warning RENAULT TWINGO 2009 2.G Panelwork Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 209

Page 135 of 209

42A-26

FRONT UPPER STRUCTURE

Dashboard cross member: Removal - Refitting

42A

REMOVAL

a

I - REMOVAL PREPARATION OPERATION

aLock the airbag computer using the Diagnostic tool

(see Fault finding - Replacement of components)

(MR 413, 88C, Airbags and pretensioners).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove:

-the dashboard (see Dashboard: Removal - Refit-

ting) (MR 412, 57A, Interior equipment),

-the steering column (see Steering column: Re-

moval - Refitting) (MR 411, 36A, Steering assem-

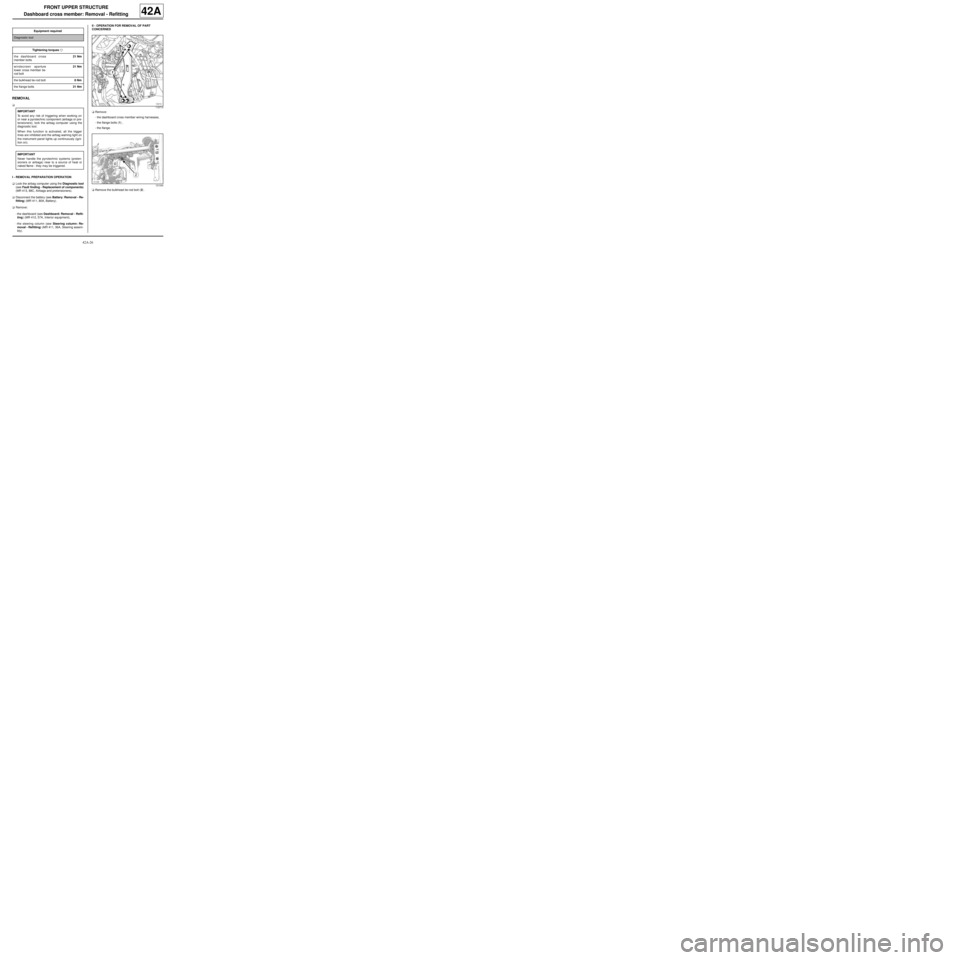

bly).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the dashboard cross member wiring harnesses,

-the flange bolts (1) ,

-the flange.

aRemove the bulkhead tie-rod bolt (2) . Equipment required

Diagnostic tool

Tightening torquesm

the dashboard cross

member bolts21 Nm

windscreen aperture

lower cross member tie-

rod bolt21 Nm

the bulkhead tie-rod bolt8 Nm

the flange bolts21 Nm

IMPORTANT

To avoid any risk of triggering when working on

or near a pyrotechnic component (airbags or pre-

tensioners), lock the airbag computer using the

diagnostic tool.

When this function is activated, all the trigger

lines are inhibited and the airbag warning light on

the instrument panel lights up continuously (igni-

tion on).

IMPORTANT

Never handle the pyrotechnic systems (preten-

sioners or airbags) near to a source of heat or

naked flame - they may be triggered.

119713

121240

Page 137 of 209

42A-28

FRONT UPPER STRUCTURE

Windscreen aperture lower cross member closure panel: Description42A

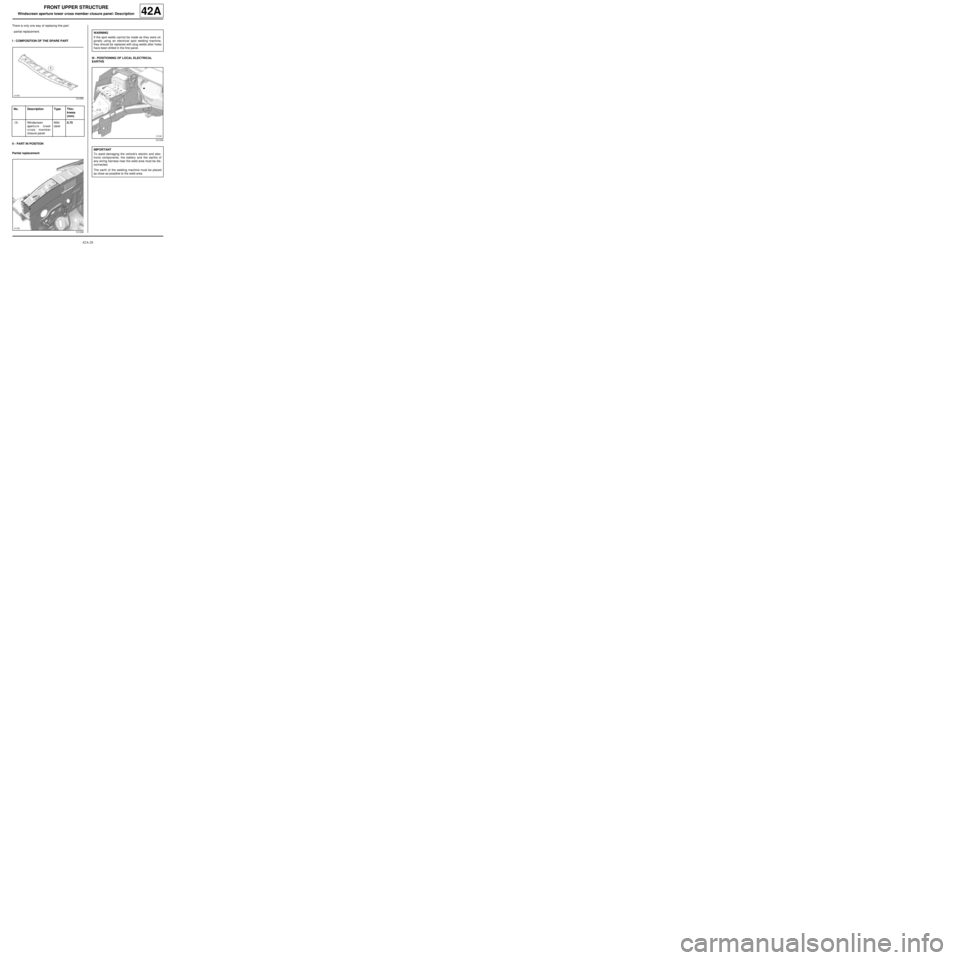

There is only one way of replacing this part:

-partial replacement.

I - COMPOSITION OF THE SPARE PART

II - PART IN POSITION

Partial replacementIII - POSITIONING OF LOCAL ELECTRICAL

EARTHS

121055

No. Description Type Thic-

kness

(mm)

(1) Windscreen

apert u r e l o wer

cross member

closure panelMild

steel0.75

121238

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

121246

IMPORTANT

To avoid damaging the vehicle's electric and elec-

tronic components, the battery and the earths of

any wiring harness near the weld area must be dis-

connected.

The earth of the welding machine must be placed

as close as possible to the weld area.

Page 138 of 209

43A-1

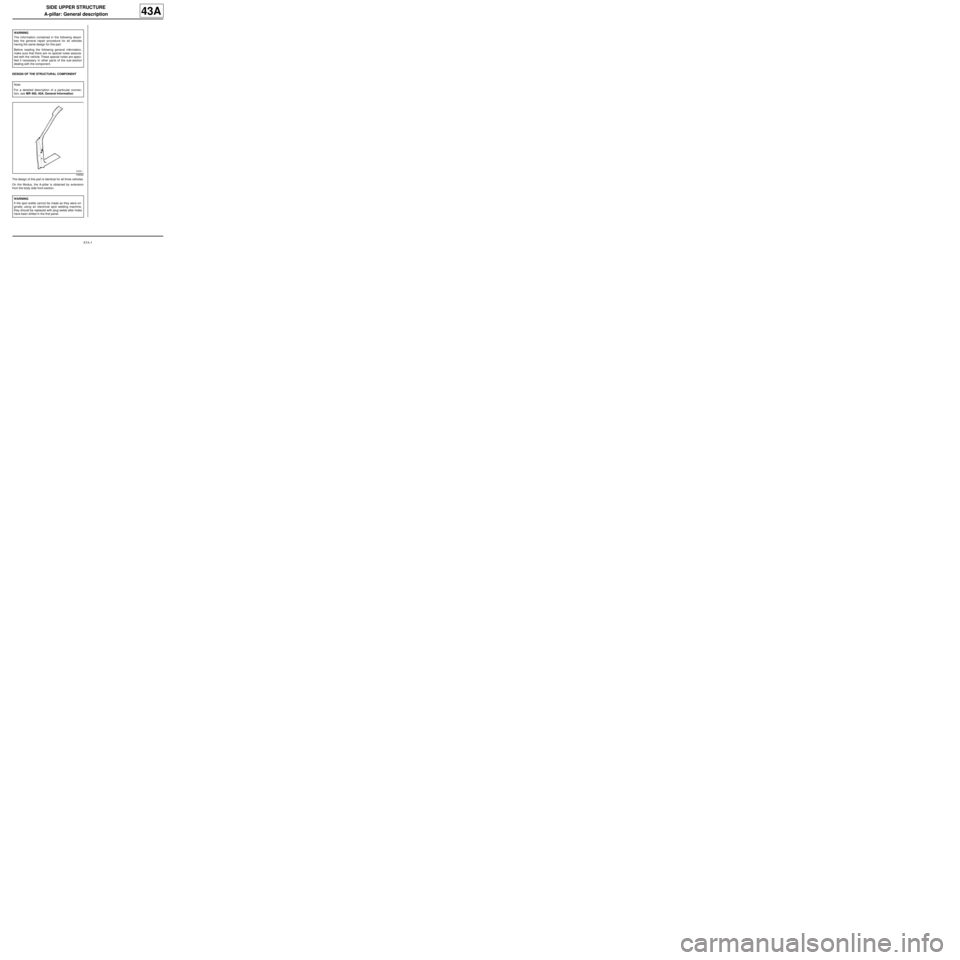

SIDE UPPER STRUCTURE

A-pillar: General description

43A

DESIGN OF THE STRUCTURAL COMPONENT

The design of this part is identical for all three vehicles.

On the Modus, the A-pillar is obtained by extension

from the body side front section.WARNING

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion, see MR 400, 40A, General Information.

109562

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

Page 140 of 209

43A-3

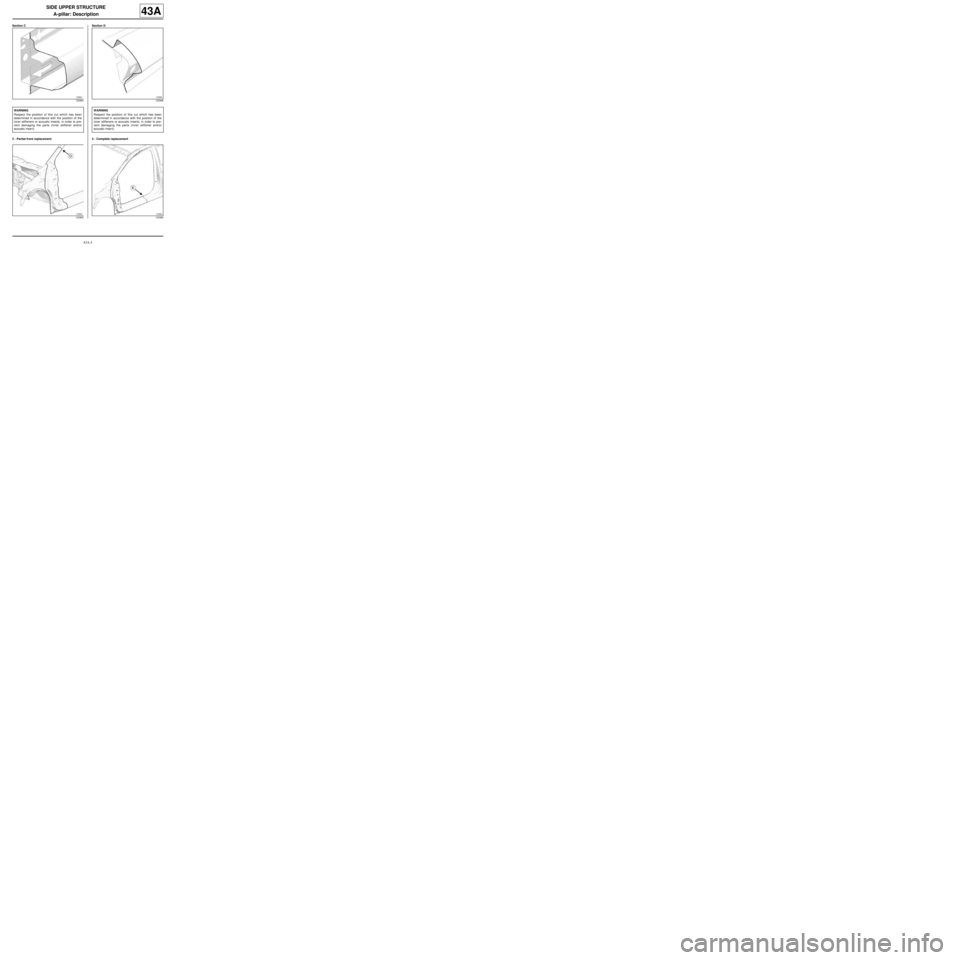

SIDE UPPER STRUCTURE

A-pillar: Description

43A

Section C

2 - Partial front replacementSection D

3 - Complete replacement

120994

WARNING

Respect the position of this cut which has been

determined in accordance with the position of the

inner stiffeners or acoustic inserts, in order to pre-

vent damaging the parts (inner stiffener and/or

acoustic inser t).

120993

120996

WARNING

Respect the position of this cut which has been

determined in accordance with the position of the

inner stiffeners or acoustic inserts, in order to pre-

vent damaging the parts (inner stiffener and/or

acoustic inser t).

120990

Page 141 of 209

43A-4

SIDE UPPER STRUCTURE

A-pillar: Description

43A

Section E III - POSITIONING OF LOCAL ELECTRICAL

EARTHS

120989

Note:

For more detailed information on welded connec-

tions with three thicknesses, see MR 400.

IMPORTANT

If the mating faces of the parts to be welded are not

accessible, make EGW plug welds to replace the

original resistance welds (see MR 400).

121245

WARNING

To avoid damaging the vehicles electric and electro-

nic components, the earths of any wiring harness

near the weld area must be disconnected.

Position the earth of the welding machine as closely

as possible to the weld area (see MR 400).

Page 142 of 209

43A-5

SIDE UPPER STRUCTURE

A-pillar reinforcement: General description

43A

DESIGN OF THE STRUCTURAL COMPONENT

This is a basic part, its only function is that of an A-pillar

reinforcement.WARNING

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion, see MR 400, 40A, General Information.

112718

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

Page 144 of 209

43A-7

SIDE UPPER STRUCTURE

A-pillar reinforcement: Description

C44

43A

III - POSITIONING OF LOCAL ELECTRICAL

EARTHS

121245

WARNING

To avoid damaging the vehicles electric and electro-

nic components, the earths of any wiring harness

near the weld area must be disconnected.

Position the earth of the welding machine as closely

as possible to the weld area (see MR 400).

Page 146 of 209

43A-9

SIDE UPPER STRUCTURE

B-pillar reinforcement: General description

43A

I - DESIGN OF THE STRUCTURAL COMPONENT

The special feature of this part is that it combines seve-

ral functions:

-B-pillar reinforcement,

-quarter panel reinforcement.

II - AREA TO BE CUT FOR PARTIAL

REPLACEMENT

III - ASSEMBLY METHOD FOR A PARTIAL

REPLACEMENT

Only the connections which are specific to the partial

replacement by cutting are indicated.If there are other issues regarding access to mating fa-

ces, the various options are described in the basic ins-

tructions for structural bodywork repair (see MR 400).

Line (2) on the drawing shows a butt weld by conti-

nuous EGW welding. Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion, see MR 400.

121054

WARNING

If the mating faces of the parts to be welded are not

accessible, make EGW plug welds to replace the

original resistance welds (see MR 400).

101971

Page 147 of 209

43A-10

SIDE UPPER STRUCTURE

B-pillar reinforcement: Description

43A

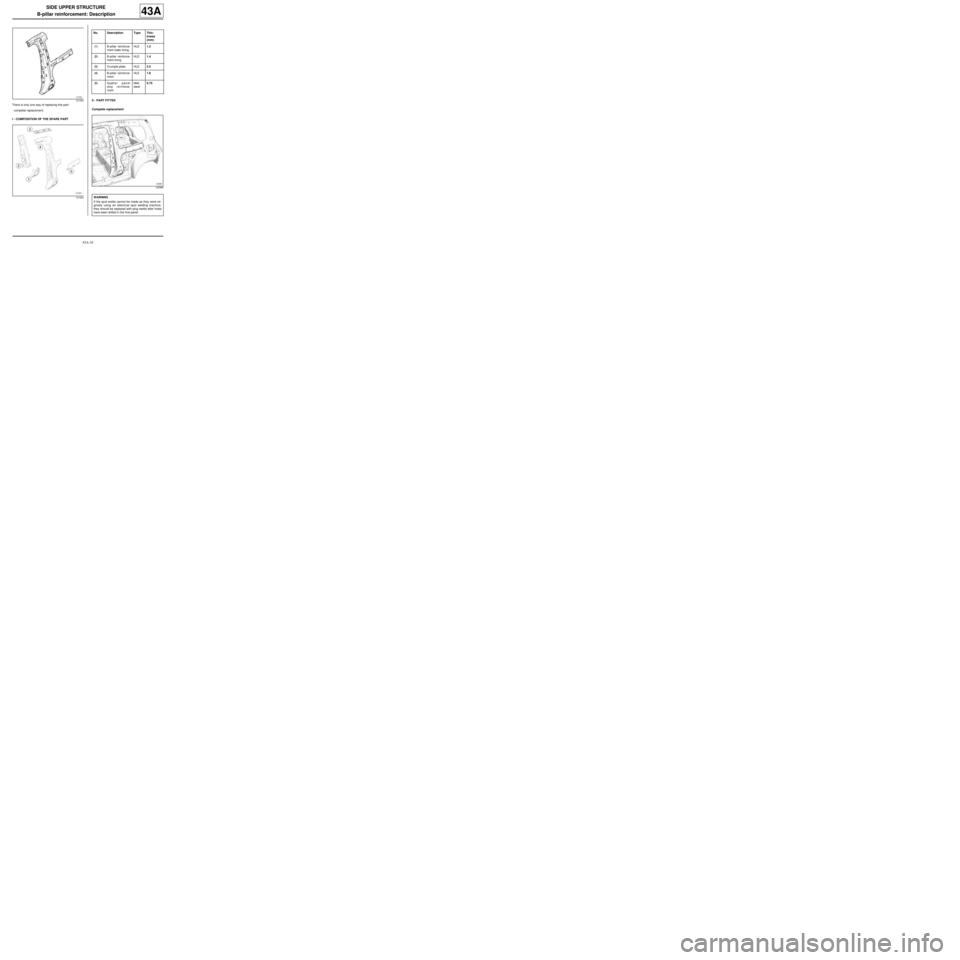

There is only one way of replacing this part:

-complete replacement.

I - COMPOSITION OF THE SPARE PARTII - PART FITTED

Complete replacement

121054

121000

No. Description Type Thic-

kness

(mm)

(1) B-pillar reinforce-

ment lower liningHLE1.2

(2) B-pillar reinforce-

ment liningHLE1.4

(3) Crumple plate HLE2.5

(4) B-pillar reinforce-

mentHLE1.8

(5) Quart e r p a n e l

strip reinforce-

mentMild

steel0.75

120999

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

Page 149 of 209

43A-12

SIDE UPPER STRUCTURE

Body side: General description

43A

DESIGN OF THE STRUCTURAL COMPONENT

The two parts must be welded at the joint (1) and butt

welded by continuous EGW welding.

If there are other issues regarding access to mating fa-

ces, the various replacement options are described in

the basic instructions for structural bodywork repair

(see MR 400).

The body side is achieved by welding the rear wing and

the body side front section.Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion (see MR 400).

113242

WARNING

If the mating faces of the parts to be welded are not

accessible, make EGW plug welds to replace the

original resistance welds (see MR 400).