Seat Arona 2017 Repair Manual

Manufacturer: SEAT, Model Year: 2017, Model line: Arona, Model: Seat Arona 2017Pages: 308, PDF Size: 6.66 MB

Page 61 of 308

The essentials

Identifying a blown fuse

A f u

se i

s blown if its metal strip is ruptured

››› Fig. 71.

● Point a lamp at the fuse to see if it has

blown.

T

o replace a fuse

● Remove the fuse.

● Replace the blown fuse by one with an

identica

l amperage rating (same colour and

markings) and identical size.

● Replace the cover again or close the fuse

box lid.

B

ulbs

Bul

bs (12 V) Depending on the level of equipment fitted in

the

v

ehic

le, LEDs may be used for part or all

of the interior and/or exterior lighting. LEDs

have an estimated life that exceeds that of

the vehicle. If an LED light fails, go to an au-

thorised workshop for its replacement.

Light source used for each function

Halogen headlights.Type

Dipped beam headlightsH7 Long Life

Main beam headlightsH7

Halogen headlights.Type

Side light/DRL (daytime running

light)W21W

Turn signalPY 21W

Halogen headlight with LED

DRLType

Dipped beam headlightsH7 Long Life

Main beam headlightsH7

Turn signalPY 21W

Side light/DRL (daytime running

light)LED a)

a)

In case of a LED failure, go to an authorised workshop to have

it replaced.

Full-LED main headlightsType

No bulbs may be replaced. All functions are with LEDs.

In case of a LED failure, go to an authorised workshop to

have it replaced.

Bulb light a)LeftRight

Brake lights2 x P21WLL2 x P21WLLSide lights

Retro fog lightP21 WLL–

Reverse light–P21 WLL

Turn signalPY 21W NA LLPY 21W NA LL

a)

The table corresponds to a right-hand traffic vehicle. The po-

sition of lights may vary according to the country.

Light with LEDs a)LeftRight

Brake lightsLEDLED

Side lightsLEDLED

Retro fog lightLED–

Reverse light–P21 WLL

Turn signalPY 21W NA LLPY 21W NA LL

a)

The table corresponds to a right-hand traffic vehicle. The po-

sition of lights may vary according to the country.

››› page 102 59

Page 62 of 308

The essentials

Action in the event of a punc-

t ur

e

R

elated video Fig. 72

Wheels What to do first

●

Park the vehicle on a horizontal surface

and in a s af

e p

lace as far away from traffic as

possible.

● Apply the handbrake.

● Switch on the hazard warning lights.

● Manual gearbox: select the 1s

t gear.

● Automatic gearbox: Move the sel

ector lever

to position P.

● If you are towing a trailer, unhitch it from

your v

ehicle.

● Have the vehicle tool kit* ›››

page 61 and

the spare wheel ›››

page 283 ready.

● Observe the applicable legislation for each

countr

y (reflective vest, warning triangles,

etc.). ●

All

occupants should leave the vehicle and

wait in a safe place (for instance behind the

roadside crash barrier). WARNING

● Alw a

ys observe the above steps and pro-

tect yourself and other road users.

● If you change the wheel on a slope, block

the wheel on the oppo

site side of the car with

a stone or similar to prevent the vehicle from

moving. Repairing a tyre with the anti-punc-

t

ur

e k

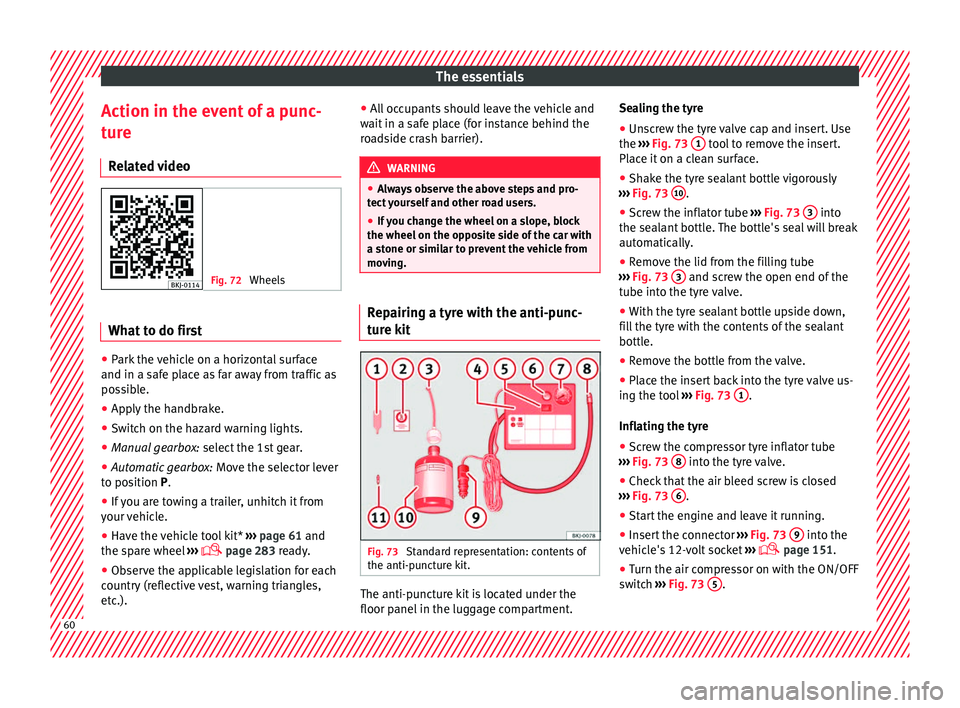

it Fig. 73

Standard representation: contents of

the anti-p u

nct

ure kit. The anti-puncture kit is located under the

floor p

anel

in the lug

gage compartment. Sealing the tyre

● Unscrew the tyre valve cap and insert. Use

the ›››

Fig. 73 1 tool to remove the insert.

Pl ac

e it

on a clean surface.

● Shake the tyre sealant bottle vigorously

›››

Fig. 73 10 .

● Screw the inflator tube ››

›

Fig. 73 3 into

the se al

ant

bottle. The bottle's seal will break

automatically.

● Remove the lid from the filling tube

›››

Fig. 73 3 and screw the open end of the

t ube int

o the ty

re valve.

● With the tyre sealant bottle upside down,

fill

the tyre with the contents of the sealant

bottle.

● Remove the bottle from the valve.

● Place the insert back into the tyre valve us-

ing the too

l ››› Fig. 73 1 .

Infl atin

g the ty

re

● Screw the compressor tyre inflator tube

›››

Fig. 73 8 into the tyre valve.

● Check that the air bleed screw is closed

› ›

›

Fig. 73 6 .

● Start the engine and leave it running.

● Insert the connector ››

›

Fig. 73 9 into the

v ehic

l

e's 12-volt socket ›››

page 151.

● Turn the air compressor on with the ON/OFF

swit c

h ››› Fig. 73 5 .

60

Page 63 of 308

The essentials

● Keep the air c

ompr

essor running until it

reaches 2.0 to 2.5 bar

(29-36 psi/200-250 kPa). A maximum of 8

minutes.

● Disconnect the air compressor.

● If it does not reach the pressure indicated,

uns

crew the tyre inflator tube from the valve.

● Move the vehicle 10m so that the sealant is

distrib

uted throughout the tyre.

● Screw the compressor tyre inflator into the

valve.

● R

epeat the inflation process.

● If the indicated pressure still cannot be

reac

hed, the tyre is too badly damaged. Stop

and request assistance from an authorised

technician.

● Disconnect the air compressor. Unscrew

the tyre infl

ator tube from the tyre valve.

● When the tyre pressure is between 2.5 and

2.0 bars, c

ontinue driving without exceeding

80 km/h (50 mph).

● Check the pressure again after 10 minutes

›››

page 95.

››› in TMS (Tyre Mobility System)* on

page 94

››› page 94 Changing a wheel

R el

at

ed video Fig. 74

Wheels Vehicle tool kit

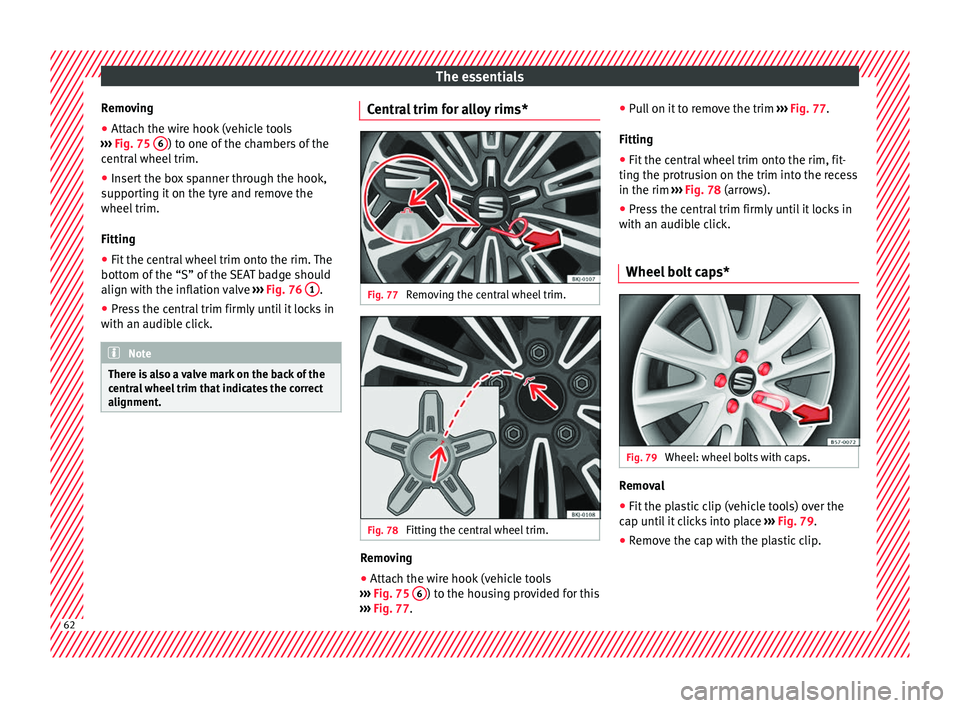

Fig. 75

Underneath the floor panel of the lug-

g ag

e c

ompartment: vehicle tool kit. An adapter for the anti-theft wheel bolts*

T

o

wline anc

horage

Box spanner for wheel bolts*

Crank handle for jack

1 2

3

4 Jack*

Hook

f

or e

xtracting the central wheel

trims*

Clip for removing the wheel bolt caps.

››› in Vehicle tools on page 93

››› page 93 Central trim for steel rims*

Fig. 76

Correct positioning of the central

wheel trim f

or s

teel rims. The central trims must be removed for access

t

o the wheel

bo

lts. »

5 6

7

61

Page 64 of 308

The essentials

Removing

● Attach the wire hook (vehicle tools

› ›

›

Fig. 75 6 ) to one of the chambers of the

c entr

al

wheel trim.

● Insert the box spanner through the hook,

suppor

ting it on the tyre and remove the

wheel trim.

Fitting

● Fit the central wheel trim onto the rim. The

bottom of the

“S” of the SEAT badge should

align with the inflation valve ››› Fig. 76 1 .

● Press the central trim firmly until it locks in

w ith an audib

l

e click. Note

There is also a valve mark on the back of the

centr a

l wheel trim that indicates the correct

alignment. Central trim for alloy rims*

Fig. 77

Removing the central wheel trim. Fig. 78

Fitting the central wheel trim. Removing

● Attach the wire hook (vehicle tools

› ››

Fig. 75 6 ) to the housing provided for this

› ›

›

Fig. 77. ●

Pul

l on it to remove the trim ››› Fig. 77.

Fitting

● Fit the central wheel trim onto the rim, fit-

ting the protru

sion on the trim into the recess

in the rim ››› Fig. 78 (arrows).

● Press the central trim firmly until it locks in

with an audibl

e click.

Wheel bolt caps* Fig. 79

Wheel: wheel bolts with caps. Removal

● Fit the plastic clip (vehicle tools) over the

c ap u

nti

l it clicks into place ››› Fig. 79.

● Remove the cap with the plastic clip. 62

Page 65 of 308

The essentials

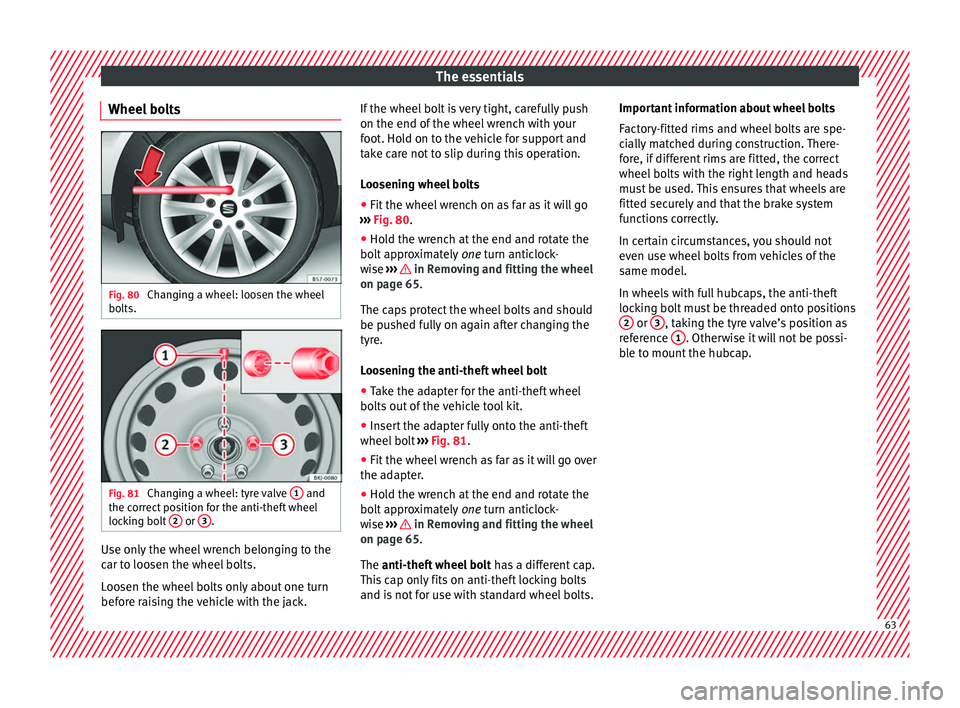

Wheel bolts Fig. 80

Changing a wheel: loosen the wheel

bo lts. Fig. 81

Changing a wheel: tyre valve 1 and

the c orrect

position for the anti-theft wheel

locking bolt 2 or

3 .

Use only the wheel wrench belonging to the

c

ar t

o loo

sen the wheel bolts.

Loosen the wheel bolts only about one turn

before raising the vehicle with the jack. If the wheel bolt is very tight, carefully push

on the end of the wheel wr

ench with your

foot. Hold on to the vehicle for support and

take care not to slip during this operation.

Loosening wheel bolts

● Fit the wheel wrench on as far as it will go

›››

Fig. 80.

● Hold the wrench at the end and rotate the

bolt ap

proximately one turn anticlock-

wise ››› in Removing and fitting the wheel

on p ag

e 65

.

The caps protect the wheel bolts and should

be pushed fully on again after changing the

tyre.

Loosening the anti-theft wheel bolt

● Take the adapter for the anti-theft wheel

bolts out

of the vehicle tool kit.

● Insert the adapter fully onto the anti-theft

wheel bolt

››› Fig. 81.

● Fit the wheel wrench as far as it will go over

the adapt

er.

● Hold the wrench at the end and rotate the

bolt ap

proximately one turn anticlock-

wise ››› in Removing and fitting the wheel

on p ag

e 65

.

The anti-theft wheel bolt has a different cap.

This cap only fits on anti-theft locking bolts

and is not for use with standard wheel bolts. Important information about wheel bolts

Factor

y-fitted rims and wheel bolts are spe-

cially matched during construction. There-

fore, if different rims are fitted, the correct

wheel bolts with the right length and heads

must be used. This ensures that wheels are

fitted securely and that the brake system

functions correctly.

In certain circumstances, you should not

even use wheel bolts from vehicles of the

same model.

In wheels with full hubcaps, the anti-theft

locking bolt must be threaded onto positions 2 or

3 , taking the tyre valve’s position as

r ef

er

ence 1 . Otherwise it will not be possi-

b l

e t

o mount the hubcap. 63

Page 66 of 308

The essentials

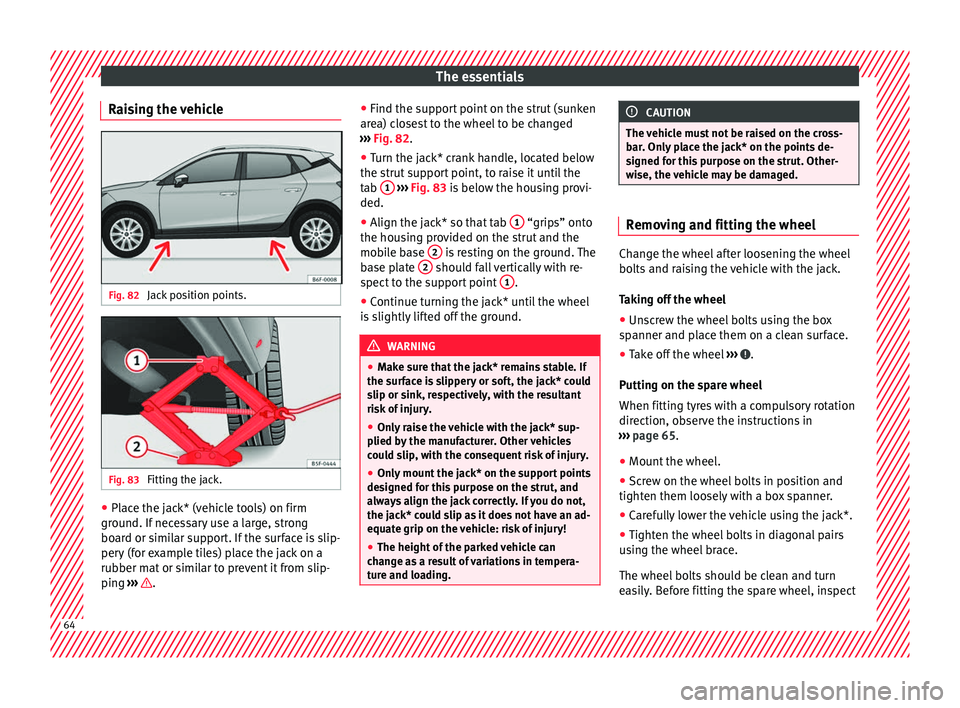

Raising the vehicle Fig. 82

Jack position points. Fig. 83

Fitting the jack. ●

Place the jack* (vehicle tools) on firm

gr ou

nd. If

necessary use a large, strong

board or similar support. If the surface is slip-

pery (for example tiles) place the jack on a

rubber mat or similar to prevent it from slip-

ping ››› . ●

Find the s up

por

t point on the strut (sunken

area) closest to the wheel to be changed

››› Fig. 82.

● Turn the jack* crank handle, located below

the strut s

upport point, to raise it until the

tab 1

› ››

Fig. 83

i

s below the housing provi-

ded.

● Align the jack* so that tab 1 “grips” onto

the hou s

in

g provided on the strut and the

mobile base 2 is resting on the ground. The

b a

se p

late 2 should fall vertically with re-

s pect

t

o the support point 1 .

● Continue turning the jack* until the wheel

i s

s

lightly lifted off the ground. WARNING

● Mak e s

ure that the jack* remains stable. If

the surface is slippery or soft, the jack* could

slip or sink, respectively, with the resultant

risk of injury.

● Only raise the vehicle with the jack* sup-

plied by

the manufacturer. Other vehicles

could slip, with the consequent risk of injury.

● Only mount the jack* on the support points

designed f

or this purpose on the strut, and

always align the jack correctly. If you do not,

the jack* could slip as it does not have an ad-

equate grip on the vehicle: risk of injury!

● The height of the parked vehicle can

chan

ge as a result of variations in tempera-

ture and loading. CAUTION

The vehicle must not be raised on the cross-

bar . On

ly place the jack* on the points de-

signed for this purpose on the strut. Other-

wise, the vehicle may be damaged. Removing and fitting the wheel

Change the wheel after loosening the wheel

bolts

and r

aising the vehicle with the jack.

Taking off the wheel

● Unscrew the wheel bolts using the box

sp anner and p

lace them on a clean surface.

● Take off the wheel ›››

.

P uttin

g on the s

pare wheel

When fitting tyres with a compulsory rotation

direction, observe the instructions in

››› page 65.

● Mount the wheel.

● Screw on the wheel bolts in position and

tighten them loosely

with a box spanner.

● Carefully lower the vehicle using the jack*.

● Tighten the wheel bolts in diagonal pairs

usin

g the wheel brace.

The wheel bolts should be clean and turn

easily. Before fitting the spare wheel, inspect 64

Page 67 of 308

The essentials

the wheel condition and hub mounting surfa-

c e

s.

These surfaces must be clean before fit-

ting the wheel.

Wheel bolt tightening torque

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is 140 Nm.

After changing a wheel, have the tightening

torque checked immediately with a torque

wrench that is working perfectly.

Before checking tightening torque, have any

rusty wheel bolts that are difficult to screw re-

placed and clean the wheel hub threads.

Never apply grease or oil to wheel bolts or to

the wheel hub threads. Even if the bolts have

been tightened to the prescribed torque, they

could come loose while driving. WARNING

If the wheel bolts are not properly tightened,

they c ou

ld come loose while driving and

cause an accident, serious injury and loss of

vehicle control.

● Use only wheel bolts which correspond to

the rim in question.

● Nev

er use different wheel bolts.

● Wheel bolts and threads should be clean,

free of oi

l and grease, and it should be possi-

ble to screw them easily.

● To loosen and tighten wheel bolts, only use

the wheel wrenc

h that came with the car from

the factory. ●

Loo sen the wheel

bolts only about one turn

before raising the vehicle with the jack.

● Never apply grease or oil to wheel bolts or

to the wheel hub thr

eads. Even if the bolts

have been tightened to the prescribed tor-

que, they could come loose while driving.

● Never loosen the screwed joints of wheel

rims with bo

lted ring trims.

● If wheel bolts are tightened below the pre-

scribed t

orque, the bolts and rims could come

loose while driving. If tightening torque is too

high, the wheel bolts or threads can be dam-

aged. CAUTION

When removing/fitting the wheel, the rim

ma y

hit and damage the brake disc. For this

reason, please take care and get a second

person to assist you. Tyres with compulsory rotation direc-

tion

A directional tread pattern can be identified

b

y

the arr

ows on the sidewall that point in

the direction of rotation. Always observe the

direction of rotation indicated when fitting

the wheel to guarantee optimum properties

of this type of tyres with regard to grip,

noises, wear and aquaplaning.

If it is absolutely necessary to fit the spare

tyre* against the direction of rotation, drive with care as this means the tyre does not of-

fer optimum drivin

g properties. This is of par-

ticular importance when the road surface is

wet.

To return to directional tread tires, replace

the punctured tyre as soon as possible and

restore the obligatory direction of rotation of

all tyres.

Subsequent work ●

Alloy wheels: rep

l

ace the wheel bolt caps.

● Plate wheels: repl

ace the wheel hubcap.

● Return all tools to their proper storing loca-

tion.

● If the replaced wheel does not fit in the

spar

e wheel housing, store it safely in the

luggage compartment ›››

page 152.

● Check the tyre pressure of the newly moun-

ted tyr

e as soon as possible.

● In vehicles fitted with a tyre pressure indi-

cator

, adjust the pressure and store it in

memory ›››

page 282.

● Have the tightening torque of the wheel

bolts c

hecked as soon as possible with a tor-

que wrench (it should be 120 Nm). Mean-

while, drive carefully.

● Have the flat tyre replaced as quickly as

pos s

ible. 65

Page 68 of 308

The essentials

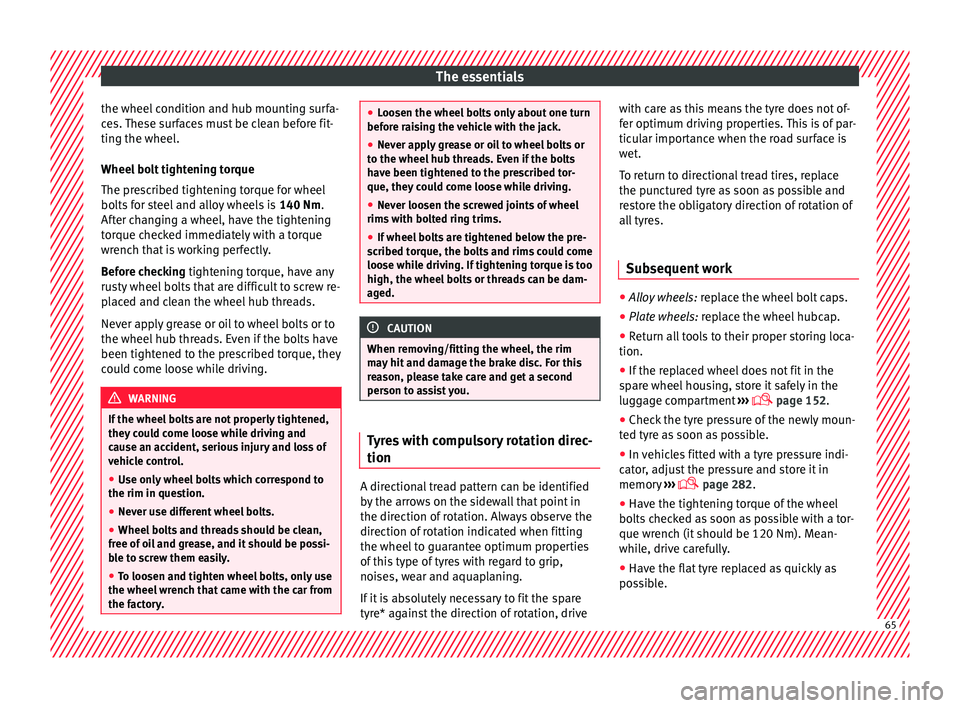

Snow chains U se Snow chains should only be used on the

fron

t

wheels.

● Check that they are correctly seated after

driving f

or a few yards; correct the position if

necessary, in accordance with the manufac-

turer's fitting instructions.

● Keep your speed below 50 km/h (30 mph).

● If there is a danger of being trapped de-

spit e h

aving mounted the chains, it is best to

disable the driving wheels (ASR) in the ESC

››› page 177.

Snow chains will improve braking ability as

well as traction in winter conditions.

For technical reasons snow chains may only

be used with the following wheel rim/tyre

combination.

195/60 R16Chains with links of maximum 13.5

mm Remove wheel covers and any integral trim

rin

g bef

or

e fitting snow chains.

Remove the chains when roads are free of

snow. Driving characteristics worsen, and the

wheels become damaged quickly and may

even be rendered unusable. WARNING

Snow chains should be correctly tightened in

acc or

dance with the manufacturer's instruc-

tions. This will prevent the chains coming in-

to contact with the wheel housing. Emergency towing of the vehi-

cl

e

T

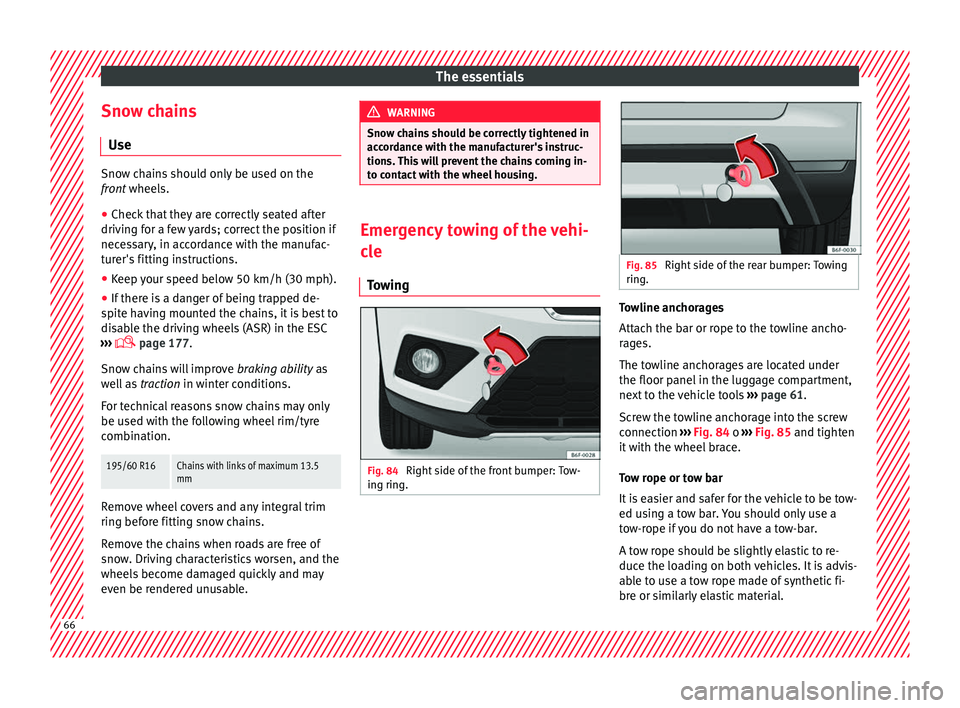

owing Fig. 84

Right side of the front bumper: Tow-

in g rin

g. Fig. 85

Right side of the rear bumper: Towing

ring. Towline anchorages

Att

ac

h the b

ar or rope to the towline ancho-

rages.

The towline anchorages are located under

the floor panel in the luggage compartment,

next to the vehicle tools ››› page 61.

Screw the towline anchorage into the screw

connection ››› Fig. 84 o ››› Fig. 85 and tighten

it with the wheel brace.

Tow rope or tow bar

It is easier and safer for the vehicle to be tow-

ed using a tow bar. You should only use a

tow-rope if you do not have a tow-bar.

A tow rope should be slightly elastic to re-

duce the loading on both vehicles. It is advis-

able to use a tow rope made of synthetic fi-

bre or similarly elastic material. 66

Page 69 of 308

The essentials

Attach the tow rope or the tow bar only to the

t o

wline anc

horages provided or a towing

bracket.

Notes for the driver of the towing vehicle

● The tow rope must be taut before you drive

off.

● Rel

ease the clutch very carefully when start-

ing the v

ehicle (manual gearbox), or acceler-

ate gently (automatic gearbox).

Driving style

Towing requires some experience, especially

when using a tow rope. Both drivers should

realise how difficult it is to tow a vehicle. In-

experienced drivers should not attempt to

tow.

Do not pull too hard with the towing vehicle

and take care to avoid jerking the tow rope.

When towing on an unpaved road, there is al-

ways a risk of overloading and damaging the

anchorage points.

The ignition of the vehicle being towed must

be switched on to prevent the steering wheel

from locking and also to allow the use of the

turn signals, horn, windscreen wipers and

washers.

Place the gear lever in neutral on vehicles

with a manual gearbox. With an automatic

gearbox, place the lever in N. The brake servo only works when the engine

is ru

nning. When not running, you must ap-

ply considerably more pressure to the brake

pedal.

As the power assisted steering does not work

if the engine is not running, you will need

more strength to steer than you normally

would.

››› in General information on page 96

››› page 96 Tow-starting

If the engine will not start, first try starting it

u

s

in

g the battery of another vehicle

››› page 67. You should only attempt to tow-

start a vehicle if charging the battery does

not work. This is done by leveraging wheel

movement.

When tow-starting a vehicle with a petrol en-

gine, do not tow it more than a short dis-

tance, otherwise unburned fuel can enter the

catalytic converter.

However, if your vehicle has to be tow-star-

ted:

● Engage 2 nd

or 3 rd

ge

ar.

● Keep the clutch pressed down. ●

Switc

h the ignition on.

● Once both vehicles are moving, release the

clutc

h.

● As soon as the engine starts, press the

clutc

h and move the gear lever into neutral.

This helps to prevent driving into the towing

vehicle.

››› in General information on page 96

››› page 96 How to jump start

Jump l e

a

ds The jump lead must have a sufficient wire

c

r

o

ss section.

If the engine fails to start because of a dis-

charged battery, the battery can be connec-

ted to the battery of another vehicle to start

the engine.

Jump leads

Jump leads must comply with standard DIN

72553 (see cable manufacturer's instruc-

tions). The wire cross section must be at least

25 mm 2

for petrol engines and at least

35 mm 2

for diesel engines. » 67

Page 70 of 308

The essentials

Note

● The v ehic

les must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected.

● The discharged battery must be properly

connected t

o the on-board network. How to jump start: description

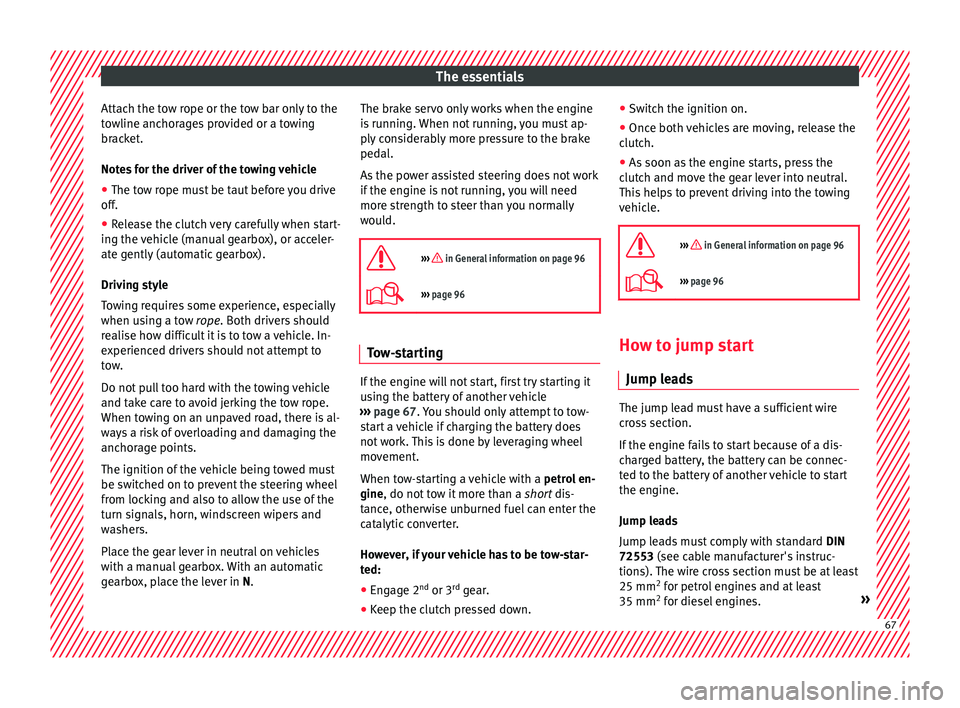

Fig. 86

Diagram of connections for vehicles

w ithout

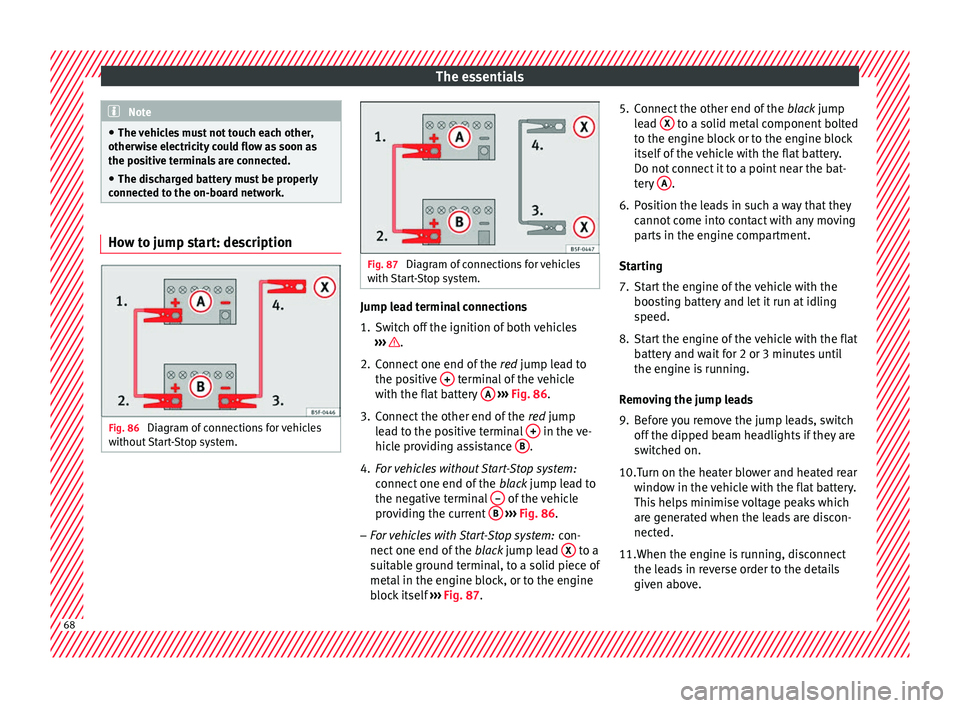

Start-Stop system. Fig. 87

Diagram of connections for vehicles

with St

art-Stop system. Jump lead terminal connections

1. Switch off the ignition of both vehicles

››

›

.

2. Connect one end of the re

d

jump lead to

the positive + terminal of the vehicle

w ith the fl

at

battery A

› ›

› Fig. 86 .

3. Connect the other end of the red

jump

lead to the positive terminal + in the ve-

hic l

e pr

oviding assistance B .

4. For vehicles without Start-Stop system:

connect

one end of

the black jump lead to

the negative terminal – of the vehicle

pr o

v

iding the current B

› ›

› Fig. 86 .

– For vehicles with Start-Stop system: con-

nect one end of

the black jump lead X to a

s uit

ab

le ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 87. 5. Connect the other end of the

black

jump

lead X to a solid metal component bolted

t o the en

gine b

lock or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot

c

ome into contact with any moving

parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boostin

g battery and let it run at idling

speed.

8. Start the engine of the vehicle with the flat batter

y and wait for 2 or 3 minutes until

the engine is running.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped be

am headlights if they are

switched on.

10.

Turn on the heater blower and heated rear

window in the vehicle with the flat battery.

This helps minimise voltage peaks which

are generated when the leads are discon-

nected.

11.When the engine is running, disconnect the lea

ds in reverse order to the details

given above. 68