change wheel Seat Alhambra 2017 Owner's Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2017, Model line: Alhambra, Model: Seat Alhambra 2017Pages: 320, PDF Size: 6.88 MB

Page 28 of 320

The essentials

Interior lightsButton/Position: Function

Switches interior lights off.

Switches interior lights on.

Switches door contact control on (central

position).

The interior lights come on automatically

when the vehicle is unlocked, a door is

opened or the key is removed from the igni-

tion.

The lights go off a few seconds after all the

doors are closed, the vehicle is locked or

the ignition is switched on.

Turning the reading light on and off

Ambient light: in the door panel, it changes

c

o

lour (whit

e or red) depending on the driv-

ing mode.

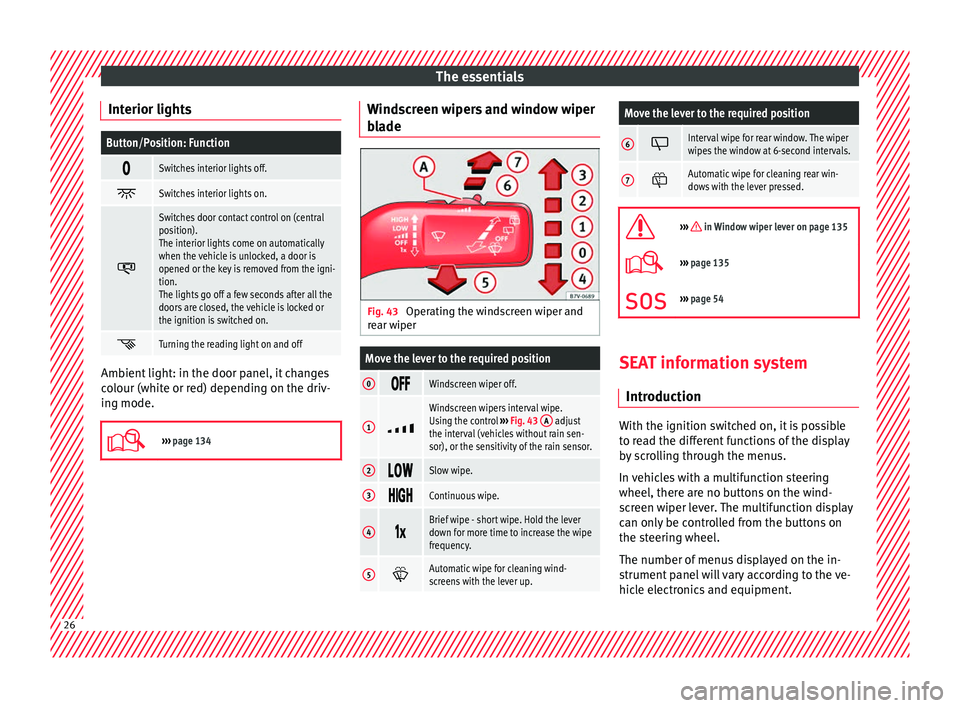

››› page 134 Windscreen wipers and window wiper

b

l

a

de Fig. 43

Operating the windscreen wiper and

r e

ar w

iper

Move the lever to the required position

0 Windscreen wiper off.

1

Windscreen wipers interval wipe.

Using the control

››› Fig. 43 A adjust

the interval (vehicles without rain sen-

sor), or the sensitivity of the rain sensor.

2 Slow wipe.

3

Continuous wipe.

4

Brief wipe - short wipe. Hold the lever

down for more time to increase the wipe

frequency.

5

Automatic wipe for cleaning wind-

screens with the lever up.

Move the lever to the required position

6 Interval wipe for rear window. The wiper

wipes the window at 6-second intervals.

7

Automatic wipe for cleaning rear win-

dows with the lever pressed.

››› in Window wiper lever on page 135

›››

page 135

››› page 54 SEAT information system

Intr oduction With the ignition switched on, it is possible

t

o r

e

ad the different functions of the display

by scrolling through the menus.

In vehicles with a multifunction steering

wheel, there are no buttons on the wind-

screen wiper lever. The multifunction display

can only be controlled from the buttons on

the steering wheel.

The number of menus displayed on the in-

strument panel will vary according to the ve-

hicle electronics and equipment. 26

Page 30 of 320

The essentials

■ Aut oho

l

d

■ Service

■ Info

■ Reset

■ Default setting

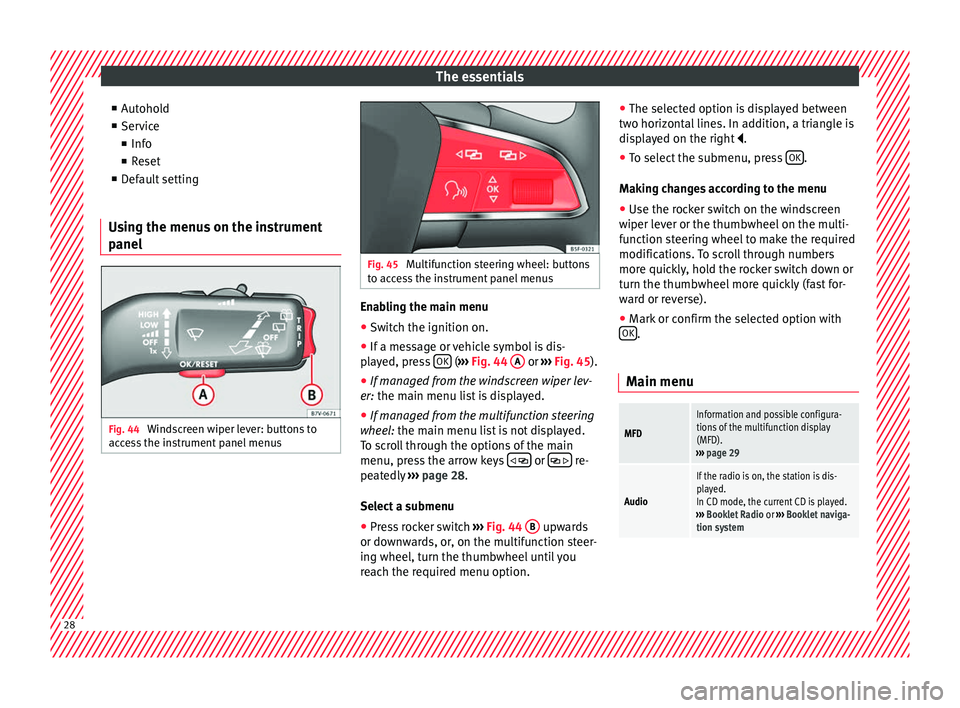

Using the menus on the instrument

panel Fig. 44

Windscreen wiper lever: buttons to

ac c

e

ss the instrument panel menus Fig. 45

Multifunction steering wheel: buttons

to ac c

ess the instrument panel menus Enabling the main menu

● Switch the ignition on.

● If a message or vehicle symbol is dis-

p l

a

yed, press OK (

››

› Fig. 44 A or

››

› Fig. 45 ).

● If managed from the windscreen wiper lev-

er: the main menu lis

t is displayed.

● If managed from the multifunction steering

wheel:

the main menu list is not displayed.

To scroll through the options of the main

menu, press the arrow keys or

re-

pe at

edly

››› page 28.

Select a submenu ● Press rocker switch ›››

Fig. 44 B upwards

or do wn

w

ards, or, on the multifunction steer-

ing wheel, turn the thumbwheel until you

reach the required menu option. ●

The selected option i

s displayed between

two horizontal lines. In addition, a triangle is

displayed on the right .

● To select the submenu, press OK .

M ak

in

g changes according to the menu

● Use the rocker switch on the windscreen

wiper lev

er or the thumbwheel on the multi-

function steering wheel to make the required

modifications. To scroll through numbers

more quickly, hold the rocker switch down or

turn the thumbwheel more quickly (fast for-

ward or reverse).

● Mark or confirm the selected option with

OK .

Main menu

MFD

Information and possible configura-

tions of the multifunction display

(MFD).

››› page 29

Audio

If the radio is on, the station is dis-

played.

In CD mode, the current CD is played.

››› Booklet Radio or ››› Booklet naviga-

tion system 28

Page 46 of 320

The essentials

Action in the event of a punc-

t ur

e

Wh

at to do first ●

Park the vehicle on a horizontal surface

and in a saf e p

lace as far away from traffic as

possible.

● Apply the handbrake.

● Switch on the hazard warning lights.

● Manual gearbox: select the 1s

t gear.

● Automatic gearbox: Move the sel

ector lever

to position P.

● If you are towing a trailer, unhitch it from

your v

ehicle.

● Keep the vehicle tool kit ready*

›››

page 82.

● Observe the applicable legislation for each

countr

y (reflective vest, warning triangles,

etc.).

● All occupants should leave the vehicle and

wait in a s

afe place (for instance behind the

roadside crash barrier). WARNING

● Alw a

ys observe the above steps and pro-

tect yourself and other road users.

● If you change the wheel on a slope, block

the wheel on the oppo

site side of the car with

a stone or similar to prevent the vehicle from

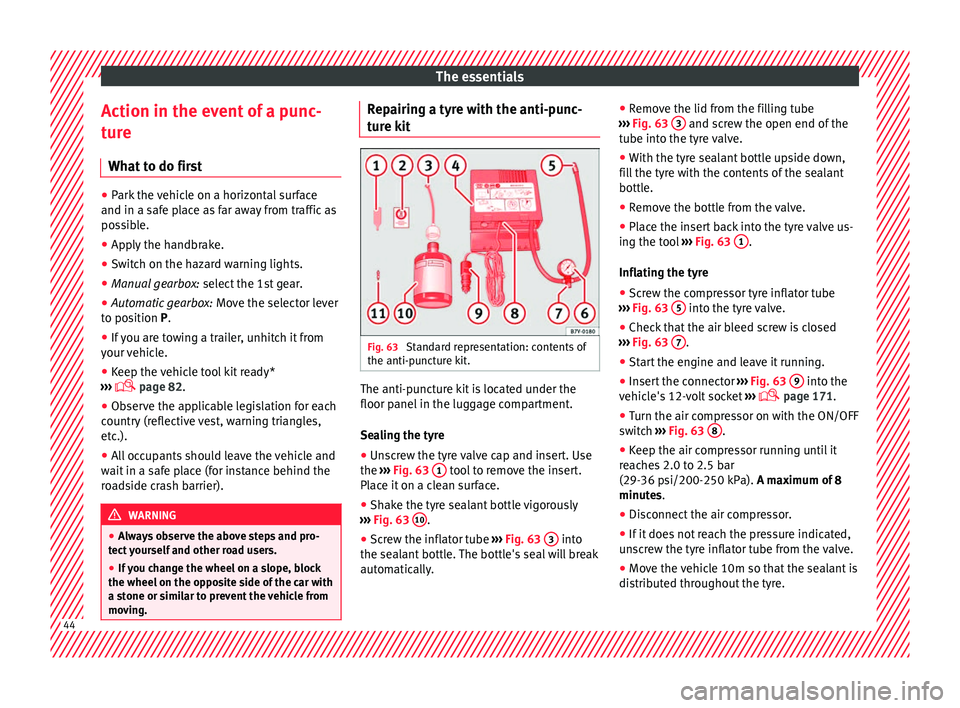

moving. Repairing a tyre with the anti-punc-

t

ur

e k

it Fig. 63

Standard representation: contents of

the anti-p u

nct

ure kit. The anti-puncture kit is located under the

floor p

anel

in the lug

gage compartment.

Sealing the tyre

● Unscrew the tyre valve cap and insert. Use

the ›››

Fig. 63 1 tool to remove the insert.

Pl ac

e it

on a clean surface.

● Shake the tyre sealant bottle vigorously

›››

Fig. 63 10 .

● Screw the inflator tube ››

›

Fig. 63 3 into

the se al

ant

bottle. The bottle's seal will break

automatically. ●

Remov

e the lid from the filling tube

››› Fig. 63 3 and screw the open end of the

t ube int

o the ty

re valve.

● With the tyre sealant bottle upside down,

fill

the tyre with the contents of the sealant

bottle.

● Remove the bottle from the valve.

● Place the insert back into the tyre valve us-

ing the too

l ››› Fig. 63 1 .

Infl atin

g the ty

re

● Screw the compressor tyre inflator tube

›››

Fig. 63 5 into the tyre valve.

● Check that the air bleed screw is closed

› ›

›

Fig. 63 7 .

● Start the engine and leave it running.

● Insert the connector ››

›

Fig. 63 9 into the

v ehic

l

e's 12-volt socket ›››

page 171.

● Turn the air compressor on with the ON/OFF

switc

h ››› Fig. 63 8 .

● Keep the air compressor running until it

r e

ac

hes 2.0 to 2.5 bar

(29-36 psi/200-250 kPa). A maximum of 8

minutes.

● Disconnect the air compressor.

● If it does not reach the pressure indicated,

uns

crew the tyre inflator tube from the valve.

● Move the vehicle 10m so that the sealant is

dis trib

uted throughout the tyre.44

Page 50 of 320

The essentials

The jack may be applied only at the jacking

points sho

wn (m

arks on chassis) ››› Fig. 69.

The mark indicates the jacking points below

the vehicle. The jacking points are on the ribs

behind the front edges ››› Fig. 70. Always the

relevant jacking point for the wheel to be

changed ››› .

R ai

se the

vehicle using only the designated

jacking points.

For your own safety and that of other passen-

gers, the following points should be ob-

served in the order given:

Select a suitable flat and firm surface for

raising the vehicle.

Switch off the engine, engage a gear

(manual gearbox) or place the selector

lever in position P ›››

page 192 and

turn on the electronic parking brake

››› page 187.

Block the wheel diagonally opposite the

wheel being changed with folding wheel

chocks* or other suitable objects.

When towing a trailer: unhook the trailer

from the towing vehicle and park it cor-

rectly.

Loosen the wheel bolts on the wheel to

be changed ››› page 46.

Look below the vehicle for the jacking

point ››› Fig. 69 closest to the tyre which

has to be changed.

1.

2.

3.

4.

5.

6. Raise the jack with the handle until it

can be inser

ted below the jacking point.

Ensure that the foot of the jack is firmly

on the ground and that it is placed im-

mediately below the lifting point on the

vehicle ››› Fig. 70.

Straighten the jack and continue raising

it using the handle until the claw holds

the vertical reinforcement beneath the

vehicle ››› Fig. 70.

Raise the vehicle until the wheel is clear

of the ground. WARNING

If the vehicle is not correctly raised, it could

fa l

l off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT f

or your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground i

s sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

plac

e a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The c

law of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 70. 7.

8.

9.

10.

●

You shou l

d never place a body limb such as

an arm or leg under a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you mus

t use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!.

● Never raise the vehicle if it is tilting to one

side or the engine i

s running.

● Never start the engine when the vehicle is

raised.

The vehicle may come loose from the

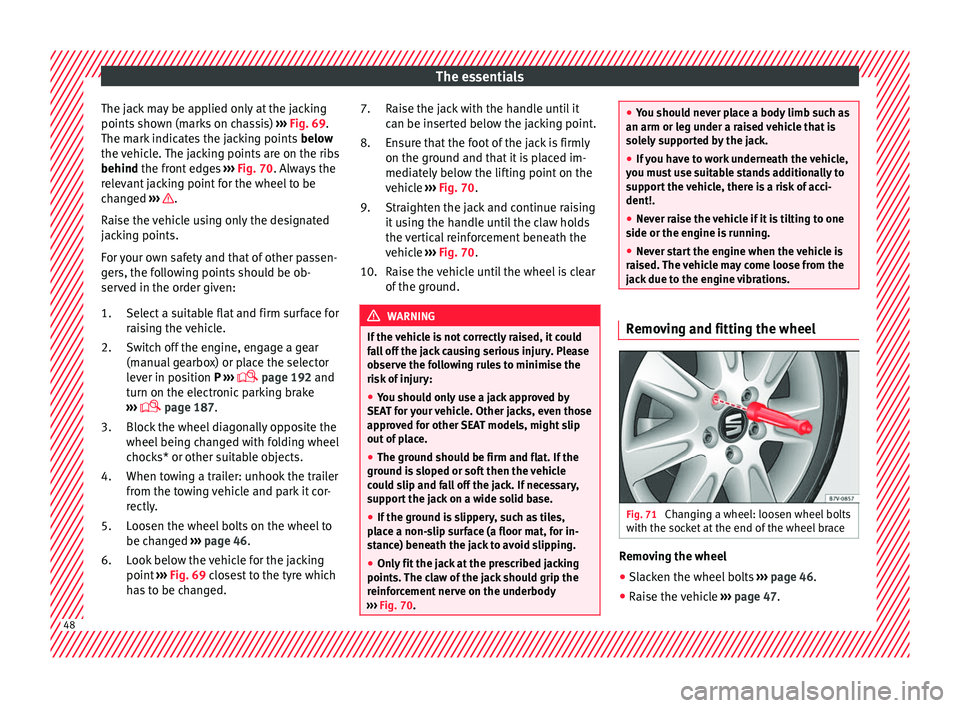

jack due to the engine vibrations. Removing and fitting the wheel

Fig. 71

Changing a wheel: loosen wheel bolts

w ith the soc

k

et at the end of the wheel brace Removing the wheel

● Slacken the wheel bolts ››

›

page 46.

● Raise the vehicle ›››

page 47. 48

Page 51 of 320

The essentials

● Us

in

g the hexagonal socket in the wheel

brace ››› Fig. 71, unscrew the slackened

wheel bolts and place them on a clean sur-

face.

● Take off the wheel.

Putting on the s

pare wheel

Check the direction of rotation of the tyre

››› page 49.

● Fit the wheel.

● Screw on the anti-theft locking bolt with

the adapt

er in position ››› Fig. 68 2 or

3 clockwise and tighten gently.

●

Replace the other wheel bolts and tighten

s ligh

tl

y using the hexagonal socket on the

end of the wheel brace.

● Lower the car with the jack.

● Tighten all of the wheel bolts clockwise

›››

. Tighten the bolts in diagonal pairs (not

in a c ir

c

le).

● Put the caps, trim or full hubcap back on

›››

page 45. WARNING

If the wheel bolts are not treated suitably or

not tight ened t

o the correct torque then this

could lead to loss of vehicle control and to a

serious accident.

● All the wheel bolts and hub threads should

be cle

an and free of oil and grease. The wheel bolts should be easily tightened to the cor-

rect

t

orque.

● The hexagonal socket in the wheel brace

should be u

sed for turning wheel bolts only.

Do not use it to loosen or tighten the wheel

bolts. Tyres with directional tread pattern

Tyres with directional tread pattern have

been des

igned t

o operate best when rotating

in only one direction. An arrow on the tyre

sidewall indicates the direction of rotation on

tyres with directional tread ›››

page 291.

Always observe the indicated direction of ro-

tation in order to guarantee optimum grip

and help avoid aquaplaning, excessive noise

and wear.

If the tyre is mounted in the opposite direc-

tion of rotation, drive with extreme caution,

as the tyre is no longer being used correctly.

This is of particular importance when the

road surface is wet. Change the tyre as soon

as possible or remount it with the correct di-

rection of rotation.

Subsequent work ●

On alloy wheels: repl

ace the wheel bolt

caps.

● On plate wheels: rep l

ace the wheel hubcap. ●

Return al

l tools to their proper storing loca-

tion ›››

page 82.

● Check the tyre pressure of the newly moun-

ted tyr

e as soon as possible.

● If the vehicle is fitted with a tyre monitoring

syst

em, this should be “reprogrammed” if

necessary whenever a tyre is changed

››› page 231.

● Have the tightening torque of the wheel

bolts c

hecked as soon as possible with a tor-

que wrench ››› page 47. Meanwhile, drive

carefully.

Snow chains

Use When using snow chains, applicable local

l

e

gi

slation and maximum permitted speed

limits must be observed.

In winter weather, snow chains not only help

to improve grip but also improve the braking

capacity.

Snow chains must only be mounted on the

front wheels , even on all-wheel drive vehi-

cles, and only with the tyre and rim combina-

tions listed below:

Tyre sizeWheel rim

205/60 R166 1/2 J x 16 ET 33» 49

Page 60 of 320

Safety

The correct sitting positions for the driver and

p a

s

sengers are shown below.

If your physical constitution prevents you

from maintaining the correct sitting position,

contact a specialised workshop for help with

any special devices. The seat belt and airbag

can only provide optimum protection if a cor-

rect sitting position is adopted. SEAT recom-

mends taking your car in for technical serv-

ice.

For your own safety and to reduce the risk of

injury in the event of an accident or sudden

braking or manoeuvre, SEAT recommend the

following positions:

Valid for all vehicle occupants:

● Adjust the head restraint so that its upper

edge is

at the same level as the top of your

head, or as close as possible to the same lev-

el as the top of your head and under no cir-

cumstances below eye level. Keep the back

of your neck as close as possible to the head

restraint ››› Fig. 80 and ››› Fig. 81.

● Short people must lower the head restraint

compl

etely, even if your head is below its up-

per edge.

● Tall people must raise the head restraint

compl

etely.

● Adjust the seat backrest to an upright posi-

tion so that

your back rests completely

against it. ●

Alwa

ys keep your feet in the footwell while

the vehicle is in motion.

● Adjust and fasten your seat belt correctly

›››

page 64.

Also valid for the driver:

● Adjust the steering wheel so that there is a

dist

ance of at least 25 cm (10 inches) be-

tween it and your chest ››› Fig. 80 and so that

you can hold the steering wheel with both

hands on the outside of the ring at the 9

o'clock and 3 o'clock positions with your

arms slightly bent.

● The adjusted steering wheel must face your

ches

t and not your face.

● Adjust the driver seat forwards or back-

ward

s so that you are able to press the accel-

erator, brake and clutch pedals to the floor

with your knees slightly angled and the dis-

tance between your knees and the dash pan-

el is at least 10 cm (4 inches) ››› Fig. 80.

● Adjust the height of the driver seat so that

you can e

asily reach the top of the steering

wheel.

● Keep both feet in the footwell so that you

have the

vehicle under control at all times.

Also valid for the front passenger:

● Move the front passenger seat back as far

as po

ssible for optimum protection should

the airbag deploy. Adjusting the steering wheel position Read the additional information carefully

›› ›

page 16. WARNING

Incorrect use of the steering wheel adjust-

ment f u

nction and an incorrect adjustment of

the steering wheel can result in severe or fa-

tal injury.

● After adjusting the steering column, push

the lever ›

›› Fig. 24

1 firmly upwards to

ens ur

e the steering wheel does not acciden-

tally change position while driving.

● Never adjust the steering wheel while the

vehicl

e is in motion. If you need to adjust the

steering wheel while the vehicle is in motion,

stop safely and make the proper adjustment.

● The adjusted steering wheel should be fac-

ing y

our chest and not your face so as not to

hinder the driver's front airbag protection in

the event of an accident.

● When driving, always hold the steering

wheel with both h

ands on the outside of the

ring at the 9 o'clock and 3 o'clock positions

to reduce injuries when the driver's front air-

bag deploys.

● Never hold the steering wheel at the 12

o'clock

position or in any other manner (e.g.

in the centre of the steering wheel). In such

cases, if the driver's airbag deploys, you may

sustain injuries to your arms, hands and

head. 58

Page 85 of 320

Self-help

especially in accidents causing serious in-

jury

.

● M

ake sure that the vehicle tools are stored

safely

in the luggage compartment. WARNING

Unsuitable or damaged vehicle tools can

c au se injur

y or accidents.

● Never work with inappropriate or damaged

tool

s. Note

After use, return the jack to its initial position

us in

g the handle in order to securely store it

in the vehicle. Components

Fig. 100

Components of the vehicle tool kit The vehicle tool kit depends on the vehicle

equipment

.

The f

ollowing is a description for

a vehicle with all options.

The individual elements of the vehicle tool

kit ››› Fig. 100

Adapter for anti-theft bolt. SEAT recom-

mend you carry the wheel bolt adapter in

the vehicle tool kit at all times. The code

number of the anti-theft wheel bolt is

stamped on the front of the adapter. In

case it is lost, another adapter can be or-

dered using this number. Note the anti-

theft bolt code for the wheels and keep it

in a place other than the vehicle.

Towline anchorage, removable.

Wheel spanner.

Jack crank handle. The crank handle

needs to be folded away before returning

it to the tool kit.

Jack. Before storing the jack in the tool

kit, fold its hook.

Screwdriver with hexagon socket in the

handle for screwing and unscrewing the

wheel bolts. The screwdriver bit is inter-

changeable. The screwdriver may be

found underneath the wheel spanner.

Wire hook for pulling off the wheel cover,

integral hubcaps and the wheel bolt

caps.

1

2

3

4

5

6

7 Note

The jack does not generally require any main-

ten anc

e. If required, it should be greased us-

ing universal type grease. Folding wheel chocks*

Fig. 101

To unfold the foldable wedges. The folding chocks are in the tool kit

› ›

›

Fig. 100.

Assemble the folding chocks

● Lift the base plate ›››

Fig. 101 1 .

● Insert the two “tabs” of the mounting plate

int o the lon

g openin

gs on the base plate 2 .

C orr

ect

use

The folding chocks may be used to block the

wheel diagonally opposite to the wheel being

changed. »

83

Technical data

Advice

Operation

Emergencies

Safety

Page 86 of 320

Emergencies

The chocks should be placed directly in front

and behind the wheel and on

ly

be used on

firm ground. WARNING

If the folding chocks are assembled or used

incorr ectly

, an accident may occur and seri-

ous injury caused.

● Never use damaged chocks.

● Never use chocks to immobilize the vehicle

on a slope. Changing a wheel*

Intr oduction Read the additional information carefully

› ›

›

page 45

All Alhambra models have TMS (Tyre Mobility

System).

If a tyre needs to be changed the tools neces-

sary are available at spare parts dealers:

● Jack,

● box spanner for wheel bolts,

● tool to remove wheel bolt caps

The tyre

s mounted on the vehicle are anti-

puncture. The wheels should only be

changed when switching from summer to

winter tyres or vice-versa. See ›››

page 290 The vehicle only comes with the necessary

tool

s for changing wheels if factory supplied

with winter tyres. If this is not the case, you

need to go to a specialised workshop to get

the wheels changed.

You should only change the wheels yourself if

the vehicle is parked in a safe place, you are

familiar with the procedure and safety stand-

ards and you have all the necessary tools!

Otherwise, you should seek professional as-

sistance. WARNING

Changing a wheel can be dangerous, espe-

ci a

lly on the hard shoulder. Please observe

the following rules to minimise the risk of in-

jury:

● Stop the vehicle safely as soon as possible.

Park at

a safe distance from surrounding traf-

fic to change a wheel.

● When changing a wheel, keep all passen-

gers, and p

articularly children, a safe dis-

tance away from the work area.

● Turn on the hazard warning lights to warn

other roa

d users.

● Ensure the ground on which you park is flat

and solid. If nec

essary, support the jack on a

wide solid base.

● If you are changing a wheel yourself, you

should be f

amiliar with the required proce-

dure. Otherwise, you should seek professio-

nal assistance. ●

Only u

se suitable tools that are not dam-

aged when changing a wheel.

● Always stop the engine, turn on the elec-

tronic p

arking brake and place the gear selec-

tor lever in position P, for an automatic gear-

box, or engage a gear for a manual gearbox to

reduce the risk of the vehicle moving acciden-

tally.

● Have the tightening torque of the wheel

bolts

checked as soon as possible with a reli-

able torque wrench. WARNING

If the wheel trims are not appropriate or not

fitted c orr

ectly, they could cause major acci-

dents or damage.

● Incorrectly mounted wheel trims may come

off whil

e driving and endanger other road

users.

● Damaged trims must never be mounted on

the wheels.

● Alw

ays ensure that the brake ventilation

and coolin

g is not cut off or blocked. This is

also valid if hubcaps are fitted later. If there

is not enough air, you may require signifi-

cantly longer braking distances. CAUTION

Remove and remount wheel trims taking care

to av oid d

amage to the vehicle.84

Page 89 of 320

Self-help

Changing the windscreen wiper

b l

a

des

Changing the windscreen and rear

window wiper blades Read the additional information carefully

›› ›

page 54.

The windscreen wiper blades are supplied as

standard with a layer of graphite. This layer is

responsible for ensuring that the wipe is si-

lent. If the graphite layer is damaged, the

noise of the water as it is wiped across the

windscreen will be louder.

Check the condition of the wiper blades regu-

larly. If the wipers scrape across the glass

they should be changed if they are damaged,

or cleaned if they are dirty ››› .

Dam ag

ed w

iper blades should be replaced

immediately. These are available from quali-

fied workshops. WARNING

Worn or dirty wiper blades reduce visibility

and incr e

ase the risk of accident and serious

injury.

● Always replace damaged or worn blades or

bla

des which do not clean the windscreen

correctly. CAUTION

● Damag ed or dir

ty windscreen wipers could

scratch the glass.

● If products containing solvents, rough

spong

es or sharp objects are used to clean

the blades, the graphite layer will be dam-

aged.

● Never use fuel, nail varnish remover, paint

thinner or simil

ar products to clean the win-

dows.

● In icy conditions, always check that the

wiper bl

ades are not frozen to the glass be-

fore using the wipers. In cold weather, it may

help to leave the vehicle parked with the wip-

ers in service position ›››

page 54.

● To prevent damage to the bonnet and the

wiper arms, only

leave them in the service

position.

● Before driving, always lower the wiper

arms. Tow-starting and towing

Intr oduction Read the additional information carefully

› ›

›

page 50

When towing, always respect legal require-

ments.

For technical reasons, it is not possible to

tow a vehicle if the battery is flat. If the vehicle comes with the Keyless Access

syst

em, towing is only allowed with the igni-

tion on!

The vehicle battery drains if the vehicle is

towed with the engine switched off and the

ignition connected. Depending on the battery

charge status, the drop in voltage may be so

large, even after just a few minutes, that no

electrical device in the vehicle may work e.g.

the hazard warning lights. In vehicles with

the Keyless Access system, the steering

wheel could lock ››› .

WARNING

A vehicle with a flat battery should never be

to w

ed.

● Never remove the key from the ignition

lock. Otherw

ise, the steering wheel lock

could suddenly lock. The vehicle would not

be controlled and a serious accident could

ensue. WARNING

When towing the vehicle, the handling and

brak in

g efficiency change considerably.

Please observe the following instructions to

minimise the risk of serious accidents and in-

jury:

● As the driver of the vehicle being towed:

– The brake mu

st be depressed must hard-

er as the brake servo does not operate. » 87

Technical data

Advice

Operation

Emergencies

Safety

Page 91 of 320

Self-help

Note the instructions for towing

› ›

›

page 50.

Fitting the towline anchorage to the rear for

vehicles without factory fitted tow hitch

● Take the towline anchorage from the vehi-

cle t

ool kit in the luggage compartment

››› page 82.

● Press on the upper cover and carefully re-

move it

back. This may require some

strength. Allow the cover to hang.

● Screw in the towline anchorage into its po-

sition antic

lockwise as far as it will go ››› .

U se a s

uit

able tool to firmly tighten the tow-

line anchorage in its location.

● After towing, remove the towline anchorage

by t

urning it clockwise and put the cover

back in place. CAUTION

● The to wline anc

horage must always be

completely and firmly tightened. Otherwise,

it could be released while towing and tow-

starting.

● Vehicles with a factory fitted towing brack-

et, can only

be used for towing with a tow

bar, specially designed to fit on a tow hitch

ball. Otherwise, the tow hitch ball and the ve-

hicle may be damaged. Otherwise, a tow rope

should be used. Towing advice

Towing requires some expertise and experi-

ence, e

s

pecially when using a tow rope. Both

drivers should be familiar with the technique

required for towing. For this reason, inexper-

ienced drivers should abstain.

While driving, avoid excessive traction forces

and jerking. When towing on an unpaved

road, there is always a risk of overloading

and damaging the anchorage points.

If the vehicle is towed, with the hazard warn-

ing lights on and the ignition switched on,

the turn signal may be used to indicate

changes of direction. Simply operate the turn

signal lever as usual. Meanwhile, the hazard

warning lights will go off. When the turn sig-

nal lever is returned to the rest position, the

hazard warning lights will be turned on auto-

matically.

Notes for the driver of the towed vehicle

● Leave the ignition on to avoid locking the

st eerin

g wheel, to release the electronic

parking brake and to activate the turn sig-

nals, the horn as well as the window wipers

and window washers.

● As the power assisted steering does not

work if

the engine is not running, you will

need more strength to steer than normally. ●

The brake mu

st be depressed must harder

as the brake servo does not operate. Avoid

hitting the towing vehicle.

● Note the instructions and information con-

tained in the Ins

truction Manual for the vehi-

cle to be towed.

Notes for the driver of the towing vehicle

● Accelerate gently and carefully. Avoid sud-

den manoeuvr

es.

● Brake well in advance than usual and brake

gently.

● Not

e the instructions and information con-

tained in the Ins

truction Manual for the vehi-

cle to be towed.

Emergency locking and unlock-

ing

Introduction Read the additional information carefully

› ›

›

page 8,

›››

page 10,

››› page 13

The doors, rear lid and panoramic sliding

sunroof can be locked manually and partially

opened, for example if the key or the central

locking is damaged. »

89

Technical data

Advice

Operation

Emergencies

Safety