Undertray bolts RENAULT TWINGO RS 2009 2.G Engine And Peripherals Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 558 of 652

19A-48

COOLING

Water chamber: Removal - Refitting

K4M

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the engine undertray.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Mot. 1202-01Clip pliers for hose clips

(large size).

Mot. 1202-02Clip pliers for hose clips

(small size)

Tightening torquesm

water chamber bolts

(initial torque)4 N.m

water chamber bolts12 N.m

heater matrix hose

bracket bolt10 N.m

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

When carr ying out a repair that requires a complete

change, it is essential to flush the circuit with clean

water, blast compressed air through the circuit to

drive out the water, fill and bleed the circuit and

then measure the effective protection.

The cr iteria to be met are:

-protection down to -25˚C ±± ± ±

2 for cold and temper-

ate countries,

-protection down to -40˚C ±± ± ±

2 for "extreme cold"

countries.

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

Page 560 of 652

19A-50

COOLING

Water chamber: Removal - Refitting

K4M

19A

II - REFITTING OPERATION

aRefit the coolant outlet unit with a new seal.

aPretighten in order and to torque the water cham-

ber bolts (initial torque) (4 N.m).

aTorque tighten in order the water chamber bolts

(12 N.m).

III - FINAL OPERATION

aClip the wiring onto the water chamber.

aFit the engine wiring channel.

aRefit:

-the coolant temperature sensor (see 19A, Cool-

ing, Coolant temperature sensor: Removal - Re-

fitting, page 19A-66) ,

-the heater matrix hose bracket.

aTorque tighten the heater matrix hose bracket bolt

(10 N.m).

aConnect to the coolant outlet unit:

-the heater matrix hose,

-the cooling radiator top hose.

aUsing the (Mot. 1448) or (Mot. 1202-01) or (Mot.

1202-02) fit:

-the heater matrix hose clip,

-the cooling radiator top hose clip.

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aRefit the engine undertray.

128456

Page 561 of 652

19A-51

COOLING

Engine cooling fan assembly: Removal - Refitting

C44, and K9K

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) )

aDisconnect the battery ( (see Battery: Removal -

Refitting) ).

aRemove:

-the engine undertray bolts,

-the engine undertray,

-the front bumper ( (see Front bumper: Removal -

Refitting) ),

-the left-hand and right-hand headlights (see Halo-

gen headlight: Removal - Refitting) .

aRemove:

-the cooling radiator retaining lug bolt,

-the expansion bottle bolt onto the front upper cross

member,

-the air filter inlet air pipe bolt on the front upper

cross member.

aUnclip and then remove from the front upper cross

member:

-the air filter inlet air pipe,

-the expansion bottle.

aRemove the bonnet lock nuts.

aRemove the « cable - bonnet catch » assembly.

aRemove the front upper cross member ( (see Front

upper cross member: Removal - Refitting) )

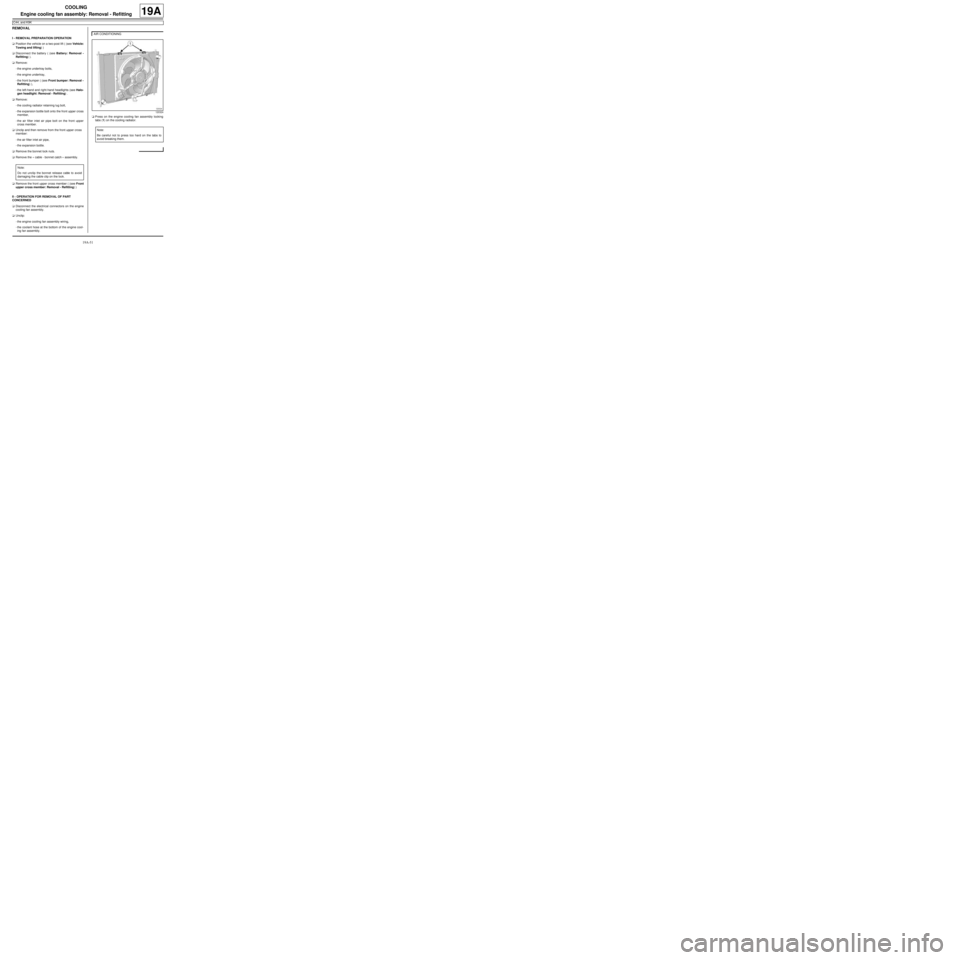

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the electrical connectors on the engine

cooling fan assembly.

aUnclip:

-the engine cooling fan assembly wiring,

-the coolant hose at the bottom of the engine cool-

ing fan assembly.aPress on the engine cooling fan assembly locking

tabs (1) on the cooling radiator.

Note:

Do not unclip the bonnet release cable to avoid

damaging the cable clip on the lock.

AIR CONDITIONING

120324

Note:

Be careful not to press too hard on the tabs to

avoid breaking them.

Page 562 of 652

19A-52

COOLING

Engine cooling fan assembly: Removal - Refitting

C44, and K9K

19A

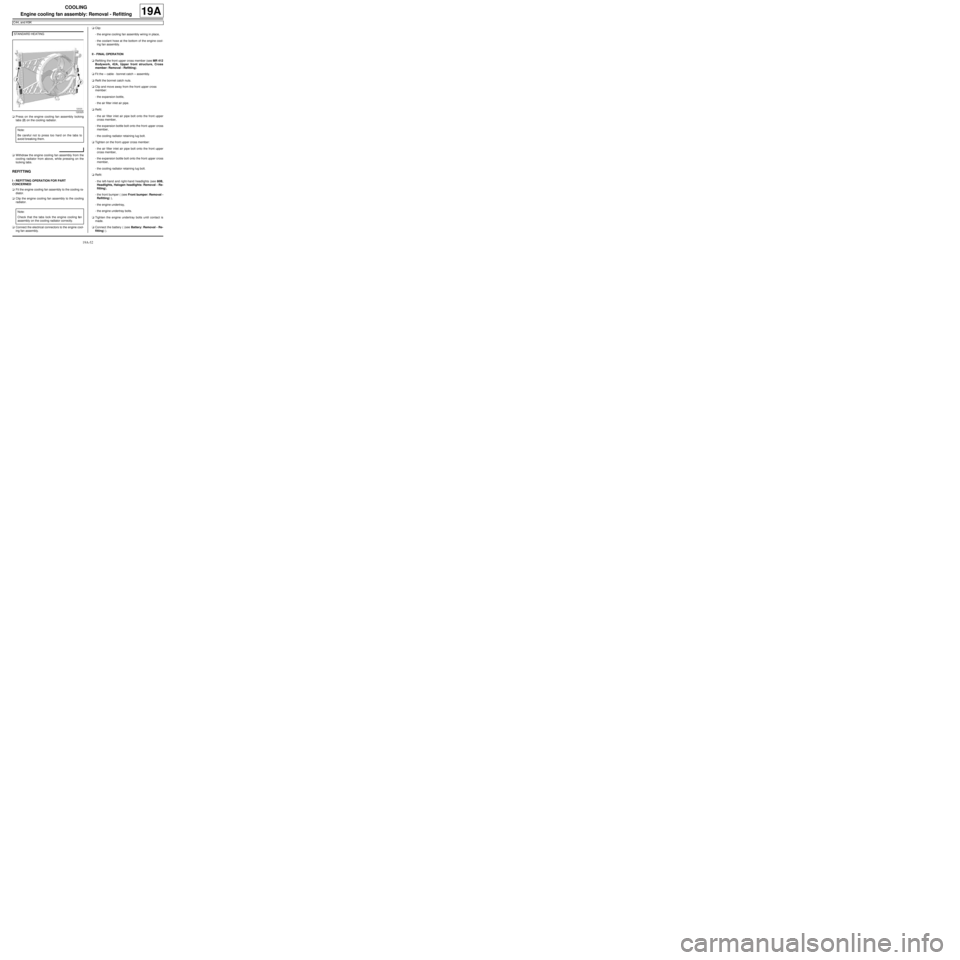

aPress on the engine cooling fan assembly locking

tabs (2) on the cooling radiator.

aWithdraw the engine cooling fan assembly from the

cooling radiator from above, while pressing on the

locking tabs.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aFit the engine cooling fan assembly to the cooling ra-

diator.

aClip the engine cooling fan assembly to the cooling

radiator.

aConnect the electrical connectors to the engine cool-

ing fan assembly.aClip:

-the engine cooling fan assembly wiring in place,

-the coolant hose at the bottom of the engine cool-

ing fan assembly.

II - FINAL OPERATION

aRefitting the front upper cross member (see MR 412

Bodywork, 42A, Upper front structure, Cross

member: Removal - Refitting).

aFit the « cable - bonnet catch » assembly.

aRefit the bonnet catch nuts.

aClip and move away from the front upper cross

member:

-the expansion bottle,

-the air filter inlet air pipe.

aRefit:

-the air filter inlet air pipe bolt onto the front upper

cross member,

-the expansion bottle bolt onto the front upper cross

member,

-the cooling radiator retaining lug bolt.

aTighten on the front upper cross member:

-the air filter inlet air pipe bolt onto the front upper

cross member,

-the expansion bottle bolt onto the front upper cross

member,

-the cooling radiator retaining lug bolt.

aRefit:

-the left-hand and right-hand headlights (see 80B,

Headlights, Halogen headlights: Removal - Re-

fitting),

-the front bumper ( (see Front bumper: Removal -

Refitting) ),

-the engine undertray,

-the engine undertray bolts.

aTighten the engine undertray bolts until contact is

made.

aConnect the battery ( (see Battery: Removal - Re-

fitting) ). STANDARD HEATING

120325

Note:

Be careful not to press too hard on the tabs to

avoid breaking them.

Note:

Check that the tabs lock the engine cooling fan

assembly on the cooling radiator correctly.

Page 571 of 652

19A-61

COOLING

Coolant pump inlet pipe: Removal - Refitting

D4F, and 780 or 782

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove the engine undertray.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aSeparate the clips on the coolant pump inlet pipe

hoses using the tool (Mot. 1448).

aDisconnect the coolant pump inlet pipe hoses.

aRemove:

-the bolts (1) from the coolant pump inlet pipe,

-the coolant pump inlet pipe,-the coolant pump inlet pipe seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: seal between cool-

ant pump inlet pipe and coolant pump.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) to clean the bearing surfaces of

the coolant pump inlet pipe.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-a new seal on the coolant pump inlet pipe,

-the coolant pump inlet pipe,

-the coolant pump inlet pipe bolts.

aTorque tighten the coolant pump inlet pipe bolts

(10 N.m).

aConnect the hoses to the coolant pump inlet pipe.

aRefit the clips on the coolant pump inlet pipe hoses

using the tool (Mot. 1448).

III - FINAL OPERATION

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aRefit the engine undertray.

aConnect the battery (see ) (80A, Battery). Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Tightening torquesm

coolant pump inlet pipe

bolts10 N.m

120956

Page 572 of 652

19A-62

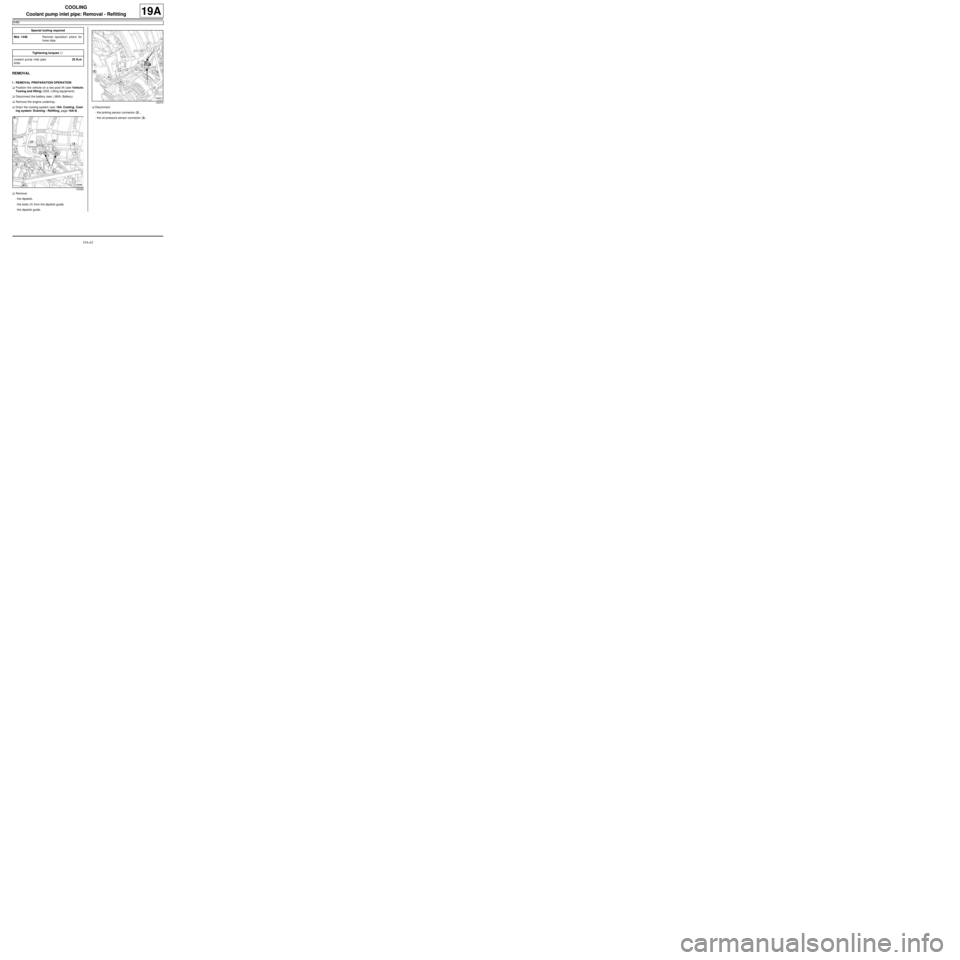

COOLING

Coolant pump inlet pipe: Removal - Refitting

K4M

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove the engine undertray.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aRemove:

-the dipstick,

-the bolts (1) from the dipstick guide,

-the dipstick guide.aDisconnect:

-the pinking sensor connector (2) ,

-the oil pressure sensor connector (3) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Tightening torquesm

coolant pump inlet pipe

bolts25 N.m

132368

132374

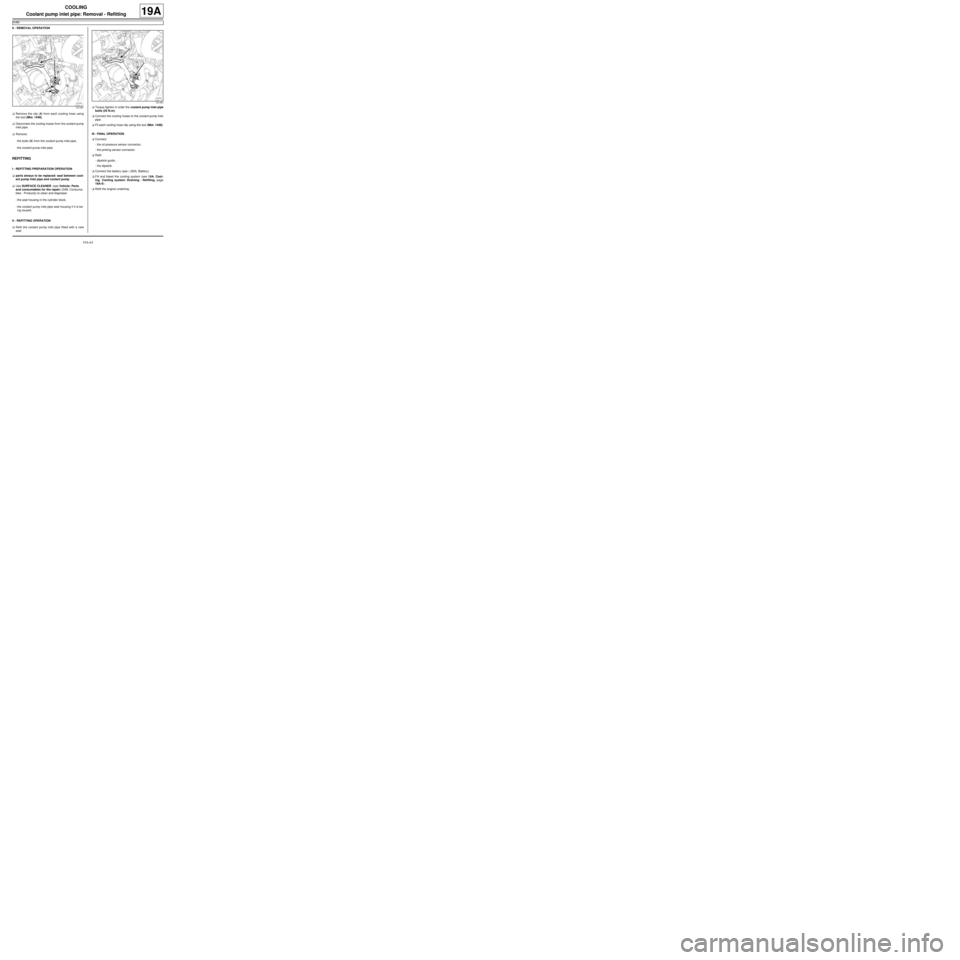

Page 573 of 652

19A-63

COOLING

Coolant pump inlet pipe: Removal - Refitting

K4M

19A

II - REMOVAL OPERATION

aRemove the clip (4) from each cooling hose using

the tool (Mot. 1448).

aDisconnect the cooling hoses from the coolant pump

inlet pipe.

aRemove:

-the bolts (5) from the coolant pump inlet pipe,

-the coolant pump inlet pipe.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: seal between cool-

ant pump inlet pipe and coolant pump.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the seal housing in the cylinder block,

-the coolant pump inlet pipe seal housing if it is be-

ing reused.

II - REFITTING OPERATION

aRefit the coolant pump inlet pipe fitted with a new

seal.aTorque tighten in order the coolant pump inlet pipe

bolts (25 N.m).

aConnect the cooling hoses to the coolant pump inlet

pipe.

aFit each cooling hose clip using the tool (Mot. 1448).

III - FINAL OPERATION

aConnect:

-the oil pressure sensor connector,

-the pinking sensor connector.

aRefit:

-dipstick guide ,

-the dipstick.

aConnect the battery (see ) (80A, Battery).

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aRefit the engine undertray.

131781

131781

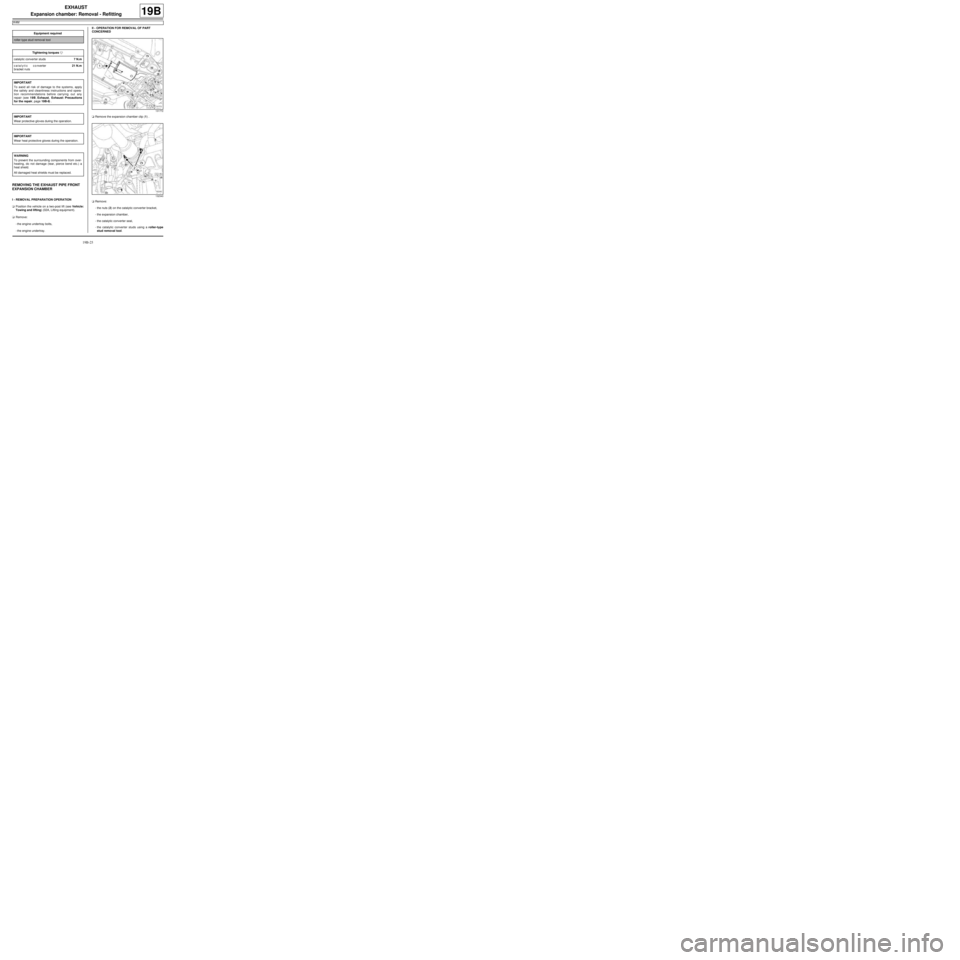

Page 607 of 652

19B-25

EXHAUST

Expansion chamber: Removal - Refitting

K4M

19B

REMOVING THE EXHAUST PIPE FRONT

EXPANSION CHAMBER

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine undertray bolts,

-the engine undertray.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the expansion chamber clip (1) .

aRemove:

-the nuts (2) on the catalytic converter bracket,

-the expansion chamber,

-the catalytic converter seal,

-the catalytic converter studs using a roller-type

stud removal tool. Equipment required

roller-type stud removal tool

Tightening torquesm

catalytic converter studs7 N.m

catalytic converter

bracket nuts21 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair (see 19B, Exhaust, Exhaust: Precautions

for the repair, page 19B-8) .

IMPORTANT

Wear protective gloves during the operation.

IMPORTANT

Wear heat protective gloves during the operation.

WARNING

To prevent the surrounding components from over-

heating, do not damage (tear, pierce bend etc.) a

heat shield.

All damaged heat shields must be replaced.

131772

132340

Page 647 of 652

19D-17

ENGINE MOUNTING

Right-hand suspended engine mounting: Removal - Refitting

K4M

19D

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the engine undertray.

aFit the (Mot. 1672) on the vehicle.

aSupport the engine oil sump on the tool (Mot. 1672).

aMark the position of the suspended engine mounting

rubber pad.II - REMOVAL OPERATION

aRemove the bolts (1) from the suspended engine

mounting rubber pad.

aSlightly raise the engine using the (Mot. 1672) until

the rubber pad detaches from the suspended engine

mounting.

aRemove:

-the bolts (2) from the suspended engine mounting

cover,

-the suspended mounting from engine.

REFITTING

I - REFITTING OPERATION

aFit the suspended engine mounting.

aTorque tighten the suspended engine mounting

cover bolts (62 N.m).

aLower the engine until the rubber pad touches the

suspended engine mounting.

aPosition the suspended engine mounting rubber pad

in line with the mark made during removal.

aTorque tighten the suspended engine mounting

rubber pad bolts (62 N.m).

II - FINAL OPERATION

aRemove the tool (Mot. 1672).

aRefit the engine undertray. Special tooling required

Mot. 1672Low er engine support.

Tightening torquesm

suspended engine

mounting cover bolts62 N.m

suspended engine

mounting rubber pad

bolts62 N.m

120040

131777

Page 651 of 652

19D-21

ENGINE MOUNTING

Lower engine tie-bar: Removal - Refitting

K4M

19D

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the engine undertray.

II - REMOVAL OPERATION

aRemove:

-the rear suspended engine mounting bolt (1) from

the subframe,-the rear suspended engine mounting bolt (2) from

the rear suspended engine mounting support,

-the rear suspended engine mounting reinforce-

ment bolt (3) ,

-the rear suspended engine mounting.

aRemove:

-the rear suspended engine mounting support bolts

(4) ,

-the rear suspended engine mounting support. Tightening torquesm

rear suspended engine

mounting suppor t bolt62 N.m

rear suspended engine

mounting suppor t bolts105 N.m

rear suspended engine

reinforcement bolt105 N.m

rear suspended engine

mounting bolt on the

rear suspended engine

mounting suppor t105 N.m

rear suspended engine

mounting bolt on the

subframe105 N.m

131769

131768