engine RENAULT TWINGO RS 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 453 of 652

16A-14

STARTING - CHARGING

Starter: Removal - Refitting

K9K

16A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).

aRemove the front engine cover.

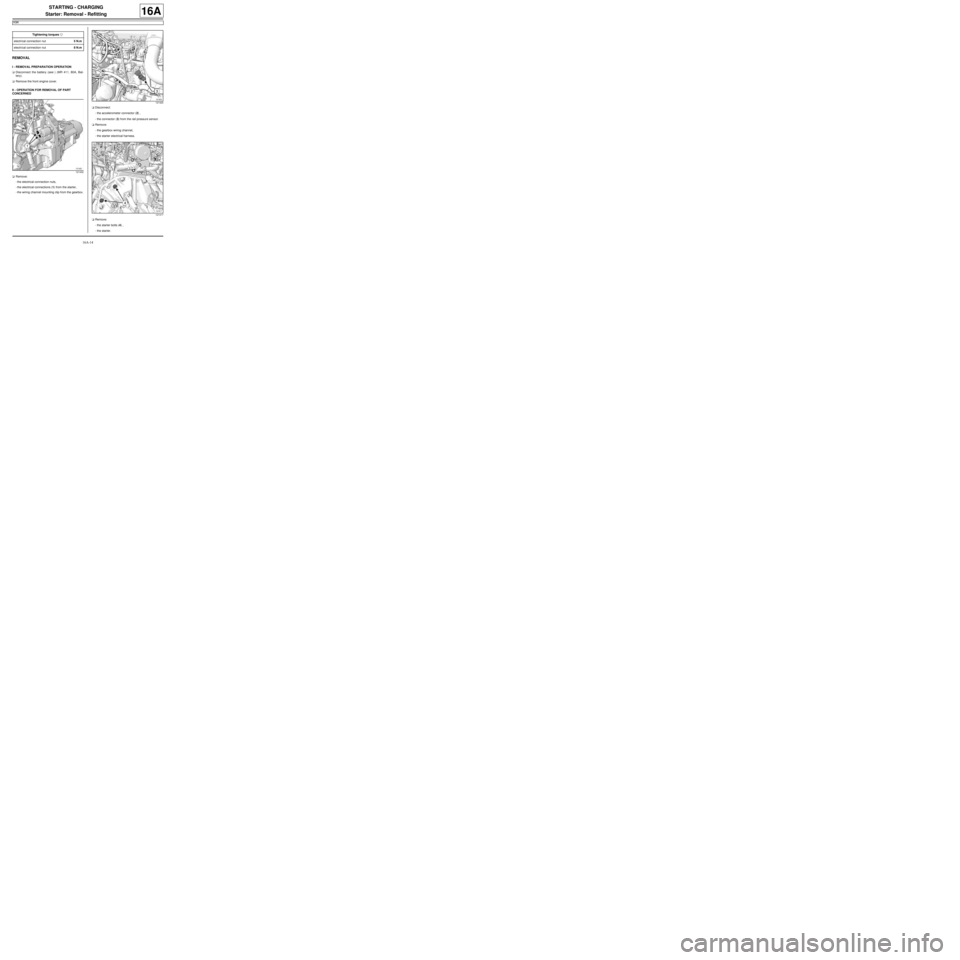

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the electrical connection nuts,

-the electrical connections (1) from the starter,

-the wiring channel mounting clip from the gearbox.aDisconnect:

-the accelerometer connector (2) ,

-the connector (3) from the rail pressure sensor.

aRemove:

-the gearbox wiring channel,

-the starter electrical harness.

aRemove:

-the starter bolts (4) ,

-the starter. Tightening torquesm

electr ical connection nut5 N.m

electr ical connection nut8 N.m

121432

121420

121417

Page 454 of 652

16A-15

STARTING - CHARGING

Starter: Removal - Refitting

K9K

16A

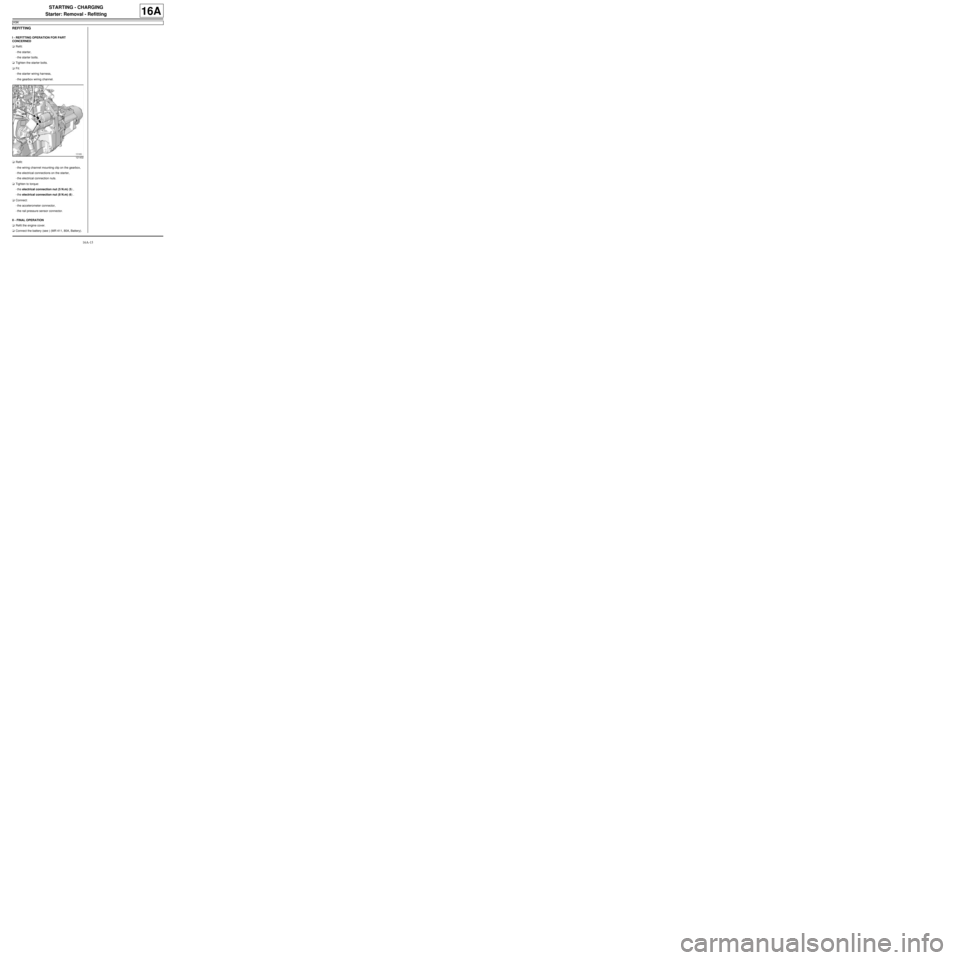

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the starter,

-the starter bolts.

aTighten the starter bolts.

aFit:

-the starter wiring harness,

-the gearbox wiring channel.

aRefit:

-the wiring channel mounting clip on the gearbox,

-the electrical connections on the starter,

-the electrical connection nuts.

aTighten to torque:

-the electrical connection nut (5 N.m) (5) ,

-the electrical connection nut (8 N.m) (6) .

aConnect:

-the accelerometer connector,

-the rail pressure sensor connector.

II - FINAL OPERATION

aRefit the engine cover.

aConnect the battery (see ) (MR 411, 80A, Battery).

121432

Page 476 of 652

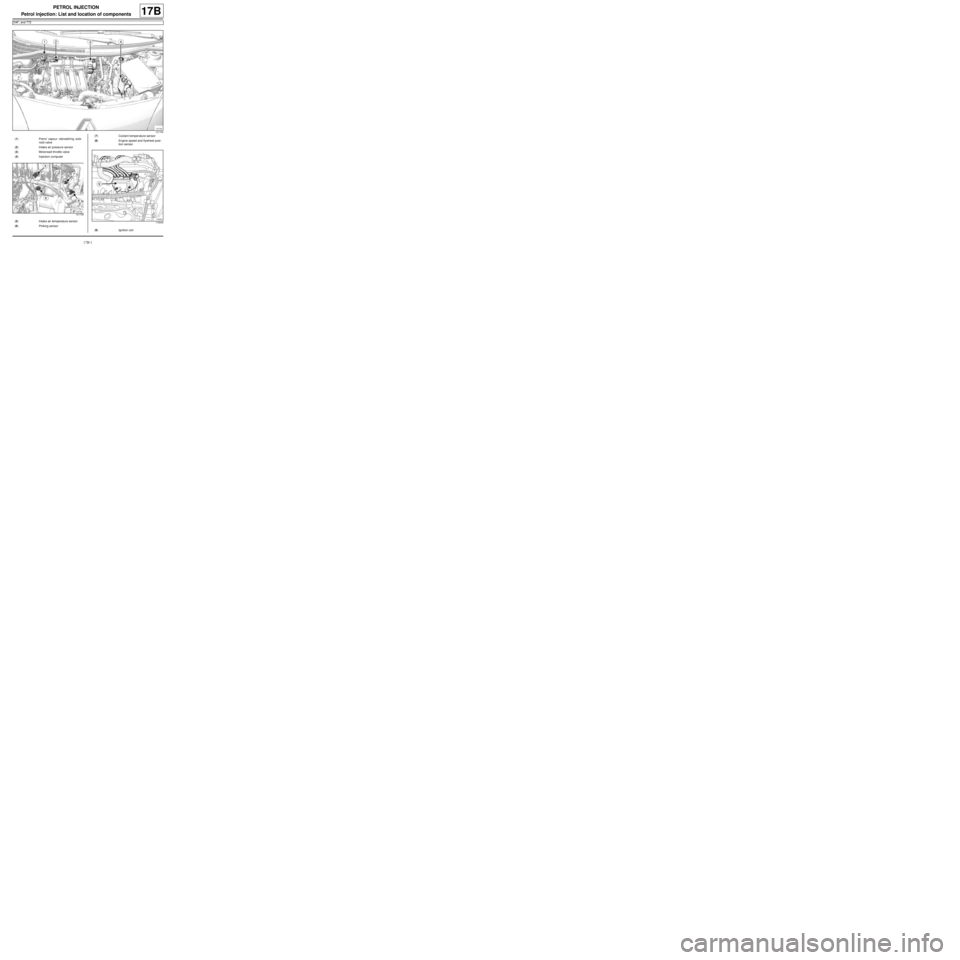

17B-1

PETROL INJECTION

Petrol injection: List and location of components

D4F, and 772

17B

121740

(1) Petrol vapour rebreathing sole-

noid valve

(2) Intake air pressure sensor

(3) Motorised throttle valve

(4) Injection computer

121739

(5) Intake air temperature sensor

(6) Pinking sensor

(7) Coolant temper ature sensor

(8) Engine speed and flywheel posi-

tion sensor

113044

(9) Ignition coil

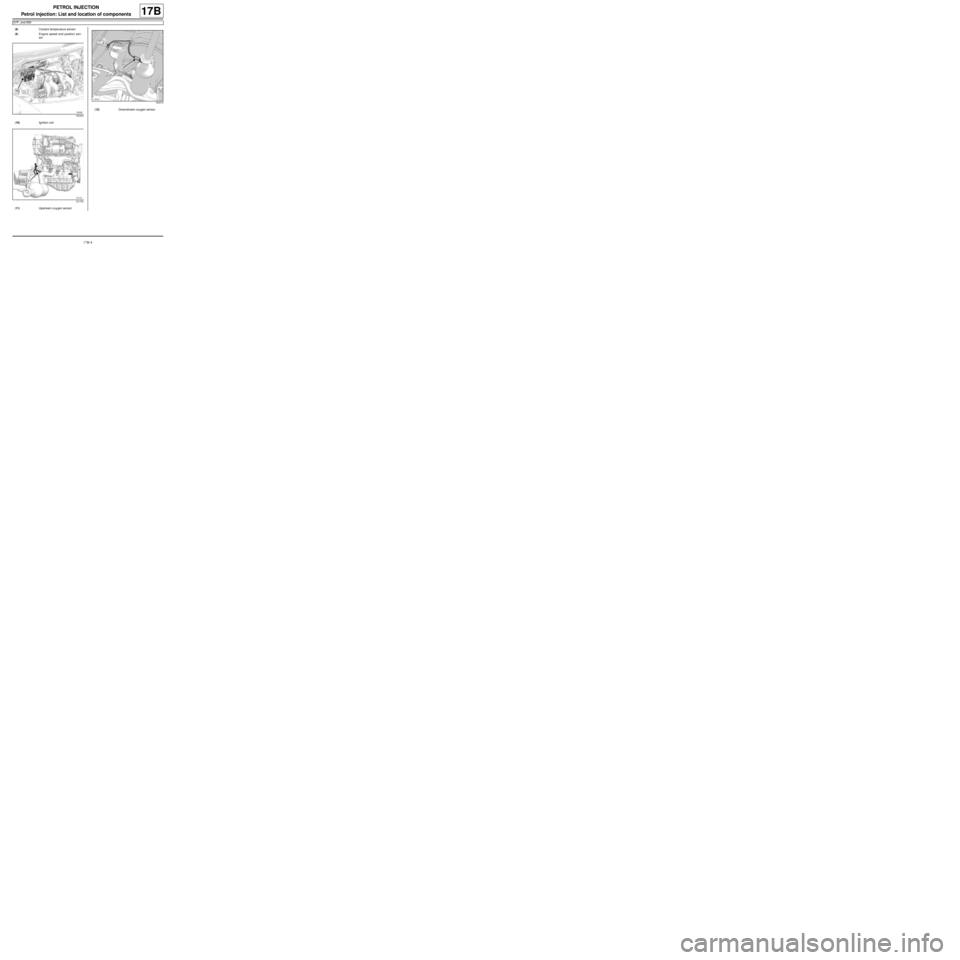

Page 479 of 652

17B-4

PETROL INJECTION

Petrol injection: List and location of components

D7F, and 800

17B

(8) Coolant temper ature sensor

(9) Engine speed and position sen-

sor

120404

(10) Ignition coil

121732

(11) Upstream oxygen sensor

120415

(12) Downstream oxygen sensor

Page 480 of 652

17B-5

PETROL INJECTION

Petrol injection: List and location of components

D4F, and 780 or 782

17B

122387

(1) Fuel vapour recirculation sole-

noid valve

(2) Upstream oxygen sensor

(3) Petrol injection computer

(4) Motorised throttle valve

(5) Ignition coil

(6) Engine compar tment connec-

tion unit

(7) Intake distributor pressure sen-

sor

(8) Turbocharger

108254

(9) Fuel injection computer

Page 492 of 652

17B-17

PETROL INJECTION

Oxygen sensors: Removal - Refitting

K4M

17B

REMOVING THE UPSTREAM OXYGEN

SENSOR

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the engine undertray.

II - REMOVAL OPERATION

aDisconnect the upstream oxygen sensor connector

(1) .

aUnclip the wiring from the upstream oxygen sensor

at (2) .

aRemove the upstream oxygen sensor . Special tooling required

Mot. 149522 mm socket for removal -

refitting of oxygen sensors -

1/2" square dr ive and 24 mm

hexagonal ext.

Mot. 1495-0122 mm socket for removal -

refitting of oxygen sensors.

Tightening torquesm

upstream oxygen sen-

sor90˚

downstream oxygen

sensor45 N.m

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice prevents the oxygen

sensor from operating correctly and results in fail-

ure to comply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical

Note 6015A, 88A, Wiring).

Note:

This procedure is for removal - refitting of the

upstream oxygen sensor and the downstream oxy-

gen sensor.

132373

132539

Page 493 of 652

17B-18

PETROL INJECTION

Oxygen sensors: Removal - Refitting

K4M

17B

REFITTING THE UPSTREAM OXYGEN

SENSOR

I - REFITTING PREPARATION OPERATION

aClean the threading of the upstream oxygen sensor

using a WIRE BRUSH.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the thread hole of the upstream oxygen sensor on

the exhaust manifold,

-the threading of the upstream oxygen sensor if it is

to be reused.

II - REFITTING OPERATION

aRefit the upstream oxygen sensor.

aAngle tighten the upstream oxygen sensor ( 90˚).

aAttach the upstream oxygen sensor wiring.

aConnect the upstream oxygen sensor connector.III - FINAL OPERATION

aRefit:

-the engine undertray.

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

REMOVAL OF THE DOWNSTREAM

OXYGEN SENSOR

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

132539

Note:

For angular tightening, make a mark (6) on the

catalytic pre-converter in the middle of the flat

surface of the upstream oxygen sensor. Move the

upstream oxygen sensor stop (7) to the mark (6)

.

Page 500 of 652

17B-25

PETROL INJECTION

Crankshaft position sensor: Removal - Refitting

D4F or D7F

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the air filter box (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aRemove the engine wiring bolt from the gearbox.

aMove the engine wiring harness to one side.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the engine speed and position sensor

connector.

aRemove the bolts (1) from the engine speed and po-

sition sensor.

aRemove the engine speed and position sensor.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the engine speed and position sensor,

-the engine speed and position sensor bolts.aConnect the engine speed and position sensor con-

nector.

II - FINAL OPERATION.

aConnect the engine wiring to the gearbox.

aRefit the engine wiring bolt to the gearbox.

aRefit the air filter box (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) . D4F

121409

D4F

Page 501 of 652

17B-26

PETROL INJECTION

Crankshaft position sensor: Removal - Refitting

K4M

17B

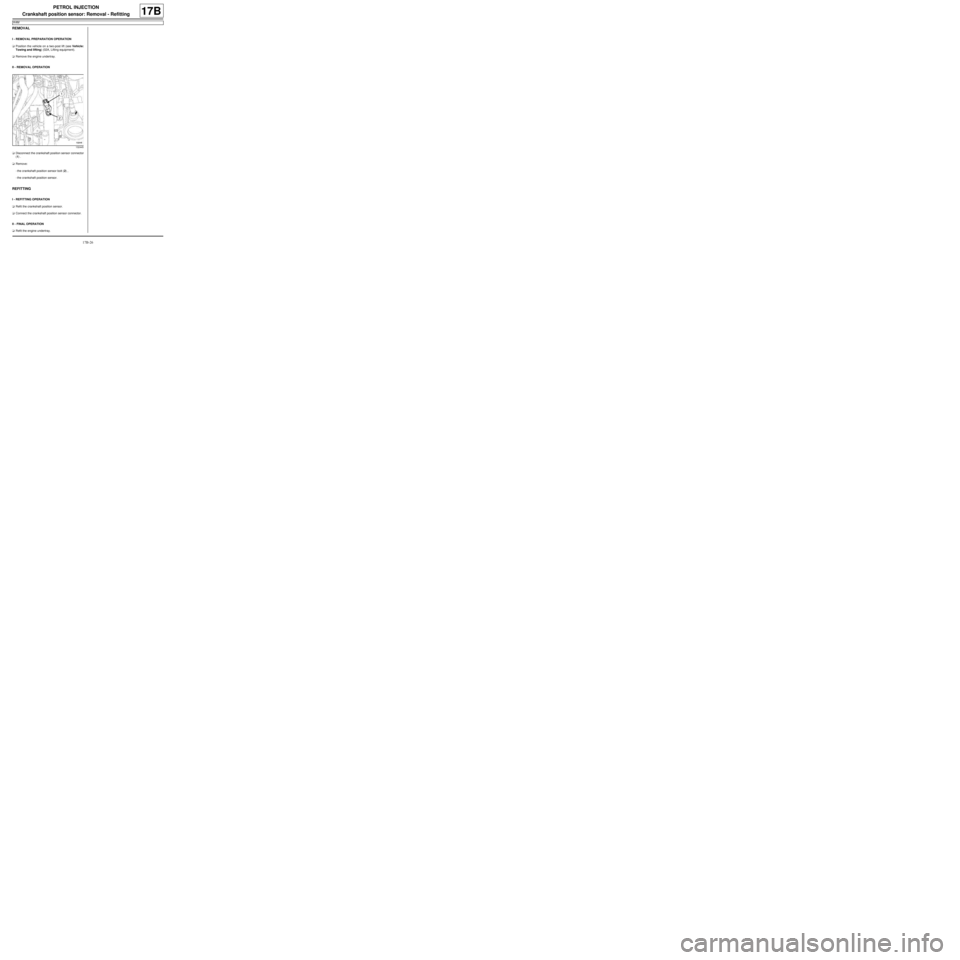

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the engine undertray.

II - REMOVAL OPERATION

aDisconnect the crankshaft position sensor connector

(1) .

aRemove:

-the crankshaft position sensor bolt (2) ,

-the crankshaft position sensor.

REFITTING

I - REFITTING OPERATION

aRefit the crankshaft position sensor.

aConnect the crankshaft position sensor connector.

II - FINAL OPERATION

aRefit the engine undertray.

132445

Page 511 of 652

19A-1

COOLING

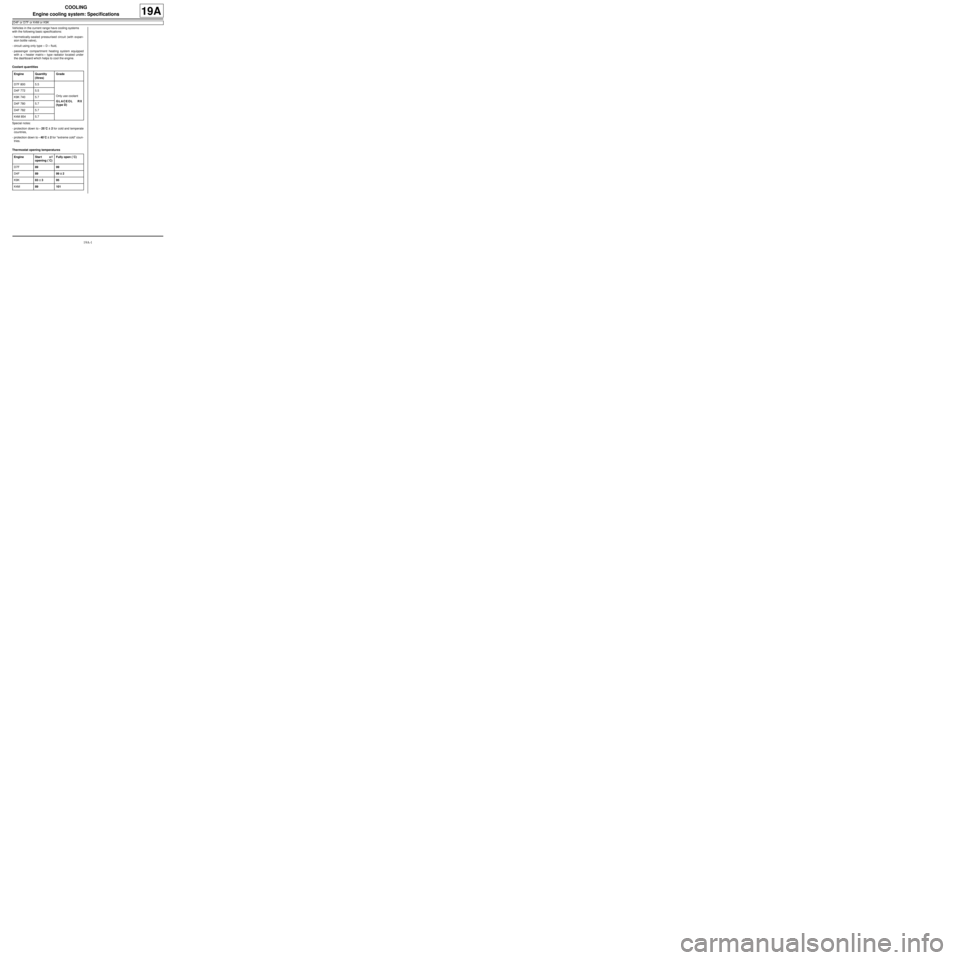

Engine cooling system: Specifications

D4F or D7F or K4M or K9K

19A

Vehicles in the current range have cooling systems

with the following basic specifications:

-hermetically-sealed pressurised circuit (with expan-

sion bottle valve),

-circuit using only type « D » fluid,

-passenger compartment heating system equipped

with a « heater matrix » type radiator located under

the dashboard which helps to cool the engine.

Coolant quantities

Special notes:

-protection down to - 25˚C ±± ± ±

2 for cold and temperate

countries,

-protection down to - 40˚C ±± ± ±

2 for "extreme cold" coun-

tries.

Thermostat opening temperaturesEngine Quantity

(litres)Grade

D7F 800 5.5

Only use coolant

GLACEOL RX

(type D) D4F 772 5.5

K9K 740 5.7

D4F 780 5.7

D4F 782 5.7

K4M 854 5.7

Engine Star t o f

opening (˚C)Fully open (˚C)

D7F89 99

D4F89 99 ±± ± ±

2

K9K83 ±± ± ±

395

K4M89 101