its

mechanical proper ties.

121249

Trending: dashboard, fuel tank removal, brake, radiator, air condition, check engine, dashboard warning lights