wiring RENAULT TWINGO RS 2009 2.G Engine And Peripherals Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 385 of 652

13B-24

DIESEL INJECTION

High pressure pump: Removal - Refitting

K9K

13B

aRefit the lower timing cover.

aRefit the accessories belt (see 11A, Top and front

of engine, Accessories belt: Removal - Refitting,

page 11A-3)

aRefit:

-the upper timing cover,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) .

aRemove the blanking plugs.

aRefit a high pressure pipe between the pump and

the rail (see 13B, Diesel injection, High pressure

pipe between pump and rail: Removal - Refitting,

page 13B-35) .

aConnect the diesel return pipe to the venturi fitted to

the high pressure pump.aRefit:

-the fuel filter mounting,

-the fuel filter (see 13A, Fuel supply, Fuel filter:

Removal - Refitting, page 13A-4) .

aRefit:

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) ,

-the engine harness channel.

aFit the engine wiring on the engine wiring channel.

aClip on the engine wiring channel.

aConnect to the high pressure pump:

-the diesel supply pipe,

-the diesel return pipe to the diesel filter.

aClip on the high pressure pump pipes.

aRemove the protection on the alternator to prevent

fuel flowing out.

aConnect the connectors of:

-the diesel temperature sensor,

-the flow actuator,

-the injectors,

-the heater plugs.

aRemove the blanking cover which protects the oil

level dipstick guide inlet opening on the cylinder

block.

aRefit:

-the dipstick guide,

-the dipstick,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing).

aPrime the fuel circuit with a manual priming pump

until the disconnected pipes are filled with fuel; if

necessary, bleed the fuel filter (see 13A, Fuel sup-

ply, Fuel filter: Removal - Refitting, page 13A-4) .

aCheck that there are no fuel leaks.

aConnect the battery (see ) (80A, Battery). K9K, and 740

19659

Note:

Make sure that the tab (23) is positioned oppo-

site the mark (24) .

Page 388 of 652

13B-27

DIESEL INJECTION

Flow actuator: Removal - Refitting

K9K

13B

aClean the diesel pipe unions on the high pressure

pump (see 13B, Diesel injection, Diesel injection:

Precautions for the repair, page 13B-1) .

aUnclip the fuel supply pipes at (2) .

aDisconnect the high pressure pump from:

-the diesel supply pipe (3) ,

-the diesel return pipe (4) to the diesel filter.

aRemove the high pressure pump pipes.aUnclip the neck at (5) .

aRemove the neck wiring harness.

aRemove:

-the neck nut (6) ,

-the neck.

aClean the high pressure pipe unions (7) between the

rail and injector number 4 (see 13B, Diesel injec-

tion, Diesel injection: Precautions for the repair,

page 13B-1) .

121423

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

To prevent impurities from entering the circuit,

plugs must be fitted to the openings of all the fuel

circuit components exposed to the open air.121419

121418

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to r un.

Page 390 of 652

13B-29

DIESEL INJECTION

Flow actuator: Removal - Refitting

K9K

13B

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

a

aFit the fuel flow actuator onto the high pressure

pump.

aTighten the fuel flow actuator bolts on the high pres-

sure pump until contact is made, without tightening

them.

aTorque tighten the fuel flow actuator bolts on the

high pressure pump (6 Nm).II - FINAL OPERATION.

a

aFit a new high pressure pipe between the rail and in-

jector number 4.

aFit the high pressure pipe unions between the rail

and injector number 4 until contact is made, without

tightening them.

aFit and lock a new clip between the high pressure

pipes on the rail and injectors number 3 and 4.

aUsing the (Mot. 1746), tighten to torque:

-the high pressure pipe unions between the rail

and injector number 4 (yellow) (24 Nm),

-the high pressure pipe unions between the rail

and injector number 4 (silver) (28 Nm).

aRefit:

-the channel,

-the neck nut.

aFit the neck wiring harness.

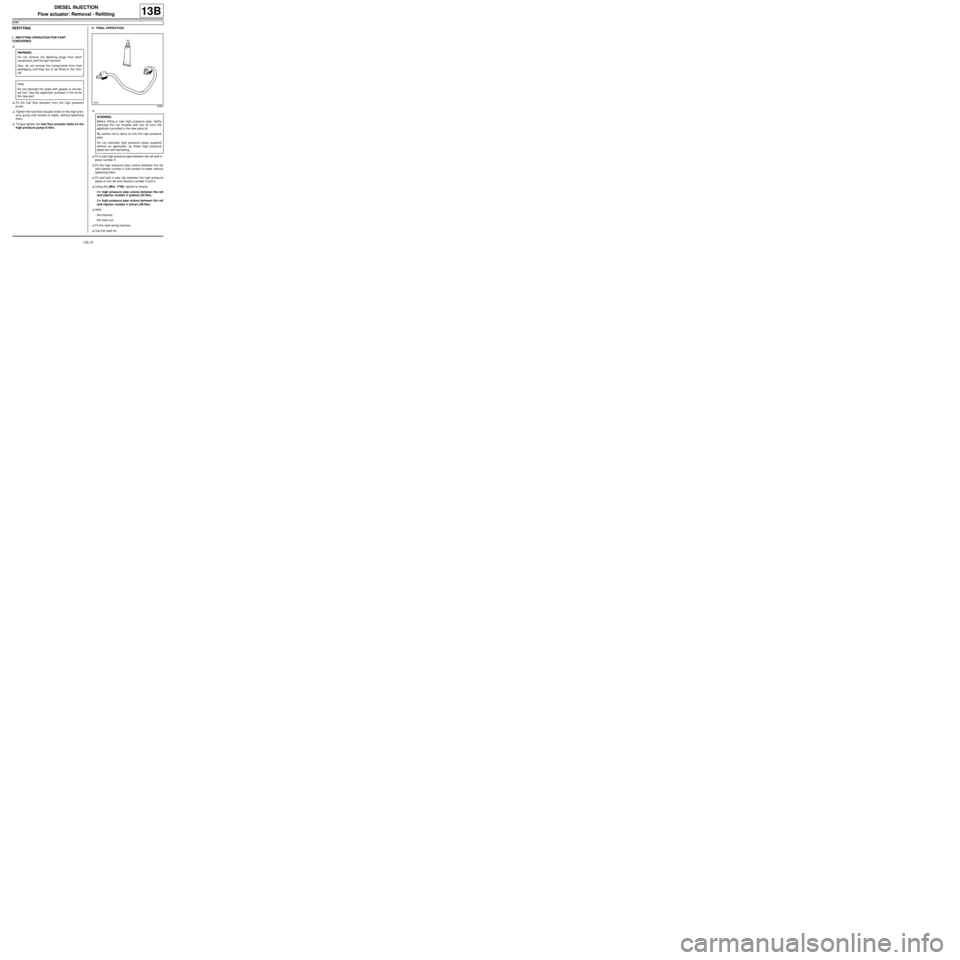

aClip the neck on. WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

Note:

Do not lubricate the seals with grease or old die-

sel fuel. Use the applicator provided in the kit for

the new part.

20960

WARNING

Before fitting a new high pressure pipe, lightly

lubricate the nut threads with the oil from the

applicator provided in the new parts kit.

Be careful not to allow oil into the high pressure

pipe.

Do not lubricate high pressure pipes supplied

without an applicator, as these high pressure

pipes are self-lubr icating.

Page 397 of 652

13B-36

DIESEL INJECTION

High pressure pipe between pump and rail: Removal - Refitting

K9K

13B

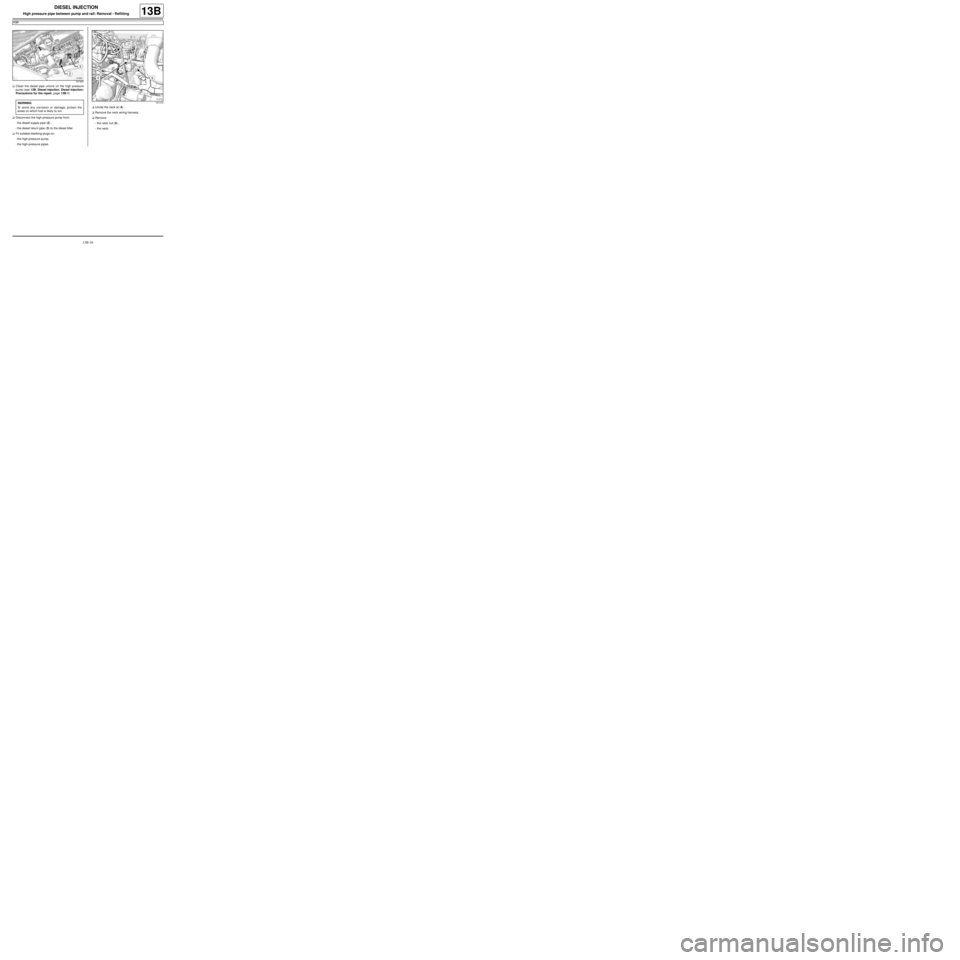

aClean the diesel pipe unions on the high pressure

pump (see 13B, Diesel injection, Diesel injection:

Precautions for the repair, page 13B-1) .

aDisconnect the high pressure pump from:

-the diesel supply pipe (2) ,

-the diesel return pipe (3) to the diesel filter.

aFit suitable blanking plugs on:

-the high pressure pump,

-the high-pressure pipes.aUnclip the neck at (4) .

aRemove the neck wiring harness.

aRemove:

-the neck nut (5) ,

-the neck.

121423

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.121419

Page 398 of 652

13B-37

DIESEL INJECTION

High pressure pipe between pump and rail: Removal - Refitting

K9K

13B

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aClean the high pressure pipe unions (6) between the

pump and the rail (see 13B, Diesel injection, Die-

sel injection: Precautions for the repair, page

13B-1) .

aRemove the high pressure pipe (6) between the

pump and the rail and discard it.

aFit suitable blanking plugs on:

-the high pressure pump,

-the injector rail.

REFITTING

I - REFITTING PREPARATIONS OPERATION

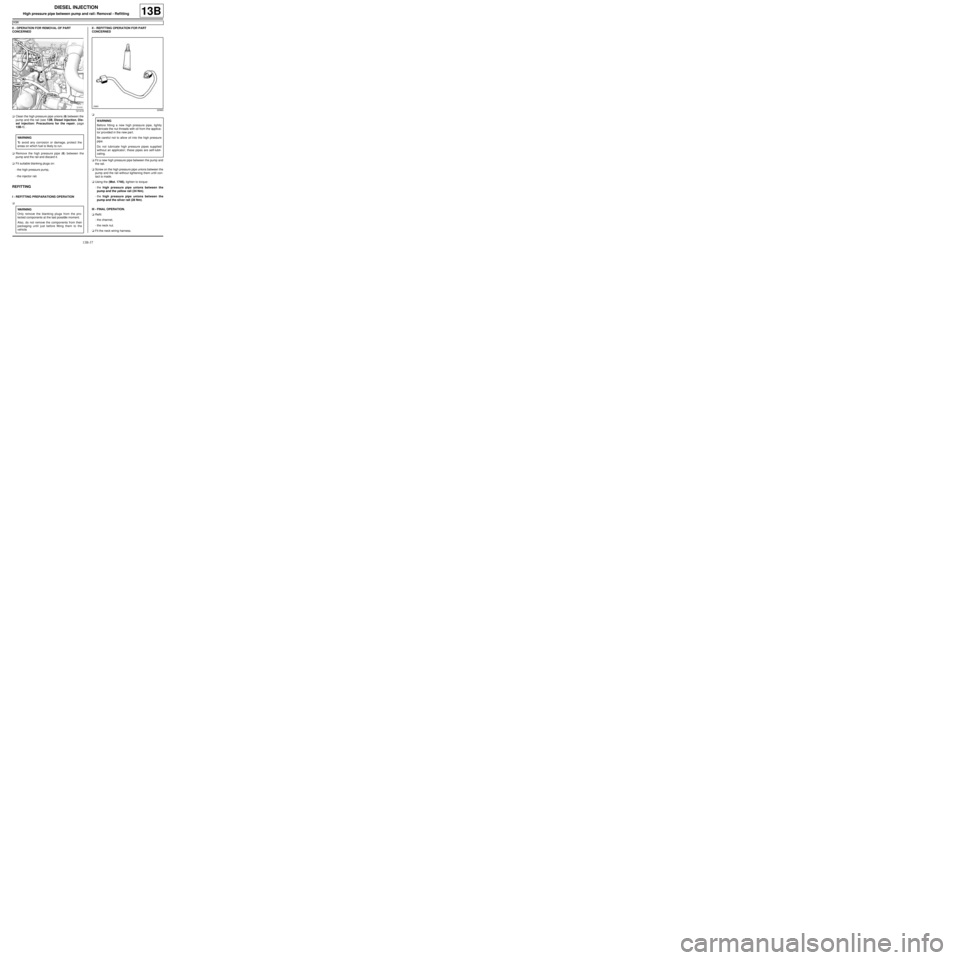

aII - REFITTING OPERATION FOR PART

CONCERNED

a

aFit a new high pressure pipe between the pump and

the rail.

aScrew on the high pressure pipe unions between the

pump and the rail without tightening them until con-

tact is made.

aUsing the (Mot. 1746), tighten to torque:

-the high pressure pipe unions between the

pump and the yellow rail (24 Nm),

-the high pressure pipe unions between the

pump and the silver rail (28 Nm).

III - FINAL OPERATION.

aRefit:

-the channel,

-the neck nut.

aFit the neck wiring harness.

121419

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

Only remove the blanking plugs from the pro-

tected components at the last possible moment.

Also, do not remove the components from their

packaging until just before fitting them to the

vehicle.

20960

WARNING

Before fitting a new high pressure pipe, lightly

lubricate the nut threads with oil from the applica-

tor provided in the new par t.

Be careful not to allow oil into the high pressure

pipe.

Do not lubricate high pressure pipes supplied

without an applicator; these pipes are self-lubri-

cating.

Page 401 of 652

13B-40

DIESEL INJECTION

High pressure pipe between rail and injector: Removal - Refitting

K9K

13B

aClean the diesel pipe unions on the high pressure

pump (see 13B, Diesel injection, Diesel injection:

Precautions for the repair, page 13B-1) .

aDisconnect from the high pressure pump:

-the diesel supply pipe (2) ,

-the diesel return pipe (3) to the diesel filter.aUnclip the neck at (4) .

aRemove the neck wiring harness.

aRemove:

-the neck nut (5) ,

-the neck.

121423

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

To prevent impurities from entering the circuit,

plugs must be fitted to the openings of all the fuel

circuit components exposed to the open air.121419

Page 403 of 652

13B-42

DIESEL INJECTION

High pressure pipe between rail and injector: Removal - Refitting

K9K

13B

aFit and lock a new clip between the high pressure

pipes between the rail and the injectors.

aUsing the (Mot. 1746), tighten to torque:

-the high pressure pipe unions between the

pump and the yellow rail (24 Nm),

-the high pressure pipe unions between the

pump and the silver rail (28 Nm).

III - FINAL OPERATION.

aRefit:

-the channel,

-the neck nut.

aFit the neck wiring harness.

aClip the neck on.

aConnect to the high pressure pump:

-the diesel fuel supply pipe,

-the diesel return pipe to the diesel filter.

aRemove the protection on the alternator and starter.

aConnect the connectors:

-the heater plugs,

-the injectors,

-the flow actuator,

-diesel fuel temperature sensor.

aRemove the blanking cover protecting the dipstick

guide inlet orifice on the cylinder block.

aRefit:

-the dipstick guide,

-the dipstick guide nut,

-the oil level dipstick.

aRefit the neck nuts.

aPrime the fuel circuit with a manual priming pump

until the disconnected pipes are filled with fuel; if

necessary, bleed the fuel filter (see 13A, Fuel sup-

ply, Fuel filter: Removal - Refitting, page 13A-4) .

aCheck that there are no fuel leaks.

aConnect the battery (see ) (MR 411, 80A, Battery).

aCheck the high pressure circuit (see 13B, Diesel in-

jection, High pressure pipe: Check, page 13B-34)

.

aUse the Diagnostic tool to check for an absence of

stored faults; deal with these and clear them as nec-

essary.

aRefit the engine cover.

Page 405 of 652

13B-44

DIESEL INJECTION

Injector rail: Removal - Refitting

K9K

13B

aDisconnect:

-the fuel flow actuator (3) ,

-the diesel temperature sensor (4) .

aAt (5) , unclip the electrical wiring from the neck.

aMove the electrical wiring to one side.aDisconnect the injector rail pressure sensor connec-

tor (6) .

aRemove:

-the dipstick (7) ,

-the oil level dipstick nut (8) ,

-the oil level dipstick guide (9) .

aPlug the oil level dipstick guide inlet opening on the

cylinder block.

aRemove:

-the bolt on the neck of the injection rail.

-the neck of the injection rail.

127907

127906127902

Page 408 of 652

13B-47

DIESEL INJECTION

Injector rail: Removal - Refitting

K9K

13B

aRemove the blanking plugs.

aFit the injector rail.

aFit the injector rail nuts without tightening them.

III - FINAL OPERATION.

a

aRemove the blanking plugs from the high pressure

pump and the injection rail and discard them.

aFit the high pressure pipe between the high pressure

pump and the injection rail.

aTighten the high pressure pipe unions between the

pump and the rail until contact is made.

aRemove the blanking plugs on the injection rail and

the diesel fuel injectors then discard them.

aFit the new high-pressure pipes between the rail and

the injectors.

aTighten until contact the unions of the high pressure

pipes between the rail and injector.aFit and lock the new clips between the high pressure

pipes on the rail and injectors.

aTighten to torque:

-the injector rail nuts (28 Nm),

-the unions for the high pressure pipes between

the rail and the yellow-coloured injector (24

Nm) using the tool (Mot. 1746),

-the unions for the high pressure pipes between

the rail and the silver-coloured injector (28 Nm)

using the tool (Mot. 1746),

-the unions for the high pressure pipes between

the pump and the yellow-coloured rail (24 Nm)

using the tool (Mot. 1746),

-the unions for the high pressure pipes between

the pump and the silver-coloured rail (28 Nm)

using the tool (Mot. 1746),

aConnect to the high pressure pump:

-the fuel return pipe to the fuel filter,

-the fuel supply pipe.

aRefit the neck on the injection rail.

aRemove the protection fitted on the inlet opening of

the oil level dipstick on the cylinder block.

aRefit:

-the dipstick guide,

-the oil level dipstick nut,

-the oil level dipstick.

aConnect the injector rail pressure sensor connector.

aPosition the wiring harness in its channel.

aFasten the electrical wiring to the channel.

aConnect:

-the diesel temperature sensor,

-the fuel flow actuator,

-the injector connectors,

-the heater plug connectors.

aPrime the fuel circuit using a manual priming pump

until the disconnected pipes are filled with fuel.

aCheck that there are no fuel leaks.

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aCheck the high pressure circuit (see 13B, Diesel in-

jection, High pressure pipe: Check, page 13B-34)

.

aRefit the engine cover.

20960

WARNING

Before fitting a new high-pressure pipe, lightly

lubricate the nut threads with the oil from the

applicator provided in the new parts kit.

Be careful not to allow oil into the high-pressure

pipe.

Do not lubricate high-pressure pipes supplied

without an applicator, as these high-pressure

pipes are self-lubricating.

Page 414 of 652

13B-53

DIESEL INJECTION

Accelerometer: Removal - Refitting

K9K

13B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the front engine cover.

aRemove:

-the dipstick,

-the oil level dipstick nut (1) ,

-the oil level dipstick guide.

aPlug the oil level dipstick guide inlet opening on the

cylinder block.

aDisconnect the following connectors :

-the heater plugs,

-the injectors,

-the flow actuator,-the diesel temperature sensor.

aDetach the channel at (2) .

aMove the wiring away from the channel.

aRemove:

-the nut (3) from the channel,

-the neck. Special tooling required

Emb. 1797Socket (24 mm) for removal -

refitting of the clutch master

cylinder

Equipment required

Diagnostic tool

Tightening torquesm

accelerometer20 N.m

114527

121419