Seat Alhambra 2014 Owner's Manual

Manufacturer: SEAT, Model Year: 2014, Model line: Alhambra, Model: Seat Alhambra 2014Pages: 381, PDF Size: 5.75 MB

Page 311 of 381

309

Wheels and tyres

Full hubcaps*

Fig. 182 Removing the

full hubcap

Removing the full hubcap

● Take the wheel brace and the wire hook from the vehicle tool kit

⇒ page 324.

● Hook the wire through one of the grooves on the hubcap.

● Insert the wheel brace onto the wire hook

⇒ Fig. 182 and pull the hub

cap in the direction shown by the arrow.

Fitting hubcaps

Before mounting the full hubcap, the anti-theft wheel lock must be threaded

into position ⇒ Fig. 185 2

or 3. Otherwise it will not be possible to mount

the full hubcap.

Press the hubcap against the wheel so that the space for the valve fits over

the tyre valve ⇒ Fig. 185 1

. Make sure that the hubcap is correctly fitted all

the way around the wheel. Wheel bolt caps

Fig. 183 Removing the

wheel bolt caps

● Take the wire hook from the vehicle tool kit

⇒ page 324.

● Insert the wire hook in the cap through the opening

⇒ Fig. 183 and pull

outwards in the direction of the arrow.

The caps protect the wheel bolts and should be remounted after changing

the tyre.

The anti-theft wheel locking bolt has a special cap. This cap only fits on an-

ti-theft locking bolts and is not for use with standard wheel bolts.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 312 of 381

310Wheels and tyres

Changing a wheel*

Introduction

The tyres mounted on the vehicle are anti-puncture. The wheels should only

be changed when switching from summer to winter tyres or vice-versa. See

⇒ page 303

You should only change the wheels yourself if the vehicle is parked in a safe

place, you are familiar with the procedure and you have all the necessary

tools! Otherwise, you should seek professional assistance.

Additional information and warnings:

● Vehicle key set ⇒ page 72

● Wheels and tyres ⇒ page 297

● Wheel trims ⇒ page 308

● Vehicle tools ⇒ page 324

WARNING

Changing a wheel can be dangerous, especially on the hard shoulder.

Please observe the following rules to minimise the risk of injury:

● Stop the vehicle safely as soon as possible. Park your vehicle as safe

distance from surrounding traffic to change a wheel.

● When changing a wheel, keep all passengers and particularly chil-

dren a safe distance away from the work area.

● Turn on the hazard warning lights to warn other road users.

● Ensure the ground on which you park is flat and solid. If necessary,

support the jack on a wide solid base.

● If you are changing a wheel yourself, you should be familiar with the

required procedure. Otherwise, you should seek professional assistance.

WARNING (Continued)

● Only use suitable tools that are not damaged when changing a wheel.

● Always stop the engine, turn on the electronic parking brake and

place the gear selector lever in position P, for an automatic gearbox, or

engage a gear for a manual gearbox to reduce the risk of the vehicle mov-

ing accidentally.

● Have the tightening torque of the wheel bolts checked as soon as

possible with a reliable torque wrench.

Preparations for changing a wheel

Check list

Before changing a wheel, complete the following operations in the order

given ⇒

:

Park the vehicle on an even and solid surface.

Connect the electronic parking brake ⇒ page 185.

Automatic gearbox: move the selector lever to position P ⇒ page 176.

Stop the engine and remove the key from the ignition ⇒ page 172.

Manual gearbox: Select a gear ⇒ page 176.

Have all vehicle occupants get out of the vehicle and wait in a safe

place (for example, behind the safety barrier).

Block the opposite wheel with wedges or a similar object.

When towing a trailer: unhook the trailer from the towing vehicle and

park it correctly.

If the luggage compartment is full: take the baggage out of the vehicle. Take the vehicle tool kit out of the luggage compartment.

Remove the wheel trims ⇒ page 308.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Page 313 of 381

311

Wheels and tyres

WARNING

Failure to follow the checklist prepared for your own safety could lead to

accidents and severe injuries.

● Always complete the operations given in the checklist and observe

the general rules of safety.

Wheel bolts

Fig. 184 Changing a

wheel: Slacken the wheel

bolts.

Fig. 185 Changing a

wheel: Tyre valve 1 and

position of anti-theft

wheel locking bolt 2

or

3

Only use the tool supplied with the vehicle to loosen the wheel bolts.

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack.

If the wheel bolt is very tight, you may be able to loosen it by pushing down

on the end of the wheel brace carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over the wheel bolt

⇒ Fig. 184.

● Hold the wheel brace at the end and rotate the bolt approximately one

turn anticlockwise ⇒

.

Loosening anti-theft wheel bolts

For wheels with full hubcap, the anti-theft wheel lock must be threaded into

position ⇒ Fig. 185 2

or 3 before mounting the hubcap. Otherwise it will

not be possible to mount the full hubcap.

● Take the adapter for anti-theft wheel bolts out of the vehicle tool kit.

● Insert the adapter onto the anti-theft wheel bolt.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 314 of 381

312Wheels and tyres

● Fit the wheel brace onto the adapter as far as possible.

● Hold the wheel brace at the end and rotate the bolt approximately one

turn anticlockwise ⇒

.

Important information about wheel bolts

The wheel rims and bolts have been designed to be fitted to factory op-

tions. If different rims are fitted, the correct wheel bolts with the right length

and correctly shaped bolt heads must be used. This ensures that wheels are

fitted securely and that the brake system functions correctly.

In some circumstances, wheel bolts from the same model vehicle should

not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel bolts for steel and alloy wheels

is 140 Nm. Have the tightening torque of the wheel bolts checked as soon

as possible with a reliable torque wrench.

If wheel bolts are rusty and it is difficult to tighten them, the threads should

be replaced and cleaned before checking the tightening torque.

Never grease or lubricate wheel bolts or the wheel hub threads. Although

they have been tightened to the prescribed torque, they could come loose

while driving.

WARNING

If the wheel bolts are not fitted correctly they could be released while

driving leading to loss of vehicle control and serious damage.

● Only use wheel bolts which correspond to the wheel rims in question.

● Never use different wheel bolts.

● The bolts and threads should be clean, free of oil and grease and easy

to thread.

● To loosen and tighten the wheel bolts, always use the wheel brace

supplied with the vehicle.

● Loosen the wheel bolts only about one turn before raising the vehicle

with the jack.

● Never grease or lubricate wheel bolts or the wheel hub threads. Al-

though they have been tightened to the prescribed torque, they could

come loose while driving.

● Never loosen the bolted joints of wheel rims with bolted ring trims.

● If the wheel bolts are not tightened to the correct torque, they may

come loose while driving, and the bolts and rims may come out. If the

tightening torque is too high, the wheel bolts and threads can be dam-

aged.

Page 315 of 381

313

Wheels and tyres

Raising the vehicle with the jack

Fig. 186 Jack position

points

Fig. 187 : jack mounted on the left front part of the

vehicle. : jack mounted on the left rear part of the ve-

hicle

The jack may be applied only at the jacking points shown (marks on chas-

sis) ⇒ Fig. 186. The mark indicates the jacking points below the vehicle. The

jacking points are on the ribs behind the front edges ⇒ Fig. 187. Always the

relevant jacking point for the wheel to be changed ⇒

.Raise the vehicle using only the designated jacking points.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 316 of 381

314Wheels and tyres

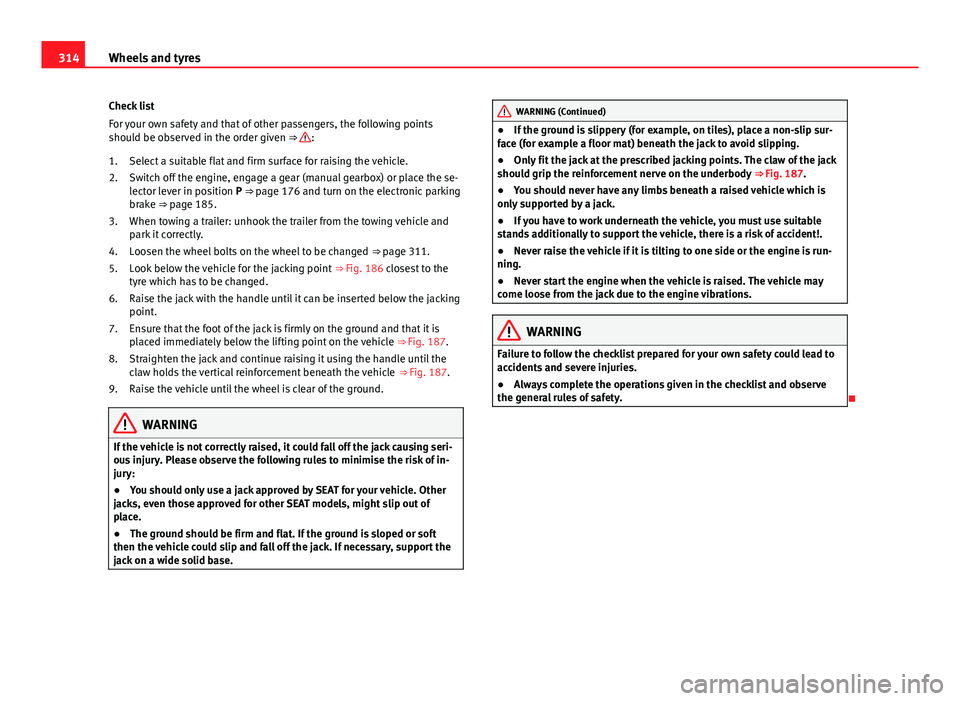

Check list

For your own safety and that of other passengers, the following points

should be observed in the order given ⇒

:

Select a suitable flat and firm surface for raising the vehicle.

Switch off the engine, engage a gear (manual gearbox) or place the se-

lector lever in position P ⇒ page 176 and turn on the electronic parking

brake ⇒ page 185.

When towing a trailer: unhook the trailer from the towing vehicle and

park it correctly.

Loosen the wheel bolts on the wheel to be changed ⇒ page 311.

Look below the vehicle for the jacking point ⇒ Fig. 186 closest to the

tyre which has to be changed.

Raise the jack with the handle until it can be inserted below the jacking

point.

Ensure that the foot of the jack is firmly on the ground and that it is

placed immediately below the lifting point on the vehicle ⇒ Fig. 187.

Straighten the jack and continue raising it using the handle until the

claw holds the vertical reinforcement beneath the vehicle ⇒ Fig. 187.

Raise the vehicle until the wheel is clear of the ground.

WARNING

If the vehicle is not correctly raised, it could fall off the jack causing seri-

ous injury. Please observe the following rules to minimise the risk of in-

jury:

● You should only use a jack approved by SEAT for your vehicle. Other

jacks, even those approved for other SEAT models, might slip out of

place.

● The ground should be firm and flat. If the ground is sloped or soft

then the vehicle could slip and fall off the jack. If necessary, support the

jack on a wide solid base.

1.

2.

3.

4.

5.

6.

7.

8.

9.

WARNING (Continued)

● If the ground is slippery (for example, on tiles), place a non-slip sur-

face (for example a floor mat) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking points. The claw of the jack

should grip the reinforcement nerve on the underbody ⇒ Fig. 187.

● You should never have any limbs beneath a raised vehicle which is

only supported by a jack.

● If you have to work underneath the vehicle, you must use suitable

stands additionally to support the vehicle, there is a risk of accident!.

● Never raise the vehicle if it is tilting to one side or the engine is run-

ning.

● Never start the engine when the vehicle is raised. The vehicle may

come loose from the jack due to the engine vibrations.

WARNING

Failure to follow the checklist prepared for your own safety could lead to

accidents and severe injuries.

● Always complete the operations given in the checklist and observe

the general rules of safety.

Page 317 of 381

315

Wheels and tyres

Changing a wheel

Fig. 188 Changing a

wheel: loosen wheel

bolts with the socket at

the end of the wheel

brace

Removing the wheel

● Please observe the check list

⇒ page 310.

● Loosen the wheel bolts

⇒ page 311.

● Jacking up the vehicle

⇒ page 313.

● Using the hexagonal socket in the wheel brace

⇒ Fig. 188, unscrew the

slackened wheel bolts and place them on a clean surface.

● Take off the wheel.

Putting on the spare wheel

Check the direction of rotation of the tyre ⇒ page 299.

● Fit the wheel.

● Screw on the anti-theft locking bolt with the adapter in position

⇒ Fig. 185 2

or 3 clockwise and tighten gently.

● Replace the other wheel bolts and tighten slightly using the hexagonal

socket on the end of the wheel brace.

● Lower the car with the jack. ●

Tighten all of the wheel bolts clockwise ⇒

. Tighten the bolts in diago-

nal pairs (not in a circle).

● Put the caps, trim or full hubcap back on ⇒ page 308.

WARNING

If the wheel bolts are not treated suitably or not tightened to the correct

torque then this could lead to loss of vehicle control and to a serious ac-

cident.

● All the wheel bolts and hub threads should be clean and free of oil

and grease. The wheel bolts should be easily tightened to the correct tor-

que.

● The hexagonal socket in the wheel brace should be used for turning

wheel bolts only. Do not use it to loosen or tighten the wheel bolts.

After changing the wheel

● Clean the wheel brace, if necessary and put it away in the luggage com-

partment ⇒ page 324.

● Have the tightening torque of the wheel bolts checked as soon as possi-

ble with a torque wrench ⇒ page 312.

Note

If the vehicle is fitted with a tyre monitoring system, this should be “reprog-

rammed” if necessary whenever a tyre is changed ⇒ page 227.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 318 of 381

316If and when

If and when

In case of emergency

Introduction

Additional information and warnings:

● Braking, stopping and parking ⇒ page 185

● Emergency locking and unlocking ⇒ page 318

● Vehicle tools ⇒ page 324

WARNING

A faulty vehicle in traffic represents a risk of accident for the driver and

for other road users.

● Stop the vehicle safely as soon as possible. Park the vehicle a safe

distance from surrounding traffic to lock all the doors in case of an emer-

gency. Turn on the hazard warning lights to warn other road users.

● Never leave children or disabled people alone in the vehicle if the

doors are to be locked. In case of an emergency, passengers will be trap-

ped inside the vehicle. Individuals locked in the vehicle can be exposed

to very high or very low temperatures.

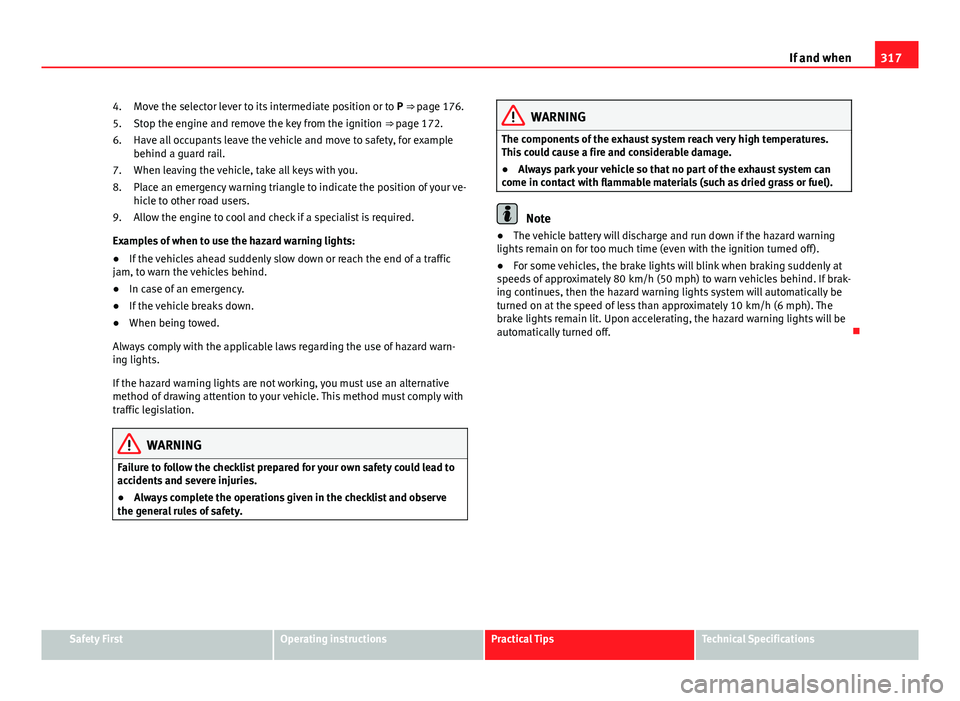

Protecting yourself and securing the vehicle

Fig. 189 In the centre of

the dash panel: Switch

for hazard warning lights

Always fulfil legal requirements for securing a broken down vehicle. In a

number of countries it is now obligatory, for example, to turn on the hazard

warning lights and use a reflective safety vest ⇒ page 318.

When being towed with the hazard warning lights on, a change in direction

or traffic lane can be indicated as usual using the turn signal lever. The haz-

ard lights will be interrupted temporarily.

Checklist

For your own safety and that of other passengers, the following points

should be observed in the order given ⇒

:

Park the vehicle a safe distance from traffic and on suitable ground

⇒

.

Turn on the hazard warning lights with the button

⇒ Fig. 189.

Connect the electronic parking brake ⇒ page 185.

1.

2.

3.

Page 319 of 381

317

If and when

Move the selector lever to its intermediate position or to P ⇒ page 176.

Stop the engine and remove the key from the ignition ⇒ page 172.

Have all occupants leave the vehicle and move to safety, for example

behind a guard rail.

When leaving the vehicle, take all keys with you.

Place an emergency warning triangle to indicate the position of your ve-

hicle to other road users.

Allow the engine to cool and check if a specialist is required.

Examples of when to use the hazard warning lights:

● If the vehicles ahead suddenly slow down or reach the end of a traffic

jam, to warn the vehicles behind.

● In case of an emergency.

● If the vehicle breaks down.

● When being towed.

Always comply with the applicable laws regarding the use of hazard warn-

ing lights.

If the hazard warning lights are not working, you must use an alternative

method of drawing attention to your vehicle. This method must comply with

traffic legislation.

WARNING

Failure to follow the checklist prepared for your own safety could lead to

accidents and severe injuries.

● Always complete the operations given in the checklist and observe

the general rules of safety.

4.

5.

6.

7.

8.

9.WARNING

The components of the exhaust system reach very high temperatures.

This could cause a fire and considerable damage.

● Always park your vehicle so that no part of the exhaust system can

come in contact with flammable materials (such as dried grass or fuel).

Note

● The vehicle battery will discharge and run down if the hazard warning

lights remain on for too much time (even with the ignition turned off).

● For some vehicles, the brake lights will blink when braking suddenly at

speeds of approximately 80 km/h (50 mph) to warn vehicles behind. If brak-

ing continues, then the hazard warning lights system will automatically be

turned on at the speed of less than approximately 10 km/h (6 mph). The

brake lights remain lit. Upon accelerating, the hazard warning lights will be

automatically turned off.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 320 of 381

318If and when

First aid kit, warning triangle, reflective vests and fire

extinguishers*

Fig. 190 On the rear lid:

Warning triangle bracket

Reflective vests

Some vehicles will have a driver door compartment to store a reflective vest

⇒ page 53.

Warning triangle

With the rear lid open, rotate the lock 90° ⇒ Fig. 190. Lower the bracket and

remove the warning triangle.

First-aid kit

There is a first aid kit

⇒ page 142 in the rear left-hand side storage com-

partment of the luggage compartment.

The first aid kit must comply with legal requirements. Check the expiry date

of the contents of the first aid kit.

Fire extinguisher

There is a Fire extinguisher underneath the front passenger seat. The fire extinguisher must conform to legal requirements, be ready for use

and be checked regularly. Check the certification seal on the extinguisher.

WARNING

Loose objects in the vehicle interior can be violently thrown in case of a

sudden manoeuvre or braking and especially in accidents causing seri-

ous injury.

● Secure fire extinguishers, first aid kit, reflective vests and warning

triangle securely to their respective supports.

Emergency locking and unlocking Introduction

The doors, rear lid and panoramic sliding sunroof can be locked manually

and partially opened, for example if the key or the central locking is dam-

aged.

Additional information and warnings:

● Vehicle key set ⇒ page 72

● Central locking and locking system ⇒ page 75

● Doors ⇒ page 81

● Rear lid ⇒ page 84

● Panoramic sliding sunroof ⇒ page 93

● In case of emergency ⇒ page 316