Undertray RENAULT TWINGO RS 2009 2.G Engine And Peripherals User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 37 of 652

10A-31

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil filter: Removal - Refitting

K4M

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove the engine undertray.

aPosition oil recovery tray under the engine.II - REMOVAL OPERATION

aRemove the oil filter using the (Mot. 1329) (1) .

REFITTING

I - REFITTING PREPARATION OPERATION

aUsing SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products), clean and degrease the cylinder

block joint faces.

aparts always to be replaced: Oil filter.

aLubricate the oil filter seal with new engine oil.

II - REFITTING OPERATION

aFit a new oil filter.

aTighten the oil filter until it makes contact.

aTighten the oil filter three-quarters of a turn using the

(Mot. 1329).

III - FINAL OPERATION

aRemove the oil recovery tray. Special tooling required

Mot. 1329Oil filter removing tool (76

mm diameter)

Equipment required

oil recovery tray

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

deliver ing the vehicle to the customer.

Note:

When topping up the engine oil, always leave at

least 10 minutes before checking the level with a

dipstick.

When removing the oil filter, check that the oil filter

seal is not still stuck to the cylinder block or oil filter

mounting.

132364

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

Page 38 of 652

10A-32

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil filter: Removal - Refitting

K4M

10A

aWipe any oil run-off with a cloth.

aTop up the engine oil with oil recommended by the

manufacturer (see Engine oil: Specifications)

(Technical Note 6013A, 04A, Lubricants).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aStart the engine and wait until the oil pressure warn-

ing light goes out on the instrument panel.

aCheck for leaks from the oil filter.

aRefit the engine undertray.

aWait at least 10 minutes.

aCheck the oil level using the dipstick.

aAdjust the engine oil level if necessary.WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

delivering the vehicle to the customer.

Page 43 of 652

10A-37

ENGINE AND CYLINDER BLOCK ASSEMBLY

Conrod bearing shell: Removal - Refitting

K9K

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the engine undertray.

aDrain the oil from the engine (see 10A, Engine and

cylinder block assembly, Engine oil: Draining -

Refilling, page 10A-22) .

aRemove the oil filter (see 10A, Engine and cylinder

block assembly, Oil filter: Removal - Refitting,

page 10A-29) .

aRemove the lower engine tie-bar (see 19D, Engine

mounting, Lower engine tie-bar: Removal - Refit-

ting, page 19D-18) .

aStrap the radiator to the vehicle using safety

strap(s).

aRemove the front axle subframe (see Front axle

subframe: Removal - Refitting) (31A, Front axle

components).

aRemove the relay bearing of the front right-hand

wheel driveshaft. Special tooling required

Mot. 1914Tool for fitting G9 con rod

bear ing shells

Mot. 1920Tool for fitting F9 / K9 con rod

bear ing shells

Equipment required

safety strap(s)

component jack

indelible pencil

torque wrench

Diagnostic tool

Tightening torquesm

con rod cap bolts20 N.m + 45˚ ±± ± ±

6˚

oil pump bolts25 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair (see Vehicle: Precautions for the repair) .

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

123838

Page 50 of 652

10A-44

ENGINE AND CYLINDER BLOCK ASSEMBLY

Conrod bearing shell: Removal - Refitting

K9K

10A

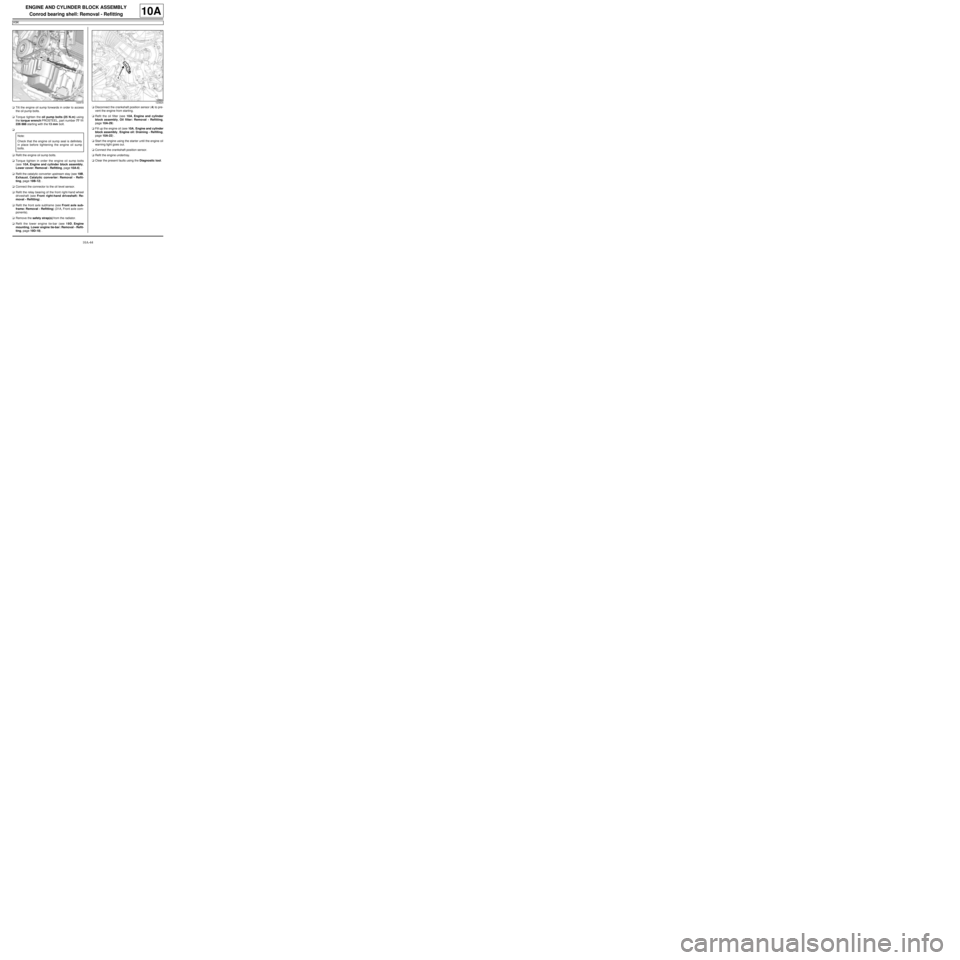

aTilt the engine oil sump forwards in order to access

the oil pump bolts.

aTorque tighten the oil pump bolts (25 N.m) using

the torque wrench PROSTEEL, part number 77 11

226 888 starting with the 13 mm bolt.

a

aRefit the engine oil sump bolts.

aTorque tighten in order the engine oil sump bolts

(see 10A, Engine and cylinder block assembly,

Lower cover: Removal - Refitting, page 10A-6) .

aRefit the catalytic converter upstream stay (see 19B,

Exhaust, Catalytic converter: Removal - Refit-

ting, page 19B-12) .

aConnect the connector to the oil level sensor.

aRefit the relay bearing of the front right-hand wheel

driveshaft (see Front right-hand driveshaft: Re-

moval - Refitting) .

aRefit the front axle subframe (see Front axle sub-

frame: Removal - Refitting) (31A, Front axle com-

ponents).

aRemove the safety strap(s) from the radiator.

aRefit the lower engine tie-bar (see 19D, Engine

mounting, Lower engine tie-bar: Removal - Refit-

ting, page 19D-18) .aDisconnect the crankshaft position sensor (4) to pre-

vent the engine from starting.

aRefit the oil filter (see 10A, Engine and cylinder

block assembly, Oil filter: Removal - Refitting,

page 10A-29)

aFill up the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22) .

aStart the engine using the starter until the engine oil

warning light goes out.

aConnect the crankshaft position sensor.

aRefit the engine undertray.

aClear the present faults using the Diagnostic tool.

140918

Note:

Check that the engine oil sump seal is definitely

in place before tightening the engine oil sump

bolts.

123824

Page 62 of 652

10A-56

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil pump: Removal - Refitting

D4F or D7F

10A

aRemove:

-the nut,

-the cover,

-the guard,

-the threaded rod.

aConnect the oil-coolant heat exchanger hoses.

aPut the clips (3) in place using the (Mot. 1448).

aRemove the hose clamps (Ms. 583) from the oil-wa-

ter heat exchanger hoses.

aConnect the oil pressure sensor connector.

aRefit:

-the timing sprocket,

-the sump (see 10A, Engine and cylinder block

assembly, Lower cover: Removal - Refitting,

page 10A-6) .

aFit the lower engine support tool (Mot. 1379).

aRemove:

-the right-hand suspended mounting support bolts,

-the right-hand suspended mounting support,

-the upper timing cover bolts,

-the upper timing cover.aRefit:

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) .

aRemove the lower engine support tool (Mot. 1379).

aRefit:

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the engine undertray,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the dipstick,

-the oil filter (see 10A, Engine and cylinder block

assembly, Oil filter: Removal - Refitting, page

10A-29) .

aTop up the engine oil (see 10A, Engine and cylin-

der block assembly, Engine oil: Draining - Refill-

ing, page 10A-22) .

aTop up the coolant level (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

20779

D4F, and 780 or 782

Page 63 of 652

10A-57

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil pump: Removal - Refitting

K4M

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the engine undertray.

aDrain the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22) .

aRemove:

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the rear engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents).

aRemove the sump (see 10A, Engine and cylinder

block assembly, Lower cover: Removal - Refit-

ting, page 10A-6) .II - REMOVAL OPERATION

aRemove:

-the oil pump bolts (1) ,

-the oil pump.

REFITTING

I - REFITTING OPERATION

aPosition the oil pump pinion on the chain.

aRefit the oil pump.

aTorque tighten the oil pump bolts (25 N.m).

II - FINAL OPERATION

aRefit the sump (see 10A, Engine and cylinder

block assembly, Lower cover: Removal - Refit-

ting, page 10A-6) .

aRefit:

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the rear engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion), Tightening torquesm

oil pump bolts25 N.m

128799

Page 64 of 652

10A-58

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil pump: Removal - Refitting

K4M

10A

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres).

aTop up the engine oil (see 10A, Engine and cylin-

der block assembly, Engine oil: Draining - Refill-

ing, page 10A-22) .

aRefit the engine undertray.

Page 77 of 652

10A-71

ENGINE AND CYLINDER BLOCK ASSEMBLY

Multifunction support: Removal - Refitting

K4M

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove the engine undertray.

aDrain the refrigerant circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the alternator (see 16A, Starting - Charging, Al-

ternator: Removal - Refitting, page 16A-1) ,

-the air conditioning compressor (see Compressor:

Removal - Refitting) (62A, Air conditioning). Equipment required

refrigerant charging station

Tightening torquesm

multifunction support

bolts 1 and 2 (initial

torque)5 N.m

multifunction support

bolt 7 on the cylinder

block (initial torque)5 N.m

multifunction support

bolts 6, 5, 4 and 35 N.m

multifunction support

bolts44 N.m

multifunction support

bolt on the cylinder

block25 N.m

Page 79 of 652

10A-73

ENGINE AND CYLINDER BLOCK ASSEMBLY

Multifunction support: Removal - Refitting

K4M

10A

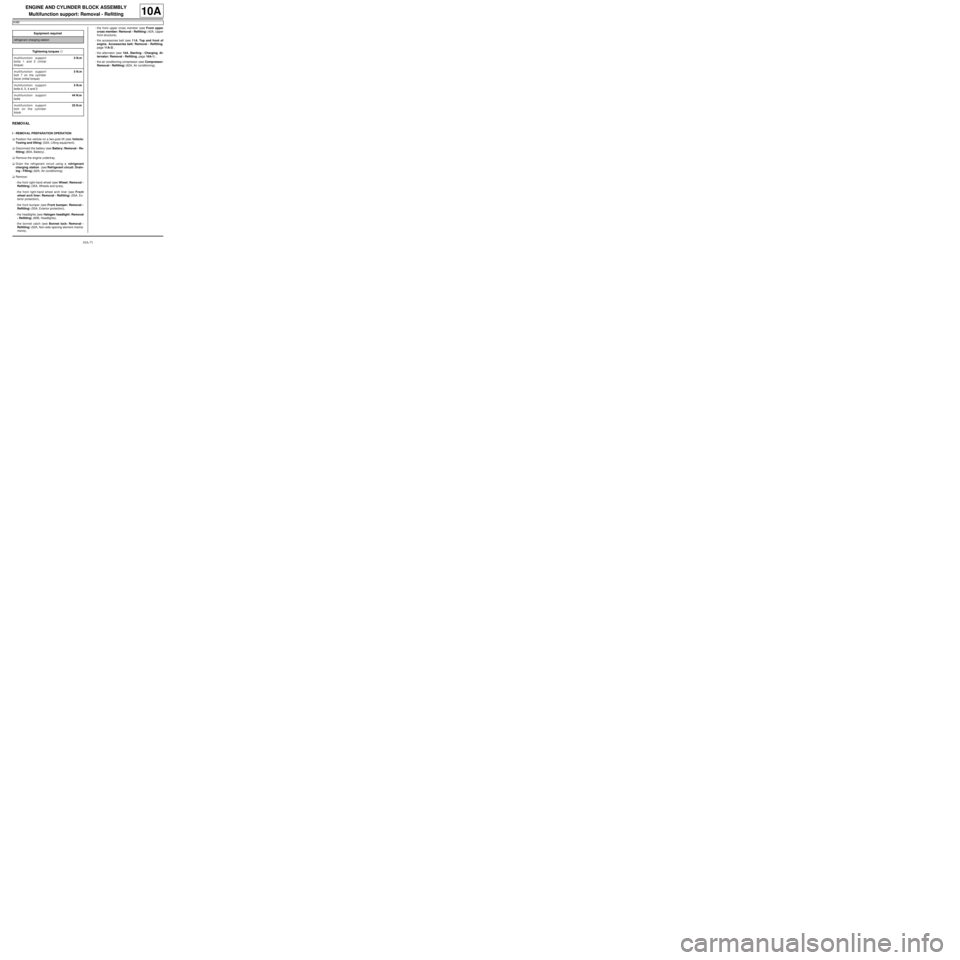

REFITTING

I - REFITTING OPERATION

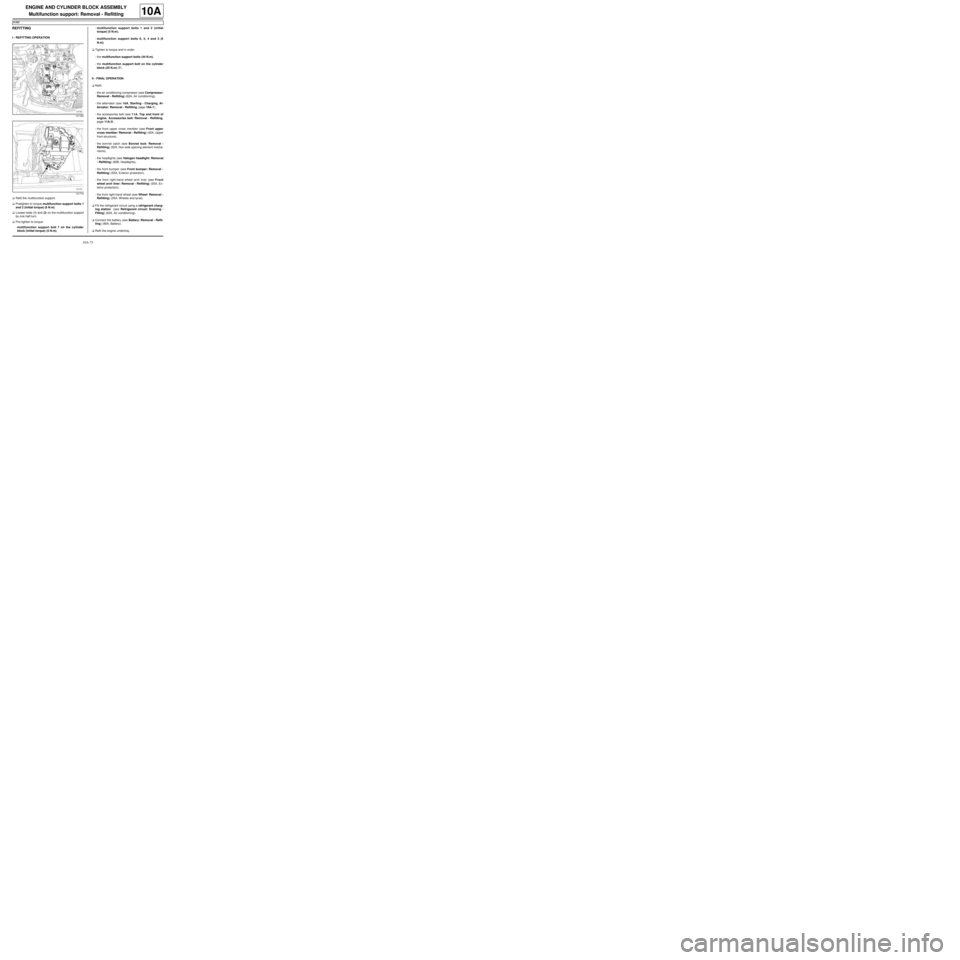

aRefit the multifunction support.

aPretighten to torque multifunction support bolts 1

and 2 (initial torque) (5 N.m).

aLoosen bolts (1) and (2) on the multifunction support

by one half-turn.

aPre-tighten to torque:

-multifunction support bolt 7 on the cylinder

block (initial torque) (5 N.m),-multifunction support bolts 1 and 2 (initial

torque) (5 N.m),

-multifunction support bolts 6, 5, 4 and 3 (5

N.m).

aTighten to torque and in order:

-the multifunction support bolts (44 N.m),

-the multifunction support bolt on the cylinder

block (25 N.m) (7) .

II - FINAL OPERATION

aRefit:

-the air conditioning compressor (see Compressor:

Removal - Refitting) (62A, Air conditioning),

-the alternator (see 16A, Starting - Charging, Al-

ternator: Removal - Refitting, page 16A-1) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aFill the refrigerant circuit using a refrigerant charg-

ing station (see Refrigerant circuit: Draining -

Filling) (62A, Air conditioning).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aRefit the engine undertray.

131780

131779

Page 102 of 652

10A-96

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K4M

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aRemove the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aRemove:

-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the engine undertray,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

aDrain:

-the gearbox (see Manual gearbox oils: Draining -

Filling) (21A, Manual gearbox),-the cooling system (see 19A, Cooling, Cooling

system: Draining - Refilling, page 19A-9) ,

-the engine, if necessary (see 10A, Engine and

cylinder block assembly, Engine oil: Draining -

Refilling, page 10A-22) ,

-the refrigerant circuit using a refrigerant charging

station (see Refrigerant circuit: Draining - Fill-

ing) (62A, Air conditioning).

aAttach the « engine cooling radiator - condenser »

assembly to the front upper cross member.

aRemove:

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) ,

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the radiator mounting cross member (see Radiator

mounting cross member: Removal - Refitting)

(41A, Front lower structure),

-the front left-hand wheel driveshaft (see Front left-

hand driveshaft: Removal - Refitting) (29A,

Driveshafts),

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the differential output seal (see Differential output

seal: Removal - Refitting) (21A, Manual gear-

box).

aRemove the catalytic converter (see 19B, Exhaust,

Catalytic converter: Removal - Refitting, page

19B-12) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

refrigerant charging station

Tightening torquesm

rubber pad mounting

bolts for the suspended

engine mounting on the

gearbox21 N.m

bolts of the suspended

mounting r ubber pad62 N.m

suspended engine

mounting shaft nut62 N.m