wiring RENAULT TWINGO RS 2009 2.G Engine And Peripherals User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 118 of 652

11A-1

TOP AND FRONT OF ENGINE

Pressure at end of compression: Check

K4M

11A

CHECK

I - PREPARATION OPERATION FOR CHECK

aRemove:

-the coils (see 17A, Ignition, Coils: Removal - Re-

fitting, page 17A-1) ,

-the spark plugs (see 17A, Ignition, Plugs: Re-

moval - Refitting, page 17A-12) .

aDisconnect the injector wiring connector (1) .aConnect a petrol compression gauge (2) .

aPut the vehicle under the starting conditions by posi-

tioning the gear lever in neutral.

II - TEST OPERATION

aActivate the starter until the needle of the petrol

compression gauge stabilises.

aMeasure the cylinder compressions, cylinder by cyl-

inder.

aFully depress the accelerator pedal in order to open

the throttle valve during the compression measure-

ments.

III - FINAL OPERATION

aDisconnect the petrol compression gauge.

aConnect the injector wiring connector.

aRefit:

-the spark plugs (see 17A, Ignition, Plugs: Re-

moval - Refitting, page 17A-12) ,

-the coils (see 17A, Ignition, Coils: Removal - Re-

fitting, page 17A-1) . Equipment required

petrol compression gauge

132371

132338

Note:

It is necessar y to wait for at least 10 seconds

before starting the engine each time (the starter

will not run due to its ther mal protection).

Page 123 of 652

11A-6

TOP AND FRONT OF ENGINE

Accessories belt: Removal - Refitting

K9K, and AIR CONDITIONING

11A

aRemove the accessories belt, passing it over its slot

between the RH side member and the crankshaft

accessories and air conditioning compressor pul-

leys.

aDiscard the accessories belt

2 - Removing the tensioning roller

a

aRaise the engine using the (Mot. 1672).

aDisconnect the connector on the alternator.

aRemove the nut from the alternator harness.

aMove the alternator harness to one side.

aRemove the alternator upper bolt.

aLoosen the alternator lower bolt.

aRemove:

-the alternator with its lower bolt fitted,

-the tensioning roller bolt,

-the tensioning roller.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

1 - Refit the tensioning roller

aRefit:

-the new tensioning roller,

-the new tensioning roller bolt.

aTorque tighten the tensioning roller bolt (40 Nm).

aRefit:

-the alternator with its lower bolt fitted,

-the alternator upper bolt.

aTorque tighten the alternator bolts (25 Nm).

aFit the alternator harness.aRefit the nut to the alternator wiring harness.

aAttach the connector to the alternator.

2 - Refit the accessories belt

aLower the engine using the (Mot. 1672).

aPartially refit the new accessories belt, passing it

over its slot between the RH side member and the

crankshaft accessories and air conditioning com-

pressor pulleys.

aRaise the engine using the (Mot. 1672).

aFit the belt on the crankshaft accessories, air condi-

tioning compressor and tensioning roller pulleys.

aSwing the accessories belt auto tensioner clockwise

using a ratchet, an extension and a 16 mm socket

aFit the belt on the alternator pulley, passing it over its

slot between the headlight carrier panel and the al-

ternator pulley.

aGently release the tensioning roller.

aCheck that the accessories belt is correctly mounted

on the crankshaft accessories, air conditioning com-

pressor and alternator pulleys.

aTurn the engine two revolutions.

aCheck that the accessories belt is correctly mounted

on the crankshaft accessories, air conditioning com-

pressor, alternator and tensioning roller pulleys.

aAdjust the engine using the (Mot. 1672) to restore

the engine's approximate original position.

II - FINAL OPERATION.

aRefit:

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) .

-the air conditioning pipe clip onto the right-hand

headlight carrier panel, Note:

Shift the engine forwards or backwards slightly

by hand if necessary to facilitate removing the

accessories belt.

Note:

The tensioning roller must be replaced every

time the accessories belt is replaced.

Note:

Shift the engine forwards or backwards slightly

by hand if necessary, to facilitate refitting the

accessor ies belt.

Note:

Shift the engine forwards slightly by hand to facil-

itate setting up the tools.

Page 128 of 652

11A-11

TOP AND FRONT OF ENGINE

Accessories belt: Removal - Refitting

K9K, and STANDARD HEATING

11A

aRemove:

-the multifunction support bolts from the cylinder

block,

-the multifunction support bolt from the sump,

-the equipped multifunction support.

aPlace the multifunction support in a vice.

aRemove:

-the tensioning roller bolt,

-the tensioning roller,

-the air conditioning compressor substitute pulley

bolts,

-the air conditioning compressor substitute pulley.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

1 - Refit the tensioning roller

aPlace the multifunction support in a vice.

aRefit:

-the new air conditioning compressor substitute pul-

ley.

-the air conditioning compressor substitute pulley

bolts,

-the new tensioning roller,

-the tensioning roller bolt,

aTorque tighten:

-the air conditioning compressor substitute pul-

ley bolts (25 Nm),

-the tensioning roller bolt (40 Nm),

aRefit:

-the equipped multifunction support,

-the multifunction support bolt onto the sump,

-the multifunction support bolts onto the cylinder

block.aTighten to torque and in order:

-the bolts mounting the multifunction support

on the cylinder block (44 Nm),

-the bolt mounting the multifunction support on

the sump (25 Nm).

aRefit:

-the alternator with its lower bolt fitted,

-the alternator upper bolt.

aTorque tighten the alternator bolts (25 Nm).

aPosition the alternator wiring harness.

aRefit the nut to the alternator wiring harness.

aAttach the connector to the alternator.

2 - Refit the accessories belt

aPartially refit the new accessories belt:

-positioning it between the air conditioning com-

pressor substitute pulley and the multifunction sup-

port,

-passing it over its slot between the RH side mem-

ber and the crankshaft accessories, tensioning roll-

er and alternator pulleys.

aTurn the accessories belt auto tensioner clockwise

using a 16 mm spanner

aFit the belt on the air conditioning compressor sub-

stitute pulley.

aGently release the tensioning roller.

120315

Page 134 of 652

11A-17

TOP AND FRONT OF ENGINE

Accessories belt: Removal - Refitting

K4M

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

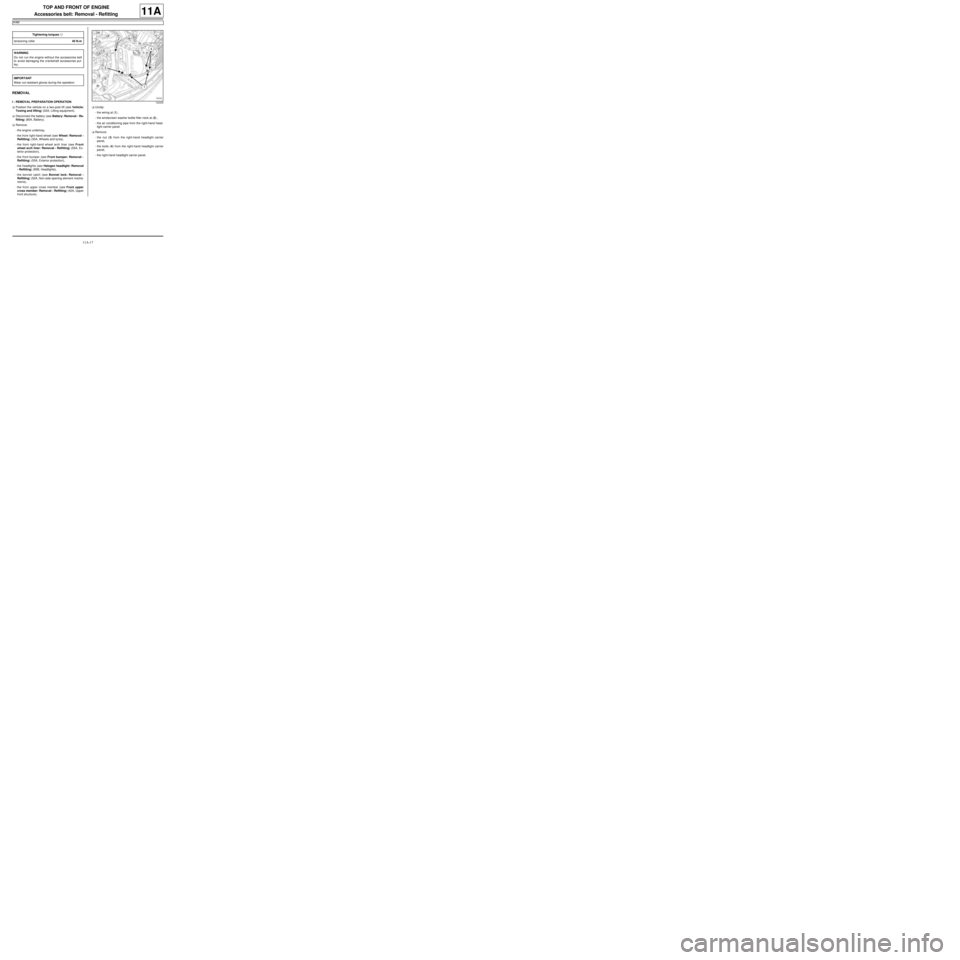

front structure).aUnclip:

-the wiring at (1) ,

-the windscreen washer bottle filler neck at (2) ,

-the air conditioning pipe from the right-hand head-

light carrier panel.

aRemove:

-the nut (3) from the right-hand headlight carrier

panel,

-the bolts (4) from the right-hand headlight carrier

panel,

-the right-hand headlight carrier panel. Tightening torquesm

tensioning roller40 N.m

WARNING

Do not r un the engine without the accessories belt

to avoid damaging the crankshaft accessories pul-

ley.

IMPORTANT

Wear cut-resistant gloves during the operation.132339

Page 135 of 652

11A-18

TOP AND FRONT OF ENGINE

Accessories belt: Removal - Refitting

K4M

11A

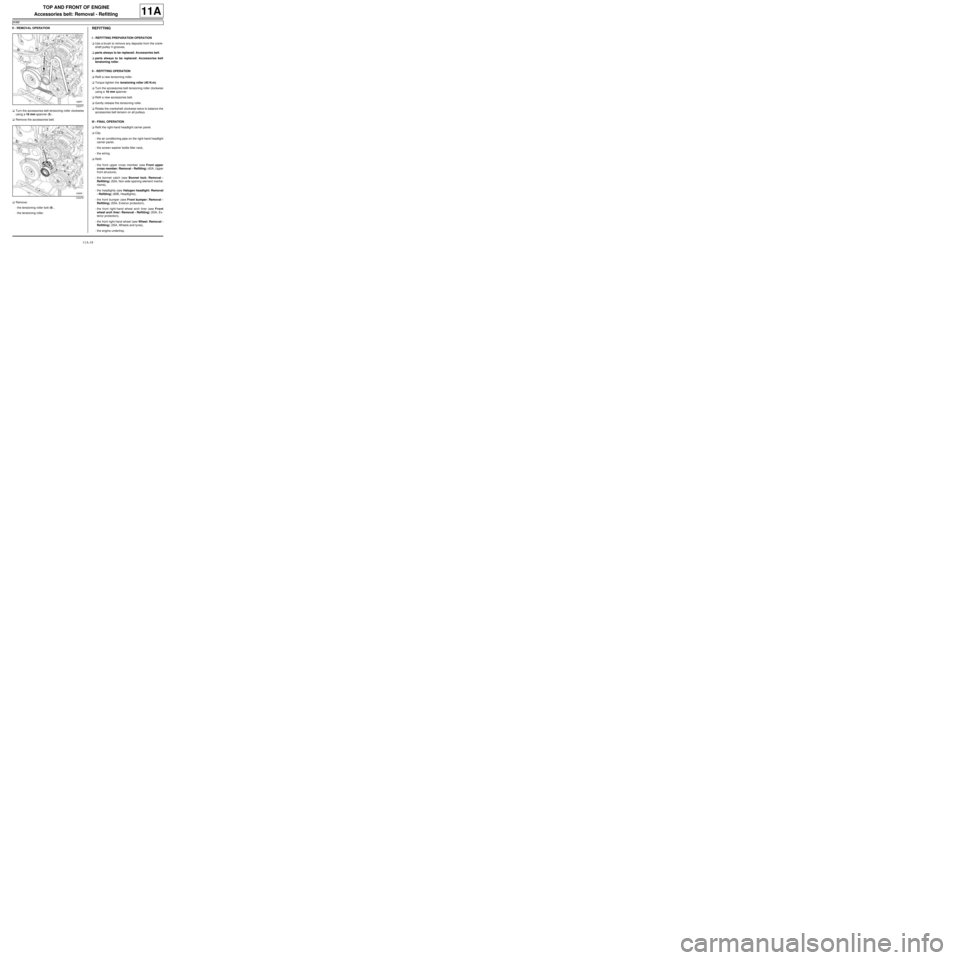

II - REMOVAL OPERATION

aTurn the accessories belt tensioning roller clockwise

using a 16 mm spanner (5) .

aRemove the accessories belt.

aRemove:

-the tensioning roller bolt (6) ,

-the tensioning roller.REFITTING

I - REFITTING PREPARATION OPERATION

aUse a brush to remove any deposits from the crank-

shaft pulley V-grooves.

aparts always to be replaced: Accessories belt.

aparts always to be replaced: Accessories belt

tensioning roller.

II - REFITTING OPERATION

aRefit a new tensioning roller.

aTorque tighten the tensioning roller (40 N.m).

aTurn the accessories belt tensioning roller clockwise

using a 16 mm spanner.

aRefit a new accessories belt.

aGently release the tensioning roller.

aRotate the crankshaft clockwise twice to balance the

accessories belt tension on all pulleys.

III - FINAL OPERATION

aRefit the right-hand headlight carrier panel.

aClip:

-the air conditioning pipe on the right-hand headlight

carrier panel,

-the screen washer bottle filler neck,

-the wiring.

aRefit:

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray.

132377

132376

Page 149 of 652

11A-32

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

D4F

11A

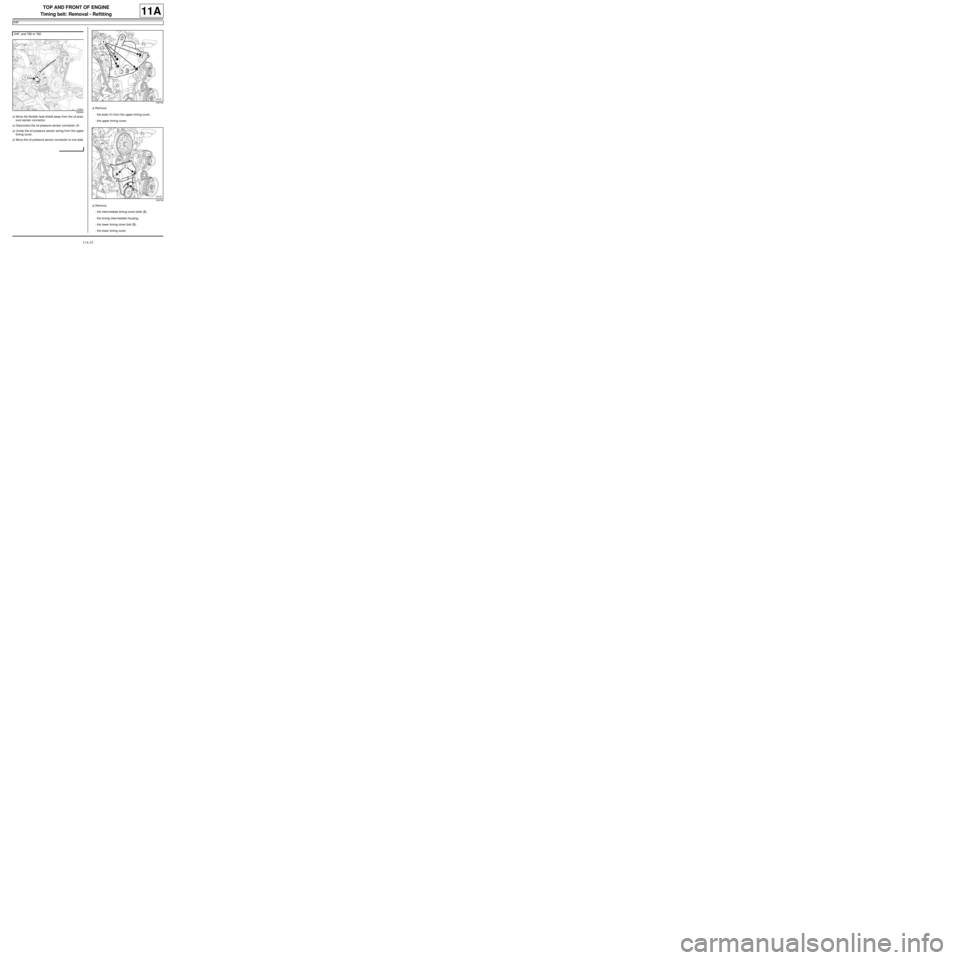

aMove the flexible heat shield away from the oil pres-

sure sensor connector.

aDisconnect the oil pressure sensor connector (1) .

aUnclip the oil pressure sensor wiring from the upper

timing cover.

aMove the oil pressure sensor connector to one side.aRemove:

-the bolts (1) from the upper timing cover,

-the upper timing cover.

aRemove:

-the intermediate timing cover bolts (2) ,

-the timing intermediate housing,

-the lower timing cover bolt (3) ,

-the lower timing cover. D4F, and 780 or 782

122664

109740

109739

Page 154 of 652

11A-37

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

D4F

11A

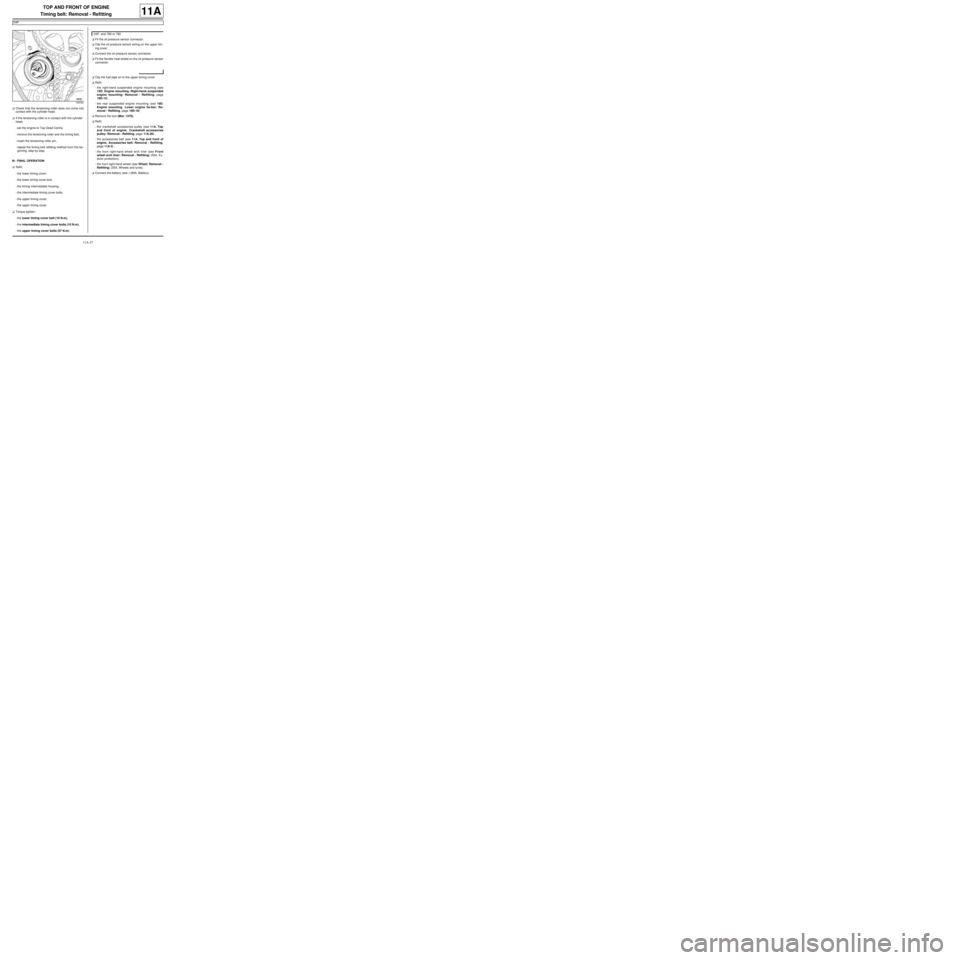

aCheck that the tensioning roller does not come into

contact with the cylinder head.

aIf the tensioning roller is in contact with the cylinder

head:

-set the engine to Top Dead Centre,

-remove the tensioning roller and the timing belt,

-insert the tensioning roller pin,

-repeat the timing belt refitting method from the be-

ginning, step by step.

III - FINAL OPERATION

aRefit:

-the lower timing cover,

-the lower timing cover bolt,

-the timing intermediate housing,

-the intermediate timing cover bolts,

-the upper timing cover,

-the upper timing cover.

aTorque tighten:

-the lower timing cover bolt (10 N.m),

-the intermediate timing cover bolts (10 N.m),

-the upper timing cover bolts (37 N.m)aFit the oil pressure sensor connector.

aClip the oil pressure sensor wiring on the upper tim-

ing cover.

aConnect the oil pressure sensor connector.

aFit the flexible heat shield on the oil pressure sensor

connector.

aClip the fuel pipe on to the upper timing cover.

aRefit:

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the rear suspended engine mounting (see 19D,

Engine mounting, Lower engine tie-bar: Re-

moval - Refitting, page 19D-18) .

aRemove the tool (Mot. 1379).

aRefit:

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aConnect the battery (see ) (80A, Battery).

109765

D4F, and 780 or 782

Page 171 of 652

11A-54

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K4M

11A

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aRemove:

-the rear suspended engine mounting bolt (1) from

the subframe,

-the rear suspended engine mounting bolt (2) from

the rear suspended engine mounting support,

-the rear suspended engine mounting reinforce-

ment bolt (3) ,

-the rear suspended engine mounting,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) .aDisconnect the upstream oxygen sensor connector

(4) .

aUnclip the wiring from the upstream oxygen sensor

at (5) .

aMove the upstream oxygen sensor wiring aside.

aUnclip the connector (6) from the lifting eye.

aRemove the lifting eye bolts (7) .

131769

132373

103271

Page 181 of 652

11A-64

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K4M

11A

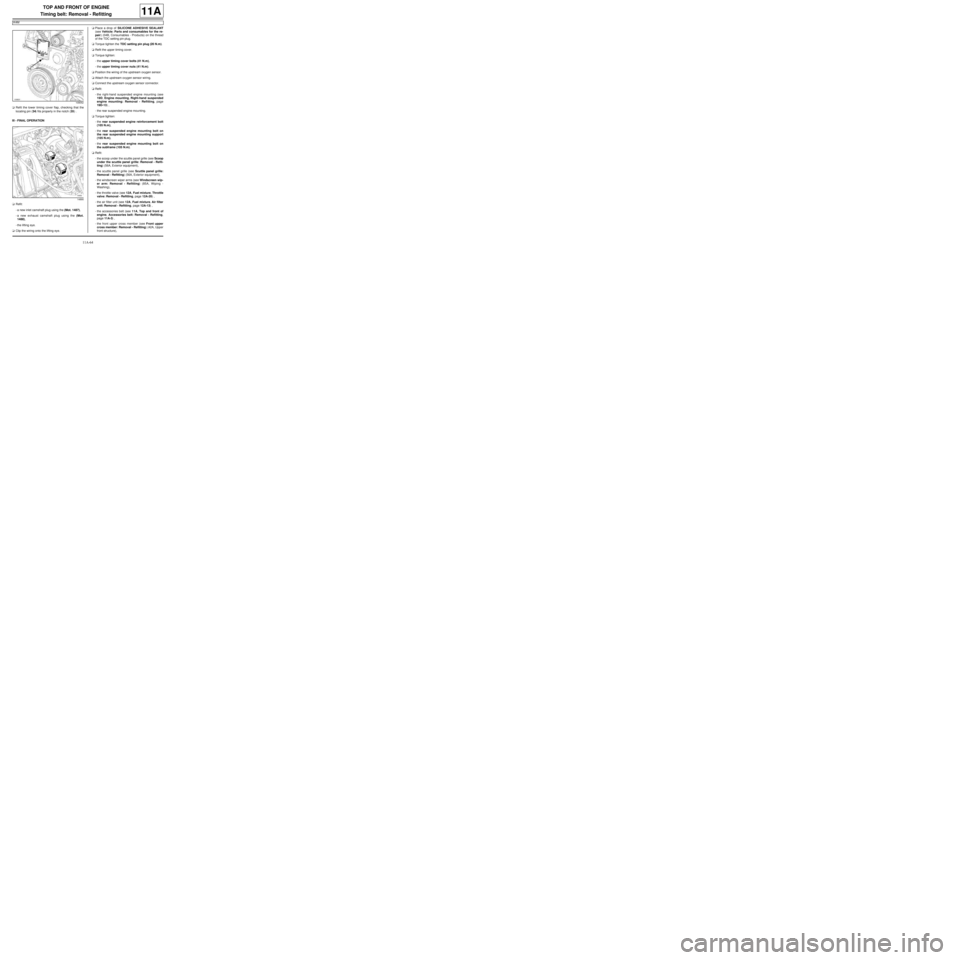

aRefit the lower timing cover flap, checking that the

locating pin (34) fits properly in the notch (35) .

III - FINAL OPERATION

aRefit:

-a new inlet camshaft plug using the (Mot. 1487),

-a new exhaust camshaft plug using the (Mot.

1488),

-the lifting eye.

aClip the wiring onto the lifting eye.aPlace a drop of SILICONE ADHESIVE SEALANT

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products) on the thread

of the TDC setting pin plug.

aTorque tighten the TDC setting pin plug (20 N.m).

aRefit the upper timing cover.

aTorque tighten:

-the upper timing cover bolts (41 N.m),

-the upper timing cover nuts (41 N.m).

aPosition the wiring of the upstream oxygen sensor.

aAttach the upstream oxygen sensor wiring.

aConnect the upstream oxygen sensor connector.

aRefit:

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the rear suspended engine mounting.

aTorque tighten:

-the rear suspended engine reinforcement bolt

(105 N.m),

-the rear suspended engine mounting bolt on

the rear suspended engine mounting support

(105 N.m),

-the rear suspended engine mounting bolt on

the subframe (105 N.m).

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the throttle valve (see 12A, Fuel mixture, Throttle

valve: Removal - Refitting, page 12A-20) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

109052

14890

Page 186 of 652

11A-69

TOP AND FRONT OF ENGINE

Rocker cover: Removal - Refitting

D4F, and 772

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-the ignition coil (see 17A, Ignition, Coils: Remov-

al - Refitting, page 17A-1) .

aUnclip the rocker cover electric wiring harnesses.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the rocker cover bolts,

-the rocker cover,

-the rocker cover gasket.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the joint faces with SUPER CLEANER FOR

JOINT FACES (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts) to dissolve any part of the seal still adhering.

aparts always to be replaced: rocker cover seal.

110422

WARNING

Do not allow this product to dr ip onto the paint-

work.

Clean the cylinder head carefully to prevent for-

eign bodies from entering the oil supply and

return galleries.

Failure to follow this advice could lead to the

blocking of the various oil inlet galleries, which

would quickly result in engine damage.