Undertray RENAULT TWINGO RS 2009 2.G Engine And Peripherals Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 492 of 652

17B-17

PETROL INJECTION

Oxygen sensors: Removal - Refitting

K4M

17B

REMOVING THE UPSTREAM OXYGEN

SENSOR

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the engine undertray.

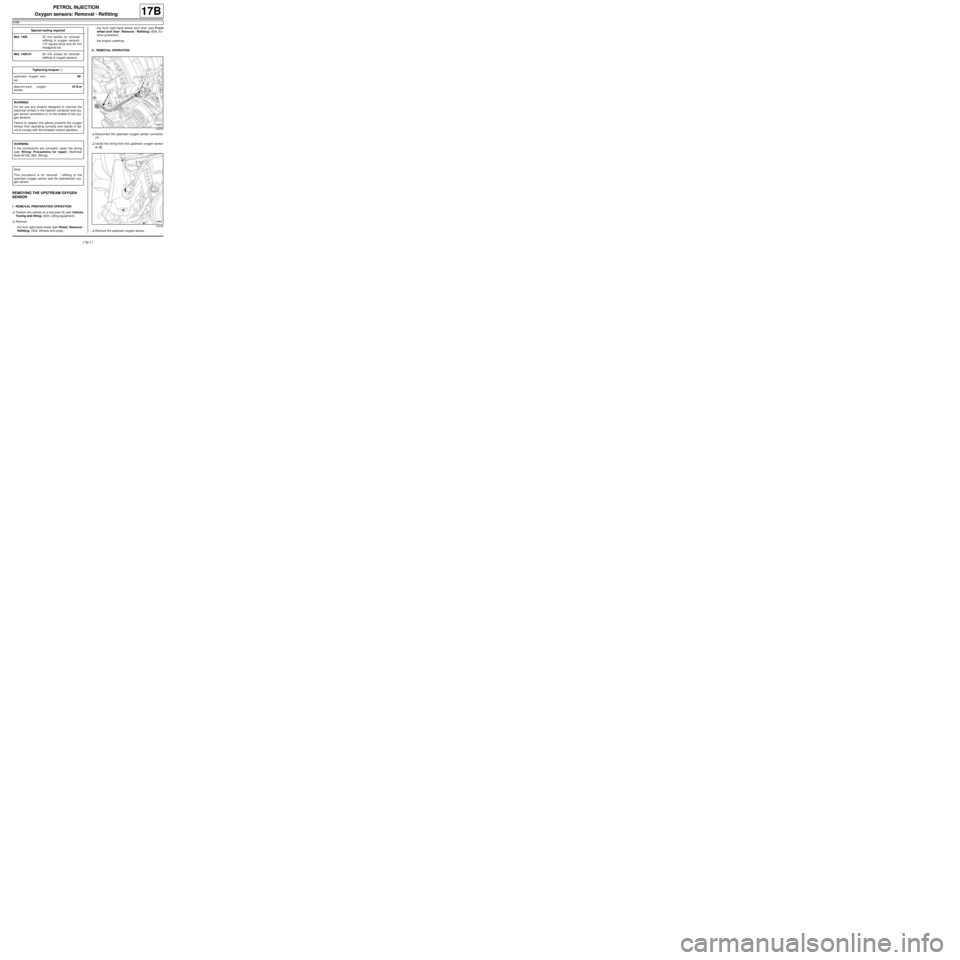

II - REMOVAL OPERATION

aDisconnect the upstream oxygen sensor connector

(1) .

aUnclip the wiring from the upstream oxygen sensor

at (2) .

aRemove the upstream oxygen sensor . Special tooling required

Mot. 149522 mm socket for removal -

refitting of oxygen sensors -

1/2" square dr ive and 24 mm

hexagonal ext.

Mot. 1495-0122 mm socket for removal -

refitting of oxygen sensors.

Tightening torquesm

upstream oxygen sen-

sor90˚

downstream oxygen

sensor45 N.m

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice prevents the oxygen

sensor from operating correctly and results in fail-

ure to comply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical

Note 6015A, 88A, Wiring).

Note:

This procedure is for removal - refitting of the

upstream oxygen sensor and the downstream oxy-

gen sensor.

132373

132539

Page 493 of 652

17B-18

PETROL INJECTION

Oxygen sensors: Removal - Refitting

K4M

17B

REFITTING THE UPSTREAM OXYGEN

SENSOR

I - REFITTING PREPARATION OPERATION

aClean the threading of the upstream oxygen sensor

using a WIRE BRUSH.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the thread hole of the upstream oxygen sensor on

the exhaust manifold,

-the threading of the upstream oxygen sensor if it is

to be reused.

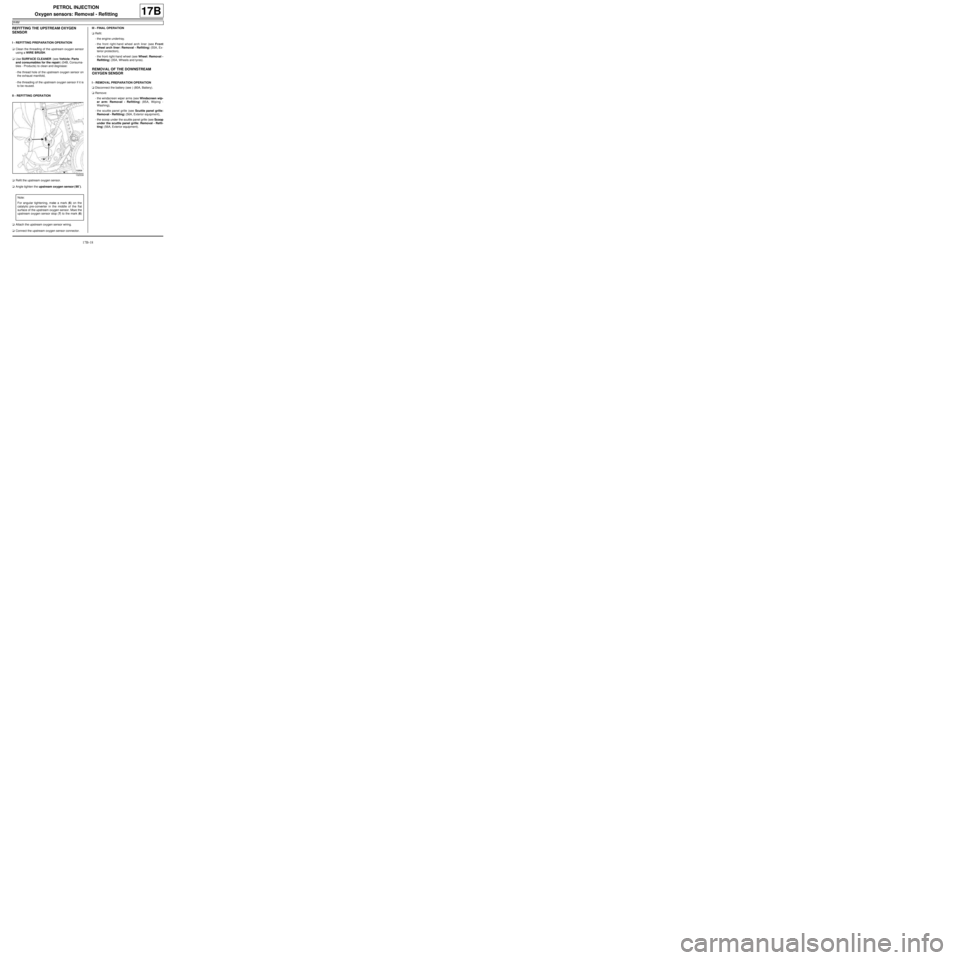

II - REFITTING OPERATION

aRefit the upstream oxygen sensor.

aAngle tighten the upstream oxygen sensor ( 90˚).

aAttach the upstream oxygen sensor wiring.

aConnect the upstream oxygen sensor connector.III - FINAL OPERATION

aRefit:

-the engine undertray.

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

REMOVAL OF THE DOWNSTREAM

OXYGEN SENSOR

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

132539

Note:

For angular tightening, make a mark (6) on the

catalytic pre-converter in the middle of the flat

surface of the upstream oxygen sensor. Move the

upstream oxygen sensor stop (7) to the mark (6)

.

Page 501 of 652

17B-26

PETROL INJECTION

Crankshaft position sensor: Removal - Refitting

K4M

17B

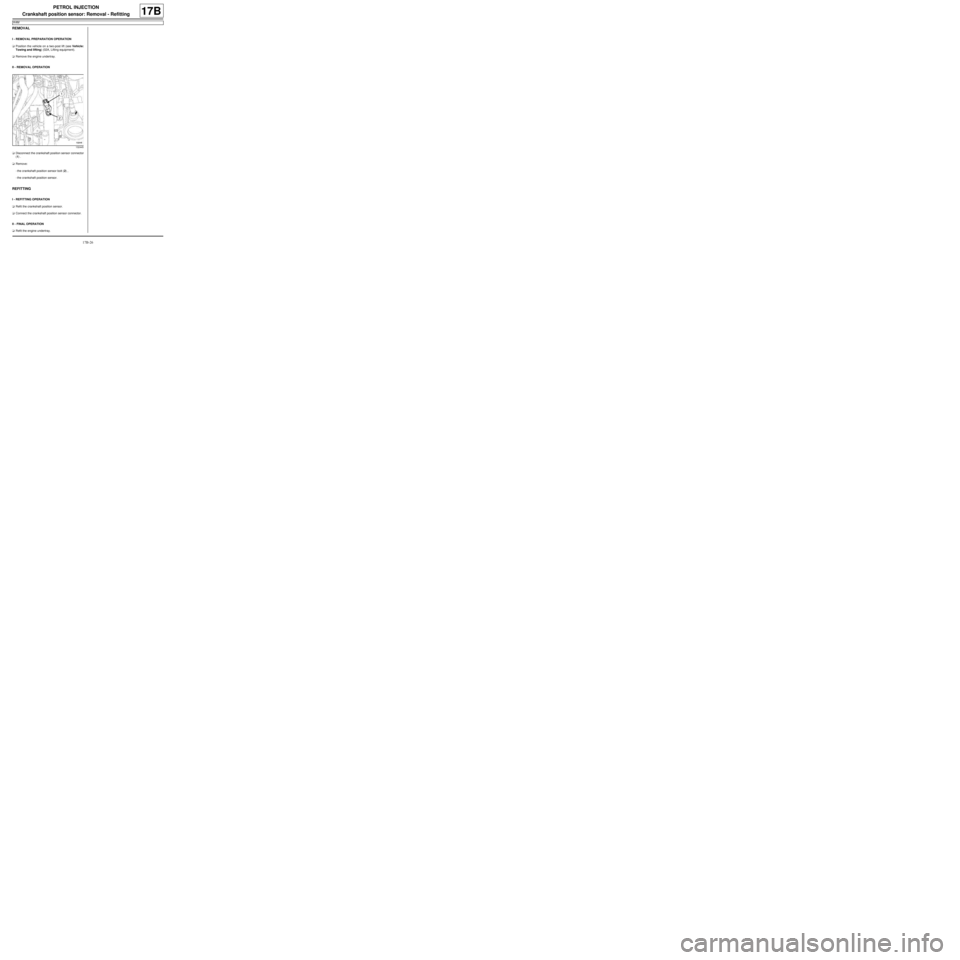

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the engine undertray.

II - REMOVAL OPERATION

aDisconnect the crankshaft position sensor connector

(1) .

aRemove:

-the crankshaft position sensor bolt (2) ,

-the crankshaft position sensor.

REFITTING

I - REFITTING OPERATION

aRefit the crankshaft position sensor.

aConnect the crankshaft position sensor connector.

II - FINAL OPERATION

aRefit the engine undertray.

132445

Page 519 of 652

19A-9

COOLING

Cooling system: Draining - Refilling

D4F or D7F or K4M or K9K

19A

a

I - DRAINING

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the expansion bottle cap.aRemove the engine undertray.

aPosition the coolant recovery tray under the vehi-

cle.

aRemove the cooling radiator bottom hose clip using

the tool (Mot. 1202-01) or (Mot. 1202-02) or (Mot.

1448).

aOpen the cooling system by removing the cooling ra-

diator bottom hose using the tool (Car. 1363).

aUse a compressed air nozzle to blow air into the

system through the expansion bottle opening to re-

move as much coolant as possible.

II - CLEANING

aFill the cooling system with water through the expan-

sion bottle.

aLet the water run until the water collected by the

cooling radiator bottom hose becomes clear.

aUse a compressed air nozzle to blow air into the

circuit through the expansion bottle opening to re-

move as much water as possible.

aRefit the hose which was removed.

III - FILLING

a

1 - Filling procedure with the tool (Mot. 1700)

aFill the cooling system with engine coolant recom-

mended by the manufacturer (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) using the tool (Mot. 1700).

For the use of this tool (see Cooling system filling

and diagnostic tool: Use) (NT 3857A, 19A, Cool-

ing). Special tooling required

Mot. 1202-01Clip pliers for hose clips

(large size).

Mot. 1202-02Clip pliers for hose clips

(small size)

Mot. 1448Remote operation pliers for

hose clips .

Car. 1363Set of tr im removal levers.

Mot. 1700Fault finding and filling -

bleeding the cooling circuit.

Ms. 554-07Instr ument for testing the

cooling circuit and the expan-

sion bottle valve. Contains

caps 554-01, 554-04, 554-06

Equipment required

coolant recovery tray

compressed air nozzle

pedal press

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unex-

pectedly (risk of being cut).

To avoid any risk of serious burns when the

engine is hot:

-do not open the expansion bottle cap,

-do not dr ain the cooling system,

-do not open the bleed screw(s).

WARNING

Before the operation, protect the electrical acces-

sories to prevent any risk of short circuiting and

protect the belts to avoid damaging them.

K4M

Note:

There are two procedures for filling the cooling

system:

-the method using the (Mot. 1700) tool is recom-

mended by Renault. It saves a considerable

amount of time because it does not require the

cooling system bleed screws to be opened,

-the procedure without a special tool.

Page 521 of 652

19A-11

COOLING

Cooling system: Draining - Refilling

D4F or D7F or K4M or K9K

19A

aMaintain the engine speed at 1500 rpm, sharply

varying the engine speed (up to the maximum) 2 to

3 times approximately every 2 minutes until the fan

assembly starts for the second time.

aMaintain the engine speed at 3000 rpm using a ped-

al press, until the fan assembly has been activated

for a third time.

aCheck that the heating is operating correctly.

aAllow the engine to cool until the engine coolant tem-

perature is less than 50˚C.

aRemove the expansion bottle cap.

aAdjust the coolant fluid level to the "Max" mark.

aRefit the expansion bottle cap.

V - FINAL OPERATION

aRemove the coolant recovery tray.

aRefit the engine undertray. K9K

K4M

K4M

Page 530 of 652

19A-20

COOLING

Cooling radiator: Removal - Refitting

K4M

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aDrain the air conditioning circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove:

-the engine undertray bolts,

-the engine undertray,

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

refrigerant charging station

safety strap(s)

Tightening torquesm

bolt of the dehydrator

reservoir - « expansion

valve connecting pipe » 8 N.m

compressor - con-

denser « connecting

pipe bolt » 8 N.m

air conditioning connect-

ing pipe bolts8 N.m

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

WARNING

When carr ying out a repair that requires a complete

change, it is essential to flush the circuit with clean

water, blast compressed air through the circuit to

drive out the water, fill and bleed the circuit and

then measure the effective protection.

The cr iteria to be met are:

-protection down to -25˚C ±± ± ±

2 for cold and temper-

ate countries,

-protection down to -40˚C ±± ± ±

2 for "extreme cold"

countries.

Page 533 of 652

19A-23

COOLING

Cooling radiator: Removal - Refitting

K4M

19A

aPerform the following operations:

-fill the air conditioning circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning),

-fill and bleed the coolant circuit (see 19A, Cooling,

Cooling system: Draining - Refilling, page 19A-

9) .

aRefit the engine undertray.

Page 540 of 652

19A-30

COOLING

Coolant pump: Removal - Refitting

K4M

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).aRemove:

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the throttle valve (see 12A, Fuel mixture, Throttle

valve: Removal - Refitting, page 12A-20) ,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the camshaft dephaser (see 11A, Top and front of

engine, Camshaft dephaser: Removal - Refit-

ting, page 11A-135) . Tightening torquesm

bolt 1 of the coolant

pump27 N.m

bolts 2 to 8 of the water

pump10 N.m

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

WARNING

When carr ying out a repair that requires a complete

change, it is essential to flush the circuit with clean

water, blast compressed air through the circuit to

drive out the water, fill and bleed the circuit and

then measure the effective protection.

The cr iteria to be met are:

-protection down to -25˚C ±± ± ±

2 for cold and temper-

ate countries,

-protection down to -40˚C ±± ± ±

2 for "extreme cold"

countries.

Page 543 of 652

19A-33

COOLING

Coolant pump: Removal - Refitting

K4M

19A

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the throttle valve (see 12A, Fuel mixture, Throttle

valve: Removal - Refitting, page 12A-20) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aRefit the engine undertray.

Page 558 of 652

19A-48

COOLING

Water chamber: Removal - Refitting

K4M

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the engine undertray.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Mot. 1202-01Clip pliers for hose clips

(large size).

Mot. 1202-02Clip pliers for hose clips

(small size)

Tightening torquesm

water chamber bolts

(initial torque)4 N.m

water chamber bolts12 N.m

heater matrix hose

bracket bolt10 N.m

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

When carr ying out a repair that requires a complete

change, it is essential to flush the circuit with clean

water, blast compressed air through the circuit to

drive out the water, fill and bleed the circuit and

then measure the effective protection.

The cr iteria to be met are:

-protection down to -25˚C ±± ± ±

2 for cold and temper-

ate countries,

-protection down to -40˚C ±± ± ±

2 for "extreme cold"

countries.

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.