engine Seat Altea 2015 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Altea, Model: Seat Altea 2015Pages: 236, PDF Size: 4.23 MB

Page 163 of 236

Checking and refilling levels

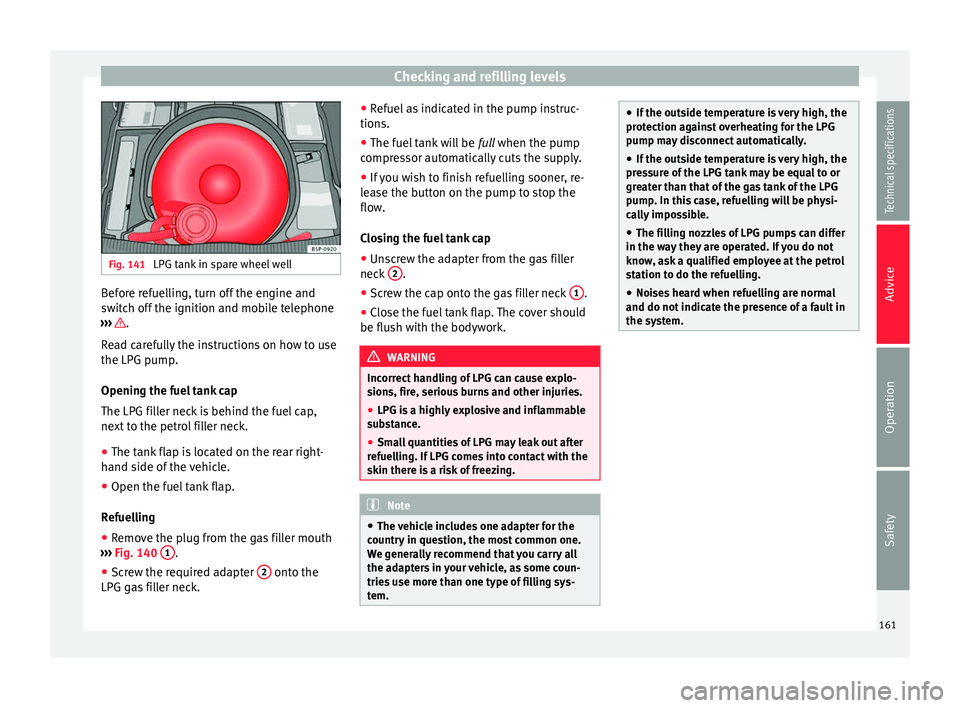

Fig. 141

LPG tank in spare wheel well Before refuelling, turn off the engine and

switch off the ignition and mobile telephone

››› .

Read carefully the instructions on how to use

the LPG pump.

Opening the fuel tank cap

The LPG filler neck is behind the fuel cap,

next to the petrol filler neck.

● The tank flap is located on the rear right-

hand side of the vehicle.

● Open the fuel tank flap.

Refuelling

● Remove the plug from the gas filler mouth

››› Fig. 140 1 .

● Screw the required adapter 2 onto the

LPG gas filler neck. ●

Refuel as indicated in the pump instruc-

tions.

● The fuel tank will be full when the pump

c ompr

essor automatically cuts the supply.

● If you wish to finish refuelling sooner, re-

lease the button on the pump to stop the

flow.

Closing the fuel tank cap

● Unscrew the adapter from the gas filler

neck 2 .

● Screw the cap onto the gas filler neck 1 .

● Close the fuel tank flap. The cover should

be flush with the bodywork. WARNING

Incorrect handling of LPG can cause explo-

sions, fire, serious burns and other injuries.

● LPG is a highly explosive and inflammable

substance.

● Small quantities of LPG may leak out after

refuelling. If LPG comes into contact with the

skin there is a risk of freezing. Note

● The vehicle includes one adapter for the

country in question, the most common one.

We generally recommend that you carry all

the adapters in your vehicle, as some coun-

tries use more than one type of filling sys-

tem. ●

If the outside temperature is very high, the

protection against overheating for the LPG

pump may disconnect automatically.

● If the outside temperature is very high, the

pressure of the LPG tank may be equal to or

greater than that of the gas tank of the LPG

pump. In this case, refuelling will be physi-

cally impossible.

● The filling nozzles of LPG pumps can differ

in the way they are operated. If you do not

know, ask a qualified employee at the petrol

station to do the refuelling.

● Noises heard when refuelling are normal

and do not indicate the presence of a fault in

the system. 161

Technical specifications

Advice

Operation

Safety

Page 165 of 236

Checking and refilling levels

LPG quality and consumption

Quality requirements for LPG are regulated

for all Europe in DIN EN 589 and permit the

use of LPG throughout Europe.

A difference is drawn between winter gas and

summer gas. Winter gas has a higher propor-

tion of propane gas. As a result, the driving

range of winter gas may be lower (due to in-

creased consumption) than that of summer

gas.

LPG supplier network

The number of LPG pumps is constantly in-

creasing.

Lists of existing LPG pumps may be found on

Internet.

LPG safety A series of collision tests performed on this

vehicle while running with LPG have con-

firmed its high level of safety.

The safety of the LPG system guarantees op-

eration without risk. The following safety

measures have been adopted:

● The LPG tank has a solenoid valve which

closes automatically when the engine is

switched off (ignition off) or when running on

petrol. ●

A solenoid type main valve disconnects the

supply of gas to the engine compartment

when the engine is switched off or running

on petrol.

● A safety valve in the LPG tank with pipes to

the outside prevents the gas from entering

the vehicle interior.

● All anchorage points and materials have

been designed to ensure the maximum pos-

sible levels of safety.

The condition of the LPG system should be

checked regularly to guarantee safe driving

conditions ››› . These checks are included

in the Maintenance Programme. WARNING

● If there is a smell of gas or a suspected

leak, stop the vehicle immediately and switch

off the ignition. Open the doors to ventilate

the vehicle. Do not carry on driving! Take the

vehicle to a specialised workshop and have

the fault repaired.

● Immediately extinguish any cigarettes and

remove from the vehicle any objects which

might produce a spark or cause a fire, and

switch off immediately if gas is smelt or a

leak is detected.

● LPG tanks are subject to pressure and must

be checked regularly. The owner of the vehi-

cle must check that these services are per-

formed correctly. ●

When parking the vehicle in a closed area

(e.g. in a garage), make sure that there is ad-

equate ventilation, either natural or mechani-

cal, to neutralise the LPG in the event of a

leak. Note

For any fault in the LPG system, please refer

to the SEAT web page, which lists the work-

shops authorised to repair these faults. Working in the engine

compartment

Safety instructions on working in the

engine compartment Before starting any work on the engine or in

the engine compartment:

1. Switch off the engine and remove the key

from the ignition.

2. Apply the handbrake.

3. Move the gear lever to neutral or the selec- tor lever to position P.

4. Wait for the engine to cool down.

5. Keep children away from the vehicle.

6. Raise the bonnet ››› page 165.

»

163Technical specifications

Advice

Operation

Safety

Page 166 of 236

Advice

You should not do any work in the engine

compartment unless you know exactly how to

carry out the jobs and have the correct tools!

Have the work carried out by a specialised

workshop if you are uncertain.

All service fluids and consumables, e.g. cool-

ant, engine oil, spark plugs and batteries,

are under constant development. SEAT pro-

vides a constant flow of information to Tech-

nical Services concerning modifications. For

this reason, we recommend you have service

fluids and consumables replaced by a Techni-

cal Service. Please observe the relevant in-

structions ››› page 147 . The engine compart-

ment of

the vehicle is a hazardous area.

››› .

WARNING

All work on the engine or in the engine com-

partment, e.g. checking and refilling fluids,

involves the danger of injury and burns, acci-

dents and even fire.

● Never open the bonnet if you see steam,

smoke or coolant escaping from the engine

compartment. Otherwise, there is a risk of

sustaining burns. Wait until no more steam or

coolant is emitted, then allow the engine to

cool before carefully opening the bonnet.

● Switch off the engine and remove the key

from the ignition.

● Apply the handbrake and move the gear

lever to neutral or selector lever to position P.

● Keep children away from the vehicle. ●

Never touch hot engine parts. There is a

risk of burns.

● Never spill liquids on a hot engine or on a

hot exhaust gas system. This is a fire hazard.

● Avoid causing short-circuits in the electri-

cal system, particularly at the points where

the jump leads are attached ››› page 190. The

battery could explode.

● Never touch the radiator fan. It is tempera-

ture controlled and could start automatically,

even when the engine has been switched off

and the key removed from the ignition!

● Never cover the engine with additional in-

sulating materials such as a blanket. Risk of

fire!

● Do not unscrew the cap on the coolant ex-

pansion tank when the engine is hot. If the

coolant is hot, the cooling system will be

pressurised!

● Protect face, hands and arms by covering

the cap with a large, thick cloth to protect

against escaping coolant and steam.

● Always make sure you have not left any ob-

jects, such as cleaning cloths or tools, in the

engine compartment.

● If you have to work underneath the vehicle,

you must use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!. A hydraulic jack is insufficient for se-

curing the vehicle and there is a risk of injury.

● If any work has to be performed when the

engine is started or with the engine running,

there is an additional, potentially fatal, safety

risk from the rotating parts, such as the drive belts, alternator, radiator fan, etc., and from

the high-voltage ignition system. You should

also observe the following:

– Never touch the electrical wiring of the

ignition system.

– Ensure that jewellery, loose clothing and

long hair do not get trapped in rotating

engine parts. Danger of death. Before

starting any work remove jewellery, tie

back and cover hair, and wear tight-fit-

ting clothes.

– Never accelerate with a gear engaged

without taking the necessary precau-

tions. The vehicle could move, even if the

handbrake is applied. Danger of death.

● If work has to be carried out on the fuel

system or on electrical components, you

must observe the following safety notes in

addition to the above warnings:

– Always disconnect the battery from the

on-board network. The vehicle must be

unlocked when this is done, otherwise

the alarm will be triggered.

– Do not smoke.

– Never work near naked flames.

– Always have a fire extinguisher on hand. CAUTION

When topping up service fluids, make sure

not to mistake them. Using the wrong fluids

could cause serious malfunctions and engine

damage! 164

Page 167 of 236

Checking and refilling levels

For the sake of the environment

Service fluids leaks are harmful to the envi-

ronment. For this reason you should make

regular checks on the ground underneath

your vehicle. If you find spots of oil or other

fluids, have your vehicle inspected in a speci-

alised workshop. Opening the bonnet

Fig. 144

Detail of footwell area on driver side:

lever for unlocking the bonnet Fig. 145

Handle for releasing the bonnet. The bonnet is released from inside the vehi-

cle.

Before opening the bonnet ensure that the

windscreen wipers are in rest position.

– To release the bonnet, pull the lever under

the dash panel ››› Fig. 144 in the direction

indic at

ed (arrow). The bonnet will be re-

leased by a spring action ››› .

– Lift the bonnet using the release lever (ar-

row) and open the bonnet.

– Release the bonnet stay and secure it in

the fixture designed for this in the bonnet. WARNING

Hot coolant can scald!

● Never open the bonnet if you see steam,

smoke or coolant escaping from the engine

compartment. ●

Wait until no more steam, smoke or coolant

is emitted from the bonnet, then carefully

open the bonnet.

● When working in the engine compartment,

always observe the safety warnings

››› page 163. Closing the bonnet

–

Slightly lift the bonnet.

– Release the bonnet stay and replace it in its

support.

– At a height of approximately 30 cm let it fall

so it locks.

If the bonnet does not close, do not press

downwards. Open it once more and let it fall

as before. WARNING

If the bonnet is not closed properly, it could

open while you are driving and completely

obscure your view of the road. Risk of acci-

dent.

● After closing the bonnet, always check that

it is properly secured. The bonnet must be

flush with the surrounding body panels.

● If you notice that the bonnet latch is not se-

cured when the vehicle is moving, stop the

vehicle immediately and close the bonnet

properly. Risk of accident. 165

Technical specifications

Advice

Operation

Safety

Page 168 of 236

Advice

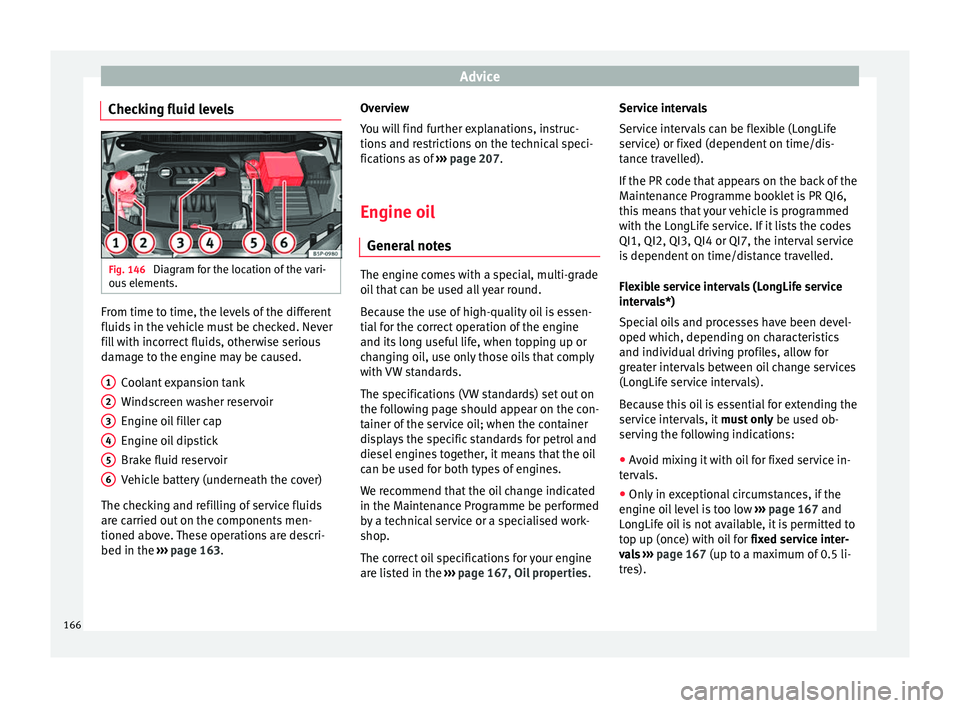

Checking fluid levels Fig. 146

Diagram for the location of the vari-

ous elements. From time to time, the levels of the different

fluids in the vehicle must be checked. Never

fill with incorrect fluids, otherwise serious

damage to the engine may be caused.

Coolant expansion tank

Windscreen washer reservoir

Engine oil filler cap

Engine oil dipstick

Brake fluid reservoir

Vehicle battery (underneath the cover)

The checking and refilling of service fluids

are carried out on the components men-

tioned above. These operations are descri-

bed in the ››› page 163 .

1 2

3

4

5

6 Overview

You will find further explanations, instruc-

tions and restrictions on the technical speci-

fications as of

››› page 207 .

En gine oi

l

General notes The engine comes with a special, multi-grade

oil that can be used all year round.

Because the use of high-quality oil is essen-

tial for the correct operation of the engine

and its long useful life, when topping up or

changing oil, use only those oils that comply

with VW standards.

The specifications (VW standards) set out on

the following page should appear on the con-

tainer of the service oil; when the container

displays the specific standards for petrol and

diesel engines together, it means that the oil

can be used for both types of engines.

We recommend that the oil change indicated

in the Maintenance Programme be performed

by a technical service or a specialised work-

shop.

The correct oil specifications for your engine

are listed in the

›››

page 167, Oil properties .Service intervals

Service intervals can be flexible (LongLife

service) or fixed (dependent on time/dis-

tance travelled).

If the PR code that appears on the back of the

Maintenance Programme booklet is PR QI6,

this means that your vehicle is programmed

with the LongLife service. If it lists the codes

QI1, QI2, QI3, QI4 or QI7, the interval service

is dependent on time/distance travelled.

Flexible service intervals (LongLife service

intervals*)

Special oils and processes have been devel-

oped which, depending on characteristics

and individual driving profiles, allow for

greater intervals between oil change services

(LongLife service intervals).

Because this oil is essential for extending the

service intervals, it

must only be used ob-

serving the following indications:

● Avoid mixing it with oil for fixed service in-

tervals.

● Only in exceptional circumstances, if the

engine oil level is too low ››› page 167 and

LongLife oil is not available, it is permitted to

top up (once) with oil for fixed service inter-

vals › ›

›

page 167 (up to a maximum of 0.5 li-

tres).

166

Page 169 of 236

Checking and refilling levels

Fixed service intervals*

If your vehicle does not have the “LongLife

service interval” or it has been disabled (by

request), you may use oils for fixed service

intervals , which also appear in

›

› › page 167,

Oil properties . In this case, your vehicle must

be serviced after a fixed interval of 1

year/15 000 km (10 000 miles)(whatever

comes first) ››› Booklet Maintenance Pro-

gramme.

● In ex

ceptional circumstances, if the engine

oil level is too low ››› page 167 and you can-

not o

btain the oil specified for your vehicle,

you can put in a small quantity of oil con-

forming to the specification ACEA A2 or

ACEA A3 (petrol engines) or ACEA B3 or

ACEA B4 (diesel engines) (up to 0.5 l).

Vehicles with a diesel particulate filter*

The Maintenance Programme states whether

your vehicle is fitted with a diesel particulate

filter.

Only VW 507 00 engine oil, with reduced ash

formation, may be used in diesel engines

equipped with particulate filter. Using other

types of oil will cause a higher soot concen-

tration and reduce the life of the DPF. There-

fore:

● Avoid mixing this oil with other engine oils.

● Only in exceptional circumstances, if the

engine oil level is too low ››› page 167 and you cannot obtain the oil specified for your

vehicle, you can use a small quantity of oil

(once) conforming to the VW 506 00,

VW 506 01, VW 505 00, VW 505 01 or

ACEA B3/ACEA B4 specification. (up to 0.5 l).

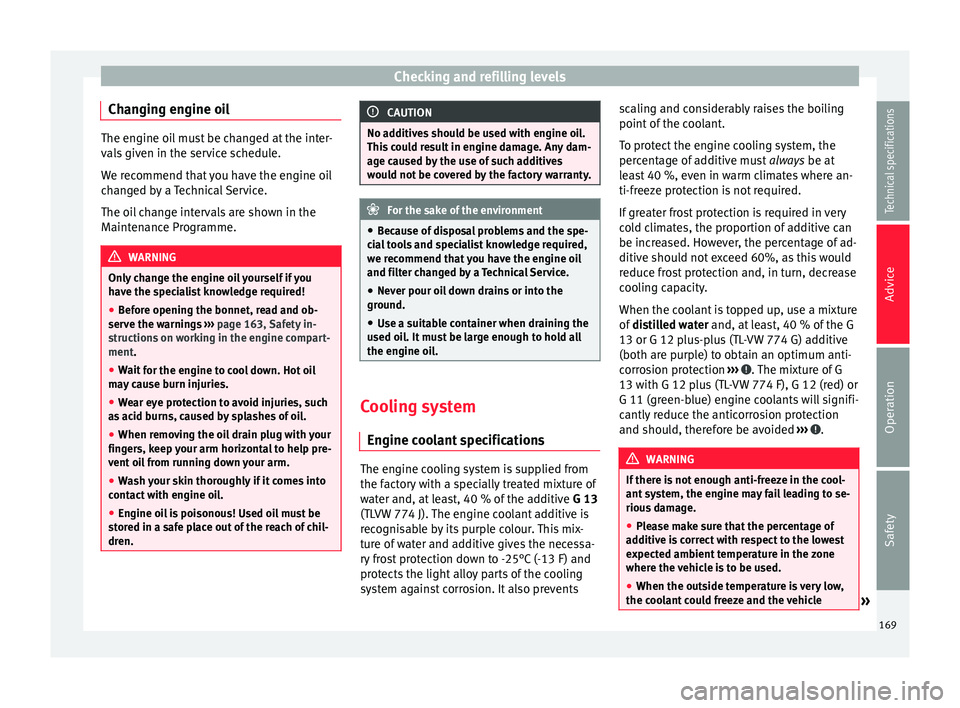

Oil properties

Engine typeSpecification

Petrol without flexible

service intervalVW 502 00/VW 504 00

Petrol with flexible serv-

ice interval (LongLife)VW 504 00

Diesel. Engines without

Particulate filter (DPF)VW 505 01/VW 506 01/VW

507 00

Diesel. Particulate Filter

Engines (DPF).

With or without flexible

service interval (with

and without LongLife) a)VW 507 00

a)

Only use recommended oils, otherwise you may damage the

engine.

Engine oil additives

No type of additive should be mixed with the

engine oil. The deterioration caused by these

additives is not covered by the warranty. Note

Before a long trip, we recommend finding an

engine oil that conforms to the correspond-

ing VW specifications and recommend keep-

ing it in the vehicle. This way, the correct en-

gine oil will always be available for a top-up if

needed. Checking the engine oil level

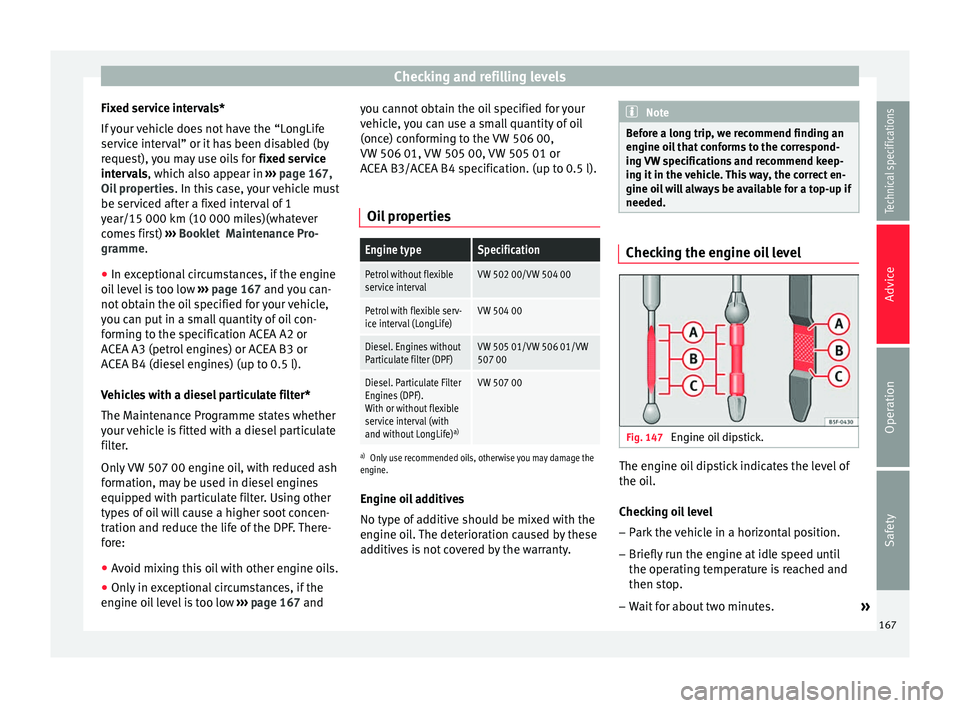

Fig. 147

Engine oil dipstick. The engine oil dipstick indicates the level of

the oil.

Checking oil level

– Park the vehicle in a horizontal position.

– Briefly run the engine at idle speed until

the operating temperature is reached and

then stop.

– Wait for about two minutes.

»

167

Technical specifications

Advice

Operation

Safety

Page 170 of 236

Advice

– Pull out the dipstick. Wipe the dipstick with

a clean cloth and insert it again, pushing it

in as far as it will go.

– Then pull it out once more and check the oil

level ››› Fig. 147 . Top up with engine oil if

nec e

ssary.

Oil level in area ADo

not

add oil ›

›› .

Oil level in area BYou

can

add oil, but keep the level in

thi

s zone.

Oil level in area COil

must be added.

Afterwards

, the oil

level should be in the lined area B .

Depending on how you drive and the condi-

tions in which the vehicle is used, oil con-

sumption can be up to 0.5 l/1000 km. Oil

consumption is likely to be higher for the first

5,000 km. For this reason the engine oil level

must be checked at regular intervals, prefera-

bly when filling the tank and before a jour-

ney. WARNING

Any work carried out in the engine compart-

ment or on the engine must be carried out

cautiously. –

–

– ●

When working in the engine compartment,

always observe the safety warnings

››› page 163. CAUTION

If the oil level is above the area A do not

start the engine. This could result in damage

to the engine and catalytic converter. Contact

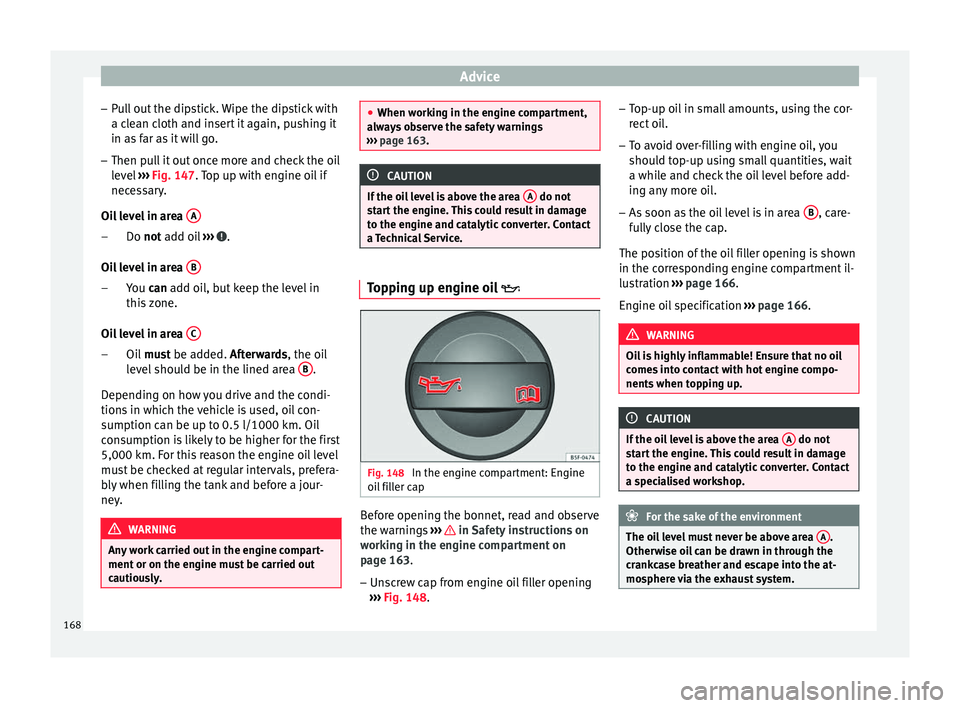

a Technical Service. Topping up engine oil

Fig. 148

In the engine compartment: Engine

oil filler cap Before opening the bonnet, read and observe

the warnings

››› in Safety instructions on

working in the engine compartment on

page 163 .

– Un s

crew cap from engine oil filler opening

››› Fig. 148. –

Top-up oi

l in small amounts, using the cor-

rect oil.

– To avoid over-filling with engine oil, you

should top-up using small quantities, wait

a while and check the oil level before add-

ing any more oil.

– As soon as the oil level is in area B , care-

fully close the cap.

The position of the oil filler opening is shown

in the corresponding engine compartment il-

lustration ››› page 166 .

En gine oi

l specification ››› page 166. WARNING

Oil is highly inflammable! Ensure that no oil

comes into contact with hot engine compo-

nents when topping up. CAUTION

If the oil level is above the area A do not

start the engine. This could result in damage

to the engine and catalytic converter. Contact

a specialised workshop. For the sake of the environment

The oil level must never be above area A .

Otherwise oil can be drawn in through the

crankcase breather and escape into the at-

mosphere via the exhaust system. 168

Page 171 of 236

Checking and refilling levels

Changing engine oil The engine oil must be changed at the inter-

vals given in the service schedule.

We recommend that you have the engine oil

changed by a Technical Service.

The oil change intervals are shown in the

Maintenance Programme.

WARNING

Only change the engine oil yourself if you

have the specialist knowledge required!

● Before opening the bonnet, read and ob-

serve the warnings ››› page 163, Safety in-

structions on working in the engine compart-

ment.

● Wait

for the engine to cool down. Hot oil

may cause burn injuries.

● Wear eye protection to avoid injuries, such

as acid burns, caused by splashes of oil.

● When removing the oil drain plug with your

fingers, keep your arm horizontal to help pre-

vent oil from running down your arm.

● Wash your skin thoroughly if it comes into

contact with engine oil.

● Engine oil is poisonous! Used oil must be

stored in a safe place out of the reach of chil-

dren. CAUTION

No additives should be used with engine oil.

This could result in engine damage. Any dam-

age caused by the use of such additives

would not be covered by the factory warranty. For the sake of the environment

● Because of disposal problems and the spe-

cial tools and specialist knowledge required,

we recommend that you have the engine oil

and filter changed by a Technical Service.

● Never pour oil down drains or into the

ground.

● Use a suitable container when draining the

used oil. It must be large enough to hold all

the engine oil. Cooling system

Engine coolant specifications The engine cooling system is supplied from

the factory with a specially treated mixture of

water and, at least, 40 % of the additive

G 13

(TLVW 774 J). The engine coolant additive is

recognisable by its purple colour. This mix-

ture of water and additive gives the necessa-

ry frost protection down to -25°C (-13 F) and

protects the light alloy parts of the cooling

system against corrosion. It also prevents scaling and considerably raises the boiling

point of the coolant.

To protect the engine cooling system, the

percentage of additive must

always be at

l e

ast 40 %, even in warm climates where an-

ti-freeze protection is not required.

If greater frost protection is required in very

cold climates, the proportion of additive can

be increased. However, the percentage of ad-

ditive should not exceed 60%, as this would

reduce frost protection and, in turn, decrease

cooling capacity.

When the coolant is topped up, use a mixture

of distilled water and, at least, 40 % of the G

13 or G 12 plu

s-plus (TL-VW 774 G) additive

(both are purple) to obtain an optimum anti-

corrosion protection ››› . The mixture of G

13 with G 12 plus (TL-VW 774 F), G 12 (red) or

G 11 (green-blue) engine coolants will signifi-

cantly reduce the anticorrosion protection

and should, therefore be avoided ››› .

WARNING

If there is not enough anti-freeze in the cool-

ant system, the engine may fail leading to se-

rious damage.

● Please make sure that the percentage of

additive is correct with respect to the lowest

expected ambient temperature in the zone

where the vehicle is to be used.

● When the outside temperature is very low,

the coolant could freeze and the vehicle » 169

Technical specifications

Advice

Operation

Safety

Page 172 of 236

Advice

would be immobilised. In this case, the heat-

ing would not work either and inadequately

dressed passengers could die of cold.

CAUTION

The original additives should never be mixed

with coolants which are not approved by

SEAT. Otherwise, you run the risk of causing

severe damage to the engine and the engine

cooling system. ● If the fluid in the expansion tank is not pur-

ple but is, for example, brown, this indicates

that the G 13 additive has been mixed with

an inadequate coolant. The coolant must be

changed as soon as possible if this is the

case! This could result in serious faults and

engine damage. For the sake of the environment

Coolants and additives can contaminate the

environment. If any fluids are spilled, they

should be collected and correctly disposed

of, with respect to the environment. Checking the coolant level and

topping up

Fig. 149

Engine compartment: coolant expan-

sion tank cap. Top up coolant when the level is below the

MIN (minimum) mark.

Before opening the bonnet, read and observe

the warnings

››› in Safety instructions on

working in the engine compartment on

page 163 .

Openin g the c

oolant expansion tank

– Switch off the engine and allow it to cool.

– To prevent scalding, cover the cap on the

coolant expansion tank with a thick cloth

and carefully unscrew the cap ››› .

Checking coolant level

– Look into the open coolant expansion tank

and read off the coolant level. –

If the level is below the “MIN” mark, top up

with coolant.

Topping up coolant – Only use new coolant liquid.

– Do not fi

ll above the “MAX” mark.

Closing the coolant expansion tank – Screw the cap on again tightly.

The position of the coolant expansion reser-

voir is shown in the corresponding engine

compartment illustration ››› page 166.

Make sure that the coolant meets the re-

quired specifications ››› page 169. Do not use

a different type of additive if additive G12+ is

not available. In this case use only water and

bring the coolant concentration back up to

the correct level as soon as possible by put-

ting in the specified additive ››› page 169.

Always top up with new coolant.

Do not fi

ll above the “MAX” mark. Otherwise

the excess coolant will be forced out of the

cooling system when the engine is hot.

The coolant additive G12+ (dyed purple) may

be mixed with G12 (dyed red) and also with G

11.

170

Page 173 of 236

Checking and refilling levels

WARNING

Any work carried out in the engine compart-

ment or on the engine must be carried out

cautiously.

● When working in the engine compartment,

always observe the safety warnings

››› page 163.

● When the engine is warm or hot, the cool-

ing system is pressurised! Do not unscrew

the cap on the coolant expansion tank when

the engine is hot. This is a burn injury risk. CAUTION

● When mixed with other additives the colour

of G12 will change to brown. If this occurs

you should have the coolant changed imme-

diately. Failure to do so will result in engine

damage!

● If a lot of coolant fluid has been lost, wait

for the engine to cool. This avoids damaging

the en gine. Lar

ge coolant losses are an indi-

cation of leaks in the cooling system. See a

specialised workshop immediately and have

the cooling system checked. Otherwise, there

is a risk of engine damage. Windscreen washer reservoir

Topping up washer fluid Fig. 150

In the engine compartment: Cap of

windscreen washer fluid reservoir The

windscreen washer

and the

headlight

washers are supplied with fluid from the

windscreen washer fluid container in the en-

gine compartment. The container holds ap-

prox. 3 litres; in vehicles with headlight

washers* it holds approx. 5.5 litres.

The reservoir is located on the right-hand

side of the engine compartment.

Plain water is not enough to clean the wind-

screen and headlights. We recommend that

you always add a product to the windscreen

washer fluid. Approved windscreen cleaning

products exist on the market with high deter-

gent and anti-freeze properties, these may be

added all-year-round. Please follow the dilu-

tion instructions on the packaging. WARNING

Any work carried out in the engine compart-

ment or on the engine must be carried out

cautiously.

● When working in the engine compartment,

always observe the safety warnings

››› page 163. CAUTION

● Never put radiator anti-freeze or other addi-

tives into the windscreen washer fluid.

● Always use approved windscreen cleansing

products diluted as per instructions. If you

use other washer fluids or soap solutions,

the tiny holes in the fan-shaped nozzles

could become blocked. 171

Technical specifications

Advice

Operation

Safety